A little history

In 1963.

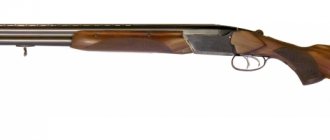

In 2009, the TOZ-25 double-barreled hunting rifle was developed and put into mass production at the Tula Arms Plant. This is a fairly reliable, easy-to-use smoothbore hunting rifle with horizontal barrels. This double-barreled hunting rifle was produced until 1968, and over the entire period about 57 thousand copies of the TOZ-25 were produced. Approximately a third of all copies were exported

The TOZ-25 smoothbore shotgun itself left only positive impressions on both professional hunters and amateurs. Currently, of course, this gun is not produced, but even on the secondary market the TOZ-25 is in demand, because even with careless care, this Tula gun is very resistant to rust.

Heap TOZ-25: cutting off the chokes

photo: Semina Mikhail

As usual, a case helped: one of my colleagues, who had stopped hunting a long time ago, decided to part with his gun.

And he had it remarkable.

I first noticed him back in 1983 or 1984, when we were on the same team going for wild boars.

Arriving at the base in the evening after a day of hunting, everyone hung their weapons on a rack on one wall, and it turned out to be a kind of exhibition of a dozen guns.

They were mostly easily recognizable models, but one of them stood out from the rest. Its lines were smooth and harmonious.

The apparently lightweight 16-gauge hammerless rifle, with a straight English walnut stock with carefully hand-made fine checkering on the thin neck and fore-end, looked elegant.

The owner was clearly a neat man and took care of it, so that it looked like new. To my surprise, the gun turned out to be domestic. This is how I first became acquainted with the TOZ-25, which a decade and a half later ended up in my hands.

A double-barreled internal trigger shotgun with horizontally paired barrels designed by V.S. Kozlov and V.I. Paramonov was mass-produced in 12 and 16 calibers in 1963 - 1966. Piece guns were produced for some time afterwards.

For example, I received a shotgun Sh-896 produced on October 24, 1967. The barrels are locked in three ways: with under-barrel hooks and with a Griner bolt on the protrusion of the breech of the barrels. The barrel channels and chambers (70 mm) are chrome plated. The castle has an original design.

The authors tried to take into account the shortcomings inherent in most hammer-operated shotgun models, both domestic and foreign made. And the main one is the weakening of the stock, associated with the placement of the trigger mechanism in its thinnest part.

Attempts to maintain the strength of the stock by placing the percussion mechanisms entirely or partially inside the receiver weaken the latter and reduce the survivability of the gun.

The TOZ-25 uses an unusual solution for a horizontal plane: the trigger mechanism is mounted on a base that forms a rigid frame structure with the box. The stock is attached to the rear projection of this frame with a screw passing through the stock (like the IZH-27).

On the sides, the trigger mechanism is closed with cheeks fastened together with a screw. When the gun is assembled, these cheeks look like a continuation of the stock and allow you to preserve its classic shape.

Thanks to the detachable cheeks, it is possible to inspect, clean and lubricate the mechanism without separating it from the receiver.

Another original solution made it possible to avoid the usual removal of metal for cocking the triggers and sharpening the working part of the sears, which usually quickly become dull, which leads to the triggers falling off the sears.

Finally, in the vast majority of guns, the mainsprings have a complex shape, are very labor-intensive to manufacture, and are not always reliable. In TOZ-25, the mainsprings work to twist. They are very simple and can be made from steel wire by any mechanic and even at home.

The weight of a 12-gauge gun is 3-3.2 kg, 16-gauge - 2.9-3.1 kg. Barrels are 70-72 cm long with muzzle constrictions of 0.5-1.0 mm. This is your passport information.

But in our country you cannot trust documents. Although the weight of 3.0 kg was written in the passport of the specimen that fell into my hands, when I put it on the scales, I saw the needle stop at 2785 g. Great, it exceeded my expectations!

But the balance was not the best: the gun was balanced at a point located 75 mm from the breech end of the barrels. The barrels with the forend separated from the stock were balanced at 24.5 cm from the breech, which completely replicates the similar indicators of the TOZ-34 and suggests that this is a standard for TOZ.

Not trusting what was written anymore, I measured the barrels: the right barrel has a muzzle constriction of 0.8, not 0.5 mm. The left barrel had a 0.95 mm choke.

| photo: Nikonova Pavel |

But I purchased this gun with a certain thought, and measurements of the barrels and balance only strengthened me in my intentions: I didn’t need a 16-gauge gun that hits too hard and is not very well balanced. I decided to rid him of the strict choke restrictions that were unnecessary to me.

In principle, it would have been enough to remove the choke only in the right barrel, but since the chrome-plated channel did not allow this, we had to solve the problem radically, that is, by sawing off the ends of both barrels to the entire length of the choke constrictions.

The internal diameter of both barrels was 16.78 mm. The narrowing in the left barrel began a little earlier than in the right: 65 mm from the muzzle, the right barrel remained cylindrical, and the left one already had a narrowing of 0.1 mm.

I wanted to ensure a difference between the barrels, so that the left one would hit at least a little more accurately than the right one. This could be done by preserving the beginning of the constriction, thereby turning it into a Parker choke, that is, a conical choke constriction without a subsequent cylindrical section of the bore just before the muzzle. Such chokes hit no worse than regular ones, but wear out faster.

I decided to cut at 55 mm from the muzzle, where the right barrel had a bore diameter of 16.57 mm, and the left one 16.46 mm. We carried out the operation together with a friend, since it was impossible to firmly clamp the trunks in a vice without damaging them.

We actually clamped not the trunks, but wooden slats placed on the connecting strips, so that the jaws of the vice did not touch the trunks at all. One sawed, and the second fixed the trunks, holding them by the chambers and using the large lever thus formed.

It turned out to be more difficult to process the cut of the trunks with a file evenly, without bevels, since in the center between them there were two strips connecting them, the steel of which was much harder than the barrel, which led to the constant collapse of the file.

Having finally dealt with this matter, we received barrels with a muzzle diameter of 16.6 mm on the right and 16.5 mm on the left, that is, with narrowings of 0.2 and 0.3 mm, respectively.

The most exciting thing remained - to check the result by shooting. I was shooting at a 16-lobe target with a diameter of 70 cm with N№7 shot, having equipped several batches of cartridges with different weights.

| photo: Fotolia.com |

The most stable results were produced by a batch containing 28 g of shot and 1.75 g of “Falcon” with a felt main and wood-fiber additional wad and cardboard spacers for gunpowder. The right barrel exceeded all expectations: at a distance of 35 m, the accuracy ranged from 50 to 607, with a concentration towards the center of 1:1.5 (where the first number is the number of holes in a small circle with a diameter of 35 mm, and the second in the peripheral ring).

The uniformity of the scree was beyond praise: the number of holes in each of the 16 fields was almost the same, differing from each other by 1-3 holes. I could only assess the sharpness of the battle by the penetration of the pellets into the dry, planed pine board. It also turned out to be beyond praise: the pellets penetrated the wood to a depth of 3-4 times their diameter.

But the results of shooting from the left barrel were far from equal: the targets were much poorer; accuracy ranged from 30 to 42%.

The scree was uneven—some fields were left completely untouched by shot—and inconsistent from shot to shot. But the most unpleasant thing was that the center of the scree was shifted to the left and up.

A meticulous examination of the muzzle of the barrels with a ruler against the light showed that we still failed to completely cope with the file: the left barrel was barely noticeably blocked. But it was impossible to fix it separately from the right trunk - then they would have turned out to be different lengths.

It was necessary to decide: to leave everything as is, having received an outstanding right barrel for a cylinder with pressure and a very mediocre left one, or, at the risk of ruining the right one without fixing the left one, cut off a little more.

After much hesitation, it was decided to cut another 5 mm. This time, special attention was paid to ensuring that the cut was perfectly smooth, without heaving, and finishing the end on a lapping plate.

Then shooting with cartridges from the same batch gave a much more modest result in accuracy from the right barrel - 39%, and from the left - 42%. The loss of accuracy with the right barrel did not upset me at all, since I don’t need it: this gun is designed to shoot almost exclusively at distances of 10-25 meters.

And now the stability and uniformity of the scree in the right trunk was maintained the same as during the first shooting, and this really made me happy.

The left barrel turned out to be corrected; now it gave the same stable and even scree as the right one, a little more crowded, but, oddly enough, with less condensation towards the center: in the targets of the right barrel in the small circle there were on average 48 holes, and in the peripheral circle 81, and in the targets On the left, there were an average of 46 pellets in the center, and 96 in the peripheral ring.

We also checked the uniformity of the scree with cartridges containing N№9 shot at a distance of 25 meters, which, in general, was already superfluous: everything was already clear - the gun hit exactly the way I needed.

All that remains is to drill a hole at the end of the sighting bar, cut the thread and place the front sight in its place.

The hole that formed between the barrels and the connecting strips was riveted with lead: tapping with a light hammer, we drove a couple of buckshots into it, then cutting off the irregularities with a shoe knife flush with the muzzle of the barrels, which immediately took on a completely finished look.

So, as a result, I got barrels 65.6 cm long, weighing 1375 g together with a forend, with a df of 0.08 mm in the right barrel and 0.18 mm in the left.

The gun now weighs 2665 g with a center of mass of 52 mm from the breech end of the barrels in the assembled gun and 22 cm in the barrels with forearm separated from the stock. For comparison: similar points in Marocchi are located respectively 55 mm and 20.5 cm from the breech.

The gun has been field tested for three seasons. In 2000, I hunted almost exclusively with this gun and, having killed about a hundred pieces of game with it in a month from under my shorthaired pointer, I was very pleased with it.

Quail hunting was equally successful during the three-week fire ban period in the summer of 2002.

| photo: Fotolia.com |

A number of questions arise for the manufacturer. First: why doesn’t he love us hunters so much? After all, it was possible to make such a gun right away, without forcing hunters to turn a friend’s kitchen into a metalworking workshop.

If TOZ himself did this right away, then there would not be a cylinder in the left barrel, but a more logical pay for it. And you wouldn’t have to cut like a living thing, in constant fear of ruining a good thing.

Question two: why was such a good model discontinued? TOZ's assortment policy is amazing - over the past few decades, this enterprise has abandoned a number of products that had stable demand: these are models A and B, with which the production of hunting rifles began at TOZ.

Moreover, model B (BM, TOZ-63, 66, 50, 54, 80), the famous hammer-fired “tulka,” was, and still remains, the most widespread and most popular hunting rifle in the outback. A rural hunter says: “A gun without triggers is like a cow without horns.”

There is also a rational grain in rural conservatism: the “tulka” is simple and reliable, and any mechanic can repair it, and in the conditions of the Russian outback this is very important.

The plant once produced cage guns, but then stopped. And here is also the TOZ-25 model. Nothing was offered in return.

The TOZ-34 model, launched in the same period, cannot be a replacement for this gun for a number of reasons: firstly, it is a sideflint, which means a product that occupies a very close, but still its own niche in the market and does not displace TOZ-25.

And, secondly, as a hunter who has used both of these models, I find that the TOZ-25 is more successful.

Firstly, because it is more beautiful: this gun has classic shapes and proportions. Secondly, it is stronger: its design successfully solves exactly the problem that is the weakest point of the TOZ-34 (the connection between the box and the stock). And thirdly, this gun was produced in 12th and 16th calibers with a weight characteristic of them, but the TOZ-34 of 20th or 28th caliber weighs exactly the same as the 12th.

And why are they needed then? If a hunter needs a weakened charge, for example a 28-gauge, then he can equip it in a 12-gauge case, but the reverse operation, that is, a 12-gauge charge in a 28-gauge case will not work. And it’s not necessary, since there is a 12th one and it weighs exactly the same.

And one more thing: the copy that fell into my hands is a “piece” gun, released for the first of a large series of Brezhnev anniversaries: the 50th anniversary of October. And although this is not a masterpiece of applied art, there are no reproaches to the taste with which the gun is made.

Today's finishing of TOZ "piece" guns is noticeably different, and not for the better. The consumer, making a choice in favor of a “piece” gun, hopes to receive a product that is carefully assembled from the highest quality components.

It would not hurt the Tula residents to take a closer look at that unobtrusive, discreet manner of decorating serial “improved” and “piece” guns, which was in use at their own factory in the 1960s.

And thanks for the gun. It’s a pity that I would like to advise readers to buy the same thing, but I can’t: I don’t want to tease.

Sergey Kolmakov August 3, 2022 at 1:50 pm