Delays when firing a pistol: types of delays, causes and solutions

A pistol, when handled correctly, carefully maintained and preserved, is a reliable and trouble-free weapon. However, during prolonged operation, due to wear and tear of parts and mechanisms, and more often due to careless handling and inattentive maintenance, delays in firing may occur.

To prevent delays when firing a pistol and ensure its safe operation, you must:

- properly prepare a pistol for shooting;

- inspect, clean and lubricate the gun in a timely manner and in compliance with all rules; Take special care to clean and lubricate the rubbing parts of the gun;

- carry out repairs in a timely manner;

- inspect cartridges before shooting;

- Do not use faulty, rusty or dirty cartridges for shooting;

- during shooting and when moving, protect the pistol from contamination and impacts;

- If the pistol is in severe frost for a long time before firing, then before loading it it is necessary to release the bolt several times by hand and release it, and after each retraction and release of the bolt it is necessary to release the trigger by pressing the tail of the trigger.

If there is still a delay during shooting, then it must be eliminated by reloading the pistol (cocking and releasing the bolt frame - editor's note) .

If the delay cannot be eliminated by recharging, then it is necessary to find out the cause of the delay and eliminate it as indicated below.

Types of delays when shooting, causes and ways to eliminate them

| Type of malfunction | Reasons for delays | Ways to eliminate them |

| 1. Misfire. The bolt is in the forward position, the trigger is pulled, but the shot does not fire. | 1. The cartridge primer is faulty. 2. Thickening of the lubricant or contamination of the channel under the firing pin. 3. The output of the striker or nick on the striker is small. | 1. Reload the pistol and continue shooting. 2. Inspect and clean the gun. 3. Poison the gun to the workshop. |

| 2. Failure to cover the cartridge with the bolt. The shutter stopped before reaching the extreme forward position; the trigger cannot be pulled. | 1. Contamination of the chamber, frame grooves, bolt cup. 2. Difficult movement of the ejector due to contamination of the ejector spring or pressure. | 1. Push the bolt forward with a push of your hand and continue shooting. 2. Inspect and clean the gun. |

| 3. Failure to feed or not advance the cartridge from the magazine into the chamber. The bolt is in the forward position, but there is no cartridge in the chamber; the bolt stopped in the middle position along with the cartridge, without sending it into the chamber. | 1. Contamination of the magazine and moving parts of the gun. 2. Bent upper edges of the magazine body. | 1. Reload the pistol and continue shooting. 2. Clean the gun and magazine. 3. Replace the faulty magazine. |

| 4. Seizing (pinching) of the cartridge case by the bolt. The cartridge case was not thrown out through the window in the bolt and became wedged between the bolt and the breech end of the barrel. | 1. Contamination of the moving parts of the gun. | 1. Throw away the stuck cartridge case and continue shooting. 2. Send the gun to the workshop. |

| 5. Automatic shooting. | 1. Thickening of the lubricant or contamination of parts of the trigger mechanism. 2. Wear of the hammer cocking or sear nose. 3. The sear spring is weakened or broken. 4. Touching the shelf of the fuse ledge of the sear tooth. | 1. Inspect and clean the gun. 2. Send the gun to the workshop. |

Checking the pistol and bringing it to battle

Combat testing is an important element in maintaining combat readiness. During the inspection, discrepancies with the factory performance characteristics are revealed, the accuracy and reliability of the weapon is verified, as well as the internal condition of the pistol and indications for use. The lubrication condition of the weapon and its ammunition is also checked in order to prevent misfires when firing.

The inspection is carried out both assembled and disassembled, the barrel and firing pin must be inspected, and the trigger and feed mechanisms are checked.

To be admitted to combat testing you must:

- Identify all possible causes of misfires when shooting;

- Eliminate all causes leading to misfires using the actions listed above, based on typical problems;

The combat check is carried out in clear weather. For testing, a target with a diameter of 250 mm is required, as well as a shield measuring 1x0.5 m. The shield with the target attached is installed at a distance of 25 meters from the shooter. The shooter is given four serviceable cartridges of the same series; the shooter can shoot from the hands or from a rest, but always in a standing position. When shooting with a rest, the hand with the pistol should be suspended.

The shooter fires four shots, each of them carefully aiming at the same point. At the same time, a weapon with normal combat is a pistol, all four hits of which fit into a circle with a radius of 125 mm. If the shots do not fit, then correction of the sighting devices is applied. After bringing the weapon to normal combat, a control notch is applied to the bolt casing, fixing the desired location of the sighting devices.

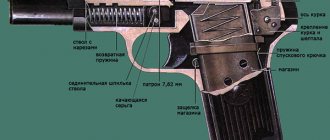

Striker offset

Allowable print offset is maximum 0.5 mm. Poorly fitted barrels contribute to the displacement of the imprint, and instead of a shot, a misfire occurs. The hinge axis or the barrels themselves are replaced. In the most extreme case, on some models it is possible to cut holes in the box and bend the striker. But then the possibility of deformation of the bottom of the capsule cannot be ruled out. The firing pin may jam, leading to a crossbow. Any independent manipulation is unacceptable - it is fraught with consequences, it is better to give the gun to a specialist.

Causes of misfires caused by weapons

The cause of misfires can be not only the breakdown of a gun part, but also improper care will cause many problems. It’s especially disappointing when a misfire occurs after seemingly perfect preparation of the weapon. Improper lubrication During the cold season, some hunters try to better lubricate their weapons. And this excessive care can provoke a misfire. In the cold, the lubricant thickens, dirt, dust, particles of steel cartridges, and unburnt gunpowder stick to it. At the factory, liquid oil is used for lubrication, all excess drains off. It is designed for approximately 6 months. In any case, when preparing a weapon for hunting, only the bore is cleaned. For preservation, a thicker lubricant is used. The same type is used in winter, so to avoid misfires, wipe all metal surfaces with a rag. The rag itself is moistened with auto scrap or other mineral oil. Lubricating the mechanism has its own nuances: Heat. A drop of liquid oil should be received by the strikers (special hole), the locking lever, and the locking plate. The excess is allowed to drip off. The procedure is carried out every six months. Moisture. Lubricate parts more often and more thoroughly. Cold. The weapon is kept almost dry. They even prevent oil from getting on the wood, as it makes it brittle. The composition of the lubricant should be taken seriously: increased acidity removes the black oxide film. You should not use sunflower oil containers for storing lubricants - its remains, if they get on the mechanisms, will stick them together.

Violation of trigger cocking

And yet, many hunters, after a misfire, use the triggers. Disturbances in their operation, leading to misfires, are caused by several cases: Increased rebound. The best option is when the firing pin is flush with the shield. Too much rebound results in loss of necessary energy. Once the trigger is cocked, the interceptors do not release it. This can happen if a very large force was applied to the trigger: the gun falls, abruptly closes. The charging chain may have a manufacturing defect or a missing part due to poor quality assembly. Misfire can also be caused by other reasons inherent to a particular type of weapon. Sometimes several causes simply overlap to form a larger problem that requires time-consuming and labor-intensive disassembly. The only thing that should not be done immediately after a misfire is to rush. By the method of elimination, the cause should be carefully and carefully determined.

Previous entry Barrel rupture. Causes and consequences

Next entry Burnishing at home

If there is a misfire

The biggest mistake after a misfire is removing the cartridge from the barrel immediately after the shot did not fire. There have been cases of a prolonged shot resulting in injuries, but cases leading to injury from a prolonged shot are rare and still one should not neglect safety precautions. After a misfire, the cartridge is taken out after waiting 5 minutes, with all caution, following safety rules. At the same time, while waiting for this time, the barrel of the weapon should under no circumstances be twisted in the hands, much less pointed towards people. It is best to hold the weapon with the barrel pointing upward to avoid accidents. A misfired cartridge is inspected by studying the mark of the firing pin on the primer: the depth of the primer, the depth of the dent, the offset relative to the center. An experienced shooter will definitely check the possibility of firing this cartridge with another gun or barrel. This should be done at home, having first rid the cartridge of gunpowder and shot. After checking, the barrels must be cleaned, since the secretions from the burnt primer are poisonous.

It's the cartridge's fault for the misfire

There may be several reasons for a cartridge misfire. Damp gunpowder or lack thereof. Inattention to equipment can easily lead to a lack of powder. Also, industrial cartridges sometimes have this drawback. Due to improper storage, gunpowder may become damp. Deflection of the bottom. Deflection can occur when pressing is carried out with a Barclay without using a support. Such cartridges are removed and repressed with a “recapper” having a stand. Brass sleeves suffer from such a flaw as subsidence of the anvil. Such cartridges are rejected. Broken capsule. A similar problem can be identified most often when working with capsules." It is difficult for the striker to break a deep-set capsule. Reinstallation required. Long-term operation of the sleeve. Repeatedly changing the primer in the sleeve helps to increase the diameter of the socket. The gas pressure also increases it. At some point, the capsule, after being hit by the striker, will simply sag in the socket, extinguishing the energy. The cartridge should be replaced. This sleeve is not suitable for equipment. There is no percussion compound in the capsule. It is missing from many capsules." There is also a problem with anvils - sometimes there are sagging ones, or they are absent altogether. Failure to ignite primer. This can happen with a defective capsule when the percussion compound peels off from the body. A similar problem occurs when pressing is done inaccurately. The cartridge is replaced.

Striker with insufficient output

Inertial release of the firing pin, in which pressure is applied directly to the firing pin, is becoming less and less common in hunting rifles. Basically there is a forced release when the trigger goes all the way. Different models of guns differ in forced ejection, the average is 1.5-2 mm. A higher rate can lead to the hammer piercing the primer through. Penetrating powder gases may cause the stock to rupture. And a shortened output, with an indicator of less than 1.0 mm, causes misfires. The output is increased by sawing the supporting surface of the part that limits the forced output. Or they replace the trigger.

Cleaning and lubricating the gun

To ensure long service life of the weapon, preventive maintenance is required, including cleaning and lubrication of the mechanisms. It is required to carry out preventive maintenance immediately after firing, upon completion of exercises or training with weapons, during combat operations - during a lull, and upon placement in storage - at least once a week.

To clean the gun you need:

- A barrel cleaning solution designed to clean the inner surface of the barrel, rifling and chamber, as well as all elements in contact with the cartridge at the time of firing;

- A rag for wiping off excess cleaner and wiping gun elements;

- Tow used in the process of cleaning the inner surface of the trunk;

Cleaning is carried out immediately upon completion of firing, while indoors.

When cleaning in the field, only liquid gun lubricant is allowed.

To clean a weapon, you need to prepare all the tools, then partially disassemble the weapon. Next you need to do the following:

- Clean the barrel. Tow impregnated with RSF is wound onto the cleaning rod. Then, inserting a cleaning rod from the muzzle of the barrel, clean the barrel with smooth movements. If necessary, replace the tow, then clean further until the barrel is completely cleaned - the rifling and the inner surface of the barrel. To check, insert a clean tow swab, and if it comes out of the barrel dirty, continue cleaning. Once cleaning is complete, wipe the inside of the barrel dry using a clean, dry rag.

- The chamber is cleaned only from the breech side of the barrel, using rotational movements of tow wound on a cleaning rod.

- Re-check the inner surface of the barrel by introducing tow soaked in RSF. If traces of carbon deposits are found, clean again, especially carefully cleaning the rifling of the barrel. After cleaning the barrel, you need to clean the chamber in the same way.

- Completely clean the weapon frame with barrel and safety guard, paying special attention to various small parts, technical holes and connections. Detected rust can be removed with tow moistened with gun lubricant.

- Clean the inside of the bolt, the spring and the bolt stop. Pay special attention to the details of the trigger. When cleaning at the end of shooting, the bolt cup is cleaned with oakum soaked in RSF until completely clean. After completion of the prevention, the parts are wiped dry with a rag. If there are no visible traces of soot or corrosion, wiping with a dry cloth is acceptable.

- All moving parts of the weapon are cleaned upon completion of firing in assembled form. After getting wet, the weapon is completely disassembled, wiped dry, and only then the pistol is completely cleaned. The handle is cleaned with a rag.

- The magazine is cleaned in assembled form, carbon deposits from the feeder are removed using radiofrequency control. After getting wet, the magazine is wiped dry, and then disassembled and fully serviced.

Lubrication of the gun is carried out in the following order:

- The rag is soaked in RJ and threaded into the slot of the cleaning rod. Next, the cleaning rod is inserted into the barrel cavity and carried out with measured movements until the inside of the barrel is completely covered. The chamber is lubricated from the breech using a circular motion.

- The remaining moving parts of the weapon are lubricated with an even thin layer. This is done in order to prevent the accumulation of dirt, and as a result, thickening and disruption of the normal operation of the weapon.

- Upon completion of the service, the gun is assembled and the functionality of the mechanisms is tested.

It should be remembered that if you bring the weapon indoors in cold weather, you need to wait some time for condensation to appear on the body. Condensation should be wiped dry, and only then preventive work should be carried out.

Rubbing moving parts

If the moving parts of the gun are difficult to move, this can also cause it to misfire. There are several reasons: Constant impacts in the mechanism contribute to slow but inevitable deformation. Swelling of the wood will cause deformation of the mechanism. Poor assembly prevents normal operation. Dirt ingress, metal corrosion. Braking in the operation of mechanisms can be detected by existing scratches, holes or abrasions. You can check the presence of contact on surfaces using soot or red lead. When the mechanism operates, there will be a mark at the contact point. They inspect the head of the butt very carefully, identifying traces of springs and triggers. IZH-27 more often misfires the lower barrel due to the right trigger hitting the butt.