The Stielhandgranaten 24 is a modified WWI Stielhandgranaten 1916. In the early 20s, the Stielhandgranaten 16 was slightly modified, its weight and size were reduced, and the brackets for attaching to the belt were removed from the grenade body. The modified version received the official name "Stielhandgranaten 24"

German Stielhandgranaten with bracket, First World War

The long handle and placement of the grenade's center of gravity allows the average soldier to throw a grenade 30-40 meters. Physically strong fighters could throw a grenade 60-65 meters.

The scattering of fragments is about 15-20 meters in the offensive version and up to 30 meters in the defensive version. To use the grenade as a defensive one, a fragmentation shirt made of metal, with or without notches, was put on the body.

Filling:

The M24 grenade was loaded with 160-180 grams of TNT, amonnal, monarchite, donarite or melenite. In Soviet grenades the mass of explosives was less (110 grams in the RG-42 and 60 in the F-1).

The main disadvantage of this grenade was the sensitivity of the grating fuse to dampness, which led to frequent failures. In addition, if the ignition cord was not pulled out sharply enough, the grating composition did not ignite and the grenade did not work.

After pulling out the ignition cord, the grenade had to be thrown, because the moderator began to burn and after 4.5-5 seconds an explosion followed (after pulling out the pins, Soviet grenades could be held in the hand for an indefinitely long time, choosing the moment and target for the throw, and if the decision to throw was cancelled, the pin could be put back in place).

To significantly increase the charge power, for example when fighting tanks, grenade bundles were used.

fragmentation jackets for M24 grenade

Coloring and marking of grenades

The bodies of the Stielhandgranaten 24 grenades were painted in the standard

German army color feldgrau (field gray) or in dark green tones, and the finishing coat was applied to a surface previously primed with red paint.

Marking on the lid of a grenade jar.

Extruded stamp of the year of manufacture and a military acceptance stamp made with white oil paint .

Sometimes the order number and manufacturer code were stamped on the jar.

An embossed mark was placed on the handle of the grenade:

Embossed stamp on the handle of a grenade

A military acceptance stamp was also placed on the handles of early production grenades.

A stencil warning inscription was painted on the side walls of the grenade: “VOR GEBRAUCH SPRENGKAPSEL EINSETZEN” (install a detonator cap before use).

Stencil inscription on the body of the grenade

The cap of the grenade also had a military acceptance stamp (WaA):

The type of explosive is reflected in the markings on the body in the form of an alphanumeric code “Mo” (monachite), “Do” (donarite), “Grf.88” (picric acid).

The stamps on grenades from different manufacturers and at different times of release could differ, in addition, there were rarely found additional stamps: The letter “K” is short for “Kalte” - that is, the grenade is adapted for use in low temperatures.

The mark of military acceptance is not applied with paint, but is embossed on the body of the grenade.

1942 jar without military acceptance mark

SS stamp on the handle of a grenade,

variant of the stamp on the handle

Personal artillery

In modern open specialized literature, and especially on the Internet, a lot of space is devoted to hand grenades. But I, a professional gunsmith, am not always satisfied with the quality of these materials. In many of them, the lack of an engineering approach on the part of their authors is clearly visible. Meanwhile, among this type of weapon there are many interesting examples that deserve a more detailed description. Below I want to tell our readers about two grenades from the Great Patriotic War.

The M-24 grenade was convenient to carry in the belt. In the photo, the author of the article during the battles for Berlin

My acquaintance with weapons in general, and grenades in particular, began at the age of fourteen. On one fine August day in 1941, the quiet lane where I lived was suddenly filled with trucks. German soldiers began to jump out from under their awnings. Some of them occupied our rather large yard, while the wheels of visiting cars mercilessly crushed the recently planted apple tree seedlings.

Columns of strange appearance wandered along the street - military men in khaki overcoats and caps of the same color, each with a long faceted bayonet with a round wooden handle dangling from its side in a scabbard. Unlike the Germans, they looked completely unthreatening. Running up to the column, I asked one of them, “Who are you?” The soldier, looking up at me with tired eyes, said in monosyllables: “Ukrainian.” Another replied “Rusin”. It seems they were Croatian units.

Once, returning to our home yard, my friend and I, squeezing between closely parked cars, noticed in the grass under the fence four German hand grenades with long wooden handles. The Germans, meanwhile, lined up with pots in their hands and went to a field kitchen located nearby. The vehicles had only one sentry left with a carbine on his shoulder and an identical grenade in his belt. Without talking to my friend, we looked at each other and waited for the sentry to turn away, instantly throwing grenades over the fence into my yard. There, after fiddling around with them a little and not understanding anything about them, we approached the sentry and, with innocent faces, started a conversation with him. When asked what was in his belt, he first waved it off, saying that it was not a child’s business, but then, yielding to our insistent requests, he took the grenade out of his belt, unscrewed the warhead and showed how the detonator was installed there, then separated the bottom cover and demonstrated a porcelain roller with a white cord that had to be pulled out before throwing.

Time passed, a “new” government was established in the city, in general there were two of them, one was the Ortskommandantur - the local military commandant’s office, the second, a civilian one, represented by the city government. A yellow-blakite flag with a black trident fluttered above the council. Then I had no idea that in a couple of years I would have to be at war in the ranks of the Polish Army, which had to deal a lot with the Bandera rump, who was rampaging through Ukraine under the same banner.

M-24 grenade

At that time, my peers and I were not yet interested in politics, and therefore we were interested in completely different things, namely: we intensively searched for and collected various weapons. These were mainly our three-line rifles, self-loading SVT and German Mauser rifles, various cartridges and hand grenades. Due to their size, rifles were difficult to store, so we quickly learned how to make sawn-off shotguns from them. Our three-ruler was best suited for this, with a good sawn-off handle coming out of the neck of the butt. This was not possible with a Mauser rifle, and it was much more difficult to saw through its barrel than ours. My “hobby” (although they didn’t know this word back then) were hand grenades and various types of fuses. Each of us kept our collection, naturally, not at home, but in a carefully disguised “shovanka”. Tracking down a colleague’s “shovanka” and robbing it was not considered a special sin.

From time to time we looked for a secluded place to test our exhibits. We were especially eager to test hand grenades in action, of which our company already had three types. I traded one of my German M-24s for an RGD-33 with a fuse from Genka Arkhangelsky, nicknamed the “red dog” for his densely freckled face. Our friend, nicknamed “Shepil,” boasted of a grenade that he had snatched from the Hungarian soldiers who were quartered in his house. It was a black barrel with three red transverse stripes and a pin with a tongue made of thick yellow leather. To test them, we chose a secluded place on the river bank opposite a deep pool. The first to volunteer was the “red dog” with my once German M-24, almost universally nicknamed “the pusher”. When Genka pulled out the porcelain roller with the cord from it, not the slightest sound was heard, and he even hesitated, thinking that there had been a misfire. But he was smart enough to throw it anyway. The grenade exploded, sinking to the bottom of the pool. The sound of the explosion was not particularly strong. Next it was my turn. I must say that this was the first grenade throw in my life, and I was a little cowardly, inserting the fuse into the pre-cocked grenade. The RGD-33, as soon as it flew out of my palm, made a loud bang and also exploded at the bottom with approximately the same sound effect as the German one. The Magyar grenade behaved completely unexpectedly for us - about halfway through its trajectory, the black cap separated from it, and it went off with a deafening roar, barely touching the water surface. Frightened of being discovered by the Germans or the Ukrainian police snooping everywhere, we instantly ran away in different directions.

After this story, the design of the Magyar grenade became very interesting to me, but none of the boys I knew had such grenades. But soon I still got it. There was a Hungarian unit in the nearby school; one day I waited for the Magyars to come out into formation and quickly dropped into one of the classrooms, the floor of which was thickly covered with straw. In the straw, I found the coveted grenade, however, it was unscrewed into two halves, each of which contained parts of the inside of the grenade.

It was with this grenade that I had an unpleasant experience. Studying it, I found that it was easily completely disassembled, and paper-wrapped explosive sticks could be easily removed from it. It was prosaic TNT - we already knew how to recognize it by its color, thick soot when burning and the specific smell of this soot. The detonator was also easily separated and the igniter primer was unscrewed. My friend Andrei Pertsov and I decided to test a grenade without explosives, with one detonator. It seemed to us that the detonator would not explode the grenade and there would not be a strong sound. This became our tragic mistake. We chose a ravine, which was not far from the house, as a “testing ground”. I threw the grenade, and not far, so that it could be easily found later. This time the cap of the grenade separated from it not in flight, but when the grenade was already rolling down the slope of the ravine. There was no explosion. Andrei was the first to run up to the grenade and immediately kicked it. The grenade exploded into small pieces right at the toe of his right boot in a ball of bright flame the size of a football. Andrey immediately turned around and ran back, but after a few steps he fell. Helping him get up, I saw Germans at the top of the ravine who jumped out of a nearby yard at the sound of the explosion. Their questions “Was ist los? Was haben sie hier gemacht?” they didn’t need my answer - it was already clear that the accident was caused by boyish frivolity. Andrei's left foot was wounded, although the grenade exploded on the toe of his right boot, without leaving even a scratch on the leather of the boot. The fragments, having pierced the skin of another boot, dug deep into the side of his foot, and Andrei then had to suffer from this wound for many years. And then the German, sadly shaking his head, applied only a light bandage and helped me bring Andrei home.

This was my first bad experience with a hand grenade. I acquired my second unsuccessful experience with a hand grenade much later - in 1945, when I was already at the front.

My unit, military unit 31943 - 2nd separate battalion of the 1st Army of the Polish Army participated in the offensive in the Pomeranian direction. One of the first on our way was the city of Hohensalz (now it is the Polish Inowroclaw). It was almost taken - only isolated isolated pockets of resistance remained, but I, as a headquarters liaison officer and a motorcyclist, was sent to army headquarters with a mandatory daily report. Returning along the same seemingly completely safe road, I unexpectedly found myself in a firefight between the Germans who had holed up in a two-story house and the Polish infantrymen who were trying to drive them out of there. Instantly turning the steering wheel of the heavy BMW and almost turning over, I slipped behind the three-story building to the Polish fighters. There were no more than a dozen of them. They were commanded by a woman - an officer with the rank of cornet. Respecting subordination, I stretched out in front of her, reporting in form who I am and what I am. After a favorable nod from the commander, I stepped aside and decided to wait out the danger behind the house. I didn’t want to get involved in this fight, and it didn’t concern me. Meanwhile, both sides only occasionally exchanged short bursts. But suddenly the cornet lady, who glanced at me attentively a couple of times, came up with an idea: “Corporal!” Cover us! Carrying out the order, I leaned around the corner of the house and fired a short burst at the hole in the wall of the second floor - it seemed to me that they were shooting from there. It was clear from the plaster falling from the wall that I had smeared it in a hurry, but in the next turn I adjusted the sight. “Tselne biye, cholera!” said one of the soldiers. Immediately the command “Clap forward!” was heard. Letting the soldiers pass in front of her, the commander followed them, unfastening her holster as she went. I don’t know why, but I, too, was caught up in the general impulse; perhaps there was some gentlemanly solidarity with the lady. Without slowing her fast pace, the cornet lady took an RG-42 grenade from her overcoat pocket and handed it to me. A moment later, the soldiers were already breaking into the house. I rushed to the building in a non-shootable area and, pressing against the wall, threw a grenade into the gap in the wall of the second floor, but it immediately flew back and exploded in the air above me. I sat down against the wall, gradually losing consciousness. When I opened my eyes, I found a nurse kneeling in front of me, her hospital bag under my head. A cloud of fragments miraculously passed me by, and only one of them tore open my left sleeve of my uniform. The Germans came out of the entrance with their hands raised. The battle was fleeting and there were no losses for both sides, since several Germans holed up in the building wisely decided not to resist. They pointed out to me the Fritz who “returned” the grenade to me. I found the strength to ask him how he was not afraid to throw away the grenade and received the answer that he was warned by the nearby pop of the fuse. This was my second bad experience with hand grenades.

Since then, I began to prefer German M24s to our grenades with “firing” UZRG fuses - those, my first, with long wooden handles. They were initiated silently, and were convenient to wear in a belt or behind the top of a boot. It was then that I realized that in some cases impact hand grenades are indispensable. For example, in street skirmishes when throwing at a high-lying target, when a miss may cause the grenade to bounce back or at moving objects. We didn’t have similar domestic grenades, but there were plenty of captured ones - German, Italian and Hungarian.

I adapted to the latter, fortunately in my recent adolescence I studied them in detail. They were compact and light, but I was underfed and weak, but I could throw such a grenade quite far. The Hungarian grenade was cocked, flying about ten meters, after the safety cap was blown off by the air flow. They tore even when they hit the window glass. However, when thrown at close range, the cap might not have time to completely separate from the grenade, and then God forbid you would trip over it!

At the same time, I clearly understood that hand grenades are generally weapons that require skilled handling. Many years have passed since then, and I have already been professionally engaged in research and development of what shoots and explodes. Probably, the impetus for my choice of specialty was the childhood experience acquired during that terrible time. This is all so firmly ingrained in my memory that in our time I have not spared time for an accurate computer reproduction of the Hungarian Frommer 37M pistol, which the Magyar officer who was quartered in our hut gave me to hold in my hands. But here an unexpected passage awaited me. The fact is that in order to depict a pistol and its device in computer format, you must first disassemble the pistol down to the smallest details in order to make a sketch with all dimensions for each of them. It must be said that in this case it is not always possible to get by with a universal measuring device - a “bar” and a micrometer; sometimes you have to use an instrumental microscope and a projector, which only serious instrumental production facilities have. In general, this operation is very tedious. I disassembled the Frommer, but I sweated over the assembly for two days, listening to the barbs of those around me. It must be said that this is a significant drawback - after all, during serious use, the weapon often falls into mud and water, and to put it in order it is no longer possible to do without complete disassembly. For example, "TT", "Parabellum" or "Walter" lend themselves to this operation without much difficulty.

Rice. 3. Throw a grenade. On the left is the initial moment of the throw. The safety cap is unscrewed from the screw until it touches its head. On the right - in flight. Under the influence of air resistance, the cap moves the upper block away from the lower one, while simultaneously unscrewing from the upper block. The spring sets the striking mechanism into the firing position

One day, rusty samples of some domestic and foreign hand grenades, memorable to me from the times of occupation and war, fell into my hands, and I set out to create their accurate and detailed computer drawings. I considered this appropriate, since the quality of their descriptions in the open press did not in any way satisfy me.

Below I present to readers the results of my research on two of the first grenades that I had to become familiar with in my life.

German M-24 grenade

The prototype of this grenade appeared in service with the German troops in 1916. In 1923-1924, after minor design changes, it received the name “Stielhandgranate M-24”, which translates as a hand grenade model 1924. During the Second World War in Germany produced more than 75 million units of these grenades. Our front-line soldiers, who often used captured M-24 grenades, called them “pusher” because of their long wooden handle. Under the name HG-42, these grenades were in service with the Swiss army until the 90s. last century.

The total length of the grenade is 360 mm. Weight - about 500 g. Such a grenade can be thrown further than a regular one. It was convenient to wear it in a belt or behind the top of a boot.

Structurally, the M-24 grenade is extremely simple, this is especially evident when comparing it with the domestic RGD-33.

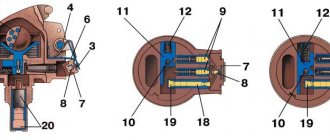

The design of the M-24 grenade is shown in Fig. 1 modeled after a 1939 grenade.

Its warhead 11, stamped from sheet steel 0.5 mm thick, contains 180 g of bulk explosives. A wide variety of explosives were used, including surrogate ones, which were used at the final stage of the war. The M-24 warhead has a strong high-explosive effect, significantly greater than that of other offensive hand grenades, with little fragmentation. The warhead is screwed onto the handle 17, for which the lower part of the warhead has a shaped stamped bottom - a nut 20, and the handle - a stamped steel tip 19 with a corresponding thread. The warhead is screwed onto the tip until it stops at the crown 18. Parts 19 and 18 are fastened to the handle with four screws. There is an option for connecting the tip to the handle with notches on the side surface of the tip after it is installed on the handle.

Rice. 4. On the left - when meeting an obstacle, both blocks slip along the bevels of the body and the sting moves by inertia, piercing the primer and initiating the detonation chain of the grenade. On the right - at the same time the rocker, interacting with the body of the capsule socket, turns and releases the tip. If the primer fails to ignite due to a weak puncture, the spring removes the tip from the primer, which eliminates the possibility of the grenade exploding during subsequent accidental shocks

The grenade had an extremely simple fuse, consisting of a duralumin threaded bushing 1, a pyrotechnic retarder 2 in the form of a steel body with an internal channel into which the pyrotechnic retarding composition is pressed, a grating igniter 4 and a lead cap 3. The grating igniter was exactly the same as the domestic igniter of modern rocket signal cartridges. A beam ignition detonator 12, which had the German designation “Sprengkapsel N8,” was inserted into the socket of the threaded bushing. This entire assembly is called a remote tube in some domestic descriptions.

A cord 5 is attached to the wire loop of the grating igniter, at the opposite end of which a porcelain roller 10 is attached. This roller fits into the socket in the bottom of the handle and is covered with a cover 6, which is screwed onto the cover 9. The cover and cover are made of thin (0.3 mm) sheet steel . To prevent the roller from dangling in its socket, it is pressed by a spring 8 through a metal disk 7.

Grenades were stored in 14 pcs. in a reusable metal closure with transport handles and screwed-in spacer tubes, but without detonators. In German terminology, these devices were designated by the abbreviation “BZ” - “Brennzunder”, which can be translated as “moderator”.

The same closure contained a wooden box with a sliding lid, which had 14 slots into which detonators were inserted. The N8 detonator is a universal detonator - the diameter of its internal cavity allows you to insert the fuse cord tightly enough into it and secure it by crimping the aluminum body. A grating igniter was attached to the opposite end of a usually half-meter piece of cord. In this configuration, the N8 detonator was used by the Germans in a wide variety of demolition devices. This device was often captured as a trophy by our front-line soldiers, who successfully used it.

For some time now, the following inscription began to appear on the body of the warhead of the M-24 grenade (obviously, not without reason): “Vor gebrauch sprengkapsel einsetzen” - “Place a detonator before use.”

To prepare the M-24 grenade for combat use, the combat head was unscrewed from it, and a detonator was inserted into the end socket of the retarding device with a grating igniter, “BZ,” screwed into the handle. Then the combat head was screwed onto the handle with the detonator until it stops at crown 18. To throw the grenade, the lid covering the porcelain roller was removed from the end of the handle and the cord with the wire from the grating igniter was pulled out behind this roller, after which the combustion of the retardant composition began. According to available descriptions, the moderator burn time is 4.5 s. I got the impression that the burning time of the retarding composition of German grenades is somewhat longer than that of domestic ones. German grenades, including the M-24, are more reliable than ours.

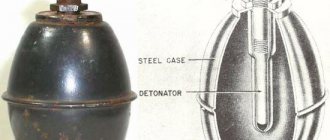

Hungarian grenade 36M

It began to enter the army in 1937. Its designer is considered to be Captain Vecsey Zoltan. Externally, it is a black barrel with three bright red ring stripes. The red color of these stripes indicates that the grenade is in combat equipment.

Blue stripes indicate a practice grenade. It differs from combat weapons only in that the explosives in it are replaced with an inert composition.

Yellow stripes indicate that the grenade is a training one, for practicing throwing techniques. Its internal part was replaced with a wooden block with a lead liner to obtain the real weight of the grenade.

Hungarian 36M impact grenade. Lightweight and compact

The body of the 36M grenade (Fig. 2) consists of two parts - cup 13 and neck 4, made by stamping from 0.6 mm sheet steel. The neck is screwed into the cup along the threads stamped on the edges of these parts. The end of the neck has a hole with a flange for guiding the cylindrical liner of the cap 7 and an annular extrusion for a pin 6, curved from 2.5 mm steel wire, securing the cap to the neck. The pin has a tongue made of thick yellow leather, which is attached to the cap by two bends formed by cutting the conical part of the cap. In the body there is a glass 12, consisting of a lower block 15 with an explosive block and a cylinder screwed into it, the bottom of which has an extrusion, where an assembly containing a pinned igniter capsule 14 is assembled (hereinafter we will simply call it a capsule). The bottom of the cylinder around this primer has three notches with bends for installing a cup stamped from 0.6 mm steel into which detonator 1 is inserted. The upper block 5 with the pin-safety mechanism and the second explosive block moves freely in the cylinder. Both explosive blocks are protected from contact with metal by paper wrapping impregnated with an insulating compound. The free movement of the upper block in the glass cylinder is slowed down by ring 3 made of spring wire by three bends of the ring through rectangular cuts in the glass. The pin safety mechanism consists of a steel sting 10, carved from a steel sheet 1.6 mm thick, a rocker arm 2, bent from a 1-mm brass sheet and a tension spring 11. When assembling a grenade, first of all, it is installed on the neck a cap that is fixed with a pin; the leather tongue of the pin is secured to the cap with two folds on its conical part. After this, the upper block is screwed onto screw 8 of the cap until it stops. The screw is steel, four-way, with a screw pitch of 12 mm. The screw is screwed into a 3.5x3.5 mm rectangular hole in the body of the pin safety mechanism, holding the tip away from the primer. Next, glass 12 with the lower block is placed on the upper block until it stops, and the neck is screwed together with the cup. A sealing gasket is placed between the end of the neck and the bottom of the cap. The thickness of the gasket is selected so that both blocks are assembled without a gap, and the cap is pressed tightly against the end of the neck. The cap and its cylindrical liner, as well as the bodies of both blocks and the glass, are made by stamping from a 0.6 mm steel sheet. All steel parts of the grenade are chemically oxidized. The black surface of the grenade has three colored stripes, the color of which indicates its type.

When throwing a grenade, if you do not hold the cap, it will partially unscrew from the screw already during the swing. This occurs under the influence of centrifugal force, and probably for this purpose the cap is weighted with two steel disks and a brass tube inside the cylindrical cap liner. Additionally, the brass tube serves as a guide for the screw head. The position of the grenade parts is shown in Fig. 1. At the initial part of the trajectory, the cap is separated and the upper block is removed from the glass of the lower block until it stops at the bottom of the neck. After the cap is completely separated and the upper block moves away, spring 11 rotates the rocker arm together with the sting so that the tip of the sting is positioned against the capsule. This position is shown in Fig. 2. When hitting an obstacle, due to the interaction of the blocks with the inner surface of the body, and by inertia the blocks move, the sting pierces the primer and the grenade explodes. This situation is illustrated in Fig. 3. At the same time, when the primer is pricked, the rocker arm arm slips along the surface of the extrusion with the igniter primer, due to which the rocker arm rotates and releases the tip. The sting, freed from adhesion to the rocker arm, is removed by a spring from the zone of interaction with the cap. This is done in order to protect the grenade in case the primer does not work due to a weak puncture.

Despite all my efforts, for a long time I could not find a description of this grenade. While still at the institute, while doing an essay on hand grenades, I received a pass to the library of the military weapons-technical school located opposite, but even there my searches were not crowned with success, although there was literature on this topic there. Only relatively recently did I find out the name of this grenade and the name of its designer, and also acquired grenade elements (by all indications obtained by “black diggers”), which allowed me to create accurate computer drawings of the grenade and its layout.

According to the author's drawings, the drawings were made by Mikhail SHMITOV

Grenade device

The main components of the grenade are: a “can” with explosives, a wooden handle with an igniter and a detonator cap. An explosive charge and a detonator cap No. 8 are placed inside the case. The ignition mechanism is a rubbing type mechanism. It consists of a spacer tube with a capsule, a cup with a grating compound, a cup cup, a wire grater with a lead (or porcelain) ball and a cord with a pull ring. When you pull out the cord connected to the wire grater, the latter, being curled into a spiral, passing through the hole in the cup, straightens, creates friction and ignites the grater composition. The flame of the grating composition ignites the powder pulp of the moderator, which burns for 4.5-5 seconds. The fire from the powder pulp will be transferred to the detonator capsule, which, when exploding, detonates the main charge.

To prepare a grenade for battle, you need to unscrew the can from the handle, insert detonator cap No. 8 into the body with the closed side up and screw the can back to the handle. To use the grenade, you need to unscrew the cap at the bottom of the handle. A white porcelain ball will fall out of the handle on a silk cord - a pull ring. Next, you should vigorously pull out the cord, holding it by the ball and immediately throw the grenade at the target.

ceramic suction ball

If the grenade did not explode in the next half a minute, then in the future it did not pose a danger.

grate igniter

The device of a grating igniter Igniter with detonator cap No. 8 Varieties of connection between a can and a grenade handle:

Various connection options

Various lanyard options

Smoke type grenade (Stielhandgranaten 39)

Holes for smoke exit on a smoke grenade mod. 1939

Based on the M-24 grenade, a smoke grenade mod. 1939, the distinctive feature of which is a white stripe on the case, as well as the presence of holes on the lower end of the case. Grayish-white smoke begins to emit approximately 7 seconds after the cord is pulled out. The resulting smoke screen lasts for 1.5-2.5 minutes.

The name of the grenade was painted in white paint on the side of the body. To determine the type of grenade in the dark, smoke grenades of the first years of production had ring grooves at the bottom of the handle. At the top end of the grenade there is a label with the inscription “Lebensgefahr beim Abbrennem ingeschlossenen Rauman” - “Dangerous to life if caught in enclosed spaces.”

Grenades | Germany

Universal grenade Gewehr Sprenggranate 30 (G. Sprgr. 30)

According to the principle of operation of the fuse and the method of application, the 30-mm high-explosive fragmentation grenade Gewehr Sprenggranate 30 (G. Sprgr. 30) was universal - hand and rifle. The grenade was a projectile with ready-made rifling on the leading belt of the bottom fuse. The grenade is equipped with two fuses: the first is a head (non-safety type), impact action (works only when using the grenade as a rifle), the second is a bottom, remote action (with a constant moderator burning time), with a spiral wire float. When using a grenade as a handheld, the bottom fuze works as the main one; when used as a rifle, it works as a self-liquidator in case of failure of the main fuse. When using a grenade as a rifle, it was thrown from a mortar mounted on a 98-K carbine. The grenade has been produced since 1941. Performance characteristics of the grenade: weight - 260-280 g; explosive mass – 32 g; grenade length - 142 mm; grenade diameter – 30 mm; delay – 4.5 s; self-destruct delay – 11 s.

Gun grenade Gewehr Panzergranate 30 (G.Pzgr.30)

The small rifle armor-piercing grenade G.Pzgr.30 was intended for firing a blank cartridge from a special mortar mounted on most German rifles during the Second World War. The grenade was a cumulative projectile with rifling on the leading belt. Smokeless powder placed in a regular 7.9 mm cartridge case was used as an expelling charge. The grenade body, ballistic tip and cumulative funnel, as well as parts of the impact mechanism were made of ferrous metal, and the stem was made of aluminum alloy. A cumulative funnel and a bursting charge were placed in the cylindrical glass of the body. The head part of the body was closed with a ballistic tip, and the bottom part was connected to the stem using threads. The stem body housed a detonating device and a bottom fuse. The grenade was produced in 1939-1942. in 7 modifications. Performance characteristics of grenades: weight – 230 – 255 g; explosive mass – 30 – 54 g; mass of expelling charge – 1 g; grenade length – 140 – 163 mm; grenade diameter – 30 mm; armor penetration - 30 mm; throwing range – 100 m.

Gun grenade Grosse Gewehrpanzergranate (gr. G. Pzgr.)

The Grosse Gewehrpanzergranate grenade (gr. G. Pzgr.) was developed on the basis of the “Gewehr Panzergranate 30” and was produced since 1942. It differed from the prototype in the design of the fuse, the shape and size of the charge. The large armor-piercing grenade was an over-caliber cumulative projectile with rifling on the leading belt of the stem. The grenade consisted of a body and a tail section with rifling. The body of the grenade with a smooth metal surface served to house a cumulative explosive charge. The tail part of the grenade, made of aluminum or plastic, contained a detonating device, an igniter primer and an inertial bottom fuse. Both parts are connected to each other by thread. The shooting was carried out from a rifle mortar attached to the muzzle of a rifle or carbine or a grenade launcher based on the PzB-39 anti-tank rifle. A special cartridge (case with an extended barrel) with a wooden bullet is used as an expulsion charge. Performance characteristics of grenades: weight – 380 g; explosive mass – 112 g of TNT with hexogen; expelling charge mass – 1.9 g; grenade length - 185 mm; armor penetration - 70 mm; grenade throwing range - 125 m.

Above - rifle grenade Gewehrpanzergranate 61. Below - Gewehrpanzergranate 46

In 1943, on the basis of the large armor-piercing grenade “Grosse Gewehrpanzergranate”, a large rifle armor-piercing grenade “Gewehrpanzergranate 46” (G. Pzgr. 46) was developed, which is an over-caliber cumulative projectile with rifling on the leading belt of the stem. The body of the grenade with a smooth metal surface served to house a cumulative explosive charge consisting of an alloy of TNT with hexogen and a detonator. After modernization, the grenade received the designation “Gewehrpanzergranate 61” (G. Pzgr. 61), which had an increased warhead length and diameter. The grenades were fired from a rifle mortar attached to the muzzle of a rifle, carbine or grenade launcher based on the PzB-39 anti-tank rifle. Performance characteristics of grenades "G. Pzgr. 46": weight - 430 g; explosive mass – 155 g; length – 195 mm; warhead length - 93 mm; warhead diameter – 46 mm; armor penetration - 90 mm; throwing range - 150 m. Performance characteristics of G. Pzgr grenades. 61: weight – 520 g; explosive mass – 200 g; length – 238 mm; warhead length - 136 mm; warhead diameter – 61 mm; armor penetration - 125 mm; throwing range – 150 m.

Pistol grenade Wurfkorper 326 Leuchtpistole (326 Lp)

The impact pistol grenade was a type of fragmentation grenade and was a ready-made shot for grenade launcher systems built on the basis of a 26 mm caliber signal pistol. The grenade was fired from a standard infantry rocket launcher with a smooth barrel, Leuchtpistole-28 and Leuchtpistole-42, or from the Sturmpistole and Kampfpistole grenade-launching pistol systems. The shot was a feathered projectile with an inertial fuse, connected to an expelling powder charge by an aluminum casing. Grenades were used for mounted firing at a distance of up to 70 - 80 m to combat enemy personnel in the offensive and defensive, suppress firing points in populated areas, and also to make passages in wire fences. At a distance of 100 m, shooting was carried out with flat fire, and starting from 150 m, the 326-LP grenade could cover targets located behind cover. Shooting at a distance of less than 50 m was strictly prohibited, since due to the large fragmentation effect, the weapon became dangerous for the shooter. A total of 19.8 thousand grenades were fired. Performance characteristics of grenades: caliber - 26 mm; length – 133 mm; weight – 140 g; explosive mass – 12 g; expelling charge mass – 0.5 g; maximum firing range – 260 m; damage radius - 30 m.

Pistol grenade Wurfkorper 361 Leuchtpistole (361-LP)

The over-caliber grenade is a type of fragmentation grenade. 361-LP is a fragmentation pistol grenade based on the Eierhandgranate hand fragmentation grenade mod. 1939. Instead of a standard grating fuse, a special plastic, metal or wooden guide rod with an igniting mechanism was screwed into it. The grenade was fired from a standard infantry rocket launcher with a smooth barrel, Leuchtpistole-28 and Leuchtpistole-42, or from the Sturmpistole and Kampfpistole grenade-launching pistol systems. A special feature of the 361-LP grenade was that it was visible in flight. With a standard igniter, the grenade body could be used like a regular Eierhandgranate grenade. In 1941-1942. 261.8 thousand units were produced. Performance characteristics of grenades: caliber - 26 mm; weight – 340 g; explosive mass – 100 g; length – 265 mm; diameter – 60 mm; maximum firing range – 100 m; armor penetration - 50 mm; damage radius – 20 m; delay – 4.5.

Pistol grenade PanzerWurfkopfer 42 LP (PWK-42 LP)

The over-caliber anti-tank cumulative pistol grenade was intended to destroy light and medium armored objects and was a shot for grenade launcher systems built on the basis of signal pistols. The 42-LP grenade consisted of a body and a rod connected to each other by a pin. Performance characteristics of grenades: weight – 600 g; explosive mass – 185 g of TNT with hexogen; length – 305 mm; grenade diameter - 61 mm; rod diameter – 23.5 mm; maximum firing range – 50 m; armor penetration - 50 - 80 mm at a distance of 75 m.

Pistol grenade Sprenggranatpatrone Z (Sp.GPZ)

The impact pistol grenade was developed in 1943 and belonged to the type of fragmentation grenades and was a ready-made shot for grenade launcher systems built on the basis of signal pistols. The grenade is combined into one piece with an aluminum casing and is a cartridge that does not require the implementation of combat readiness techniques before using it. The housing, made of aluminum, serves to place the bursting charge and secure the fuse, as well as to be damaged by fragments when bursting. In addition, the grenade body has ready-made rifling, thanks to which the grenade receives a rotational movement when fired, which helps improve accuracy. Performance characteristics of grenades: caliber - 26 mm; weight – 145 mm; explosive mass – 23 g; length – 130 mm; maximum firing range – 200 m; damage radius - 30 m.

GG/P-40 rifle grenade

The anti-tank cumulative grenade was intended for paratroopers and was fired from the K-98k grenade launcher. The grenade body was made of thin steel filled with hexogen. The tail was supposed to provide stabilization of the grenade in flight. The grenade has been produced since 1941. Performance characteristics of the grenade: weight - 550 g; explosive mass – 175 g; length – 236 mm; case length – 79 mm; diameter – 61 mm; firing range - 275 m; armor penetration at a distance of 100 m – 35 mm.

Gun grenade GewehrBlendgranate 42 (Gw. B. Gr. 42)

The smoke grenade has been produced since 1944. Performance characteristics of the grenade: weight - 630 g; length – 190 mm; diameter – 52 mm.

M-24 hand grenade (Stielhandgranaten 24)

The prototype of the M-24 anti-personnel grenade was put into service in 1916. In 1923-1924. Minor changes were made to the previous design, as a result of which the grenade received the name Stielhandgranate 24 (M-24) and was produced in this form until the end of the war. The grenade consisted of a metal body, a detonator and a hollow wooden handle covered with a screw cap at the bottom. The handle housed a Terek-type ignition mechanism. The grenade could be converted into a defensive one using a steel "jacket" with notches. Bundles of grenades were used to combat armored targets and destroy obstacles and firing points. To use a grenade, you had to unscrew the cap at the bottom of the handle, vigorously pull the cord with a porcelain ring that fell out, and immediately throw the grenade at the target. In total, more than 74 million units were produced. Performance characteristics of grenades: weight - 500 g; explosive mass – 180 g of TNT or ammonal; length - 356 mm; case height - 75 mm; case diameter - 60 mm; delay - 4.5-5 s; damage radius - 10 - 15 m, with a "shirt" - 30 m.

Smoke grenade M-39 (Nebelhandgranate)

Smoke grenade M-39B (Nebelhandgranate)

Smoke grenade M-39V without handle

On the basis of the M-24 grenade, the M-39 smoke grenade was developed, which was intended to set up smoke screens and temporarily blind the enemy. It differed from the prototype by a white stripe on the body, as well as by the presence of holes on the lower end of the body. The emission of grayish-white smoke began 7 seconds after the cord was pulled out. The resulting smoke screen lasted for 1.5–2.5 minutes. In addition to the Nebelhandgranate 39 grenade model, there was a Nebelhandgranate 39 B model, which was distinguished by its smoke-generating composition. In addition, a white stripe was additionally applied to the handle of the M-39B grenade, and to determine the type of grenade in the dark, the handle at the bottom was equipped with ring grooves. The grenade body was marked Nb in white paint. Hgr. 39B. In addition, at the end of the war, the M-39 was launched without a handle, which also had a grating fuse. During the war years, more than 7 million smoke grenades were manufactured. Performance characteristics of grenades: weight - 850 g; mass of smoke-forming composition – 160 g; length - 356 mm; case diameter - 60 mm; delay - 4.5 - 5 s.

Stielhandgranate M-43 smoke hand grenade

Defensive "shirts"

Stielhandgranate M-43 fragmentation grenade

The grenade was the result of the modernization of the M-24 in 1943 in order to reduce production costs. The fuse was simplified, the wooden handle did not have through drilling. A defensive “shirt” could be worn on the body of the grenade. The grenade could also be used without a handle. Performance characteristics of grenades: weight – 480 mm; explosive mass – 165 g; length with fuse - 345 mm; diameter – 67 mm; delay – 4-4.5 s; damage radius – 3 m.

Defensive "shirt" M-39

Eihandgranate M-39 hand grenade

An anti-personnel high-explosive fragmentation offensive grenade with a grating fuse was produced since 1939. It consisted of an egg-shaped metal body, an igniter and a detonator. The body consisted of rolled upper and lower hemispheres. On the lower hemisphere of the body there could be a metal ring intended for carrying a grenade. Grenades without a ring were carried in pouches or backpacks. When using a grenade, you had to unscrew the cap, pull it, and throw the grenade at the target. By replacing the conventional fuse with a special tube, the grenade could be fired from a 26-mm flare pistol. The grenade could be equipped with a defensive “shirt,” which increased the damage radius to 15 m. In total, more than 84 million units were manufactured. Performance characteristics of grenades: weight: 220 g; explosive mass – 110 g trinitroluene; length - 98 mm; case height - 76 mm; diameter - 60 mm; delay – 4.5 – 7.5 s; damage radius – 3 m.

Panzerwurfmine1-L cumulative grenade

Panzerwurfmine1-L cumulative grenade with deployed stabilizer

In 1943, the Luftwaffe adopted the Panzerwurfmine1-L (PWM 1-L) cumulative grenade, which was intended to combat tanks and other armored targets. The teardrop-shaped body of the grenade was made of metal. The grenade handle was made of wood; it was inserted into the hole in the body and secured with screws. The explosive charge consisted of a main charge placed inside the body and an additional detonator placed inside the handle. The stabilizer consisted of four springs with fabric feathers placed on them. After throwing a grenade, the safety cap remains in the hand and releases the springs, which straighten and tighten the stabilizer panels, which gives the grenade stability along the trajectory. In the stowed position, the grenade was suspended from the waist belt, for which there was a hole in the head of the body. During transportation and storage, a cover was put on the grenade handle to protect it from moisture and dust. During 1943, 204 thousand grenades were fired. Performance characteristics of grenades: weight – 1.4 kg; explosive mass – 525 g of TNT with hexogen; grenade length - 530 mm; diameter – 114 mm; armor penetration - 130 mm.

Panzerwurfmine Kz cumulative grenade

The modernized Panzerwurfmine1-L grenade was designated Panzerwurfmine Kz. (PWM Kz). It had a modified design for stabilizing the grenade in flight. Stabilization was provided by long canvas folds that extended from the rear (handle) of the grenade when thrown. The grenade penetrated armor - at an angle of 90º - up to 150 mm, and at an angle of 60º - up to 130 mm. In this case, a hole with a diameter of about 30 mm was formed in the armor. Performance characteristics of grenades: weight – 1 kg; charge mass – 525 g of TNT and hexogen; grenade length - 330 mm; diameter – 114 mm.

Hand-held cumulative mine (grenade) Panzerhandmine

The Panzerhandmine manual magnetic mine was intended to combat lightly armored vehicles, against pillboxes, armored caps, and armored embrasure flaps and was produced until 1942. Its body was made of metal. At the top of the body there was a thread onto which the adapter sleeve was screwed. A felt pad impregnated with an adhesive compound was attached to the bottom of the hull, with the help of which the grenade stuck to the armor of the tank. The pillow was closed with a safety cover placed on the body. An explosive charge is located inside the housing.

The deceleration time of a grenade depends on the type of fuse used in it. The fuse with a blue cap had a deceleration time of 4.5 seconds, with a yellow one - 7. To install a mine, a soldier must approach the tank as close as possible, taking advantage of the “dead” space around the tank and shelters on the ground. In addition, the Panzerhandmine could be thrown, but its cumulative effect was greatly reduced. Performance characteristics of grenades: weight – 420 g; charge weight – 205 g.

Hand-held cumulative mine (grenade) Panzerhandmine 3 (RNM-3)

A hand-held anti-tank cumulative magnetic mine was intended to combat light and medium tanks and armored vehicles. It was put into service in 1942 to replace the Panzerhandmine. The grenade consisted of a body, an explosive charge, magnets and a fuse. The bottle-shaped body of the grenade is made of metal. In the upper part of the body there was a threaded socket intended for screwing in the fuse. Inside the case there was a cumulative funnel with a steel lining and an explosive charge. The funnel was covered with a metal plate insert. At the bottom of the case there were six magnets for installation on a metal surface. The grenade was equipped with a metal ring with spikes for attaching the mine to a wooden surface. For transportation, the mine was equipped with a fabric loop attached to the upper part of the hull. To activate the fuse, it was necessary to unscrew the cap and jerk sharply, holding it in the palm of your hand. The mine could be attached to any point on the surface of the tank, mainly on horizontal planes, but most often they tried to install it opposite the most vulnerable places (on the engine, opposite the location of ammunition, fuel tanks). Performance characteristics of grenades: weight – 3 kg; explosive mass – 1 kg; grenade height – 270 mm; diameter – 140 mm; armor penetration - 130 mm; delay – 7 s.

Cumulative mine (grenade) Haft-Hohlladung 3(HHL-3)

The hand-held anti-tank cumulative magnetic mine was part of the “Panzerhandminen” series and was put into service in 1942. The grenade body was made of metal and consisted of two parts - cylindrical and conical, connected to each other. At the bottom of the body there was a cumulative funnel with steel lining. Using screws, the housing is connected to an ebonite plate on which three powerful magnets are attached that can withstand a force of 45 kg. In the transport position they are covered with a steel plate to prevent demagnetization. The explosive charge was located inside the housing and consisted of two blocks. An additional detonator is located in the cylindrical part of the body, and the main charge is located in the conical part. The mine used two types of fuses - with a delay of 4.5 s. (blue head) and 7 s. (yellow head). When attaching a mine to a vertical or inclined plane, the two mounting legs had to be directed upward. The safety ring was removed from the magnets when installing the mine. In 1942-1944. About 554 thousand grenades were fired. Performance characteristics of grenades: weight - 3 or 3.5 kg; explosive mass – 1.5 or 1.7 kg of TNT or hexogen; height – 275 or 300 mm; diameter – 150 mm; armor penetration - 150 - 180 mm.

Rocket-propelled grenade RPzB Gr.4322

A number of active-reactive cumulative grenades have been developed for rocket-propelled grenade launchers. So for the Raketenwerfer 43 Puppchen grenade launcher, the RPzB.GR-4312 grenade was used.

For the RPzB-43 “Ofenrohr” grenade launcher, 88-mm RPzB.GR grenades were used. 4322, as well as training grenades 4329-Ex, 4320-Ub and 4340-Ub. On the tail of the RPzB.GR-4322 grenade with an engine that was adapted to winter conditions, there was the inscription “arkt”. The grenade had a powder engine, a ring stabilizer was attached to its nozzle, and a wooden block onto which the electric fuse contacts were connected. The tail part and the body were connected by threads. The shaped charge consisted of TNT and hexogen. The grenade had a head impact fuse and a ring stabilizer with 6 feathers. Grenades were transported in wooden boxes of 2 pieces. in fully equipped form. Performance characteristics of grenades: caliber – 88 mm; weight – 2.7 kg; explosive mass – 862 g; length – 655 mm; initial speed – 120 m/s; armor penetration - 150-180 mm ha at a distance of 150 m. For the RPzB-54/1 grenade launchers, the RPzNGR-4992 grenade was used, which used a new brand of fast-burning powder charge, which increased the armor penetration to 200 - 240 mm, and the firing range to 200 m. Total 2.2 million grenades of all types were fired.

Volkshandgranate 45 hand grenade

In the last months of the war, due to a lack of materials, a simplified version without a handle was created on the basis of the Stielhandgranaten-43 hand grenade - Volkshandgranate-45. The cylindrical body of the grenade was made of concrete and filled with cement, gravel and small scrap metal. At the center of this mixture was an explosive. The top of the grenade body was closed with a metal lid with a central tube for installing the fuse. The grenades used simple grating fuses. To activate the fuse, you need to unscrew the cap and pull it sharply, holding it in your palm. Since January 1945, 784 thousand “folk” grenades have been produced. Performance characteristics of grenades: weight – 400 g; explosive mass – 150 g pyrolite; length – 74 mm; case diameter – 50 mm; deceleration time – 4.5 s.

Hand grenades Stielhandgranate Beton

The grenade was produced at the end of the war. The explosive (55 g) was filled with concrete (100 g) with steel fragments. Sometimes the form was ordinary tin cans (length - 90 mm, diameter - 70 mm). The detonator is of the Terek type.

Glashandgranate glass hand grenade

The grenade was produced at the end of the war. The body was made of cast glass. Performance characteristics of grenades: weight – 325 g; explosive mass – 123 g; height – 110 mm; diameter – 58 mm.

Smoke grenade "Blendkorper-1Н"

Smoke grenade Blendkorper-2Н

The smoke grenade, called the Blendkorper - “blinding device”, was a pear-shaped glass vessel filled with a liquid that turned into smoke upon contact with air. After the grenade body is destroyed, a bright flash and a cloud of thick smoke appears, which does not dissipate within 15-20 seconds, blinding the tank crew. The tear component of the grenade forced the crew to abandon the tank. The grenade was produced in two versions. The first model, Blendkorper 1H (BK-1H), was a sealed glass flask filled with F-substance (titanium tetrachloride). The weight of the BK-1H grenade is 370 g, diameter is 60 mm, height is 150 mm. After the production of 225 thousand BK-1H, production was switched to the production of the next model - BK-2H. The new grenade had the same pear-shaped appearance, but was reduced in height - to 128 mm. BK-2H was filled with 290 g of a mixture of calcium chloride, titanium tetrachloride and silicon tetrachloride. The total weight was 400 g. The design of the BK-2H differed from its predecessor and consisted of two glass vessels nested one inside the other. The outer vessel, which served as the housing, was filled with a mixture of titanium tetrachloride and silicon tetrachloride. A glass “test tube” filled with 36 g of calcium chloride was placed in it. The average throwing range of grenades was 25 - 30 meters. A total of 5.1 million grenades were fired.

Nebeleihandgranate M-42 hand smoke grenade

The body of the grenade consisted of two halves made of thin sheet. At the bottom of the body there is a metal loop for carrying a grenade. There are three openings at the top of the body to release smoke. A detonator was screwed into the end part. A total of 1.8 million grenades were fired. Performance characteristics of grenades: weight – 280 g; mass of smoke-forming composition – 170 g; length – 135 mm; diameter – 60 mm.

Smoke grenade Nebelkerze 39/39В

The body of the smoke grenade is made of thin sheet steel. The grenade could be used both manually and from installations on armored vehicles. Performance characteristics of grenades: weight – 1.8 – 2.5 kg; length – 140 mm; diameter – 90 mm; smoke emission time is 4-7 minutes.

Flare RauchSichtzeichen

The orange signal smoke grenade had an aluminum body and was produced in three versions. The first, designated “80,” had a length of 82 mm, a diameter of 40 mm, and a weight of 90 g. The second, “160,” had a length of 82 mm, a diameter of 54 mm, and a weight of 140 g. The third, “350,” had a length of 76 mm. , diameter – 82 mm, weight – 300 g.

Signal smoke grenade Мeldebüchse See

The naval aircraft flare grenade had an aluminum body and emitted yellow smoke. To give a signal over water, it could be dropped from a height of up to 150 m. Length - 374 mm, diameter - 60 mm, smoke emission time - 2.5 minutes.

Meldebüchse Land signal smoke grenade

The aircraft flare grenade had an aluminum body and emitted yellow smoke. To send a signal to ground troops, it could be dropped from a height of up to 100 m. Length - 404 mm, diameter - 60 mm.

Aviation signal smoke grenades

To give signals at airfields in poor visibility conditions, cone smoke grenades of red, white, green and yellow colors were used.

The expelling charge was located in the cone of the grenade. The shot was fired from a special 122-mm cardboard throwing tube. The fuse is Terek. Grenades have been produced since 1941. Grenade weight – 500 g, smoke height – 180 m; smoke release time - 6 - 8 s. Share to: