Operating principles

The main difference between weapons lies in the different operating principles of the mechanism. Thus, some rifles are inflated with atmospheric air directly during loading, while others require refueling using a cylinder. There are also those who need to be “fed” with carbon dioxide canisters.

Spring-piston system

This principle of operation is the most common for modern air blowers. Since the design is simple to manufacture and maintain, such rifles are often low in cost, but have good muzzle velocity and allow accurate shooting at distant targets.

In order to fire a shot, the rifle must be cocked each time. This is usually done by breaking the trunk. At this moment, the spring is compressed, and the weapon comes into combat readiness. The moment the trigger is pressed, the energy of the spring is released and it begins to push the piston. Since its power is quite high, the latter accelerates to a speed of 15-20 meters per second.

This results in the creation of powerful compression pressure transferred to the charge. Typically a lead bullet weighing up to 1 gram is used. When the piston travels about 90 percent of the way, the bullet breaks off and begins to accelerate down the barrel. At this moment, the pressure can already exceed 200 atmospheres. All these factors ensure an initial bullet speed of at least 300 meters per second.

Gas cylinders

Such mechanisms are most often used on short-barreled pistols, although they are sometimes found in full-size rifles. The main source of energy for the shot is compressed CO2 gas, located in a durable cylinder under high pressure. Usually it is enough for 20-30 shots without loss of power, then the projectile begins to slow down.

A metal ball is usually used as a projectile; in rare cases, a lead bullet is used. The gas from the can constantly presses on the outlet valve. At the moment of firing, it opens for a short time, the duration of which depends on the power of the installed spring. As a result, carbon dioxide finds its way out through the barrel, in which the ball or bullet is already located. The projectile's flight speed varies between 100-120 meters per second.

Compression and multi-compression

The mechanics of this type of rifle are somewhat reminiscent of those in gas-cylinder systems. However, a compressed gas cylinder is not required here. The energy source is a reservoir, which is pre-inflated by the shooter using a special lever with atmospheric air.

The difference between a compression and multi-compression mechanism is that in the first case all the air is released in one shot, while in the second it can be enough to provide several shots with the same power.

When you pull the trigger, the release valve opens and the compressed air that escapes pushes the bullet down the barrel. The power of the shot can be adjusted using additional pumping. Typically, the speed of a bullet in such rifles is approximately 280 meters per second.

Pre-pumping (PCP)

It is an improved version of the multi-compressor system. It has a built-in or removable tank capable of maintaining pressure up to 300 atmospheres. It is pumped using a separate pump or a pre-prepared large-volume cylinder. Both atmospheric air and nitrogen can be used as a filler.

The tank capacity is enough for an average of 20 powerful shots. The bullet's flight speed after exiting the barrel is at least 350 meters per second when fully pumped. Most of these rifles are equipped with a reduction gear, as this allows shots to be fired at the same power for maximum time, and ensures long life of the exhaust valve.

Inflating the cartridge

Quite a rare, but practical system. It differs in that the loaded cartridges outwardly resemble those used in firearms. Only inside, instead of gunpowder, there is air compressed to 200 atmospheres. And at the exit there is a small lead bullet or metal ball.

At the moment of firing, the capsule is struck, which activates the release valve located in the cartridge itself. All the air is suddenly released, pushing the bullet forward down the barrel of the weapon. Since its volume is often small, these rifles are inferior in power to those described earlier. The initial speed of a bullet ranges from 100 to 140 meters per second.

Recoil

An important criterion when choosing an air rifle or pistol is the presence of recoil. When hunting or sport shooting, it can significantly complicate the process.

All types of “air guns” that use compressed gas of any type are practically devoid of this concept, since the power of the remaining air leaving the barrel after a shot is negligible. But systems with a spring-piston mechanism have quite strong recoil due to the internal movement of the heavy piston. If the bullet is heavy, it may not have time to leave the barrel before the piston hits the front edge of the chamber, which leads to poor shooting results.

Electrician's tool: Assembling the Toua GSN40A gas pistol

Good afternoon, dear readers. I wrote this article by accident, I didn’t plan it in advance. There are many video reviews of mounting guns on the Internet, including an excellent video on assembly and disassembly from GNGroup. But I couldn’t find just text with pictures and decided to write about it.

For those who do not know about this tool, the next section.

What kind of instrument is this?

A gas nailing gun is a direct installation tool whose task is to drive nails into concrete and metal at a theoretical speed of up to 1 nail per second (in practice, 1 nail every 2-3 seconds).

In electrical work, this is necessary, first of all, for fastening the cable, which becomes incredibly fast and enjoyable with this tool.

Cables in corrugated PVC pipes, attached to the floor with punched tape using a gas mounting gun.

Cables in corrugated PVC pipes, attached to the ceiling with special clips using a gas mounting gun.

Also very important is the fact that working with a pistol bothers the Customer’s neighbors an order of magnitude less than drilling holes with a hammer drill. Compare a relatively loud, but very short clap, which is muffled and almost does not attract attention after 2-3 floors, with drilling one hole with a hammer drill for about 10 seconds. Which, according to those not participating in the drilling, is heard “from all sides” in the house has 7 floors in both directions vertically.

At the same time, the cost of consumables (if we talk about the Toua brand) is comparable or even cheaper than when working with a hammer drill. For these and other reasons, gas mounting guns are now becoming increasingly popular and, in fact, are owned by many multipliers.

The driving force for driving nails in this type of gun is the controlled explosion of gas in the combustion chamber. The older (and older) brothers of gas pistols are powder mounting pistols. They have a much lower operating speed, but colossal impact force, incomparable to gas pistols.

The younger brothers of gas pistols are pneumatic nailers (the driving force in them is compressed air). Door installers often use them to hammer thin pins into wood. By the way, here is an interesting video from Stroyhak_Youtube about what a pneumatic nailer can penetrate.

As far as I know, the ancestor of gas mounting guns is the Spit company. The photo shows a chic Spit Pulsa 700E mounting gun:

And here are the numerous “clones” of the original idea that subsequently appeared - from Aiken and Toua to Hilti.

The photo shows pistols from different manufacturers.

History of the article

It so happened that during the installation of one of the objects, at the end of summer, the piston of my GSN50 pistol broke (I managed to hammer 15,000 nails, usually such pistons last longer).

In order not to delay work at the site while replacing the piston, I took Oleg_V’s pistol, Toua GSN 40A, intended for general construction work, to drive for a couple of days. As a result, the project was completed and I returned the GNS40A to Oleg. And after some time, when Oleg needed a pistol, it turned out that the pistol did not fire every time and Oleg asked to look into it and fix it.

During my time with the GSN50, I have learned how to assemble and disassemble it, as I perform maintenance and major cleaning on my GSN50 more often than the manufacturer recommends. Fortunately, GNGroup, the official distributor of mounting guns, including Spit and Toua, is loyal to such operations with Toua.

My GSN-50 is in a case.

By the way, if you are thinking of buying yourself a mounting gun, I recommend contacting them.

The guys deal only with this topic and are well versed in it, they will help you choose a gun and consumables, they will let you try to work with different guns and different nails, etc. In addition, they have excellent support - before I began to fully service the instrument myself, at first I often turned to them and they always helped. And at the same time, the main thing is the prices; at GNGroup they are not higher than the market average, and more often, even lower due to large volumes - for example, many owners of similar tools I know buy tools and consumables from them. Returning to Oleg’s pistol, I will say that diagnostics (it can be done in a minute) showed that the reason for the failure is wear of the gas adapter, due to the fact that it was not changed for a long time.

Adapter with a gas cylinder connected to it

That is, it was possible to get by only by replacing the adapter, but as Oleg told me, the gun had never undergone maintenance (although it was not used very often, as I understand it, mainly by drywall workers).

Therefore, as a sign of gratitude, I decided to sort out and clean the gun at the same time, since dust accumulates on the rubbing parts, including in the combustion chamber, during long-term use without cleaning. In addition, if you do not clean the tool for a long time, the walls of the combustion chamber are gradually covered with a layer of burnt lubricant (contained in the gas), which can impair the performance of the tool.

So, the gun was completely disassembled, all parts were cleaned of dust and carbon deposits using WD-40 and a soft rag, then the rubbing parts were lubricated with the special lubricant included in the kit.

Unfortunately, I did not take pictures of the disassembly and cleaning process. It was not possible to assemble the pistol right away - as it turned out, some of the rubber gaskets on the GSN-40 are essentially disposable and require replacement. True, complete disassembly of the combustion chamber, which requires replacing these gaskets, is usually not required.

In general, it didn’t make sense to go to GNGroup for two gaskets; Oleg didn’t need a gun yet; in general, he decided to wait for the next order to order the gaskets along with nails for the object. The pistol parts were put in a basin (so as not to lose anything), covered with film and placed on a shelf, where they remained for a couple of weeks.

In general, as soon as I needed to order the next batch of nails, I ordered these rubber bands at the same time. The rubber bands arrived and it was time to put the gun back together. I decided to photograph the assembly process.

Assembly of Toua GSN-40A

For a better understanding, I provide an explosion diagram of the tool and a list of spare parts. It is in the manufacturer's instructions that come with the gun.

Assembly begins with the working cylinder.

A piston (37) with two sealing rings (36) is inserted into the chamber (pos. 48) and secured with a locking ring (35) in a special groove using long-nose pliers or round nose pliers.

Then you should assemble the exhaust gas exhaust unit (item 40) from the appropriate parts and secure it to the cylinder body:

It is almost impossible to clean these parts completely, but this condition is much better than the one they were in. When reassembling, it is important to position the exhaust valve (44) correctly - it should be located outside the mounting plate (46) - so that exhaust gases can escape freely. Assembly begins with mounting the mesh with cells (47) onto the cylinder body:

Next, install the plate for mounting the exhaust valve.

The whole thing is screwed in with screws pos. 41 (M4x8) - the plate is attached to the body with two screws, and the muffler (43) is inserted directly onto it. Then the outer casing is secured with two more identical screws.

There is a suspicion that the muffler also acts as a catalyst (since, in addition to the propane-butane mixture, the cylinder contains oil to lubricate the combustion chamber, and burnt oil is, as it were, not environmentally friendly). Therefore, I always carefully clean this element from carbon deposits. Before tightening, I wipe the threads of all screws with a cloth soaked in WD-40:

Next, the working cylinder is mounted to the combustion chamber housing. The combustion chamber in Toua pistols is movable and prefabricated - this is one of the main safety elements of these pistols. That is, when the tool is in the non-working position, the combustion chamber is separated into two parts, and even if gas enters the chamber and explodes (which does not happen due to the presence of other blockages), the shock wave will apparently not create sufficient pressure to push the piston, and, most likely, the gas will simply evaporate through the holes.

When the gun is pressed, the blockages are released, including the combustion chamber being “assembled” due to the entry of the chamber “tail” (pos. 17) into the corresponding grooves of the fan block (pos. 12).

So, the cylinder is inserted into the main element of the combustion chamber (pos. 19), springs are inserted into special grooves (pos. 49):

Then the left and right levers (pos. 50 and 51) are attached there, the levers are pressed in and their travel is limited by two pins (20) shown in the figure:

How not to confuse the left and right lever? It is very easy to check - place the base of the barrel (pos. 58) so that the mounting holes in the cylinder correspond to the holes on the base (in the photo you can see the corresponding thread on the cylinder through the holes in the base). The levers should “lie” on the groove along which they will ride:

We fix the levers with studs:

Next, you need to assemble and secure the “tail” of the combustion chamber. It consists of two parts and two rubber bands (the same disposable ones). If you remove the “tail” when disassembling the pistol, then be prepared to order new rubber bands since the old ones will not fit properly:

The tail is secured with four M4×16 screws (item 16):

So, the working block is assembled:

Next, the trigger lock is attached to the reverse side (pos. 33). It is simply inserted into the appropriate holes. This part is needed so that when not in working condition it is impossible to pull the trigger (it blocks the trigger with its crossbar):

Block with interlock installed:

Next, all this stuff is inserted into the body (pos. 54) so that the trigger lock goes into a special hole for it.

The next step in this pistol model is to assemble the barrel base (item 58). Unlike the GSN-50, which has a replaceable barrel, the GSN 40 has a barrel base that must be secured before installing the handle, otherwise it will not be possible to install the base later.

IMPORTANT!! When installing the base, make sure that the piston head fits into the corresponding hole in the base. If it is skewed and rests against the base, as shown in the photo, then you will probably be able to assemble the gun (by pushing the piston deeper into the chamber), but at the first shot it will be hopelessly damaged:

An example of a piston misalignment! Make sure that this is not the case and that the piston can move freely.

The base is attached to the cylinder with four M5×15 screws (item 59). If you use a screwdriver for assembly, hand-tightening all screws after this is mandatory. Moreover, it is better to tighten it twice, sequentially.

Next, the handle assembly is attached. There is no need to disassemble it for cleaning, but this will be required, for example, if the trigger breaks.

To attach the handle you will need the following parts:

- White plastic locking lever (item 67).

- Bushing (pos. 66) with M5x10 fasteners (1)

The locking lever is placed on the seat in the handle, the body protrusions are inserted into special grooves, then this entire structure is fastened through with a bushing and a screw.

Lastly, the fan unit complete with the back cover is assembled and attached. There is no need to disassemble this unit when cleaning. The rubber seal (item 13) can be easily removed and cleaned. The fan blades, rear cover of the combustion chamber, gas inlet and spark plug are also indiscriminately cleaned. Due to the presence of stiffeners, this procedure takes longer than all others.

Also, using a thin strip of fabric (it is twisted and carefully pushed into the channel with a needle, then pulled out) you can clean the gas supply channel in which oil accumulates. If you have compressed air in your household, then it is better to blow through this channel from the side of the combustion chamber.

IMPORTANT! When cleaning and assembling, be careful not to bend the fan blades. If this happens, the efficiency of mixing the gas-air mixture will decrease and the gun may operate unstably.

The fan unit with the rear cover assembly is attached to the case with 4 M5x20 screws (item 11), the photo shows the seats of these screws:

One of the screws also holds the protection of the fan and spark plug power wires, which in this model run along the outer part of the case.

The fan assembly is attached to the chassis. In the photo, the wire protection is visible at the top right; the wires themselves are secured in the corresponding sockets:

The back cover is secured with an M5x10 screw (item 1) - in the photo above to the left of the fan you can see the seat of this screw.

Now you should install the gas adapter. This is a consumable item and needs to be replaced as soon as the pistol begins to fire unstably. The photo shows the old and new adapter:

Since there is a limit on the length of the text, I will write about the adapter in the comments!

In the photo the adapter is rotated 180 degrees, but this is not important - the seating depth is important.

Now we attach the barrel to the combustion chamber levers. This is done very simply with the help of two short screws (pos. 62).

Next, we attach the barrel casing (pos. 57) to the screw, attach the pre-cleaned clip (it becomes clogged with abrasive and the carriage begins to move poorly), a gas cylinder and battery, and the gun is ready:

After which it must be checked by shooting a couple of nails into concrete or wood of the appropriate thickness.

As you can see, it is very easy to disassemble, clean and reassemble the Toua gas pistol. If you have the skill, you can assemble/disassemble it in half an hour.

Thank you for attention.

Charging and injection systems

They are divided into manual and automatic. The former are most often used only on rifles, but are occasionally found in short-barreled weapons. In order to cock such a pistol, you need to break the barrel or use a special lever. This allows you to not depend on consumables during shooting, but significantly increases the time between shots. In addition, it usually requires a lot of effort, resulting in reduced accuracy.

Automatic systems are all rifles that use pre-pumping or consumables in the form of gas cartridges. They allow you to shoot almost continuously, but require either additional equipment or a supply of cartridges.

Gas self-defense weapon - gas pistol (revolver)

Life in the modern world is fraught with a number of different dangers, many of which directly threaten human health - this is at best.

However, having protected yourself by purchasing one or another self-defense weapon, since the market for such goods is simply overcrowded, you can feel much more confident in the realities of the modern world.

If, from the variety of weapons for self-defense, a gas pistol has been chosen, then you must take note of the recommendations below.

First of all, you should clearly understand that a gas pistol is a weapon solely for self-defense, unless, of course, you use it as a hammer.

That is, it is impossible for them to cause any catastrophic harm to the health of the attacker!

However, it is worth remembering that this weapon can be used at a distance of no less than half a meter from the attacker.

Otherwise, hot particles of gunpowder, as well as a shock wave, can cause quite serious wounds.

By the way, this distance absolutely does not depend on the type of cartridges loaded in the pistol - they are gas or blank.

The gas pistol itself is actually an exact copy of a combat pistol, with the exception of the absence of an automatic firing function.

Depending on a particular caliber - that is, the diameter of the barrel, there is a difference in the range of action of the pistol.

The length of the barrel in gas models, which cannot be said about its fighting brothers, is not significant. In addition, gas weapons are divided into pistols and, of course, revolvers.

Pistols are a newer type of weapon, and they are more convenient to carry, although, in principle, this is a matter of taste.

However, this type is easy to use - the cartridges are in a magazine that can be changed with one movement, and the number of charges, usually from 5 to 10 pieces, attracts people more.

The disadvantages include only one quality, which, by the way, is also found in a combat pistol - the cartridge can misfire for one reason or another.

Therefore, it takes some time to bring the gun into the proper position, which, in some extreme situations, is fraught with unpleasant consequences.

The revolver has been known to mankind for more than 100 years, however, at least humanity has not yet come up with anything more reliable and easy to use.

The problem with misfire is solved instantly - you just need to press the trigger again and the drum will automatically place another cartridge under the firing pin.

However, many believe that the revolver is inconvenient to carry, and also, in order to reload it, and the drum holds 5-6 rounds, it takes time.

You just need to remember that this is a self-defense pistol, and in order to protect yourself, 5 rounds of ammunition is enough.

In conclusion, it should be recalled that gas self-defense weapons, strictly speaking, and ammunition for them, can only be purchased with a license, which is issued by the licensing authority at the place of registration.

In addition, you can purchase no more than 5 weapons per license, and after purchasing them, you must register the weapon with the same authority where the permit was issued.

Watch a video review of the Blow f06 gas flare pistol:

USM

The presence of a trigger mechanism is mandatory in any type of weapon. But in some types of pneumatics, only the trigger is used due to the uselessness of the blow itself. This allows you to get rid of excessive recoil and increase shooting accuracy, as well as simplify the design, which has a positive effect on its maintenance.

Impact mechanism

The use of an impact device is more relevant for pistols and rifles with pre-pumping or additional equipment with a container of compressed air. The principle of operation is extremely simple - at the moment when you need to fire a shot, the trigger hits directly the exhaust valve, which leads to its opening. The compressed gas is released, but the valve returns back under the influence of the spring, and the process can be repeated again.

In order for the blow to have sufficient force, it is transmitted using a mainspring. The more powerful it is, the longer the exhaust valve will be open. Increasing power leads to greater gas consumption, but allows you to achieve an initial bullet speed of 180 meters per second even on short-barreled pistols.

Mainsprings are divided into plate and screw. This is not to say that one type is better than the other, it is simply a design feature. The hammer itself is located between the trigger and the valve stem. In order for the spring to be cocked, a trigger sear is used.

The trigger can be made in both open and hidden versions. In the first case, the shooter has the opportunity to cock it manually, in the second, everything is given to automation.

Trigger

It is used in single-shot weapons and is intended to keep it cocked until the moment of release. Manufacturers strive to achieve maximum smoothness of its operation, since shooting accuracy and recoil power directly depend on this.

All trigger mechanisms that are used in modern air guns are divided into three main types:

- Single action. A distinctive feature is the need for an initial cocking of the hammer, and only after that the shot becomes possible.

- Double acting only. An automatic system with self-cocking, in which, at the moment the trigger is pressed, the trigger pulls the trigger, which leads to a strike on the valve using the mainspring. Arming does not occur and is performed manually by the shooter each time.

- Double action. A universal system that combines the two previous ones. As a result, the shooter can either use automatic weapons or cock the hammer manually.

It is worth noting that when shooting with self-cocking, much more force is required, which negatively affects shooting. This point must be taken into account if you plan to participate in competitions.

Diagram of the main parts of a firearm

The automation of modern pistols is based on the principle of using the energy of powder gases. There are two basic principles used in modern pistols - the use of blowback recoil energy and the use of semi-blowback recoil energy.

A free bolt is a bolt that is pressed against the breech end of the barrel only by the return spring and does not engage with it in any way. The bolt rolls back under the pressure of the powder gases on the cartridge case. The design of pistols with such a bolt is not difficult to manufacture, but it is successfully used in a large number of pistols of the twentieth century.

The design of a combat pistol with a semi-blowback is structurally similar to that of a blowback, with the exception of the presence of one part - the retarder. The retarder, as the name suggests, slows the rear movement of the bolt during firing, thus maintaining the integrity of the pistol frame. It is used in models of pistols and submachine guns that use powerful cartridges (caliber from 40 S & amp; amp; amp; amp; W). It is used infrequently thanks to various weapon recoil dampers developed in the mid-twentieth century.

The barrel of a pistol serves to give direction to the bullet, as well as to give it the necessary acceleration with the help of rifling in the inside of the barrel. As a rule, the barrel of a combat pistol is made using the cold forging method, and in the case of a traumatic one, options for milling and drilling the barrel are possible (for the sake of manufacturability and cost reduction). The barrel, as a rule, is conventionally divided into the muzzle (from which the bullet flies out when fired) and the breech (where the cartridge is loaded), to which the locking mechanism of the pistol presses the bolt.

The main part of the pistol is the trigger mechanism . It is this part that is responsible for firing from any weapon, be it a pistol or an artillery piece. There are two types of pistol trigger mechanisms:

Trigger , as a rule, with an open hammer arrangement, allows you to simplify the design of the pistol as much as possible, as well as ensure the safe release of the weapon from cocking without installing additional mechanisms.

The striker -fired trigger mechanism is somewhat more complicated to manufacture, but it has the ability to install several automatic fuses at once, increasing the reliability of the pistol. This mechanism is usually used on foreign-made pistols - Fabrique National, Glock, Smith & Wesson.

According to the operating principle, triggers are divided into single and double action. A single-action trigger requires the weapon to be cocked before firing, while a double-action trigger has a preliminary cocking, and re-cocking is done when the trigger is pressed, but you can also cock the hammer manually by moving the bolt. Double-action triggers are more widespread in the modern world.

The only drawback of the double-action trigger is the tight release when firing without first cocking the hammer.

Circuit breakers

As with firearms, air pistols and rifles must be protected against accidental discharges as the bullet's power is sufficient to cause serious injury. Globally, non-automatic fuses can be divided into two separate types.

The first is the locking trigger mechanism. When the weapon is put on safety, one of the key parts is blocked, as a result of which the descent becomes impossible. The trigger also becomes motionless.

The second is the separating firing mechanism. This type of fuse simply breaks the connection between the trigger and the rest of the system. As a result, you can press on it, it remains mobile, but the shot will not occur. This system can be compared to placing a car's transmission in neutral, in which the engine is disconnected from the transmission.

In addition to them, there are also automatic versions of fuses. In this area, manufacturers are constantly experimenting and offering unusual solutions. So, for some pistols, the shot will not occur without the full grip of the handle. Others block the release if the bore is not closed.

There are additional security methods. Some pistols are equipped with special indicators that show whether they are on safety or not. Some of them can be unloaded without firing the final shot, which can also be useful, especially if the pistol needs to be disassembled for servicing indoors.

Cleaning and lubrication - general recommendations

Umarex Airgun Cleaning Kit

When disassembling the pistol, you must follow the manufacturer's instructions specified in the weapon's passport. Cleaning and lubrication is carried out in several stages:

- wiping the barrel with a piece of oily rag on a cleaning rod until foreign deposits are completely removed (especially lead when using lead shot - 4.5 mm or “00”). Finally, the remaining lubricant is wiped dry with a cloth;

- lubrication of the trigger mechanism (trigger mechanism) . In practice, this is conveniently done by adding a drop of oil on top of the moving parts, after which it is advisable to fire several blank shots. The trigger should not be completely disassembled unless necessary;

- removing excess traces of oil from the surface of the gun without wiping it dry. This will allow the oil to form a thin film that protects the metal surface from corrosion.

Now let's look at specific tips for correcting breakdowns and defects of popular air pistols - heavy-duty clones of well-known firearms.

Why such a low price for a Kalashnikov pneumatic assault rifle? Comparison of AK prices from two manufacturers: Cybergun (Taiwan) and Junker-4 (Russia). Advantages and disadvantages of each model. Targets for shooting and training with air guns in A4 format can be viewed here. Choose between concentric circles and silhouettes.

Dispensers

This type of equipment is used on weapons with pre-pumping or gas cartridges. Its task is to release a limited amount of gas into the barrel at the time of cocking or firing, depending on the design.

Gas cylinder systems

In most gas-operated guns, the dispensers look and operate the same. To ensure proper functioning, the dispenser has three different openings. The first of them is intended for installing a can and is equipped with a special sealing gasket and a needle for piercing the membrane.

After the canister takes its place and is punctured, the gas enters a special chamber, behind which the release valve is located. Due to the high pressure, the valve does not allow gas to pass through until the release occurs. When the trigger is pulled, the trigger hits the stem, causing the valve to open. It returns to its place under the action of a spring and pressure.

The stronger the spring, the stronger the shock, and the longer the valve will remain open. Therefore, the spring itself and the stiffness of the valve can be considered the main metering devices of a pistol with gas cylinder equipment.

There are systems that do not have a third hole for the rod. In this case, the descent occurs due to the impact of the barrel itself with a weight on the exhaust valve.

Pre-pumped systems

Since the pressure in such a weapon can vary from shot to shot, it has two additional features. The first is a built-in reducer that controls the pressure directly in the dispenser chamber. Due to this, it is possible to maintain approximately the same power over several shots.

When the number of atmospheres in the container begins to decrease, the valve no longer fits so tightly, which can lead to a smooth release of air. To prevent this, additional pressure of the valve to the gasket is provided using a spring.

Repair of TT air pistol

A rather interesting and structurally complex development is the pneumatic version of the TT pistol. Its design ensures reliable operation of the gas system, which, if necessary, will be quite problematic to repair.

Sights

TT sights - rear sight and front sight

The rear sight and front sight of the pneumatic “analogue” of the Tula Tokarev are unregulated and can be repaired in the same way as in the Makarov pistol. The maximum that you can do yourself is to correct the slot in the rear sight with a needle file, moving the middle point of impact. This operation is not recommended for beginners, at least after a couple of thousand shots, when the shooter knows all the intricacies of his weapon.

Trigger mechanism

A distinctive feature of the pistol is the small number of moving parts and the absence of a powerful mainspring, so breakdown of the trigger mechanism is extremely unlikely.

You can see how the USM works in the video:

Shop

The original scheme, according to which the magazine is arranged separately from the gas supply system, reduces the adjustment and repair of the magazine to replacing the supply spring. The tightness of the cylinder puncture unit usually does not cause any complaints, and therefore requires only periodic visual inspection.

Air valve

The differences between the pneumatic TT and the much-loved PM model lie in the widespread use of pins and screws. To get to any part of the pistol, you must disassemble the bolt group or handle .

Replacing the mainspring

Since there is no powerful mainspring on the pistol, the repair consists of replacing one of two simple springs (see video about the operation of the trigger). Complete disassembly of a pneumatic TT is too difficult for novice users. If you suspect a serious breakdown, the best solution is to contact a repair center.

In case of major damage to the pistol, it is advisable to purchase a used model and make one working pistol out of two pistols.

For most DIY repairs, the standard diagnostic scheme and our advice are quite suitable. We hope that they will be useful not only in troubleshooting, but also in choosing a model - it is always better to initially know what you may encounter during operation.

Trunk

Not only the comfort and accuracy of shooting, but also the ease of its maintenance and cleaning depends on exactly how and how well the barrel is made. This is especially true for rifled barrels, which are used in most rifles and pistols.

Generally, the barrel design can be divided into three main parts:

- Threaded part;

- Pool entrance;

- Chamber.

The last of these elements is rare, since it is used only in weapons with a pre-pumped cartridge. In other models it is simply not necessary.

The bullet entrance is usually made in the form of a truncated cone, and is designed to correctly position the bullet or ball in the barrel before firing. This feature is easiest to notice in a single-shot rifle, which is cocked by breaking the barrel. The bullet is placed in place and held there securely until fired, and does not roll deeper down the barrel precisely due to its conical structure.

The rifled part is responsible for giving maximum acceleration and spinning of the bullet. Due to rotation, a fired bullet can cover a greater distance without losing speed, and fly much more accurately.

Most air rifles are made in 4.5 mm caliber because it does not require any special approval. But on sale you can also find “air guns” designed for firing bullets of larger calibers, up to 14.5 mm. Their exploitation is already associated with bureaucratic difficulties. They are usually used for hunting and have a pre-inflation system.

Lead bullets are used to fire rifled weapons; it is prohibited to use steel balls in them, since they are harder and can damage the barrel. In turn, the latter itself is made of steel. It is less common to find weapons with brass barrels.

In order to increase shooting accuracy, it is recommended to use rifles with a fixed barrel. More expensive models, which still use movable barrels, have compensation equipment, which is also used in conventional firearms.

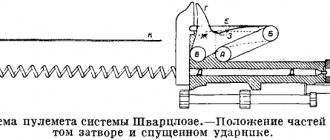

Automatic weapons. Systems using barrel recoil energy

Maxim Popenker. first published on All4Shooters.com

The use of recoil energy from a barrel that is movable relative to the weapon is one of the oldest and most successful principles for constructing automatic small arms. In more than a century since the appearance of the first such systems in the world, a wide range of weapons with a movable barrel have been produced - from compact pistols to machine guns and automatic cannons. However, it should be noted that there are significant gaps in this spectrum. In particular, only a very small number of models of hand-held long-barreled weapons with such automatic equipment (smoothbore guns and especially rifles) achieved any noticeable success. We will briefly discuss why this happened below.

Recoil is a fundamental property of any throwing weapon, stemming from Newton’s third law, which states that any mechanical action causes a reaction equal in magnitude but oppositely directed. In our case, this means that throwing a bullet or other projectile by the force of expanding gases leads to the fact that the throwing weapon receives a momentum of motion equal to the total impulse of the projectile (bullet) and the powder gases leaving the barrel, but directed in the opposite direction. It is this impulse that forms the recoil - the movement of the weapon in the direction opposite to the direction of the shot. In the case of a weapon with a fixed barrel and a rigid locking of the barrel, all this impulse from the barrel is transferred to the body of the weapon and through it to the hands or shoulder of the shooter or to the installation.

The first who managed to practically use the previously wasted recoil energy of a weapon to carry out its automatic reloading was the American inventor Hiram Maxim, who lived in Europe at that time. In 1883, he filed a patent application describing a conversion of the Winchester repeating carbine with a Henry brace and an under-barrel magazine. Having added a spring-loaded butt plate to the carbine, Maxim connected this butt plate with a system of rods and levers with a shortened reloading lever located in front of the trigger guard, so that with each shot, the movement of the entire carbine back relative to the butt plate resting on the shooter’s shoulder caused automatic reloading of the weapon. Soon this highly experienced self-loading carbine was followed by the first fully automatic machine gun of its own design, in which the barrel with its shank and the bolt connected to them by an cranked pair of levers were able to move under the influence of recoil inside the weapon box, stretching the return spring. This first machine gun was followed by others, and by the beginning of the twentieth century, Maxim machine guns had long become one of the most popular and successful weapons in their class.

diagram from the patent for the first self-loading carbine of the Maxim system using the recoil of the entire weapon relative to the butt plate, 1883

Soon other inventors followed Maxim. In 1893, Hugo Borchard created the first more or less commercially successful self-loading pistol with a moving barrel. The very next year, the Mauser company received a patent for its version of the C96 self-loading pistol, using the recoil energy of a movable barrel; in 1896, John Browning joined this glorious cohort with his first “pistol” patents. By the beginning of the twentieth century, various versions of automation systems using the recoil of a moving barrel firmly took their place among the most successful designs of self-loading and automatic weapons.

diagram from the patent for Borchard's 1893 self-loading pistol

diagram from a patent for a Browning self-loading carbine with a moving barrel (long stroke), 1900

It should be noted that the main competitor of automation systems with a moving barrel - a system using the pressure of gases removed from the barrel while the barrel is stationary - appeared almost simultaneously with the systems described here. However, for quite a long time, gas exhaust systems were noticeably less popular, and here’s why.

The earliest automatic weapon systems were created during the transition from black powder to smokeless powder; the intra-ballistic properties of the new smokeless powders were still very poorly studied, and the gunpowders themselves could have very different characteristics in terms of the development of pressures in the barrel when fired. At the same time, systems with a movable barrel depended only on the total recoil impulse when fired, and therefore were much less sensitive to variations in the powder charge and projectile, provided that the total impulse received by the barrel at the time of the shot was within limits determined by the designer, often quite wide. The main disadvantage of systems with a moving barrel was, as is usually the case, the source of its main advantages - that is, the moving barrel itself. In order to ensure the required reliability of the weapon in conditions of expansion of the barrel caused by heating, as well as accumulating carbon deposits or dust and dirt penetrating from outside, the barrel, of necessity, had to have some gaps at the interface with the stationary elements of the weapon. This inevitably led to a loss in accuracy and shooting accuracy compared to systems with a fixed barrel. In addition, the movable barrel needed support at at least two points - at the breech and in the muzzle of the barrel, or, in extreme cases, near its middle. For this reason, most systems with a moving barrel had a casing that covered the barrel along its entire length (or at least to the front fulcrum), which inevitably increased the weight and cost of the weapon.

As a result of the above, very few rifles with a moving barrel were produced in the world. The most successful (in terms of number of units produced) army model was probably the American Johnson system rifle model 1941 (Johnson M1941), produced in quantities of several tens of thousands of units. The most popular commercial model of a rifle with a moving barrel was the American hunting rifle Remington model 8 and its development model 81. Between 1906 and 1950, about 140 thousand units of this rifle designed by the legendary John Browning were produced. For comparison, gas-operated self-loading rifles and carbines were produced on both sides of the conflict during the Second World War alone, with a total circulation of more than 10 million units. The production of machine guns with a moving barrel (Maxim, Browning systems, German MG-34, MG-42 and others) during the same period also amounted to millions of units. True, there was one exception here - a self-loading shotgun of the same Browning system, known as Browning Auto-5, was produced in Belgium for almost 100 years, from 1902 to 1999, with a total production of over 2 million units. Additionally, over 800 thousand units of the licensed version of this system, the Remington model 11 shotguns, were produced in the United States. All other shotguns with a moving barrel ever created in the world could not even remotely repeat this success.

In the period after the Second World War, in connection with the development of both knowledge about the internal ballistics and dynamics of weapons, and the creation of more advanced gunpowders, the development of new machine gun systems with a moving barrel gradually began to fade away, giving way to simpler and easier-to-use systems with gas-operated automatics . True, a number of designs created before or during the Second World War still remain in service. First of all, these are the German MG-3 machine gun and the American Browning M2HB heavy machine gun.

But pistols with a movable barrel are still produced all over the world in quantities that are difficult to calculate, which can most simply be described as “millions of pieces per year.” This is explained by the ease of use of this scheme when combining the functions of the automation engine and the locking unit in the barrel of the weapon. The influence of the moving barrel on the accuracy of fire at typical “pistol” distances is very small, so systems with a moving barrel will remain the most suitable for use in powerful service and combat pistols for a considerable time.

Speaking about the technical aspects of systems with a moving barrel and its rigid locking at the moment of firing, it should be mentioned that all such systems, as a rule, are divided into two classes - “with a long barrel stroke” and “with a short barrel stroke”.

In systems with a short stroke of the barrel, the length of its rollback under the influence of recoil until the moment of disengagement with the bolt is, as a rule, significantly less than the length of the cartridge. Typically, for hand-held small arms, this length ranges from 0.5 cm to 3 cm, after which the barrel and bolt are disengaged, the barrel stops, and the bolt, under the influence of accumulated inertia, continues to move backward, removing and ejecting the spent cartridge case in recoil. Then, during the recoil, the bolt sends a new cartridge into the barrel and, at the end of its path, again engages with the barrel for the next shot. In most long-barreled systems (for example, machine guns), the mass of the bolt, as a rule, is noticeably less than the mass of the barrel, so that most of the momentum accumulated during their joint initial recoil is “lost” uselessly when the barrel, after disengaging from the bolt, stops in the receiver. In order to make good use of this “lost” impulse, many systems have introduced a so-called shutter accelerator. This mechanical device in the form of a lever or a pair of rollers interacts with the bolt and fixed structural elements of the weapon so as to transfer part of the impulse from the barrel to the bolt by accelerating the bolt relative to the barrel with associated braking of the barrel. In pistols where the weight of the barrel and bolt are usually comparable, or even where the bolt is heavier than the barrel, such a scheme has no practical application. Almost the only serial pistol that had a lever-action accelerator in its design was created in the mid-1930s in Finland (Lahti m35) and had a relatively short and therefore light bolt. Classic examples of short-stroke systems are the Colt M1911, Glock, Beretta 92 and many, many others.

typical scheme of automatic operation using the recoil energy of the barrel during its short stroke

Systems with a long barrel stroke are distinguished by the fact that in them the barrel, coupled with the bolt, together go through the full recoil path inside the receiver, and the length of this path is necessarily greater than the full length of the cartridge. At the end of the recoil, the bolt is intercepted in the rear position by a special sear, and the barrel, under the action of its return spring, begins to move forward. In this case, first the bolt is unlocked, then the barrel, moving forward, “leaves” the spent cartridge case remaining on the mirror of the stationary bolt. Once the cartridge case is completely out of the chamber, it is ejected from the weapon. When the barrel reaches its extreme forward position, it automatically turns off the sear holding the bolt, and the bolt, under the action of its spring, rushes forward, sending a new cartridge into the barrel and, at the end of the roll, again engaging with the barrel. Due to the large mass and long path of movement of the moving system, designs with a long barrel stroke, as a rule, have a low rate of fire, as well as a somewhat more complex design. Therefore, they are much less common than systems with a short barrel stroke. In addition to the Browning Auto-5 shotguns mentioned above, an example of a long-stroke system is the French Shosha CSRG M1915 submachine gun.

typical scheme of automatic operation using the recoil energy of the barrel during its long stroke

As we can see from this very brief review, systems with a moving barrel have a number of undoubted advantages that determined their success both in the early stages of creating automatic weapons and at the present time (though mainly only for self-loading pistols). The shortcomings of these systems have led to the fact that gas-operated automatics have now become the dominant design in long-barreled weapons.

Locking

The shutter is very rare in pneumatics, at least in its classical sense. Here, this system has a slightly different task - it must ensure blocking the release of gas after a shot in multi-shot rifles and pistols.

Gas pistols often use a system of retractable bushings that return the valve to its place in time. A simpler solution is to use a moving barrel, but this leads to a decrease in shooting accuracy.

Nutrition

Due to this mechanism, air pistols and rifles have the ability to avoid manual loading after each shot. Multi-shot models have a manual or automatic method of loading a bullet. In its turn. Projectiles can be automatically fed using two methods: gravitational and forced.

Gravity feeding can be used for explosive balls, however, they must be of high quality. When using it, the bunker is located at the top of the weapon. A similar principle is used in airsoft and paintball drives to ensure rate of fire and ease of reloading.

Forced feeding is ensured through the use of magazines with a conveyor or spring-loaded mechanism. Such stores can be equipped in advance and contain enough balls to consume an entire cylinder of compressed carbon dioxide.

In the case of bullets, the best option is to use a revolver-type drum, since they are quite soft. Some manufacturers have tried to produce pistols with spiral-fed magazines, but this design is difficult to maintain and less reliable, so it is extremely rare.

In some cases, pistol magazines inserted into the handle also contain a valve assembly. This allows you to equip each of them with a can in advance, so that later during shooting you do not have to count the number of shots until the power decreases.

Passport for gas pistol IZH-79-9T “Makarych”

4. Unnecessarily, do not point the gun with the barrel towards the person; when shooting, keep it at arm’s length.

5. Do not store the pistol in places accessible to others.

6. Do not use a defective gun.

Operating procedure

1. Before firing a pistol:

- equip the magazine with cartridges:

insert the magazine into the gun;

ATTENTION! When firing gas and blank cartridges, after each shot, reload by moving the bolt to the rearmost position

2. At the end of shooting:

- separate the store;

- make sure there is no cartridge in the chamber. If there is a cartridge, remove it;

- carry out partial disassembly of the pistol, for which: separate the bolt from the frame by pulling the trigger guard down, move the bolt to the rearmost position and lift its rear end;

- clean and lubricate the gun;

- assemble the gun and check its functionality;

- move the fuse to the “safety” position.

3. Clean the gun after each use.

Instructions for using rubber bullet cartridges

1. Cartridges must be used for firing only from serviceable weapons.

2. FOR SHOOTING FROM THE IZH-79-9T PISTOL, ONLY 9mm R.A. CALIBER CARRIAGES CAN BE USED. WITH RUBBER BULLET ACCORDING TO TU 7272-042-13052820-03 PRODUCED BY JSC “TEKHKRIM”, designed and tested within the framework of a single “cartridge-weapon” complex.

3. To meet forensic requirements for the inability to fire cartridges with a metal bullet, there are inserts in the pistol barrel (item 17, Fig. A.2) that allow the passage of only an elastic bullet with a certain rigidity.

4. The inserts are designed in such a way that only when using cartridges with a bullet of a certain hardness, reliable operation of the automatic pistol is ensured with the extraction of the spent cartridge case and the feeding of the next cartridge into the chamber.

5. The gun bore is protected from corrosion: the walls of the bore are chrome-plated, the barrel inserts are made of stainless steel.

6. It is prohibited to use cartridges that have expired.

7. After cleaning the gun, visually check that there are no foreign objects in the barrel bore.

Instructions for the use of gas cartridges

1. Cartridges must be used for firing only from serviceable weapons.

2. Cartridges should be stored only in the manufacturer’s packaging in a plastic box sealed around the perimeter with adhesive tape. It is not allowed to carry cartridges in clothing pockets.

3. After opening the box of cartridges, you must make sure that there is no substance C5 in the form of white deposits or powder on the inner surface of the box. The box with traces of the substance is closed and sealed around the perimeter with adhesive tape.

4. If, after opening a box of cartridges, symptoms of the presence of a substance are felt (sneezing, sore throat, burning in the eyes and nose, lacrimation, nasal discharge), it is necessary to wipe the cartridges with a cotton swab moistened with alcohol or an alcohol-containing liquid.

5. It is not allowed to apply significant force to cartridges that are not included in the pistol magazine.

6. It is not recommended to touch the face and especially the eyes with hands that have been in contact with gas cartridges or parts of the pistol after firing gas cartridges.

7. When using a pistol, it should be taken into account that when fired, solid particles from the projectile can cause serious harm to the health of an object located at a distance of less than 1 m from the muzzle.

8. When firing, the pistol must be held at arm's length. After the shot, you must immediately move a few meters away from the shot site to avoid exposure to the aerosol cloud.

9. In a headwind, there is a danger of the shooter being exposed to an aerosol cloud.

10. After shooting, it is necessary to disassemble and clean the pistol. If this is not possible, you should place the gun in an airtight package, for example, a tightly tied plastic bag.

11. The gun is cleaned with a cloth moistened with alcohol, alcohol solutions, or alcohol-containing liquids. The outer surface of the frame and magazine must be cleaned. The inner surface of the barrel is washed with an alcohol-containing liquid.

12. The gun should be cleaned outdoors. When cleaning the gun, do not touch your face and especially your eyes. After cleaning, wipe your hands with alcohol or an alcohol-containing liquid and rinse with plenty of warm water.

13. If the CS substance is spilled, it must be collected with a swab moistened with alcohol, alcohol solutions, or alcohol-containing liquids.

14. After a shot fired indoors, or if there are signs of CS substance in the air, you must leave the room, ensuring it is ventilated for an hour. For intensive ventilation, it is advisable to provide a draft or ventilation, for example, using a household fan.

15. If substance C5 gets on your skin, wipe the skin with alcohol or alcohol solutions and rinse with plenty of warm water.

16. If substance C5 gets into your eyes, rinse your eyes with plenty of warm water. In case of severe pain, drip into the eyes a mixture of 3...4% novocaine solution and 1% atropine solution in a 1:1 ratio (“Safety instructions for working with CS”, Volgograd, NIIGTP, Ministry of Health of the Russian Federation).

17. Cartridges must be stored in dry, heated rooms at temperatures from 278K (+5°C) to 313K (+40°C).

18. It is prohibited to use cartridges that have expired.

19. Heating of cartridges and contact with dust, dirt and atmospheric precipitation is not allowed.

20. It is not allowed to store cartridges near heating devices and open fires, as well as together with flammable substances.

21. It is necessary to protect cartridges from impacts and falls.

22. Depressurized cartridges and cartridges with expired storage life are rendered harmless by firing under conditions that guarantee no impact on people.

The pistol must be stored indoors or other premises with natural ventilation without artificially controlled climatic conditions, where fluctuations in temperature and air humidity are significantly less than in the open air (for example, stone, concrete, metal with thermal insulation and other storage facilities), which may be located in any macroclimatic areas, including areas with a tropical climate.

The shelf life of the pistol in undamaged original packaging (subject to the conditions specified above) is 12 months from the date of preservation at the manufacturer, after which it is necessary to re-preserve it.

manufacturer's warranty

The warranty period for the pistol is 6 months.

The warranty period is determined from the date of sale indicated in the passport, subject to the name and address of the trade organization that sold the gun, the store stamp and the seller’s signature. In the absence of such, the warranty period is calculated from the date of manufacture indicated in this passport.

The list of requirements that the consumer can present when identifying defects in the pistol during the warranty period is determined by Art. 18 of the Law of the Russian Federation “On the Protection of Consumer Rights” dated 01/09/1996.

Warranty obligations become invalid in the following cases:

- violation by the consumer of the rules for use, storage or transportation of goods;

- occurrence of defects in the goods due to the actions of third parties or force majeure after the goods are transferred to the consumer.

To carry out repairs and maintenance of the pistol, you should contact only specialized workshops for repairing sporting and hunting weapons.

Address of the head warranty workshop at the manufacturer: 426063, Izhevsk, st. Promyshlennaya, 8, FSUE “Izhevsk Mechanical Plant”, tel. 75-95-59. The addresses of workshops located in other regions are listed in the insert attached to the passport. In addition, the store where you purchased the pistol should provide you with the address of the warranty workshop.

Warranty repairs of the pistol are carried out in the workshop within no more than 20 days from the date the owner contacts the workshop (the date of withdrawal of the pistol is indicated in the stub of the warranty repair coupon).

If the workshop cannot restore the pistol due to a lack of spare parts, then the pistol is sent to the manufacturer, and the deadline for warranty repairs should not exceed 45 days.

Addresses of workshops for repair of sporting and hunting weapons: Republic of Kazakhstan, Aktobe, st. Zhankozha-Batyra, 24, tel. 21-16-59, fax 96-06-75; Arkhangelsk, st. Voskresenskaya, 118-172, tel. 23-63-32; Barnaul, st. E. Alekseeva, 17, tel. 33-60-27; Blagoveshchensk, st. Amurskaya, 133, tel. 44-99-33; Alania, Vladikavkaz, st. Galieva, 77-s, tel. 52-49-76; Volgograd, st. Chuikova, 23, tel. 36-45-22; Ekaterinburg, st. Rosa Luxemburg, 19, tel. 37-95-73; Izhevsk, st. Pesochnaya, 11, tel. 59-87-92; Kazan, st. Vosstaniya, 8, tel. 42-82-78, fax 19-02-90; Kemerovo, st. Kirova, 41, tel. 36-25-71; Kirov, st. Komsomolskaya, 13, tel. 62-69-69; Kirov, st. Moskovskaya, 1-v, tel. 62-46-94; Krasnodar, st. Machugi, 78, tel. 09/37/91; Republic of Belarus, Minsk, st. Bogdanovicha, 46, tel. 234-77-51; Republic of Belarus, Minsk, st. Sharangovicha, 7, tel. 210-24-38; Murmansk, st. Chelyuskintsev, 37, tel.: 42-06-66, 42-34-99; Nadym, st. Polyarnaya, 1, tel. 4-10-67; Novosibirsk, Kommunistichesky Ave., 43, tel. 23-13-44; Novy-Urengoy, microdistrict “Northern Communal Zone”, tel.: 5-11-39, 5-11-29; Orenburg, st. Kobzeva, 59, tel. 77-71-75; Orenburg, Parkovy Ave., 11, tel. 77-05-17; Orekhovo-Zuevo, Central Boulevard, 3, tel. 12-58-18; Perm, st. Kuibysheva, 66, tel. 45-93-54; Rostov-on-Don, st. 2nd Krasnodarskaya, 145, tel. 24-15-83; Samara, st. Entuziastov, 27, tel. 70-54-56; St. Petersburg, st. Lvovskaya, 8, tel. 540-08-30; Stavropol, st. Lenina, 287, tel. 35-55-67; Tomsk, st. Nakhimova, 18, tel. 41-63-46; Tula, Timiryazev Ave., 2, tel. 31-94-11; Tyumen, st. Vodoprovodnaya, 40, tel. 46-22-33; Ulyanovsk, st. Lokomotivnaya, 207-a, tel. 46-06-43; Cheboksary, st. I. Franko, 17, tel. 20-96-07; Chelyabinsk, st. Tchaikovsky, 183, tel. 97-02-39.

Automation

If previously most air rifles were single-shot spring-piston mechanisms, now you can find many automatic and semi-automatic offers on sale.

Pistols equipped with the BlowBack system are fully automatic and autonomous, which allows continuous shooting until the magazine is completely empty. On the shelves you can find rifles with a bolt action similar to that used on sniper firearms.

From this we can conclude that in terms of automation of the charging and cocking process, air guns have already fully achieved the progress that is in the case of firearms.

Pistols with Blowback

Gunsmiths rarely produce airguns with Blowback. Models with such a system are chosen only by true weapon connoisseurs. Popular companies that manufacture air pistols with a moving bolt frame: Gletcher, Crosman, Umarex. Externally, pneumatics with Blowback resemble military weapons. Pneumatic simulators of firearms are purchased by fans of realistic shooting.

Unlike the original, you do not need permission to purchase a 4.5 mm caliber copy. Low-power modifications with a moving shutter are intended for sports and training activities. When purchasing a pneumatic gun, it is enough to present your passport.

The Makarov pistol

An air pistol (for example, MP-658K), similar in appearance to the legendary Makarov pistol, is intended for training. Thanks to the bolt frame moving when firing, you can feel how a real combat firearm behaves. The “imitation” Makarov has a 4.5 mm caliber, a magazine with steel balls, runs on a CO2 cylinder, and costs about $120.

Gletcher TT

This is a pneumatic “imitation” of a real TT combat firearm (Tula Tokarev).

The size of the copy is identical to the original. The presence of the Blowback system allows you to experience the beauty of realistic shooting. True, the copy shoots 4.5 mm steel balls, runs on a CO2 cylinder, and costs about $80.

Gletcher BRT-92FS

The BRT-92FS air gun is reminiscent of the Italian Beretta 92FS firearm. The replica has a metal construction identical to the original and weighs 1.1 kg. True, the pneumatic gun shoots 4.5 mm steel balls and is powered by a can of CO2. The cost of a copy with the Blowback system is about $100.

Walter PPK-S

The air pistol from Umarex - Walther PPK-S - is an exact copy of the German Walther PPK self-loading firearm. The moving bolt carrier allows you to feel the true recoil. “Imitation” shoots 4.5 mm steel balls, is powered by CO2 cartridges, and costs $130.

Crosman Benjamin Trall NP

Crosman's air pistol, the Benjamin Trail NP, operates on a spring-piston mechanism with a gas spring. The model itself resembles a firearm. True, Blowback is not available in this modification. But the pneumatic version of the Benjamin Trail NP shoots 4.5 mm lead bullets and is loaded by breaking the barrel. During a shot, the shooter feels the real recoil of a military weapon. The model costs $110.

Crosman C31

The pneumatic model C31 is somewhat reminiscent of a real Beretta 90-Two combat firearm. The presence of a moving frame allows you to feel the true impact. The copy runs on CO2 cylinders and shoots 4.5 mm steel balls. The “imitation” costs $90.

Gletcher CLT-1911

This is just a pneumatic copy of a Colt military firearm. True, the “imitation” shoots exclusively with 4.5 mm steel balls. Thanks to the moving bolt, the shooter can feel real recoil. Pneumatics operate on 12-gram gas cartridges. The moving shutter model costs $95.

Gletcher APS

This pneumatic modification looks like a Stechkin combat pistol. To the great joy of fans of the original - identical sizes and a realistic Blowback. When firing from a pneumatic replica, the shooter may think that he is holding a Stechkin firearm in his hands. The “imitation” with 4.5mm steel balls runs on CO2 and costs $105.

Glock 17

The pneumatic gun from Umarex is reminiscent of a real Austrian self-loading Glock-17. The design of the copy is similar to the original. The shutter movement system allows you to feel the recoil of a genuine firearm. The pneumatic gun shoots 4.5 mm steel balls and is powered by a can of CO2. A copy costs $205. There are also airsoft Glock-17 models on sale with Blowback, which shoot plastic balls and are gas-powered.

Aim

Initially, rifles and pistols can be equipped with simple sighting devices, such as grooves, sighting bars with front sights and the like. However, all modern models have the ability to install additional equipment due to the provided mounts.

Thus, any sight designed for a firearm, from a collimator to powerful optics, can be installed on the air gun. Some pistol models also have this capability, and are even equipped with optics directly from the manufacturer. Therefore, the shooter himself can choose which type of sight to use.

Hold

The same elements used in firearms are used to hold air rifles and pistols. In the case of the former, this is the stock, forearm and butt. Sometimes there is a rubber butt pad in the rear, which is designed to reduce the recoil of the most powerful models.

The pistols have a comfortable handle, which also serves to place a carbon dioxide cylinder inside the magazine. Some models, modeled after submachine guns, may have a folding or clip-on stock.

Additional items

Airguns can be upgraded and improved with certain types of additional equipment. Here are four examples of devices that can help you achieve higher accuracy and shooting comfort:

- Silencers. Used in models with pre-pumping. They slightly reduce the power of the shot, but make its sound noticeably quieter, which is important for hunting. Some rifles may have false suppressors installed, which are subsequently replaced by shooters with full-fledged equipment.

- Shock absorbers. Used to reduce recoil on single-shot rifles with a spring-piston mechanism.

- Compensators. In most cases, they are installed for decorative purposes, but in powerful rifles they can reduce tilting at the moment of firing, which will improve shooting accuracy.

- Muzzle. It is made as a thickening at the end of the barrel, which makes it easier to reload, creates an additional reference point when aiming and simply decorates the rifle.

How to disable blowback

If desired, Blowback in some models can be disabled independently. The deactivated bolt carrier movement option will save gas consumption, increase shot power and shooting accuracy.

In order to disable Blowback, it is necessary to disassemble the weapon and remove the small lever responsible for the movement of the bolt during shooting. The fact is that the design has a special lever, which at the moment of firing activates the recoil of the bolt frame. If you remove it, the shutter will stop moving back and forth and will stand in one place.

True, some shooters do not know how to disassemble a weapon themselves. In addition, during disassembly you can accidentally damage the structural mechanisms. If disassembling the pistol is problematic, it is better to buy a pneumatic without Blowback. Such a pneumatic gun even costs an order of magnitude less.