Type of hand grenade/rifle grenade

| Type 99 "Pussy" hand grenade | |

| Japanese Type 99 hand grenade | |

| Type | Hand grenade/rifle grenade |

| Place of origin | Japan |

| Service history | |

| In service | 1939–1945 |

| Used | Imperial Japanese Army Imperial Japanese Navy |

| Wars | Second Sino-Japanese War Second World War |

| Production history | |

| Designed by | 1939 |

| Characteristics | |

| Weight | 300 grams |

| Length | 87 mm |

| Diameter | 41 mm |

| Filling | Cast picric acid |

| Filling weight | 58 grams |

| Detonation mechanism | Pyrotechnic delay from 4 to 5 seconds. |

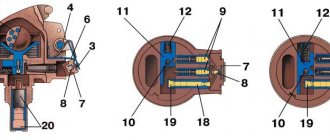

Type 99 grenade cutout

Type 99 hand grenade

(九九式手榴弾, kyukyu-shiki Teryūdan) also known as

the Pussy Grenade

in the US Army was an improved version of the Type 97 fragmentation grenade used by the Imperial Japanese Army and the Imperial Japanese Navy SNLF during World War II. [1]

Type 99 (machine gun)

| Type 99 | |

| Type 99 | |

| Type | light machine gun |

| A country | Japan Japan |

| Service history | |

| Years of use | 1939-1945 |

| Adopted | 1939 |

| In service | Imperial Japanese Army |

| Wars and conflicts | World War II, Vietnam War |

| Production history | |

| Constructor | Kijiro Nambu |

| Designed by | 1936 |

| Characteristics | |

| Weight, kg | 9,8 |

| Length, mm | 1181 |

| Barrel length, mm | 550 |

| Cartridge | 7.7×58 mm Arisaka |

| Caliber, mm | 7,7 |

| Work principles | removal of powder gases, wedge breech |

| Rate of fire, rounds/min | from 250 to 850 |

| Initial bullet speed, m/s | 715 |

| Type of ammunition | 30-round box magazine |

| Type 99 at Wikimedia Commons | |

History[edit]

The Japanese Army, noting that grenades were short-range weapons, began efforts to optimize the weapon for close infantry combat. The first Type 10 fragmentation grenade was the first Type 10 fragmentation grenade. Shortly after the Type 10 grenade was introduced to frontline troops, a number of problems arose. When thrown by hand, the instability and imprecision of the fuze mechanism made the Type 10 almost as much of a threat to the thrower as it was to the recipient. In addition, the weapon was considered small and did not have the desired lethality.

The Japanese Army continued to experiment with rifles and hand grenades between the wars and adopted a family of fragmentation grenades with near-universal adaptability. Introduced in 1931, the Type 91 fragmentation grenade could be thrown by hand, fired by a cup-type grenade launcher (Type 100), fired by a light mortar searchlight (Type 89 grenade launcher or knee mortar

). [2] or equipped with a finned tail and fired from a sleeve-type rifle grenade launcher.

"Death machine". Japanese anti-tank rifle "Type 97".

Rather, it’s not so much about the officials. It’s more about the warriors. It was the warriors who noticed this minus of the anti-tank guns. And the armor effect of the anti-tank guns’ ammunition was actually very weak. Somehow the website already provided data on the number of tanks destroyed by both sides. There it was laid out in detail how many tanks were destroyed by what anti-tank means. AT guns have very modest results. The most effective weapon was AT artillery with a caliber of 57-105 mm. By the end of 1943, Germany practically stopped producing sub-caliber projectiles made of tungsten carbide. The same applied to projectiles for all guns with conical barrels, since in addition to being difficult to manufacture, they required the same tungsten carbide projectiles. The usual 75 mm PT gun Rak- 40 cost 12 thousand marks. It had a fairly powerful HE shell, which made it possible to use it as a field gun. If the Germans had started production of a more powerful, improved version of the 75 mm Rak-42 PT gun, it would have been even better for them and much worse for the tankers of the anti-Hitler coalition countries. For the Japanese, the situation was different. And they did not have much experience in fighting tanks. We could buy a license from the Germans to produce the 75 mm Rak-40 cannon and get a universal means of combating… Read more »

"Smoke funfirik": Blendkorper 1H and Blendkorper 2H

Fighting tanks is not an easy thing. Here you need artillery, anti-tank guns, mines and other serious things. It’s difficult for a simple infantryman to deal with a tank: not every grenade will defeat an iron monster, and other types of explosives won’t save you enough. So German engineers decided to find an alternative way to deal with the enemy's armored vehicle.

The bet was made on chemistry. If you can’t cope with the tank itself, you need to kick its crew out into the open air. This is how the Blendkorper 1H grenade with a glass body appeared.

Blendkorper 1H and Blendkorper 2H smoke hand grenades

After the body broke, the irritant interacted with oxygen. A flash and smoke formation followed - the cloud remained in the open air for 15-20 seconds.

Only a quarter of a million of these grenades were produced - the military demanded the creation of something more convenient and less slippery. Then the 2N model went into production. The body was filled with a mixture of silicon and titanium tetrachlorides, and calcium chloride was placed in the inner glass flask. This mixture was even more effective, and the new-shaped vessel with a stopper fit better in the palm of the hand. From 1943 until the end of the war, the Germans managed to rivet more than five million of these “smoke tubes.”

Many people have dabbled with glass to make the body of grenades and mines. You can recall the British “sticky bomb” No. 73ST, domestic ampoules and Molotov cocktails, Japanese chemical grenades with hydrocyanic acid, and the like. However, after World War II, this fragile material began to be abandoned: the era of plastics began.

Every year, humanity invented new deadly weapons of war. Grenades have evolved - and the further, the more seriously. But, as always, the main thing in the creation process was not to accidentally run into your own inventions...

Design

The grenade consists of a body, an explosive charge, a remote fuse and a bottom cylinder with an expelling powder charge and an igniter primer. The cylindrical body is made of cast iron with vertical and horizontal notches and is equipped with an explosive charge (trinitrotoluene or trinitrophenol). In the upper part of the body there is a cover with a hole for screwing in the fuse, in the lower part there is a bottom cylinder

The fuse consists of a housing, inside of which there is a firing pin with a striker, a counter-safety spring, an igniter primer and a powder retarder. The firing pin is screwed into the firing pin body, which is secured with a safety cap and a safety fork. When throwing a grenade by hand, it was necessary to screw the firing pin into the firing pin body, pull the safety fork by the rope tied to it, hit the grenade against a hard object and then throw it. When the head of a grenade hits an obstacle, the firing pin overcomes the resistance of the counter-safety spring and punctures the capsule, igniting the powder retarder, which burns for 7-8 seconds, and then ignites the detonator capsule, which leads to the explosion of the main charge

The bottom cylinder, which is screwed into the bottom of the case, contains an expelling powder charge and is closed with a plug with a hole. To use it as a grenade launcher, the grenade, after pulling out the safety plug, was lowered into the barrel, while through the hole in the plug the igniter primer was pierced and the charge was ignited, which, under the pressure of powder gases, ejects the grenade over a considerable distance (based on the principle of a mortar mine). It was also possible to use the Type 91 grenade as a rifle grenade, for which a stabilizer tube attached to the bottom cylinder was used, which was placed on the rifle barrel, a shot from which would ignite the expelling charge and launch the ammunition

Anti-tank weapons of the Japanese infantry in World War II

The Japanese army first encountered Soviet-made tanks and armored vehicles in the late 1930s during the fighting in China and during military conflicts in the area of Lake Khasan and the Khalkhin Gol River. Soviet, Chinese and Mongolian forces used T-26, BT-5, BT-7 light tanks and BA-10 armored vehicles with bulletproof armor, which were vulnerable to 37 mm anti-tank guns and 20 mm anti-tank rifles.

Soviet armored car BA-10, shot down during the fighting near the Khalkhin Gol River

Type 97 anti-tank rifle

During the fighting at Khalkhin Gol, Japanese infantry first used the 20-mm Type 97 anti-tank rifle. It entered service in 1937 and was used by Japanese troops until the end of World War II. The Type 97 anti-tank rifle was heavy and not very easy to handle, but it significantly increased the capabilities of the Japanese infantry in the fight against enemy armored vehicles.

Type 97 anti-tank rifle, which became a trophy of the Red Army during the fighting at Khalkhin Gol

For firing from the Type 97 PTR, 20x124 mm ammunition was used, originally developed for use in 20 mm anti-aircraft guns. The ammunition could include: armor-piercing tracer, high-explosive tracer, high-explosive incendiary and incendiary tracer shells. For firing at armored vehicles, an armor-piercing tracer projectile weighing 109 g was used, which left a barrel 1064 mm long at a speed of 865 m/s. At a distance of 250 m, normally it could penetrate 30 mm of armor, which in the second half of the 1930s was a very good indicator.

The automation of the 20-mm anti-tank gun worked by removing part of the powder gases. In order to increase the reliability of the weapon’s operation in various conditions and for the use of different types of ammunition, the gas outlet tube of the anti-tank gun was equipped with a regulator that made it possible to change the gas pressure on the piston. Food was supplied from a detachable 7-round magazine. The combat rate of fire reached 12 rounds/min. Sighting devices made it possible to fire at a range of up to 1000 m.

Type 97 PTR crew at a firing position

Although the armor penetration and rate of fire of the Type 97 PTR were excellent at the time of its creation, the anti-tank rifle had a lot of shortcomings. Automatic firing caused up to 5% delays. The most common cause was the spent cartridge not being ejected. But if calculations accepted this, then transporting anti-tank missiles to the battlefield caused many problems. Before carrying the gun, the crew had to install special metal handles. The designers believed that the anti-tank rifle would be carried by two crew numbers, but in practice, transporting weapons required the involvement of more people. Typically, the Type 97 PTR was carried by three or four soldiers. The weight of the weapon, without handles and shield, was 52.2 kg. The unloaded gun with shield and handles weighed 68 kg. Due to its heavy weight, the Type 97 PTR was used mainly in defense. To reduce the very strong recoil, the gun had a muzzle brake, but when fired, powder gases scattered in the horizontal plane raised dust, which made observation and aiming difficult, and also unmasked the firing position.

Type 97 anti-tank rifle with carrying handles

But, perhaps, the main disadvantage of the Type 97 anti-tank rifle was its very high cost. In 1941, the price of one 20-mm anti-tank rifle manufactured in the Kokura arsenal was 6,400 yen. By comparison, the 6.5mm Type 38 rifle cost only 77 yen. Due to the high cost, after the production of approximately 1,100 copies, production of the Type 97 PTR was curtailed in the second half of 1941. However, in 1943, Nihon Seikosho received an order to produce new guns. The workload of the enterprise did not allow it to produce a large number of anti-tank rifles, and a little more than 100 anti-tank rifles were delivered to the military.

Despite the relatively small circulation, the Type 97 anti-tank rifle was used in combat until the Japanese surrender in August 1945. 20 mm shells penetrated the relatively thin side armor of M3/M5 Stuart light tanks, and also successfully hit amphibious LVT transporters from any direction. When repelling the landings on the Pacific islands, the Type 97 anti-tank missiles created many problems for the American Marines. At the same time, the excessive mass of the 20-mm gun forced fire from stationary positions, which were quickly identified and suppressed. In addition, even if the armor was penetrated, the damaging effect of 20 mm shells was relatively small.

Although the Red Army used armored vehicles in fairly large quantities at Khalkhin Gol, the command of the Imperial Japanese Armed Forces did not draw the appropriate conclusions and did not bother to equip the infantry units with a sufficient number of effective anti-tank weapons. This was partly due to the fact that the Japanese ground army was financed on a residual basis, it did not participate in the battles of the First World War and did not face a strong enemy until the second half of the 1930s. After the advent of tanks with shell-proof armor, 20-mm anti-tank rifles no longer met modern requirements, and the problem of anti-tank infantry defense had to be urgently solved by using various improvised and surrogate means.

Anti-tank grenades, bundles and incendiary bottles

The simplest means of combating enemy armored vehicles, which could be quickly produced in the field, is a bunch of hand grenades.

The Type 98 grenade, which was an adapted copy of the German M-24 “beater,” was best suited for this. It differed in appearance from the German prototype by its shortened handle. Type 98 hand grenade

The body of the grenade was made of cast iron and had a thread at the bottom for attaching a wooden handle. The picric acid charge was placed inside the case and packaged in a paper cap. With a grenade weight of 560 g, it was loaded with 50 g of explosive. The deceleration time of the fuse is 6-7 s. In order to destroy the caterpillar or damage the chassis of the tank, it was necessary to attach 5-6 grenade bodies to a grenade with a fuse, and the weight of the bunch was 2.5-3 kg. It is clear that such a design could only be used relatively safely from a trench. To increase the high-explosive effect, the body of the Type 98 grenade was often tied with melinite bombs.

Hand grenade Toure 97

Also, the Japanese military used several types of grenades without handles with cast bodies that had vertical and horizontal notches. Such grenades could be attached with wire or rope to a wooden stick. The Toure 97 grenade weighed 450 g and contained 65 g of TNT. The fuse deceleration time is 4-5 s.

A common feature of all Japanese fragmentation grenades was the inconvenience of their use and low effectiveness in anti-tank warfare. Due to the imperfection of the fuses, their firing time varied greatly, which could pose a danger to those who used them. In 1943, the Type 3 anti-tank hand grenade was adopted by the Imperial Army, which the American Marines called the “Fox Tail” for its unique appearance.

Type 3 anti-tank grenade

The design of the Type 3 grenade was very simple, and its production used readily available and cheap materials. The explosive charge was placed in a cloth case. At the top of the charge, a metal ring with a thread was attached using a clamp, into which the fuse was screwed. The same clamp secures the fabric cover. A stabilizer made of hemp or silk twine was attached to the grenade using a clamp. From below, the charge rests on a wooden base. At the head of the grenade there was a cumulative funnel lined with steel or aluminum 3 mm thick. Before throwing, the cloth tape was removed from the grenade and the safety pin was removed. Thanks to the stabilizer, the Type 3 grenade flew head first. The inertial fuse was triggered when it hit an obstacle.

Several modifications of the Type 3 grenade are known: Ko (Type A), Otsu (Type B) and Hei (Type C). They differed in size, weight and filling. The Type A modification (bag color - white or brown-yellow) weighed 1270 g and was loaded with 853 g of a mixture of hexogen and trinitroaniline. Option Type B (bag color - white or brown-yellow) had a mass of 855 g and contained a mixture of TNT and PETN. The last most compact and light modification (the color of the bag is yellow) with a mass of 830 g contained 690 g of picric acid.

English-language reference books say that all modifications, when hit at right angles, had the same armor penetration - 70 mm. Which, however, given the use of various metals for lining the cumulative funnel and explosive components that differed in detonation speed and power, is extremely unlikely. It is now impossible to reliably establish what thickness of armor a particular modification of the Type 3 anti-tank grenade could penetrate. But this armor penetration theoretically made it possible to defeat the frontal armor of the M4 Sherman tank. A well-trained and physically developed soldier could throw a Type 3 Hei anti-tank grenade at 25 m, but usually the aimed throw range did not exceed 15 m. This anti-tank grenade contained a minimum of metal parts and gave the grenade launcher a better chance of surviving than a bunch of fragmentation grenades.

Quite predictably, the Japanese military tried to fight the tanks with glass bottles filled with fuel. At the first stage, these were bottles filled by the troops with a mixture of low-octane gasoline and used engine oil. Before throwing such an incendiary projectile at an enemy tank, it was necessary to light the fuse-plug made of tow.

Since 1943, the industrial production of glass incendiary grenades, filled with a flammable liquid with rubber dissolved in it, was organized. The rubber acting as a thickener, which prevented the incendiary mixture from draining, quickly caused the ignited liquid to stick to the armor of the tank and, when it came into contact with the viewing devices, an opaque film was formed. The burning of the rubber-thickened fire mixture was accompanied by thick black smoke, severely limiting visibility for the tank crews. The industrially produced bottle of incendiary fluid was sealed with a sealed cap. When broken against armor, ignition of the fuel was ensured by a special chemical composition in fabric bags, which were attached to the bottle with ribbons. Incendiary bottles were supplied to the troops in cardboard or tin cases, which protected them from mechanical damage.

Japanese glass smoke and incendiary grenades

Along with incendiary grenades, the Japanese army actively used smoke glass grenades filled with titanium tetrachloride. After the glass wall of the grenade was destroyed, a chemical reaction occurred in which titanium tetrachloride, evaporating, reacted with water vapor contained in the air. At the same time, the chemical compound decomposed into titanium dioxide and hydrogen chloride, producing thick smoke. The smoke cloud blinded the tank crews and allowed the Japanese infantry to approach the tanks. Smoke glass grenades were used especially actively in Okinawa. Often seeing clouds of thick white smoke ahead, American tankers preferred to retreat and called in artillery fire or air support.

American infantrymen take cover from Japanese fire behind a Sherman tank.

Anti-tank mines

In addition to grenades and bottles, Japanese infantry could use several types of mines to fight tanks. The Type 99 magnetic mine, adopted for service in 1939, was intended for direct installation on armor. Like most Japanese anti-tank mines, its design was extremely simple and cheap.

Type 99 anti-tank magnetic mine

The body of the mine was a canvas bag containing eight bombs of melinite and TNT. On top there was a delayed action fuse designed for 7-10 seconds. The mine is attached to the side of the tank using four magnets located on the side of the canvas bag. Before attaching the mine to the tank, you had to pull the safety pin by the cord and hit the fuse head on a hard object. With a magnetic mine weighing 1.23 kg, it contained 680 g of explosives. Mine diameter – 121 mm, height – 40 mm. The magnetic mine had only a high-explosive effect and could penetrate 20 mm thick armor. To increase armor penetration, several mines could be fastened together. Two magnetic mines could penetrate 38 mm of homogeneous armor, three – 46 mm. The mines were supplied in canvas bags, which also contained the fuse.

Type 99 mine with carrying bag

Japanese soldiers were expected to attach magnetic mines to the bottom of tanks passing over their trenches, or to run up to a moving tank and place mines on the side or stern. In this case, the fuse should have been initiated in advance. It is clear that with this method of application, the probability of survival for the one who installed it was small. However, Type 99 mines were used until the end of hostilities.

A pole mine with rubber suction cups was intended for mounting on the side or stern of the tank. The tin body of the mine contained up to 2 kg of TNT alloy with hexogen. This amount of explosives was enough to break through 30 mm thick armor. Even if there was no through-break, pieces of metal broke off from the inner surface of the armor, striking the crew.

Drawing of a Japanese pole mine with rubber suction cups

The fighter, having secured the mine on the suction cups, activated the grating igniter, which ignited the fire cord, which burned for 12-15 seconds. During this time, the soldier of the imperial army had to leave the affected area or take refuge in a trench.

At approximately the same time as the high-explosive anti-aircraft mine, which was attached to the tank’s armor using rubber suction cups, the Ni04 high-explosive pole mine came into service, which could be placed under the tank’s track.

Drawing of an anti-tank pole high-explosive mine Ni04

This anti-tank ammunition had a metal body in the form of a hemisphere, filled with 3 kg of TNT or melinite. At the top of the hemisphere there was a pressure fuse, which was activated when the tank hit a mine. Taking into account the fact that the length of the bamboo pole was no more than 2 m, a close explosion of a 3 kg charge of powerful explosives in an open area was guaranteed to kill the one who used the mine against the tank. If a Japanese soldier managed to hide in a trench before the explosion, then at best he received a severe concussion.

The Japanese infantry also had at their disposal Type 93 universal mines, which, depending on the fuse, could be used as anti-tank and anti-personnel mines. The pressure fuse was supplied in two versions - with an actuation force of either 31-32 kg or 110-120 kg. The body of the mine, made of tin, contained 907 g of melinite; the mine itself, when loaded, weighed 1.36 kg. Case diameter – 171 mm, height – 45 mm.

Type 93 mine

Unlike other engineered ammunition used for laying anti-tank minefields, the Type 93 mine was intended from the very beginning for use by infantry. Due to its relatively small mass and dimensions, it was quite easy to move with it on the battlefield and quickly install it in the path of moving tanks. Also on the body there were rings for ropes, with the help of which the mine could be dragged under the tank's caterpillar. However, with excess power for use as an anti-personnel mine, the explosive charge insufficient for an anti-tank mine did not allow it to cause serious damage to the tank. In most cases, when a Type 93 mine exploded a Sherman medium tank, the result was a broken track.

In addition to the Type 93 metal-cased mine, the Japanese infantry had at its disposal the Ni 01 and Type 3 wooden-cased anti-vehicle mines. Among the most commonly used was the extended anti-vehicle mine, designated in the United States as the Yardstick.

Japanese anti-vehicle extended mine

The anti-vehicle mine had a metal body with an oval cross-section 94 cm long. The total mass was 4.76 kg, of which 1840 g was explosive (melinite). The mine had four pressure-action fuses with an actuation force of about 120 kg. Due to its greater length, the likelihood that the tank would run into an extended mine was higher.

Once it became clear that the balance in the Pacific theater was tipping in favor of the Allies, the Japanese armed forces made extensive use of kamikaze tactics not only in air and sea battles, but also on land. Initially, Japanese suicide soldiers blew up British and American armored vehicles, hanging themselves with grenades and explosives, or threw themselves under a tank with an anti-tank mine in their hands. Later, special backpacks with surrogate explosives based on ammonium nitrate and cumulative Ni05 instant action pole mines were used.

Drawing of a pole cumulative mine Ni05

In American sources, this anti-tank ammunition is referred to as the Lunge Mine. According to its design and method of application, Ni05 belongs to anti-aircraft cumulative mines. Structurally, the mine is very simple. A TNT charge weighing about 3.5 kg was placed in a cone-shaped case made of tin. At the bottom of the body there is a cumulative recess lined with iron. Three metal legs are welded to the lower plane of the body, designed to ensure that at the moment of explosion the charge is at a strictly defined distance from the armor, which ensures optimal formation of a cumulative jet. The upper part of the body is a short cylindrical tube with external threads. A long tube is screwed onto this tube, the end of which is wide and has an internal thread. A bamboo pole up to 2 m long is inserted into a long tube. The total mass of the mine is about 6.5 kg. The diameter of the case at the bottom is 20.3 cm, the length of the case is 48 cm. Armor penetration is more than 150 mm.

Before using the mine, the soldier had to remove the safety pin. He then ran towards the tank, holding the mine horizontally in front of him like a pike, aiming at the side of the tank. At the moment the mine's legs hit the side, the pole, moving forward by inertia, broke the shear pin. The striker acted on the detonator capsule, which led to its explosion and transferred the detonation to the shaped charge. The explosion of a shaped charge led to the penetration of armor and the destruction of the tank. Kamikaze also died in a mine explosion.

Anti-tank grenade launchers

Although from the second half of 1943 the Japanese command in the fight against tanks relied on primitive anti-tank ammunition used by land kamikazes, it should not be assumed that Japan did not create “remote” anti-tank weapons, in which the risk of injury to personnel from shrapnel and shock was minimized wave and there was no need to leave the shelter. As part of military-technical cooperation with Germany, in 1941, documentation was received for rifle anti-tank 30-mm cumulative grenades Panzergranate 30 (G.Pzgr.30). Japanese designers adapted the Panzergranate 30 to their production capabilities and created the Type 2 rifle grenade launcher.

The Type 2 grenade launcher was installed on Japanese rifles 6.5 mm Type 38 and 7.7 mm Type 99. While the German Mauser 98k rifles used blank cartridges with a case rolled with an “asterisk” to shoot grenades, the Japanese used 7.7 mm cartridges with wooden bullet. This slightly increased the range of the shot, but it was necessary to strengthen the bottom of the grenade. The maximum firing range from a Type 99 rifle at an elevation angle of 45 ° is about 300 m. The sighting range is no more than 45 m. The firing range of grenades from 6.5 mm rifles was approximately 30% less.

To stabilize the grenade in flight, in its tail there was a belt with ready-made rifling, which coincided with the rifled part of the mortar. The head of the grenade was made of tin, and the tail was made of aluminum alloy. In the head part there was a cumulative funnel and a charge made of an alloy of TNT with hexogen weighing 50 g, and in the rear there was a bottom fuse. A cumulative 30-mm grenade weighing about 230 g normally could penetrate 30 mm of armor, which made it possible to fight only light tanks and armored vehicles. Due to insufficient armor penetration, a 40-mm cumulative grenade with an over-caliber warhead soon entered service. The weight of the grenade increased to 370 g, while its body contained 105 g of explosives. The thickness of the armor penetrated when hit at an angle of 90° was 50 mm, and the maximum firing range from a rifle grenade launcher was 130 m.

Type 2 rifle grenade launcher with 30 mm and 40 mm cumulative grenades

Theoretically, infantrymen armed with Type 2 grenade launchers with 40 mm grenades could hit American M3/M5 Stuart light tanks from any direction, and medium M4 Sherman tanks on the side. However, the accuracy and firing range of cumulative rifle grenades was low, and the reliability of timely operation of the bottom inertial fuse left much to be desired.

After captured American bazookas fell into the hands of Japanese designers, work began in Japan on creating their own anti-tank rocket launchers. In July 1944, a 74-mm grenade launcher was adopted, designated Type 4.

74 mm Type 4 anti-tank rocket launcher

Apparently, the design of the Type 4 RPG was influenced not only by the American Bazooka, but also by the German Panzerschreck. By analogy with the American M9 Bazooka grenade launcher, the Japanese Type 4 RPG, created by the designers of the army arsenal in the city of Osaka, was collapsible and consisted of two parts that were assembled together only before the battle, and on the march the grenade launcher was carried in a disassembled state. A bipod from a Type 99 light machine gun was attached to the front of the Type 4 grenade launcher, and a pistol grip and trigger mechanism were attached to the rear. Sights consisted of a rear sight and a front frame with front sights.

Although the Type 4 grenade launcher showed features of the American and German designs, it had a number of significant differences. Thus, the stabilization of a Japanese rocket-propelled grenade in flight was carried out not by the tail, but by rotation caused by the outflow of powder gases from inclined nozzles. Another difference between the Type 4 and the American and German grenade launchers was the replacement of the electrical launch device for the rocket's jet engine with a mechanical one. The trigger was connected by a cable to a spring-loaded striker with a striker attached to the top at the rear end of the barrel. Before loading, the striker was cocked and locked, and when the trigger was pressed, the cable released the striker and it, turning on an axis, broke the igniter primer in the center of the nozzle bottom of the rocket-propelled grenade

74-mm rocket-propelled grenade in firing position and disassembled

Structurally and externally, the rocket-propelled grenade resembled a 203-mm Japanese rocket. At the head of the rocket-propelled grenade there was a fuse from an 81-mm mine. It was followed by a steel notch and a shaped charge. At the rear there was a jet engine with oblique nozzles. Pyroxylin gunpowder served as jet fuel. With a length of 359 mm, the rocket-propelled grenade weighed 4.1 kg. Of which 0.7 kg was explosive. A powder charge of a jet engine weighing 0.26 kg accelerated a grenade in a pipe to 160 m/s. The maximum firing range is 750 m, the effective range is 110 m. The mass of an unloaded grenade launcher in firing position is 8 kg, length is 1500 mm.

The grenade launcher crew consisted of two people: a gunner and a loader. Shooting, as a rule, was carried out from a prone position. An experienced crew could produce up to 6 rounds/min. When firing behind the grenade launcher, due to the ejection of the jet stream, a dangerous zone with a length of about 20 m was formed.

Compared to other Japanese anti-tank weapons, the Type 4 grenade launcher was a big step forward. However, at the final stage of hostilities, Japanese industry was unable to equip the army with the required number of 74-mm rocket-propelled grenade launchers. According to American data, before the end of World War II, about 3,000 rocket-propelled anti-tank grenade launchers were produced in Japan. In addition, the rotation of the rocket-propelled grenade reduced armor penetration due to the “spraying” of the cumulative jet due to centrifugal force. During the fighting, it turned out that with the stated armor penetration of 80 mm normal, a cumulative grenade cannot guarantee reliable penetration of the frontal armor of American Shermans and British Matildas.

Due to the insufficient armor penetration of the Type 4 RPG, at the beginning of 1945, a 90-mm RPG was created, which was structurally similar to the Type 4, but had an increased caliber. Due to the significant increase in weight, the 90-mm grenade launcher received an additional support located in the rear of the barrel.

90 mm anti-tank rocket launcher

The mass of the new grenade launcher was about 12 kg, the rocket-propelled grenade - 8.6 kg (of which 1.6 kg was the explosive and 0.62 kg the propellant charge of the jet engine). The initial speed of the grenade was 106 m/s, armor penetration - 120 mm, effective firing range - 100 m. Despite successful tests in the army, mass production of 90-mm grenade launchers was not established.

Japanese tank destroyer tactics

To fight tanks, the Japanese formed special detachments of 10-12 people. The group was instructed to act coherently and from an ambush. Two or three people were engaged in setting up a smoke screen, 5-6 people at this time tried to immobilize the tank by exploding the caterpillar, installed a magnetic mine on board or struck a pole with a cumulative mine, and blew up the tank with a backpack bomb. The rest threw Molotov cocktails and grenades, and also covered the detachment’s actions, firing at enemy infantry, and diverting the attention of the tank crews to themselves. Very often, Japanese troops took refuge in “fox holes”, lined with bamboo shields and vegetation on top. Having waited for an opportune moment, all members of the detachment attacked the approaching tanks.

Measures to protect against Japanese infantry tank destroyers

The creation of rocket-propelled anti-tank grenade launchers in Japan began too late, and the RPGs that entered the troops did not have a noticeable impact on the course of hostilities.

To combat American and British armored vehicles, the Japanese used the “one soldier - one tank” tactic, which meant that, sacrificing themselves, one Japanese soldier must destroy one tank. This approach brought the desired effect only at the first stage. Faced with land kamikazes, the Americans, Australians and British began to avoid using tanks in places where it was possible to covertly approach them to plant a magnetic mine, hit a cumulative mine with a pole, or use a backpack bomb. In addition to using specially designed anti-tank weapons against enemy tanks, Japanese infantrymen were instructed to use other techniques: jamming the chassis with metal rods, breaking optical instruments by jumping onto the tank through open hatches, and throwing fragmentation grenades inside. It is clear that such methods of fighting armored vehicles led to colossal losses among those who dared to do so. The actions of the Japanese infantry were facilitated in part by poor visibility when fighting in the jungle. Having suffered losses, the Americans began to actively burn vegetation with napalm aircraft tanks, use flamethrower tanks and backpack infantry flamethrowers.

Flamethrower tank M4A3R3 during the battles on the island of Iwo Jima, March 1945

Also, to protect their tanks, the US Army and Marine Corps began to attract infantrymen armed with automatic weapons and proactively comb suspicious areas with machine gun and artillery and mortar fire. Due to the increased consumption of ammunition, it was often possible to disperse and destroy Japanese tank destroyer groups hidden among tropical vegetation.

American infantrymen escort Sherman tanks

American tank crews also used passive means of protection: the sides were sheathed with boards, the armor was increased by hanging tracks, and nails were welded onto the hatches with their points up or covered with a mesh, which prevented the installation of a magnetic mine directly on the hatch. The upper armor was reinforced with sandbags.

Japanese ground kamikazes, armed with pole mines and loaded with explosive packs, tried to delay the advance of Soviet tanks in Manchuria and Korea. However, extensive experience in combat operations at the start of the war with Japan allowed the Red Army to avoid any noticeable losses in armored vehicles. Long before the USSR entered the war against Japan, infantry escort of tanks became standard. As a rule, a squad of machine gunners was placed on each tank. In this way, even during the battles in Germany, tanks were protected from “faustniks”.

Notes

- Bishop, The Encyclopedia of Weapons of World War II

- Meyer, The Rise and Fall of Imperial Japan. p. 53.

- Meyer, The Rise and Fall of Imperial Japan. p. 55

- https://www.dailykos.com/story/2013/6/19/1214235/-The-Japanese-Type-96-Light-Machine-Gun-a-troubled-weapon

- Japanese Type 11, Type 96 and Type 99 light machine guns

- https://katanasforsale.com/japanese-machine-guns-japanese-firepower/

- https://www.ibiblio.org/hyperwar/Japan/IJA/HB/HB-9.html#III TM-E 30-480 (1945)

- https://www.forgottenweapons.com/ria-nambu-type-96-type-99-lmgs/

- https://www.ibiblio.org/hyperwar/Japan/IJA/HB/HB-9.html#III TM-E 30-480 (1945)

- https://zonwar.ru/pulemet/Type-96.html

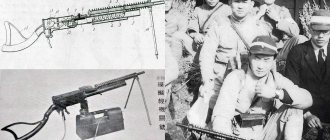

After the battles in Manchuria and China, the military command of the Imperial Japanese Army decided to replace the standard 6.5x50 mm Arisaka rifle cartridge. The insufficient effectiveness of the bullets was the main reason for replacing the old cartridge. Also, with a small caliber, it was difficult to produce special bullets. It was decided to develop a new cartridge with a larger caliber. As a result, the new 7.7x58 mm Arisaka cartridge, created on the basis of the English .303 British cartridge, was adopted. A whole family of new weapons was developed for the new cartridge, including the Type 99 light machine gun.

Structurally, the new machine gun was almost completely identical to its predecessor, the Type 96. The reason is that the Japanese military assumed that it would be much easier to convert an existing machine gun to a new cartridge and use ready-made industrial lines with minimal changes, but practice has shown otherwise. It turned out to be impossible to simply replace the barrel and bolt designed for the old cartridge, since the new cartridge was much more powerful than its predecessor and required the use of more durable materials, as well as much more precise processing of machine gun parts. Such requirements and the overload of Japanese industry greatly complicated large-scale production of the machine gun, which, in fact, began only in 1941. He began enlisting en masse only in 1943.

Design

The grenade consists of a body, an explosive charge, a remote fuse and a bottom cylinder with an expelling powder charge and an igniter primer. The cylindrical body is made of cast iron with vertical and horizontal notches and is equipped with an explosive charge (trinitrotoluene or trinitrophenol). In the upper part of the body there is a cover with a hole for screwing in the fuse, in the lower part there is a bottom cylinder

The fuse consists of a housing, inside of which there is a firing pin with a striker, a counter-safety spring, an igniter primer and a powder retarder. The firing pin is screwed into the firing pin body, which is secured with a safety cap and a safety fork. When throwing a grenade by hand, it was necessary to screw the firing pin into the firing pin body, pull the safety fork by the rope tied to it, hit the grenade against a hard object and then throw it. When the head of a grenade hits an obstacle, the firing pin overcomes the resistance of the counter-safety spring and punctures the capsule, igniting the powder retarder, which burns for 7-8 seconds, and then ignites the detonator capsule, which leads to the explosion of the main charge

Design

The Type 97 has the same characteristics as most fragmentation grenades of the era: a square and segmented "pineapple" shell that disperses sharp fragments when detonated. To activate it, you first had to screw in the firing pin so that it protruded from the base of the fuse. The pin was then removed by pulling on a string to remove the protective cover from the fuze. A strong impact on a hard surface such as a rock or hull will cause the spring to give out and crush the thin deck. brass, allowing the firing pin to engage the primer and initiate a pre-ignition sequence before launching it at the target.[2] However, compared to Allied grenades, the Type 97 was weaker at the time and due to the lack of an automatic ignition mechanism, in practice it was an unreliable grenade launcher and even dangerous in use due to imprecise fuse.[3]

Physically, the Type 97 was almost indistinguishable from the Type 91, except for the absence of a threaded fitting at its base for attaching an auxiliary propellant container. Paper labels with production dates warned of a delay of 4-5 seconds.[4]

Development

Initially, for use in tanks and other armored vehicles, the Army Technical Bureau produced the "type 91 mobile machine gun", based on the type 11 light machine gun. However, the main disadvantages of the type 11 remained, including its tendency to jam due to the slightest ingress of sand or dirt, as well as the low lethality and stopping effect of the 6.5x50 mm Arisaka cartridge.

During the early stages of the Second Sino-Japanese War, Japanese forces captured several Czech ZB vz light machine guns. 26 National Revolutionary Army of China. The numerous design advantages of the Czech machine gun led to the development of the Type 97 tank machine gun based on it.

Type 99 (ZTZ99) main battle tank (China)

Type 99 main battle tank ( ZTZ99 ) was developed on the basis of the Type 98 tank and is essentially an improved modification of it. One of the first versions of this tank was demonstrated in 2000 under the designation Type 98G. In the same year, the first batch of 40 tanks was manufactured. In the future, the production of tanks is carried out at a very slow pace, mainly due to their complexity and high cost; to date, no more than 100 units have been manufactured. Type 99 main battle tank ( ZTZ99 ) is a Type 98 tank with improved performance;

increased mobility due to the installation of a more powerful 1500-horsepower turbocharged diesel engine. an improved fire control system, increased protection due to the installation of built-in dynamic protection on the frontal projections of the turret and hull. The armor of the frontal projections of the turret and hull has been strengthened by installing built-in dynamic protection units. On the first production samples, the EZ blocks were installed on top of the main armor parts. On subsequent vehicles they were built into the main armor. The configuration of the blocks also changed - they became more beveled on the sides. The modular design of the reservation allows you to quickly replace damaged blocks with new ones. The tank is equipped with an integrated laser active countermeasures system JD-3.

The improved control system includes combined sights for the gunner and commander with independent stabilization, a laser rangefinder, a thermal imager, a digital ballistic computer, a two-plane weapon stabilizer, and a set of sensors (atmospheric conditions, barrel wear, etc.). multifunctional commander panel with color indicator and automatic target tracking system. The image from the thermal imager is displayed on the color displays of the commander and gunner (multiplicity x11.4 and x5). In addition, the tank is equipped with a navigation system with inertial and satellite (GPS) channels, data from which is also displayed on the commander’s display and superimposed on a digital map of the area. The Type 99 tank is equipped with a modern radio station and TPU.

The tank has a diesel engine with a power of 1500 hp. created on the basis of the German MV871 Ka501. The tank accelerates from zero to 32 km/h in just 12 seconds. The mechanical planetary transmission provides 7 speeds for forward movement and one in reverse. Torsion bar suspension with gyro shock absorbers.

Type 99 tanks took part in a military parade in Beijing on October 1, 2009 to commemorate the 50th anniversary of the founding of the People's Republic of China. 18 combat vehicles (judging by the remote control units, early production) from the 334th regiment of the 112th tank division of the 38th army group of the PLA passed through the Tananmen square.

TACTICAL AND TECHNICAL CHARACTERISTICS OF THE Type 99 TANK COMBAT WEIGHT, t; 54. CREW, people: 3. OVERALL DIMENSIONS, mm: length - 10920, width - 3372, height on the turret roof - 2200, ground clearance - 470. ARMAMENT: 1 ZPT-98 cannon of 125 mm caliber, 1 machine gun "86" caliber 7.62 mm, 1 W-85 anti-aircraft machine gun of 12.7 mm caliber, 10 installations for launching smoke grenades. AMMUNITION: 41 rounds, 2000 rounds of 7.62 mm caliber. 300 rounds of 12.7 mm caliber, AUTOMATIC LOADER: electromechanical, with a constant loading angle. WEAPONS STABILIZER: two-plane electro-hydraulic. GUIDED WEAPONS COMPLEX: 9K119 “Reflex” with TUR 9M119, controlled by a laser beam. AIMING DEVICES: gunner's periscope combined sight with thermal imager and laser rangefinder, commander's periscope combined sight-observation device. RESERVATION, .mm: anti-ballistic combined with dynamic protection complex. ENGINE: MTU МВ871 Ka501, 8-cylinder diesel four-stroke V-shaped liquid cooled with turbocharging; power 1500 hp (1102 kW). TRANSMISSION: mechanical planetary (7+|). CHASSIS: six dual-slope rubber-coated road wheels on board, four support rollers, rear drive wheel with removable ring gears (lantern engagement), idler wheel; individual torsion bar suspension with hydraulic shock absorbers on the 1st, 2nd, and 6th suspension units; caterpillar with RMS, rubberized treadmill and rubber cushions. MAX SPEED, km/h: 60, POWER RESERVE, km: 450. OBSTACLES TO OVERCOME: ascent angle, degrees. - thirty; ditch width, m - 2.7; wall height, m - 0.85; ford depth, m - 1.4 (with OPVT - 5 m). COMMUNICATIONS: radio station Ture 889B and intercom VIC-8.