Possible delays and malfunctions of the machine gun when firing, ways to eliminate them

Parts and mechanisms of an assault rifle (machine gun), with proper handling and proper care, work reliably and without failure for a long time. However, as a result of contamination of the mechanisms, wear of parts and careless handling of the machine gun (machine gun), as well as malfunction of the cartridges, delays in firing may occur.

The delay that occurs during shooting should be tried to be eliminated by reloading, to do this, quickly pull the bolt frame back by the handle until it stops, release it and continue shooting. If the delay has not been resolved, then it is necessary to find out the cause of its occurrence and eliminate the delay as indicated below.

| Delays and their characteristics | Reasons for delays | Remedy |

| Failure to feed cartridge The bolt is in the forward position, but the shot did not occur - there is no cartridge in the chamber | 1. Contamination or malfunction of the magazine | Reload the machine gun (machine gun) and continue shooting. If the delay occurs again, replace the magazine. |

| 2. Malfunction of the magazine latch | If the magazine latch is faulty, send the machine gun (machine gun) to a repair shop | |

| Sticking a cartridge The bullet cartridge hit the breech end of the barrel, the moving parts stopped in the middle position | Magazine malfunction | While holding the bolt handle, remove the stuck cartridge and continue shooting. If the delay occurs again, replace the magazine. |

| Misfire The bolt is in the forward position, the cartridge is in the chamber, the trigger is pulled - no shot fired | 1. Chuck malfunction | Reload the machine gun (machine gun) and continue shooting |

| 2. Malfunction of the firing pin or firing mechanism; contamination or hardening of the lubricant (no or small pin prick on the primer) | When the delay is repeated, inspect and clean the firing pin and trigger mechanism; If the trigger mechanism breaks down or wears out, send the machine gun (machine gun) to a repair shop | |

| 3. Jamming of the firing pin in the bolt | Separate the firing pin from the bolt and clean the hole in the bolt under the firing pin | |

| Failure to remove the cartridge case The cartridge case is in the chamber, the next cartridge rests against it with a bullet, the moving parts have stopped in the middle position | 1. Dirty cartridge or chamber contamination | Pull the bolt handle back and, holding it in the rear position, separate the magazine and remove the buried cartridge. Using a bolt or cleaning rod, remove the cartridge case from the chamber. Continue shooting. If the delay repeats, clean the chamber and cartridges Inspect and clean the ejector from dirt and continue shooting. If the ejector malfunctions, send the machine gun (machine gun) to a repair shop |

| 2. Contamination or malfunction of the ejector or its spring | ||

| Case sticking or non-reflection The cartridge case was not thrown out of the receiver, but remained in it in front of the bolt or was sent back into the chamber by the bolt | 1. Contamination of rubbing parts, gas paths or chamber | Pull the bolt handle back, eject the cartridge case and continue shooting If the delay repeats, clean the gas paths, rubbing parts and the chamber; Lubricate rubbing parts. If the ejector malfunctions, send the machine gun (machine gun) to a repair shop |

| 2. Dirty or faulty ejector | ||

| Lack of movement of the bolt frame to the forward position | Return spring failure | Replace the spring (in a combat situation, turn the front part of the spring with the tucked end back and continue shooting) |

Tags: fire training

so UNT / Textbooks on CVP / Textbook on CVP for 10th grades of secondary schools (Mektep 2010)

§ 8.4 Delays when firing from a machine gun (machine gun) and ways to eliminate them

Parts and mechanisms of an assault rifle (machine gun), with proper handling and proper care, work reliably and without failure for a long time. However, as a result of contamination of the mechanisms, wear of parts and careless handling of the machine gun (machine gun), as well as unsuitable cartridges, delays in firing may occur.

The delay that occurs during shooting should be tried to be eliminated by reloading, for which you need to quickly pull the bolt frame back by the handle until it stops, release it and continue shooting (see Table 1).

Table 1

| Delays and their characteristics | Reasons for delays | Remedies |

| 1 | 2 | 3 |

| Failure to feed cartridge. The bolt is in the forward position, but there is no shot - there is no cartridge in the chamber. | 1. The magazine is dirty or malfunctioning. 2. Malfunction of the magazine latch. | Reload the machine gun (machine gun) and continue shooting. If the delay recurs, replace the magazine. Send the machine gun (machine gun) to a repair shop. |

| Sticking the cartridge. The cartridge hit the breech end of the barrel like a bullet, the moving parts stopped in the middle position. | Malfunction store. | While holding the bolt handle, remove the stuck cartridge and continue shooting. If the delay recurs, replace the magazine. |

| Misfire. The bolt is in the forward position, the cartridge is in the cartridge - | 1. Unsuitability of the cartridge. | Reload the machine gun (machine gun) and continue shooting. |

Continuation

| 1 | 2 | 3 |

| Nick, the trigger was pulled - there was no shot. | 2. Malfunction of the firing pin or firing mechanism; contamination or hardening of the lubricant (no or small pin prick on the primer). 3. Jamming of the striker in the shutter. | When repeating the delay, inspect and clean the firing pin and firing mechanism; If the trigger mechanism breaks down or wears out, send the machine gun (machine gun) to a repair shop. Separate the firing pin from the bolt and clean the hole in the bolt under the firing pin. |

| Failure to remove the cartridge case. The cartridge case is in the chamber, the next cartridge rests against it with a bullet, the moving parts have stopped in the middle position. | 1. Dirty cartridge or contaminated chamber. 2. Contamination or malfunction of the ejector or its spring. | Pull the bolt handle back and, holding it in the rear position, separate the magazine and remove the buried cartridge. Using a bolt or cleaning rod, remove the cartridge case from the chamber. Continue shooting. If the delay repeats, clean the chamber and cartridges. Inspect and clean the ejector from dirt and continue shooting. If the ejector malfunctions, send the machine gun (machine gun) to a repair shop. |

| Sticking or non-reflection of the sleeve. The cartridge case was not thrown out of the receiver, but remained in it in front of the bolt or was sent back into the chamber by the bolt. | 1. Contamination of rubbing parts, gas paths or chamber. 2. The ejector is dirty or malfunctioning. | Pull the bolt handle back, eject the cartridge case and continue shooting. If the delay repeats, clean the gas paths, rubbing parts and the chamber; Lubricate rubbing parts. If the ejector malfunctions, send the machine gun (machine gun) to a repair shop. |

| Lack of movement of the bolt frame to the forward position. | Return spring failure. | Replace the spring (in a combat situation, turn the front part of the spring with the tucked end back and continue shooting). |

Accessories for the machine gun (machine gun)

Accessories (Fig. 69) are used for disassembling, assembling, cleaning, lubricating the machine gun (machine gun) and quickly loading the magazine with cartridges. Accessories include: cleaning rod, cleaning rod, brush, screwdriver, drift, pencil case, oiler, clips and adapter.

The cleaning rod is used for cleaning and lubricating the barrel bore, as well as the channels and cavities of machine gun parts. It has a head with a hole for a punch and a thread for screwing on a wiper or brush.

Rubbing is used to clean and lubricate the barrel bore, channels and cavities of other parts of the machine gun (machine gun). It has an internal thread for screwing onto a cleaning rod and a slot for rags or tow.

The brush is used to clean the barrel bore with an RFS solution.

A screwdriver and a drift are used when disassembling and assembling an assault rifle (machine gun). The cutout at the end of the screwdriver is for screwing in and unscrewing the front sight, and the side cutout is for securing the wiper to the cleaning rod. For ease of use, a screwdriver is inserted into the side holes of the pencil case. When cleaning the bore, it is placed in the pencil case on top of the ramrod head.

The pencil case is used to store cleaning cloths, brushes, screwdrivers and drifts. It closes with a lid. The pencil case is used as a handle for a screwdriver when screwing in and unscrewing the front sight and for turning the gas tube closure, as well as a handle for a cleaning rod. The pencil case has through holes into which a ramrod is inserted when cleaning the machine gun, oval holes for a screwdriver and a rectangular hole for turning the gas tube lock when disassembling and assembling the machine gun.

The single-neck oiler is used to store lubricant and is carried in the pocket of a magazine bag.

The clip is designed to carry cartridges and quickly load the magazine with cartridges. The clip holds 15 rounds. It has two longitudinal grooves and a leaf spring that keeps the cartridges from falling out. In addition, the leaf spring ensures a strong connection between the cage and the adapter.

The adapter is used to connect the clip to the magazine when loading it with cartridges. It has: at the bottom (widened part) - two bends that fit into the corresponding grooves on the neck of the magazine; on top there are two longitudinal grooves for the holder, a hole for the holder spring and a stop that limits the advancement of the holder when inserting it into the adapter.

Tasks:

1. Tell us about the common characteristic causes of delays during shooting and how to eliminate them.

2. Name the accessories for the machine gun (machine gun) and their purpose in use.

3. Complete task No. 8 in your workbook.

Operation of parts and mechanisms during shooting

Operation of parts and mechanisms during automatic firing

34. To carry out automatic firing, you must put the translator on automatic fire (AB), if it was not set during loading, and press the trigger.

When the translator is placed on automatic fire, the translator's sector releases the rectangular protrusion of the trigger (unlocks the trigger) and remains in the cutout of the single-fire sear. The trigger is able to rotate around its axis; the sear of a single fire from turning, together with the trigger, is held by the translator sector.

When you press the tail of the trigger, its figured protrusion disengages from the cocking of the hammer. The trigger, under the action of the mainspring, rotates on its axis and vigorously strikes the firing pin. The firing pin breaks the cartridge's primer. The impact composition of the cartridge primer ignites, the flame penetrates through the seed holes in the bottom of the cartridge case to the powder charge and ignites it. A shot occurs.

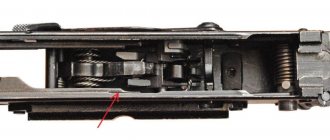

The bullet, under the influence of powder gases, moves along the bore; as soon as it passes the gas outlet, part of the gases rushes through this hole into the gas chamber, puts pressure on the gas piston and throws the bolt frame back. Moving back, the bolt frame (as when moving it back by the handle) with the front bevel of the figured cutout turns the bolt around the longitudinal axis and brings its lugs out from behind the lugs of the receiver - the bolt is unlocked and the barrel is opened, the protrusion of the bolt frame releases the lever self-timer, it rises slightly upward under the action of the spring, and the self-timer sear is pressed against the front plane of the trigger. By this time the bullet will fly out of the barrel.

After the bullet leaves the bore of the machine gun, the powder gases enter the rear chamber of the muzzle brake-compensator, expand and, flowing through the compensation holes, create a reactive force that deflects the muzzle of the machine gun in the direction opposite to the location of the holes (to the left, down). Some of the powder gases, hitting the front walls of the rear and front chambers, reduce recoil. The meeting of gases escaping from the cracks of the rear chamber with gases reflected from the front wall of the front chamber reduces the sound of the shot.

The bolt frame with the bolt continues to move backward by inertia; the cartridge case, held by the ejector hook, collides with the reflective protrusion of the receiver and is thrown out.

Subsequently, the operation of parts and mechanisms, with the exception of the operation of the trigger and retarder, occurs in the same way as during loading. The trigger is placed on the upper protrusion of the self-timer sear and is held there when the bolt frame and bolt are returned to the forward position. After the bolt has sent the upper cartridge from the magazine into the chamber, the barrel bore is closed and the bolt is locked, the bolt frame, continuing to move forward, removes the self-timer sear from under the cocking of the self-timer trigger. The trigger rotates under the action of the mainspring and strikes the trigger retarder latch; the retarder turns back, exposing the front protrusion to the trigger; As a result of these impacts on the retarder, the forward movement of the trigger slows down somewhat, which allows the barrel, after hitting it with the bolt frame with the bolt, to take a position close to the original one, and thereby improve the accuracy of the fire. After striking the front protrusion of the retarder, the trigger strikes the firing pin. A shot occurs. The operation of the parts and mechanisms of the machine gun (machine gun) is repeated. Automatic firing will continue as long as the trigger is pressed and there are cartridges in the magazine.

To stop shooting

release the trigger. In this case, the trigger will rotate under the action of the mainspring and its figured protrusion will stand in the way of the cocking movement. The trigger stops when cocked. The shooting stops, but the machine gun (machine gun) remains charged, ready for further automatic shooting.

Operation of parts and mechanisms when firing single shots

35. To fire a single shot, you must put the translator on single fire (OD) and press the trigger.

When setting the translator from the safety position to the single-fire position (OD), the translator sector releases the rectangular protrusion of the trigger (unlocks the trigger), completely comes out of the single-fire sear cutout and does not take part in the operation of the trigger mechanism when firing.

When you press the tail of the trigger, its figured protrusion disengages from the cocking of the hammer. The trigger, under the action of the mainspring, rotates on its axis and vigorously strikes the firing pin. A shot occurs. After the first shot, the parts and mechanisms will do the same work as during automatic firing, but the next shot will not happen, since the single-fire sear turned forward along with the trigger and its hook got in the way of the cocking movement. The cocking cock of the trigger will jump behind the sear of a single fire, and the trigger will stop in the rear position (Fig. 51).

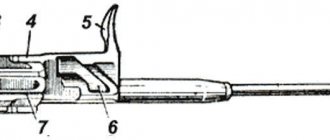

Rice. 51. The position of the parts of the firing mechanism after the shot with the translator installed on a single fire:

1 — trigger; 2 — trigger retarder; 3 — sear of a single fire; 4 - trigger; 5 — self-timer sear; 6 — bolt frame

To fire the next shot, you must release the trigger and press it again. When the trigger is released, it will rotate under the action of the ends of the mainspring together with the single-fire sear; the single-fire sear will disengage with the cocking hammer and release the hammer. The trigger rotates under the action of the mainspring, strikes first the retarder latch, then its front protrusion and is cocked. When you press the trigger, its figured protrusion disengages from the cocking of the hammer and the operation of the parts and mechanisms repeats. There will be another shot.

Elimination of delays that occur when using small arms

The most typical delays are the following: misfire, stuck or non-extraction of the cartridge case, failure to reach the front position of the bolt frame, failure to feed the cartridge from the magazine into the chamber, involuntary firing, transverse rupture of the cartridge case (inherent in PK/PKM, SGM, RP-46 machine guns), tight cartridge case extraction . Delays are largely due to such deficiencies in weapon maintenance such as contamination, non-compliance with the rules for disassembling and assembling weapons, and most often careless handling and inattentive care, etc. In most cases, these delays can be prevented or eliminated by the person (crew) in charge of weapon secured. Some failures are caused by natural wear of parts, deterioration of the bolt cup, barrel bore, spring settlement, etc. The occurrence of such failures cannot be prevented, but it is possible to identify them in a timely manner. Thus, during inspections, the possibility of a misfire due to the fault of the weapon can be excluded by identifying the condition of the firing pin (marked, crushed), the magnitude of the firing pin output, and the possibility of a delay - non-reflection of the spent cartridge case - by checking for interaction using a training cartridge. A significant number of delays are observed due to non-compliance with the firing schedule and the frequency of maintenance. For example, for a KPVT machine gun it is unacceptable to fire continuous bursts of more than 100-150 rounds, since heating the barrel causes an increase in friction between the rubbing surface of the barrel and the receiver. This leads to disruption of the automation. Violation of the frequency of maintenance also negatively affects the operation of the automatic machine gun. Therefore, the operational documentation for the KPVT machine gun states that under normal conditions, moving parts are lubricated after 450-600 shots, and at high ambient temperatures and in rainy weather, moving parts are lubricated after 150-300 shots. The main way to eliminate any delay is to reload the weapon. To do this, you need to quickly pull the bolt frame by the handle (in machine guns and machine guns) or the bolt casing (pistols) back until it stops, sharply release it and continue shooting. If the delay is not eliminated in this way or, after elimination, repeats again, then the magazine or tape is replaced; if after this the delay is repeated, then the weapon is unloaded, and then the cause of the delay is determined and only after that they begin to eliminate it. For example, in PK/PKM machine guns, the delay is eliminated in the following sequence: adjustment with the gas regulator, cleaning and lubrication of moving parts, the gas chamber and the gas regulator, replacement of faulty parts with serviceable ones from individual spare parts. To eliminate the delay when the barrel is very hot, it is recommended to remove the cartridge by sharply pulling the moving parts back. Otherwise, if the moving parts do not move forward or misfire, spontaneous ignition of the cartridge powder in the chamber may occur and a shot may occur with the bolt not closed. After 250 continuous shots from a single PK/PKM machine gun, self-ignition of the cartridge in the chamber can occur in 7-20 s. When firing from a weapon with a less massive barrel, self-ignition of a misfired cartridge can occur after a shorter period of time, approximately 5-7 s. When eliminating delays, do not use excessive force, which could lead to damage to parts. To ensure trouble-free firing of weapons, you must know and implement the following measures to prevent delays: follow the rules for handling, storage, disassembly and assembly, cleaning and lubrication, inspection and preparation of weapons and ammunition for firing; keep the weapon in full working order at all times; inspect, clean and lubricate weapons in a timely manner and in compliance with all rules, eliminating identified defects; especially carefully monitor the cleanliness and serviceability of moving parts, the barrel bore, gas paths and the box with tape (in a single PK/PKM machine gun); before shooting, wipe the barrel bore, clean and lubricate the surfaces of parts that rub during shooting with a thin layer of lubricant, inspect the weapon and cartridges; Do not use faulty or dirty cartridges for shooting; When shooting and moving, protect the weapon from contamination and impacts; in combat, after prolonged shooting, at the first opportunity, clean the gas passages and lightly lubricate the bolt and bolt frame; in case of heavy contamination (sand, mud, snow), the weapon must be disassembled and cleaned; observe the fire mode, avoiding overheating of the barrel; if the weapon was in the cold for a long time or was brought from the frost into a warm room, then before loading it is necessary to cock the bolt frame (casing-bolt) several times and release it; be able to eliminate delays dexterously by touch, in a limited time in the most difficult environmental conditions (in a combat vehicle, in a trench, at night); systematically monitor the technical condition of weapons; inspect cartridges before shooting; Do not use faulty, rusty or dirty cartridges for shooting. To better develop stable skills among military personnel in eliminating delays that arise during shooting, it makes sense to show the technique of artificially creating delays on the Kalashnikov AK-74 assault rifle, as well as the order of their description. To make it easier to display and monitor delays, the cover of the machine’s receiver must be separated. Name of the delay Failure to feed the cartridge The procedure for creating the delay and its description. It is necessary to take a magazine, equip it with several training cartridges and attach it to the machine gun so that it does not reach the uppermost position and the magazine latch does not jump over its supporting protrusion. To prevent the magazine from falling out, you need to support it with your left hand. With your right hand, remove the machine gun from the safety lever, use the handle to move the bolt frame to the rearmost position and release it. The machine gun is loaded and ready to fire. Then you need to pull the trigger. Indicate that shooting (shot) is not taking place. After reloading, the cartridge does not reflect. Therefore, it is necessary to offer to inspect the chamber - there is no cartridge there. After which we can conclude that a delay occurred - a cartridge was not fed into the chamber, during which the bolt was in the forward position, but the shot did not occur, since there is no cartridge in the chamber. Sticking a cartridge It is necessary to attach a magazine to the machine gun. Use the magazine lid to rest the machine gun on the table. With your right hand, grab the bolt handle and pull it back a little. Take the training cartridge in your left hand and place it between the bolt and the barrel so that it rests like a bullet on the breech end of the barrel. Release the bolt handle. Indicate that there was a delay - sticking the cartridge. The cartridge hit the breech end of the barrel like a bullet. The moving parts stopped in the middle position. Misfire It is necessary to charge the machine. Pull the trigger. Indicate that shooting (shot) is not taking place. The moving parts are in the extreme forward position. After which we can conclude that there was a delay - a misfire, in which the cartridge is in the chamber, the trigger is pulled, but the shot does not fire. Failure to remove the cartridge case. Support the machine gun against the table with the magazine cover. With your right hand, grasp the bolt handle and pull it back so that the front of the bolt passes the magazine. Take the cartridge case in your left hand and insert it into the chamber. Release the bolt handle, the bolt will send the next cartridge forward, and it will hit the bottom of the cartridge case like a bullet. Indicate that there was a delay - failure to remove the cartridge case. With this delay, when the bolt frame moved back, the cartridge case remained in the chamber, the next cartridge hit the cartridge case like a bullet, and the moving parts stopped in the middle position. Sticking or non-reflection of the cartridge case Place the machine gun with the attached magazine with the magazine cover against the table. With your right hand, pull the bolt handle back slightly. With your left hand, take the cartridge case and place it sideways, with the bottom inside the receiver, in front of the bolt. Smoothly releasing the bolt frame, ensure that the cartridge case jams between the front cut of the bolt and the front wall of the receiver or the breech cut of the barrel. After which we can conclude that there was a delay - the spent cartridge was stuck or not reflected. There is no cartridge in the chamber. The moving parts have not reached the forwardmost position. Let's look at eliminating delays using the PC machine gun as an example. The identified delay begins to be eliminated in the simplest way and only standard accessories are used. So, when a delay occurs—spontaneous automatic firing—the machine gun is unloaded, and then the rubbing parts of the machine gun are cleaned and lubricated. After removing contaminants (sand, carbon deposits, etc.), the moving parts (bolt frame with bolt) of the machine gun must be stopped by the sear when firing. If the delay in the machine gun cannot be eliminated by cleaning, then move the gas regulator to a higher division. In this case, a greater impulse of powder gases will act on the bolt frame piston. Repeated delay of the machine gun indicates defects in the trigger mechanism (settlement or broken springs, rounding of the sear or cocking of the frame, nicks and dents in the receiver). In the latter case, the method for eliminating the delay is complex and is only possible at a repair agency. All delays that cannot be eliminated by reloading, adjustment and cleaning are recorded in the machine gun and grenade launcher records. Frequent delays are also taken into account. Delays characteristic of Kalashnikov AKM/AK-74 assault rifles and Kalashnikov RPK/RPK-74 light machine guns when firing, and ways to eliminate them Delays and their characteristics Non-feed of cartridge . The bolt is in the forward position, but there is no shot - there is no cartridge in the chamber. Reasons for delays. 1. The magazine is dirty or malfunctioning. 2. Malfunction of the magazine latch. Remedies. Reload the machine gun and continue shooting. Replace magazine. Sticking the cartridge . The cartridge hit the breech end of the barrel like a bullet, the moving parts stopped in the middle position. Reason for delays. Curvature of the bends of the side walls of the magazine. Remedies. While holding the bolt handle, remove the stuck cartridge and continue shooting. If the delay recurs, replace the magazine. Misfire . The bolt is in the forward position, the cartridge is in the chamber, the trigger is pulled - there is no shot. Reasons for delays. 1. Cartridge malfunction. 2. Malfunction of the firing pin or trigger mechanism, contamination or hardening of the lubricant. Remedies. Reload the machine gun and continue shooting. When the delay is repeated, inspect and clean the firing pin and firing mechanism. Failure to remove the cartridge case . The cartridge case is in the chamber, the next cartridge has buried a bullet in it, the moving parts have stopped in the middle position. Reasons for delays. 1. Dirty cartridge or contaminated chamber. 2. Contamination or malfunction of the ejector or its spring. Remedies. Pull the bolt handle back and, holding it in the rear position, separate the magazine and remove the buried cartridge. Using a bolt or cleaning rod, remove the cartridge case from the chamber. Continue shooting. If the delay repeats, clean the chamber and cartridges. Inspect and clean the ejector from dirt and continue shooting. Case sticking or non-reflection . The cartridge case was not thrown out of the receiver, but remained in it in front of the bolt or was sent back into the chamber by the bolt. Reasons for delays. 1. Contamination of rubbing parts, gas paths or chamber. 2. The ejector is dirty or malfunctioning. Remedies. Pull the bolt handle back, eject the cartridge case and continue shooting. If the delay repeats, clean the gas paths, rubbing parts and the chamber; Lubricate rubbing parts. Delays characteristic of single Kalashnikov PK/PKM/PKT machine guns when firing, and ways to eliminate them Delays and their characteristics Shortage of the bolt frame in the forward position . The frame, not reaching the forward position, stopped, another cartridge was in the chamber, the extractor hooks did not capture the cartridge in the receiver. Reasons for delays. 1. Contamination of the receiver or chamber, carbon deposits in the gas chamber pipe. 2. The cartridge or tape is dented or dirty. Remedies. Without disassembling the machine gun, lubricate the chamber, rubbing parts, and gas chamber pipe. Clean the machine gun or replace the barrel as soon as possible. Replace cartridges or tape. Misfire . The bolt carrier is in the forward position, the cartridge is in the chamber, the shot did not occur. Reasons for delays. 1. Cartridge malfunction. 2. Malfunction of the drummer. 3. The machine gun is dirty or the lubricant has hardened. Remedies. Inspect the cartridge removed from the chamber and, if there is no deep dent on the primer, clean the bolt, chamber and rubbing parts. Failure to remove the cartridge case . The bolt frame stopped in an intermediate position, the cartridge case remained in the chamber, and the next cartridge buried a bullet in it. Reasons for delays. 1. Malfunction of the ejector or its spring. 2. Contamination of the chamber or cartridge, failure of the rim of the sleeve. Remedies. If the cartridge case cannot be removed from the chamber during reloading, knock it out with a cleaning rod or replace the barrel. If the rim of the cartridge case breaks, clean the chamber, lubricate the cartridges in the tape and move the regulator to a lower division. Sticking of the sleeve . The cartridge case removed from the chamber remains in the receiver or is pinched in its window by the bolt. Reasons for delays. 1. Contamination of rubbing parts, gas paths or chamber. 2. Malfunction of the reflective protrusion or flap pusher. 3. Malfunction of the ejector or its spring. Remedies. Remove the cartridge case from the receiver and continue shooting. If the delay is repeated, lubricate the rubbing parts and the chamber. Transverse rupture of the sleeve . The bolt frame did not reach the forward position, since the front part of the ruptured cartridge case remained in the chamber and did not allow the chambered cartridge to enter it. Reasons for delays. 1. Large gap between the breech end of the barrel and the bolt. 2. Cartridge malfunction. Remedies. If, when reloading a machine gun, the ejected cartridge removes the front part of the cartridge case, continue shooting. If the front of the case remains in the chamber, remove it using a case extractor or replace the barrel. To remove the front part of the cartridge case, you need to unload the machine gun, insert the extractor into the chamber, and release the bolt frame. When the delay is repeated, move the barrel back, to do this, knock out the pin of the barrel lock screw, unscrew the screw one turn with a screwdriver and insert the pin. Incomplete retraction of the bolt frame . The bolt frame stopped in an intermediate position, the cartridge removed from the receiver remained in the extractor hooks. Reasons for delays. 1. Contamination of rubbing parts. 2. The tape is jammed in the cartridge box. The tape is skewed in the receiver. Remedies. Using the reloading handle, cock the bolt frame and continue firing. When repeating the delay, after unloading the machine gun, inspect the placement and correctness of the tape. If the tape is laid and equipped correctly, move the regulator to a larger division. Clean and lubricate the machine gun as soon as possible. Involuntary shooting . When the trigger (electric trigger button or trigger lever) is released, shooting does not stop. Reasons for delays. 1. Malfunction of the trigger mechanism. 2. Rounding of the bolt carrier cocking. 3. Contamination of the machine gun, hardening of the lubricant. 4. Malfunctions of the electric trigger. Remedies. Stop shooting by pressing the tape against the receiver with your hand. Unload the machine gun, inspect the sear and combat platoon. If they are in good condition, move the regulator to a larger division and lubricate the rubbing parts. Disconnect the electrical trigger plug and continue shooting using the trigger lever. Failure to capture or loss of the cartridge by the extractor hooks . The bolt carrier has stopped in the forward or intermediate position. Reasons for delays. 1. Malfunction of the extractor hooks. 2. Settlement of the feed finger spring or upper finger spring. Remedies. Remove the cartridge case from the chamber or receiver. Load the machine gun and continue shooting. When repeating the delay, inspect the extractor hooks and the springs of the feed finger and upper fingers. Electric trigger failure . When you press the electric release button, the bolt frame does not release from cocking. Reasons for delays. 1. Low voltage on the tank’s on-board network. 2. Lack of contact in the electrical trigger plug connector, wire break. Remedies. Continue shooting using the trigger lever. Check the connection of the plug connector. As soon as possible, check the electric trigger circuit and eliminate any faults. Delays characteristic of Makarov PM pistols when firing, and ways to eliminate them Delays Misfire . The shutter is in the extreme forward position, the trigger is pulled, but the shot does not fire. Reasons for delays. 1. The cartridge primer is faulty. 2. Thickening of the lubricant or contamination of the channel under the firing pin. 3. The handle screw is not fully screwed in (in pistols without a mainspring bolt). 4. The output of the striker or nick on the striker is small. Remedies. 1. Reload the pistol and continue shooting. 2. Inspect and clean the gun. 3. Screw in the handle screw until it stops. 4. Send the gun to the workshop. Failure to cover the cartridge with the bolt . The shutter stopped before reaching the extreme forward position; the trigger cannot be pulled.

Reasons for delays. 1. Contamination of the chamber, frame grooves and bolt cup. 2. Difficult movement of the ejector due to contamination of the ejector spring or pressure. Remedies. 1. Push the bolt forward with a push of your hand and continue shooting. 2. Inspect and clean the gun. Failure to feed or advance a cartridge from the magazine into the chamber . The bolt is in the forward position, but there is no cartridge in the chamber; the bolt stopped in the middle position along with the cartridge, without sending it into the chamber. Reasons for delays. 1. Contamination of the magazine and moving parts of the gun. 2. Bent upper edges of the magazine body.

Remedies. 1. Reload the pistol and continue shooting. Clean the gun and magazine. 2. Replace the faulty magazine. Seizing (pinching) of the cartridge case by the bolt . The cartridge case was not thrown out through the window in the bolt and became wedged between the bolt and the breech end of the barrel. Reasons for delays. 1. Contamination of the moving parts of the gun. 2. Malfunction of the ejector, its spring or reflector. Remedies. 1. Throw away the stuck cartridge case and continue shooting. 2. If the ejector with a spring or reflector malfunctions, send the gun to a workshop. Automatic firing Causes of malfunction. 1. Thickening of the lubricant or contamination of parts of the trigger mechanism. 2. Wear of the hammer cocking or sear nose. 3. The sear spring is weakened or broken. 4. Touching the shelf of the fuse ledge of the sear tooth. Remedies. 1. Inspect and clean the gun. 2. Send the gun to the workshop.