Rdultovsky model 1914 hand grenade / RG-14

grenade arr.

1914 (RG-14) Just before the start of the First World War, Rdultovsky improved the design of his grenade mod. 1912 and the grenade mod. entered service with the Russian army. 1914 (RG-14).

The design of the hand grenade mod. 1914 was not fundamentally different from the 1912 model grenade. But there were still changes in the design.

The 1912 model grenade did not have an additional detonator.

In the 1914 model grenade, when loaded with TNT or melitin, an additional detonator made of pressed tetryl was used, but when loaded with ammonal, an additional detonator was not used. Equipping grenades with different types of explosives led to a variation in their weight characteristics: a grenade loaded with TNT weighed 720 g, with melitin - 716-717 g. grenade arr.

1914 (RG-14) Various materials were used in the production of grenades. Tin was used to make the body, handle, funnel and grille; the pin and spacer tube were made from brass; the hook, mainspring, and guy spring were made from steel; rivets, tubes, a small capsule, and a detonator cap were made from red copper.

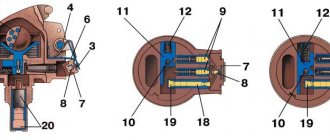

Design of a hand grenade mod. 1914 consisted of a tin shell, a striking mechanism, a charge, fragments and a fuse. The tin shell consisted of a body with a lid, a funnel, a handle and a tin plate, under which the impact mechanism was located.

The body of the grenade had a cylindrical shape with a neck. Body length - 104.5 mm, handle length - 112 mm, handle diameter - 30-35 mm. Tinplate was used to make the body.

Between the charge and the shell, two 1 mm thick gratings with cross-shaped slits were placed, which, when the grenade exploded, produced about 230-250 small, but quite lethal, almost square fragments. To make one grating, a metal plate with dimensions of 125.2x105.6 mm was required.

The following explosives were used to equip grenades during their serial production: ammonal, melitin, TNT and Favier's composition. There was 400-410 grams of TNT in the pomegranate, 307 grams of melitin. The range of destruction of manpower with RG-14 grenades of the first samples was 4-5 steps, the main production model was from 6 to 12 steps. Scattering of individual fragments up to 30-50 steps.

The impact mechanism of the grenade consisted of a hammer with a hammer, a mainspring, a coupling attached to the shell and a pin. A hardened steel needle was tightly inserted into one end of the striker; its other end had a head, which was used to grab the guy hook, which rotated on an axis and was equipped with a spiral spring.

As an additional fuse for the grenade, a ring was put on the handle, covering the guy with its narrow part, and with its wide end adjacent to the brass stop embedded in the handle.

The grenade's fuse consisted of an aluminum ignition tube and a detonator cap. The longitudinal channel of the ignition tube and both of its elbows, adjacent to the small primer and the tube, were filled with stopin to transfer fire from the small primer to the remote composition. The outlets of this channel were clogged with pieces of fiber or cork, covered with mastic and varnished. The deceleration time of the RG-14 was about 4 seconds.

A detonator was tightly placed on a thimble soldered to the lid, after which the lid was soldered to the grenade body. The molten explosive was poured from the side of the handle into the shell, where it hardened. After soldering the bottom to the handle, the explosive charge became hermetically sealed inside the shell and was reliably stored in the field and in arsenals.

The grenade was stored without a fuse and with the striker released.

Before throwing, the fighter had to put the grenade on safety and load it. The first meant: remove the ring, pull back the firing pin, recess the lever in the handle (the hook of the lever captured the head of the firing pin), place the safety pin across the trigger window and put the ring back on the handle and lever. The second is to move the funnel lid and insert the fuse with the long arm into the funnel, the short one into the chute and secure the fuse with the lid. grenade arr.

1914. To throw a grenade, the grenade was held in the hand, the ring was moved forward, and the safety pin was moved with the thumb of the free hand. At the same time, the lever compressed the spring and pulled the striker back with its hook. The mainspring was compressed between the clutch and the trigger. When thrown, the lever was pressed back, the mainspring pushed the firing pin, and it pierced the igniter primer with the striker. The fire was transmitted along the threads of the stopin to the retarding composition, and then to the detonator cap, which detonated the explosive charge.

During the First World War, the RG-14 hand grenade became the main one in the Russian army.

Every day the front needed a significant number of such grenades. Therefore, a large number of Russian “state-owned” and private enterprises were involved in the production of grenades. The grenades were equipped at the Okhtensky and Samara plants. Since March 1916, the production of grenades mod. In 1914, the Troitsk equipment plant began, designed, built and operated under the leadership of Rdultovsky. The workshops of the Sveaborg fortress artillery, artillery warehouses and many other enterprises were involved in equipping grenades. “combined” grenade arr.

1914 Despite the introduction of heavy high-explosive grenades for destroying wire fences, fragmentation hand grenades were also adapted for the same purposes. Grenade arr. 1914 was strengthened - an additional charge in a cylindrical tin shell was put on it and cords with weights were attached, so that the total mass of the charge reached 1.65 kg, and the grenades - 2.05 kg. Such grenades were called “combined”. To make a passage 6-7 m wide, 4-8 grenades were required for the aperture and 20-36 for the wire net.

Interesting were the attempts to create various grenade launchers for hand grenades. In mid-1915, court adviser Makarov proposed converting captured Austrian Mannlicher rifles for throwing grenades mod. 1914. The rifle barrel was cut off, and a “tube (mortar) with the caliber of a grenade handle” was welded onto the cut—about 35 mm. The end of the grenade lever was cut to 6.4 mm to fit into the mortar, and a seal was put on the handle. The shot was fired with a blank cartridge at 100-170 steps - the range of ranges was limited by the constant installation of the fuse. The rate of fire was 3-4 rounds per minute; a single target at 120 steps was hit with 1-2 shots.

11,000 converted grenades from September 1915 to March 1916 were tested by the troops of the Southwestern Front and received a positive assessment.

Although the Art Committee of the Main Artillery Directorate was skeptical about this weapon, due to the urgent need, the Petrograd Arsenal was given an order to convert 20,000 hand grenades, and the Petrograd Cartridge Plant was given an order to convert 8 mm blank cartridges. Until the spring of 1917, the ordered grenades were sent to the Southwestern Front and were “completely used up.” With a long delay in the delivery of rifle grenades, Makarov’s surrogate weapons played a role. grenade arr.

1914 Method of “throwing hand grenades mod. 1914 from a mortar" for the Russian three-line rifle was proposed on February 4, 1916 by Lieutenant Koscenic. But Artcom rejected this proposal, citing consideration of Makarov’s method.

| Grenade weight, g | 716 — 720 |

| Charge mass, g | 307 — 410 |

| Grenade length, mm | 220 |

| Transverse size, mm | Ø 45 – 49.3 |

| Damage radius, m | 4 — 30 |

| Number of fragments, pcs. | 200 — 250 |

| Throwing range, m | 35 — 40 |

| Deceleration time, s | 4 |

The interesting “Sling” design was a typical improvisation of “trench warfare”, and in January 1916 it was rejected - in terms of range, projectile power and accuracy, it was noticeably inferior to the mortars that had begun to enter the army by that time.

By May 1915, troops received 155,720 units. garnet arr. 1914, by August 1915, 780,336 of these grenades were produced. By December 1916, 10,403,368 RG-14s had been delivered.

Grenade arr. 1914 was in service with the Russian and then the Red Army until 1930. The grenade was widely used in combat during the First World War and in the Civil War.

| grenade arr. 1914 (RG-14) |

History of creation

At the end of the 1930s, the GSKB-30 design bureau at plant No. 58 (Leningrad) received an assignment from the Main Artillery Directorate of the Red Army (GAU RKKA) to develop an anti-personnel hand grenade to replace the existing RGD-33.

The design bureau demonstrated the highest pace of development and already in 1940 presented two prototypes of grenades for military testing. The first sample was a grenade designed by I. Ya. Budilov - P. I. Gavrikov, the second was a grenade designed by N. P. Belyakov. The latter was recognized as the best. Soon, in 1941, after a slight design improvement, the development was adopted by the Red Army under the designation RG-41 (hand grenade model 1941).

RG-41 grenade

Terms of use

RG-41 belongs to the offensive class anti-personnel fragmentation hand grenades. The grenade is delivered to the target exclusively by throwing it with the fighter’s hand. The explosion occurs 3.2-3.8 s after the throw.

In order to load a grenade, you need to move the lever that holds the hook to the end of the slot, and then open the cap. Then insert the igniter into the central tube, slam the lid and return the lever to the default position.

How to charge RG-41

To use a grenade, you had to take it in your hand and press the folding bar against the body with your fingers. Then, without pressing your fingers, pull the cotter pin by the flag with your other hand, make a swing and throw.

If a fighter changes his mind about throwing a grenade, then it can be returned to a safe state - without unclenching his hand, return the pin to its place and separate its ends.

To discharge a grenade, it was necessary to perform the same steps as in the loading process, except that the fuse had to be removed.

Construction[edit]

The design of the RG-12 grenade was relatively simple. A plate with a percussion mechanism tube was riveted to the box-shaped body, made of a metal sheet; inside the tube there was a rod with a striker and a mainspring. On the side of the tube there was a fuse made in the form of a valve. The body had two covers: a wooden handle was attached to the bottom, and the top had a hole for installing a fuse. The grenade handle had a slot in which a spring-loaded lever was installed, connected to the striker rod of the impact mechanism. The fuse had the form of a U-shaped tube assembled from three parts, inside of which there was a moderating composition and a primer made of mercury fulminate. The grenade was filled with ammonal. Inside, in addition to the explosive charge itself, there were four zinc plates with cross-shaped slots and about 300 zinc triangles - all of this served as ready-made fragments. In total, the explosion produced about 800 fragments. The loaded grenade weighed 1300 grams.

To throw a grenade, the grenade was taken in the right hand so that the safety ring was between the fingers of the hand, and the grenade lever was pressed. Then the bolt was moved to the side, after which the grenade was thrown at the target. At the moment of the throw, the safety ring remained in the hand. The grenade's guy rotated around its axis and the striker pierced the fuse primer. After the retarding composition burned out, the detonator and grenade charge exploded.

Application and effectiveness

The grenade was widely used by the Red Army forces in the very beginning of the Second World War.

Compared to its predecessor, it had a number of advantages - convenience, ease of use, manufacturability. And in terms of the effectiveness of its application, it can hardly be called “weaker”. But she was never able to “get through” the war - she disappeared from the trenches already in 1942, which cannot be said about the RGD-33, which turned out to be a universal fighter and went through the war with the fighters from the invasion of German troops into the territory of the Ukrainian SSR until their surrender in Berlin.

Design of RG-41

To summarize, the grenade was quite modern for its time and had a technological design. But after the creation of the fuse, the UZRG improved it - this is how they created the RG-42 grenade, which was safer, structurally simpler and more technologically advanced.