The new Maxus semi-auto offers 18% less felt recoil for greater comfort, 44% less muzzle flip for more accurate follow-up shots, 19% faster bolt speeds and 24% faster lock-up times than its closest competitors.

Design Features:

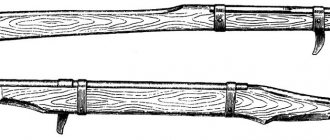

Speed Lock Forearm is one of the most innovative features found on the Browning Maxus Semi-Automatic Shotgun. A simple lift of the lever allows you to remove the handguard in less than a few seconds. Additionally, the same lever is used to attach or remove the belt just as quickly.

Most semi-automatics use a screw-on cap on the end of the tube magazine - these caps can be difficult to remove, especially after exposure to dirt in a field, forest or swamp. The Speed Lock Forearm allows for quick and easy removal of the handguard to allow easy access to the magazine or allow for quick cleaning during extended periods in the field without the risk of losing the relatively small magazine plug.

The quick-release trigger is designed to provide a smooth, crisp release with minimal movement. With an average lock time of 5.20 milliseconds, the Lightning trigger is 24% faster than its closest competitors, making every click nearly perfect. It is also easy to remove for cleaning.

Power Drive Gas System. Years of extensive research and testing resulted in a new gas piston that was designed to be more reliable in all conditions, fire a wider range of ammunition, reduce recoil and feed ammunition faster. The new gas engine features larger exhaust ports that exhaust gases faster and more efficiently when using high-powered ammunition, while the piston has approximately 20% more stroke for reliability under light loads.

An all-new, patented, closed design keeps powder debris out of the mechanism for cleaner, more reliable operation. This, combined with the longer piston stroke, makes it particularly reliable under light loads.

The rate of fire of the new Maxus is guaranteed by the Speedload Plus system. This is Browning's new system that automatically loads the first round into a tubular magazine while actuating a check valve for safety. The Speedload Plus system makes reloading easier because there is no need to reload the bolt to remove individual cases.

The centerpiece of the new Browning Maxus semi-auto is complemented by a Turnkey geared magazine and spring extractor that ensure consistent case ejection regardless of cartridge type. A Bolt-Latch button is located adjacent to the trigger, locking the moving components in the rearward position when the magazine tube is empty and releasing a new round when the magazine is loaded. Also new to the new Maxus is Inflex II technology, which uses a revolutionary internal guide concept: when firing, the force vector is directed downward, away from the shooter's face.

The new Maxus is equipped with Invector DS (Double Seal) chokes, which provide excellent performance thanks to the optimal length of 80 mm, a special internal shape and a patented sealed segment that prevents the breakthrough of powder gases. Invector DS chokes optimize shooting performance at any range, ensuring uniformity across both lead and steel bullets, as they feature a patented segment that provides a seal that prevents the penetration of propellant gases (so the chokes and serrations do not become contaminated). The system used keeps the chokes clean, making it easier to disassemble the gun in any conditions.

Maxus Hunter

Gloss walnut stock and receiver with brushed nickel finish.

| Technical | characteristics |

| Caliber | 12/76; 12/89 |

| Total length, mm | 1190, 1250, 1295 |

| Barrel length, mm | 660, 710, 760 |

| Magazine capacity | 4+1 rounds |

| Receiver material | Aluminium alloy |

| Choke constrictions | Full, Modified, Improved Cylinder |

| Weight, kg | 3,2 |

Maxus Stalker

Matte black barrel and receiver, plastic stock and forend.

| Technical | characteristics |

| Caliber | 12/76; 12/89 |

| Total length, mm | 1200, 1250 |

| Barrel length, mm | 660, 710 |

| Magazine capacity | 4+1 rounds |

| Receiver material | Aluminium alloy |

| Choke constrictions | Full, Modified, Improved Cylinder |

| Weight, kg | 3,1-3,2 |

Maxus Ultimate

Grade 3 walnut stock with a high-gloss finish, polished slide, brushed nickel laser-etched receiver. The engraving on the gun shows pheasants on the right side and mallards on the left.

| Technical | characteristics |

| Caliber | 12/76 |

| Total length, mm | 1190, 1250, 1295 |

| Barrel length, mm | 660, 710, 760 |

| Magazine capacity | 4+1 rounds |

| Receiver material | Aluminium alloy |

| Choke constrictions | Full, Modified, Improved Cylinder |

| Weight, kg | 3,2-3,3 |

Owner's comment

Browning Maxus is a new generation shotgun. It could be called a technological toy, if not for the “adult” parameters.

When I selected this product, I first of all paid attention to the reliability of the unit. In addition, my friend, a master of sports in the discipline of skeet shooting, spoke very highly of this model. He has been hunting with guns of this brand since the times of the USSR and is able to discern a clear difference between one gun or another.

There has never been a time when Maxus let me down on a hunt. This is a beautiful, powerful, fast-firing weapon. It is quickly disassembled and assembled, the recoil is practically not felt. Now I won’t think about buying a new gun for a very long time.

Maxus All Purpose Hunter - Mossy Oak Break-Up Country

The Maxus model features a camouflage pattern suitable for almost any terrain.

| Technical | characteristics |

| Caliber | 12/89 |

| Total length, mm | 1200 |

| Barrel length, mm | 660 |

| Magazine capacity | 4+1 rounds (with 12/70 rounds) |

| Receiver material | Aluminium alloy |

| Choke constrictions | Full, Modified, Improved Cylinder |

| Weight, kg | 3,2 |

Wicked Wing shotguns feature a Cerakote Burnt Bronze camo finish on the receiver and Burnt Bronze on the barrel. The large slide stop button makes it easier to manipulate the weapon with gloves. Full chrome plated bore improves corrosion resistance and durability.

| Technical | characteristics |

| Caliber | 12/76; 12/89 |

| Total length, mm | 1200, 1250 |

| Barrel length, mm | 660, 710 |

| Magazine capacity | 4+1 rounds |

| Receiver material | Aluminium alloy |

| Choke constrictions | Full, Modified, Improved Cylinder |

| Weight, kg | 3,2 |

Browning Maxus - from idea to implementation

A Chinese proverb says: “A long journey begins with a small step.” Likewise, the design of a new model of a hunting rifle begins long before the first line is drawn on the sheet. However, who is drawing now? Computers with CAD/CAM/CAE programs have long been included in the arsenal of designers, but still, before starting design, the designer must clearly understand what he wants to achieve in the end.

A century ago

It would not be entirely correct to begin the story about the creation by the designers of the Browning company of the Browning gas-operated semi-automatic machine in 2004, when the first sketches of the future model were created. We must start ab ovo, because, as Lenin wrote, “you can become a communist only when you enrich your memory with the knowledge of all the riches that humanity has produced.” And in this case, we need to go back more than a hundred years ago, to 1898, when John Moses Browning designed the Auto-5 semi-automatic (the patent for it was received in 1900), giving hunters, especially waterfowl hunters, exactly that the weapons they needed. Over the next hundred years, the Auto-5 model was a kind of standard with which all new semi-automatic models that appeared were subsequently compared.

The new product was received with a bang in various countries around the world. The Russian hunting magazine of that time, Okhotnichiy Vestnik, which was extremely popular, wrote that “the magazine will revolutionize the hunting world: you can fire 5 shots in 15 seconds at a rising flock of geese, without taking the gun off your shoulder... This gun can be called a miracle of weapons technology.”

The design of the Auto-5 was so perfect that it took many years before designers were able to come up with something that could compete with the semi-automatic that has stood the test of time. This does not mean that since 1898 gunsmiths have not been able to offer anything worthy of attention. This statement is also true of the Browning company itself. Thus, John Browning's son Val designed the Double Auto semi-automatic with a short barrel stroke. It was a semi-automatic machine that did not have an under-barrel magazine, due to which a significant reduction in weight was achieved. The name reflects the fundamental design feature: one cartridge was inserted into the chamber, the second was placed on a tray in the bolt box under the bolt.

The Double Auto semi-automatic with a steel gearbox weighed 3.4 kg, with an alloy gearbox - 2.9 or even 2.5 kg, depending on the version. Shotguns with light alloy frames were valued by pheasant hunting enthusiasts and were often found in the arsenal of women who were keen on hunting. Alas, this semi-automatic model was not popular with its predecessor. Firstly, it was significantly inferior to the Auto-5 in terms of firepower, and secondly, the designer’s calculation that hunters would perceive this model as an alternative to a double-barreled shotgun turned out to be a miscalculation, although everyone who picked up the gun noted it excellent posadistost and excellent balance inherent in high-quality shotguns. From 1955 to 1971, about 65 thousand semi-automatic machines of this model were produced.

Offensive "Gas vent"

In the last quarter of the 20th century, self-loading guns with a gas-operated reloading mechanism and a tubular under-barrel magazine began to dominate in the production programs of most of the world's leading arms companies. They actually pushed models with a movable barrel out of production. In 1974, Browning entered the market with the B-2000 12-gauge gas-operated model. Production of this model ceased in 1980. Instead, production of the gas-operated semi-automatic Browning B-80 with a tubular under-barrel magazine that holds 4 rounds was launched.

| Power drive system effectively reduces recoil energy |

Even though the demand that determined the supply clearly turned towards gas-operated semi-automatic machines, the Browning company did not abandon the idea of using recoil energy for reloading, which was implemented when the A-500 model was launched in 1987. It is interesting to note that almost simultaneously (in 1988) the company began producing the same model, but with a gas-operated reloading mechanism. The markings of the A-500 semiautomatic devices included the letters: R (recoil), indicating the reloading mechanism, and G (gas).

In 1993, the gas-operated semi-automatic Browning Gold went on sale. Its design was so successful that it soon became a prototype for creating new models based on it. In fact, the Browning Gold model was the first real alternative to the Auto-5. For fifteen years, hundreds of thousands of hunters and shooters have chosen the Gold model. Ultimately, it was the popularity of the Browning Gold that ended nearly a century of production of the self-loading shotgun designed and built by John Browning.

New century - new challenges

Even the most durable and reliable guns have a limit to their survivability. And therefore, at a time when the Browning company was just entering the market with a completely new model of a gun, employees of its design department were already carrying out preparatory work to create the next model.

| Back bore vector pro drill reduces kickback and improves shot uniformity |

Preparatory work for the creation of a new model of a self-loading gas-operated gun was carried out in the bowels of the company's design department, although no official command was received from above. Perhaps this work could not even be called preparatory, so some sketches and estimates were made informally. And only in 2003, after a series of meetings and consultations at the top, an official decision was made on the need to create a self-loading rifle of the 21st century. By the end of 2003 - beginning of 2004. the implementation of the decision began to take concrete forms. A group was formed in the design department and tasked with starting work on a new project. In June 2004, Marc Lezanfant, an employee of the Browning design department in Gerstal (Belgium), was seconded to the company's design department in Utah (USA). He was assigned to lead the work on the project. Given its importance, Browning management decided to additionally involve the entire design department of the company, whose work was personally supervised by the company's vice president Joseph Russo, to work on the project.

| A new method of attaching the forend (speed look system) simplifies assembly |

It must be said that Mark Lezanfant was an experienced designer who led the work on creating self-loading rifles. Among his successful works one can name such a semi-automatic machine as the Winchester Super X2, the production of which began in 1999.

Coded "Peggy"

The company's management set a task for the designers: taking into account forty years of experience in designing gas-operated self-loading guns, to create, based on the latest achievements of science and technology, a semi-automatic model that would be superior to all currently produced models and would be absolutely inaccessible to competitors. The group's employees were instructed to conduct a thorough analysis of all technical solutions ever implemented in the designs of Browning self-loading shotguns in order to select those that could be used in a new semi-automatic device, having previously brought them to absolute perfection. Moreover, to create a new model, they decided to use “feedback”: dealers, marketers, journalists from specialized media, hunters and shooters expressed their ideas about what a gun of the 21st century should be. At the end of June 2004, a group led by Marc Lezanfant began work on the project, codenamed "Peggy". In violation of all then existing canons, mechanical engineers began to work closely with designers from the very beginning of work on the project.

By the end of 2005, Browning had already invested a very significant amount in the creation of a new model, so management, who had already tirelessly supervised the progress of work, began to take an interest in the results achieved. By this time, the designers had already worked out a number of conceptual ideas and solutions. Even at the very beginning of the work, a proposal was made to abandon the cap nut. This proposal was truly revolutionary, overturning centuries-old foundations. Not a single weapons company in the world has dared to break the rules. The abandonment of the cap nut inevitably entailed a change in the design of the forend, and, consequently, in the order of assembling and disassembling the gun.

The designers made a number of other proposals, some of which were so radical that the company’s management considered it better to refuse to implement them, giving preference to those aimed at improving the technical characteristics and consumer properties of the new model of a self-loading gun. The technical solutions implemented in the new semi-automatic model, which had not yet even left the walls of the design bureau, have already been protected by six patents.

| In the last quarter of the 20th century, self-loading guns with a gas-operated reloading mechanism and a tubular under-barrel magazine began to predominate. |

In addition to changing the design of the forend, which has already been mentioned, a lot of work was done to modernize the trigger mechanism, as a result of which its response time was significantly reduced and the reliability of the trigger as a whole was increased. 0.0052 seconds - this is exactly how much time passes from pressing the trigger until the firing pin hits the primer. Changes made to the design of the trigger made it the fastest among semi-automatic machines; the closest pursuer is 24% behind in this indicator.

The semi-automatic rifle has a new buttplate shape. Its design can be called intelligent: when fired, the recoil impulse vector is directed down and away from the shooter’s face.

The shutter was improved, its speed increased by 19%. Changes were also made to the barrel bore profile. The projectile entrance became five centimeters longer than that of other semi-automatic devices. When passing along a flatter cone of the projectile entry, the shot shell is less deformed, which helps to increase the accuracy and uniformity of the scree and reduce the recoil impulse. The new projectile entry geometry provides a smooth transition from the chamber to the projectile entry and from the projectile entry to the bore. In accordance with the change in the profile and dimensions of the barrel bore, replaceable chokes were also modified.

A lot of work was done to optimize the functions of the feed mechanism and the cartridge reflector.

The heart of any gas-operated semiautomatic device is the gas engine. For the model under development, an essentially new gas engine was created with its elements: a gas piston, rod, ring and spring.

First tests

The first working prototype was released in September 2006. Within a month he was tested for “killability”. Yes, yes, specifically for “killability”, and not for survivability. The purpose of these tests, as the company's test engineers admit, is to identify all the weak points in the design, so that during the tests everything that can break will break. And then find out the cause of the breakdown and eliminate it, so that later, on a hunt or on a stand, the gun works like a clock, without causing any complaints from the owner.

The designers, who were awaiting the testers' verdict with trepidation and bated breath, were delighted to receive the news: despite the harsh test conditions, the final result was positive - the prototype passed them successfully, its design turned out to be extremely reliable.

In January 2007, a second working prototype was manufactured. And again tests for “killability”. And again success. In fairness, it must be admitted that during the tests the pin broke. The pin was replaced and the pin never broke again.

After completing the tests, the company's management decided to produce 20 semi-automatic prototypes. To avoid a possible leak of information, the production of parts for a self-loading gun was distributed across three company enterprises in different countries - Portugal, the USA and Belgium. The assembly of weapons took place at a factory in Portugal.

The first tests took place in July 2007. Tests followed in October of the same year. Two guns from this batch were tested for survivability during October tests. The results obtained pleased everyone who was involved in the creation of a new model of a self-loading gun.

Perfection in everything

Now marketers are faced with a task that is probably no less difficult than the designers who began creating a new model in 2004. The code name "Peggy" became part of the company's history and became a thing of the past. It was necessary to find a suitable name for a new self-loading gun - a gun of the 21st century. From the huge number of proposals received for a kind of competition, the “name” of the new semi-automatic device began to gradually emerge - MAX. It seemed to speak for itself - maximum excellence and perfection in everything. The trouble was that such “Maxes,” as they say, are a dime a dozen, and the name needed was short, bright and memorable.

And that's when the name Maxus appeared. You could even hear echoes of gladiator battles in it. The new name for the new model of Browning semi-automatic shotgun was adopted unanimously. This is how Maxus was born.

In March 2008, Maxus had to undergo its first test in real hunting conditions. It was a goose hunt, therefore, shooting was carried out with magnum cartridges with maximum shot loads. In April, tests took place in Argentina on pigeon hunting. This hunt was destined to become a kind of “moment of truth” in the future fate of the semiautomatic device. The fact is that the Maxus was originally created and designed as a gun designed for shooting maximum loads of shot. Everyone was concerned about how reliably the automatic reloading system would work when firing cartridges with 28 g shot loads. And Maxus won this battle with honor: more than four thousand were made from each of the 18 prototypes (the same ones that were already tested in July 2007) shots, while lubrication and cleaning of the barrel bore and gas chamber parts were not carried out.

While prototypes that had already acquired a name were being tested in Argentina, work continued in Portugal to optimize the design of the semi-automatic and its final development.

In September 2008, Browning invited leading US gun journalists to a pheasant hunt to give them the opportunity to be the first to try out the new semi-automatic in real hunting conditions.

It was October 2008. No, that's wrong! Here you still can’t say better than Pushkin:

October has already arrived - the grove is already shaking off the last leaves from its naked branches; The autumn chill has breathed... my neighbor hurries to the departing fields with his desire, And the winter crops suffer from mad fun, And the barking of dogs awakens the sleeping oak groves.

By October 2008, testing of the new semi-automatic device was successfully completed. Therefore, it was decided to hold a presentation of the Maxus self-loading shotgun at the company’s annual dealer meeting. The presentation of a gun, as you might guess, is not limited to talking about its technical characteristics and consumer properties. Dealers had to sell a new model, so they were given the opportunity to actually check whether this semi-automatic machine was as good as the designers (who would criticize their brainchild?) and the sales department employees talked about it.

Andrey Ugarov Photo by Francois Gallego

Maxus Sporting

The stock and fore-end are made of high quality walnut with a glossy finish. The stock is adjustable and comes with one 1/4″ spacer. The sight is equipped with a HiViz Tri-Comp fiber optic front sight and an additional white bead in the middle of the rear sight.

| Technical | characteristics |

| Caliber | 12/76 |

| Total length, mm | 1240, 1295 |

| Barrel length, mm | 710, 760 |

| Magazine capacity | 4+1 rounds |

| Receiver material | Aluminium alloy |

| Choke constrictions | Full, Improved Modified, Modified, Improved Cylinder, Skeet |

| Weight, kg | 3,2 |

Browning Maxus shotgun

Home | Weapons | Smoothbore weapons | Belgium | Browning Maxus

The receiver of the Browning Maxus small-bore self-loading shotgun is made of durable aluminum alloy and has grooves for installing mounts for additional sighting devices.

The ammunition supply system is equipped with a cut-off device that allows the shooter to replace a cartridge without feeding the next one from the under-barrel magazine. A capacity limiter is installed in the under-barrel magazine. Thanks to the Turnkey Magazine Plug system, shooters can easily increase magazine capacity to maximum capacity when needed.

To power the magazine, the company's patented Speed Load Plus loading system is used, which allows for rapid loading of a cartridge into the chamber and rapid discharge of the under-barrel magazine.

To reload the Browning Maxus shotgun, the Power Drive Gas System is used, which allows the use of cartridges from 24 g to 64 g with maximum efficiency. The Lightning Trigger System provides an easy and at the same time confident trigger release with minimal trigger idling.

The Browning Maxus smoothbore semi-automatic shotgun has open sights: a ventilated rib with anti-reflective notches and a replaceable Hi-Viz fiber optic front sight for improved aiming in low visibility conditions.

In the production of the Maxus shotgun barrel, BackBored drilling technology is used - the bore diameter increases from the standard 18.4 mm to 18.8 mm. This increase in barrel diameter makes it possible to achieve an increase in flight speed and penetration power of the charge, better discharge of the charge and low recoil when fired.

The Browning Maxus hunting rifle features VectorPRO extended bullet entry technology. Together with the BackBored barrel drilling technology, this allows for minimal deformation of the shot charge when fired.

The wooden parts of the Browning Maxus shotgun are made from grade 2 walnut and oiled. The handguard has an original design developed by Browning specialists and fine checkering for better grip and control of the shotgun.

The handguard received a patented Speed Lock system, which allows you to quickly disassemble this unit for the necessary manipulations with it.

The ergonomic pistol grip stock has a wide range of options to tailor the shotgun to the shooter's individual characteristics. For this purpose, a set of gaskets is used to adjust the bend of the butt and a gasket to lengthen the butt (adapts to the butt plate). To dampen recoil, a butt pad made using Inflex Technology is used, which allows you to minimize its effect after the shot.

Replaceable Invector-Plus chokes provide excellent shot spray. The shotgun is equipped with 6 interchangeable Invector-Plus choke tubes. The Browning Maxus shotgun comes with an ABS case.

Technical characteristics of the Browning Maxus shotgun Caliber: 12/76 Weapon length: 1295 mm Barrel length: 760 mm Weight without cartridges: 2.9 kg. Magazine capacity: from 4 rounds

Smoothbore weapons

- India

- South Korea

- South Africa

- USA

- Russia

- Türkiye

- Belgium

- Ukraine

- Italy

- Philippines

Maxus Sporting Golden Clays

Maxus Sporting model in luxury design with gold plated engraving of game birds turning into a clay plate (quail on the right, mallard on the left).

| Technical | characteristics |

| Caliber | 12/76 |

| Total length, mm | 1240, 1295 |

| Barrel length, mm | 710, 760 |

| Magazine capacity | 4+1 rounds |

| Receiver material | Aluminium alloy |

| Choke constrictions | Full, Improved Modified, Modified, Improved Cylinder, Skeet |

| Weight, kg | 3,3 |

note

The model turned out to be light and well balanced. I would especially like to note the soft and precise operation of the gun itself and the bolt mechanism in particular.

The gun reloads very quickly - thanks to the specially designed Speed Load Plus system. The forend is perhaps the narrowest of the entire Browning series of self-loading shotguns. The fore-end latch resembles the latches of over-and-under shotguns, meaning the shooter does not need to exert any additional effort to remove it.

Another “trick” is the special bore diameter. As a result, the frictional abrasion of pellets on the walls of the gun barrel is reduced, which allows increasing the speed of the projectile, as well as the sharpness and accuracy of the hit.

A special valve regulates the amount of gas needed to reload the gun. This allows you to load both fairly light 24-gram shells and “heavy” 64-gram shells. Even after a long shooting session, the gas system and magazine tube can be cleaned without difficulty.

The Browning Maxus rifle's butt plate increases comfort when shooting by absorbing recoil energy, and also increases its effectiveness by reducing the degree of barrel bounce at the moment of firing.

The trigger system is also designed in a special way - now the trigger time of the Maxus is almost a quarter faster than that of similar self-loading rifles.

Maxus Sporting Carbon Fiber

Sleek and aggressive look. Hydrographically decorated carbon fiber trim covers the upper and lower receivers, barrel and composite stock with length adjustment via spacers.

| Technical | characteristics |

| Caliber | 12/76 |

| Total length, mm | 1240, 1295 |

| Barrel length, mm | 710, 760 |

| Magazine capacity | 4+1 rounds |

| Receiver material | Aluminium alloy |

| Choke constrictions | Full, Improved Modified, Modified, Improved Cylinder, Skeet |

| Weight, kg | 3,1-3,2 |