| SHTZ-NATI | |

| Issued, gg. | 1937—1952 |

| Manufacturer | Stalingrad Tractor Plant, Kharkov Tractor Plant, Altai Tractor Plant |

| Instances | 191000 |

| Propulsion type | crawler |

| Operating speed, km/h | 3,8—7,9 |

| Gross weight, t | 5,1 |

| Location | |

| Cabin | behind |

| Engine | front |

| Engine | |

| Power, hp (kW) | 52 (38,2) |

| Suspension and handling | |

| Suspension type | interlocked in pairs, on coil springs |

| Equipment | |

| Pneumatic equipment | No |

| The lineup | |

| Subsequent model | DT-54 |

| Media files on Wikimedia Commons | |

SHTZ-NATI

(STZ-3) is a brand of caterpillar tractor produced from 1937 to 1952 at tractor factories of the USSR. The first mass-produced tractor with a completely domestic design[1]. In 1938, at the World Industrial Exhibition in Paris, the tractor received a Grand Gold Medal and a Grand Prix diploma.

Story

In 1929, after comparative tests of many foreign tractors, NATI specialists formulated technical requirements for domestic tractors and recorded them in the articles “Technical Standards for the Russian Tractor” and “On the Type of Tractor for Russia.” The STZ-NATI model was developed based on these requirements. This unified agricultural and transport machine, with an elastic roller suspension, a metal caterpillar track with cast links, and a semi-closed cabin, most fully met the conditions of production and operation in the Soviet Union.

In July 1935, at the experimental field of NATI, in Likhobory, STZ showed members of the Politburo of the CPSU Central Committee and the government three samples of tracked tractors, KhTZ - one. The tractors pulled seven-share couplings from two plows. According to the terms of the competition, in order to ensure a stable plowing depth, a semi-rigid suspension should have been used, but Seversky Plant engineers, violating the requirements, used an elastic one. As a result, the Stalingrad model showed higher technical qualities, and the Kharkov one lost, but both the Stalingrad and Kharkov tractor plants decided to transfer to the production of a new domestic crawler tractor. A new new tractor rolled off the large assembly line of the Stalingrad TZ on July 11, 1937.

In 1937, the Stalingrad and Kharkov tractor plants stopped producing SKHTZ 15/30 wheeled tractors and switched to producing SKHTZ-NATI tracked tractors.

SHTZ-NATI in the GDR

Due to the fact that during the Great Patriotic War the Kharkov plant was evacuated to the city of Rubtsovsk in the Altai Territory, the production of tractors began there, in the Altai Tractor Plant, which was created during the war years. The first SHTZ-NATI tractors left the workshops of the Altai plant in August 1942[2].

The Altai Tractor Plant produces tractors designated ATZ-NATI

, continued until 1952; production at the Stalingrad and Kharkov plants was curtailed earlier; in 1949, they gave way to DT-54 tractors on the assembly line [3].

Firstborn of Russia

Our country has always been rich in talent. It was also famous for its inventors. Among them were those who worked in the field of creating equipment for agriculture.

The issue of mechanization of agriculture was raised back in the 18th century. agronomist I.M. Komov. By the middle of the 19th century. D. A. Zagoyaksky and V. P. Guryev developed steam tractors intended for plowing. The first such tracked unit was assembled and tested in 1888 by F.A. Blinov.

However, the official date of the emergence of the Russian tractor industry is considered to be 1896. It was then that at the fair in Nizhny Novgorod the world's very first steam tractor on caterpillar tracks was demonstrated to the assembled public.

By the beginning of the 20th century. designer Ya. V. Mamin invented a non-compression engine that ran on heavy fuel. It was great for vehicle operation. The first tractor, which was equipped with an 18-kilowatt internal combustion engine, was assembled in 1911. This unit was called very patriotically - “Russian”. After modernization, this tractor received a 33 kW engine. This gave him more power. Small-scale production of such tractors was mastered at the Balaklava plant. This equipment was produced individually in Kolomna and Bryansk, Kharkov and Rostov, Kichkass and Barvenkov, as well as in some other settlements. However, the total number of tractors produced in Russia was so small that it could not have a significant impact on the state of affairs in agriculture. By 1913, there were 165 tractors in the country. However, at the same time, the Russian Empire actively imported agricultural machinery. By 1917, 1,500 pieces were brought into the country.

Design

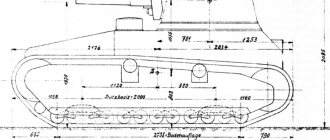

The SHTZ-NATI tractor had a frame structure with a riveted frame consisting of two spars and four cross members.

Elastic suspension of the running gear on four balancing carriages with coil springs.

The tractor cabin was semi-closed.

Kerosene carburetor four-cylinder engine with a capacity of 52 hp. With. attached to the frame at three points. Engine cooling is water.

The gearbox is a three-way gearbox, the track is made of links cast from high-manganese steel.

Ancestor Election

The most important issue that had to be resolved when designing the future plant was what kind of tractor to produce. Since the USSR did not have its own developments in this area at that time, we could only talk about copying one of the foreign models.

However, which one exactly? The Glavmetal commission, which was tasked with creating the project, approached this issue in a rather original way. Five young engineers were asked to consider one of the foreign models and defend it in front of tractor specialists.

Of the presented projects, the American “International” and the Swedish “Advance” aroused the greatest interest. However, both had both advantages and disadvantages. "Advance" was easy to assemble and ran on cheap oil. It coped better with work on virgin lands, but under heavy loads it could lose control and tip over.

"International" turned out to be more reliable and, despite the more expensive fuel - kerosene, more economical. Ultimately the choice was made on him. An important advantage of the International was that all tractor components were unified and easily replaced. This is what allowed production to quickly become widespread.

Notes

- History of tractor manufacturing (Russian). AGROnet.ru

. Access date: December 3, 2008. Archived April 23, 2008. - Altai Tractor Plant / V. S. Yakovenko // A - Angob. - M.: Soviet Encyclopedia, 1969. - (Great Soviet Encyclopedia: [in 30 volumes] / chief editor A. M. Prokhorov; 1969-1978, vol. 1).

- Plowing tractor SHTZ-NATI (Russian). Museum of Russian Tractor Manufacturing. Access date: December 3, 2008. Archived June 20, 2006.

- Ogonyok magazine No. 8, 1947

"Kolomenets-1"

The principle of creating a single tractor farm, which was laid down by Lenin, could be realized thanks not only to the production of “iron horses”, but also to the adoption of a set of measures that contributed to the organization of a testing and research base, as well as solving issues of organization and repair, opening various courses on training of masters and instructors.

The first tractors of the USSR were produced in 1922 at the Kolomensky plant. The leader of this project was E. D. Lvov. He is considered the founder of the Russian school of tractor building.

The first unit was named “Kolomenets-1”. Without any doubt, he was a real symbol of the beginning of a new era in the country's agriculture.

DT-175

1986 – 1992

You can complete the answer to the question of what Soviet tracked tractors exist with this model, later named “Volgar”. Traction class 3 was produced at the Volgograd plant and they began to use torque converters in the device, changing the torque from the engine to the gearbox. The equipment was modernized several times, but the basis was the SMD-66 with 6 cylinders and a power of up to 170 horses. such powerful tracked tractors of the USSR for the first time and were amazed at the capabilities of the designers. The machine is controlled using a lever and pedal, there is a ventilation unit in the cabin, there is enough space for two, but there is only one door.

- Weight: 8.03 t

- Length: 5.17 m.

- Height: 2.9 m.

- Width: 1.9 m.

- Power: 170 hp

- Speed: 7.9 km/h

Russified American

The transfer of American technology to Russian soil was accompanied by many difficulties. , fearing possible competition in the future, refused Soviet specialists consultations and even banned visits to its factories.

In the absence of any documentation, production parameters often had to be calculated empirically. Sometimes this required original solutions. For example, engineers developed a project for assembling a tractor by observing drivers who did it by hand. The obtained data was adapted to factory conditions and became the basis of the technological process.

The International was not the first tractor copied in the USSR. A few years earlier, the production of Fordsons was launched at Krasny Putilovets. However, while during the development of the latter the American inch system of measures was retained, for STP all calculations were transferred to the metric system - for the first time in the country.

In divisional artillery

The shortage of tractors forced the use of Komsomolets to tow heavier artillery systems, for example, divisional artillery guns. As an example, we can give a description of the activities of the special battery of the Red Banner Artillery Command Improvement Course (AKKUKS). According to the directive of the Chief of the General Staff No. 395889 of December 23, 1937, in the Luga area, in the period from February 14 to March 17, it was planned to test F-22 guns with the participation of a newly formed four-gun battery of the AKKUKS artillery regiment.

According to the state, reconnaissance and communications were to be transported by Komsomolets tractors, and guns were to be transported by STZ-5. However, the STZ-5 tractors were not ready on time, and it was decided to tow the guns by Komsomol members. This made it possible to determine their capabilities to ensure the necessary maneuverability of a battery of 76-mm F-22 guns on the move and in battle, to determine the tactical mobility of the battery, to establish the strength and reliability of the tractor as a whole and its individual mechanisms, as well as the convenience of attaching guns, stowing reconnaissance equipment and communications, deployment of personnel.

In total, eleven Komsomolets tractors arrived for testing, arriving directly from plant No. 37. Eight tractors were included in the battery: four of them were intended for transporting guns and four for transporting reconnaissance and communications. The F-22 gun weighed 1670 kg, and in the stowed position with the front end loaded - 2400 kg, and was clearly too heavy for Komsomolets, so during testing it was transported without a front end. The tractor's coupling device made it possible to hook the F-22 without a front end to only one eye, which made it difficult to turn with a gun and led to damage to the trunk sheets of the opener and their fastenings in a traveling manner.

During the tests, the battery completed daytime marches of 100 km (lasting 5 hours 40 minutes) and 150 km (8 hours) on a slippery, packed snow highway. A night march of 35 km along a forest road was also planned, which began at 2 o'clock, but due to difficult road conditions (snow depth up to 0.5 m) it lasted 10 hours and ended at 12 noon, i.e. Most of the route was covered in daylight. Although the average speed was 3.5 km/h, it actually took up to 3 hours to cover individual sections of only 500 m in length.

During the tests, the following were revealed: the average tactical speed of the battery when driving on a highway covered with dense, rolled and slippery snow (actually ice) - 19 km/h; average technical speed – 22 km/h; maximum speed – 40 km/h. The average technical and tactical speeds when moving on virgin soil day and night with headlights on were approximately the same and amounted to about 3.5 km/h. The virgin snow, more than 350 mm deep, turned out to be practically impassable for the Komsomolets, as it sat on its belly and skidded.

With a gun on a trailer, T-20 tractors overcame slopes of 25° and slopes of up to 25° on frozen sandy soil. With snow cover more than 200 mm deep, due to slipping, they could not overcome inclines of more than 11°.

In general, the T-20 Komsomolets tractors showed satisfactory cross-country ability, overcoming destroyed trenches covered with snow, holes 1 m deep and 3.5 m wide. However, their reliability in these tests left much to be desired.

Operational facilities were described as inadequate. In particular, they pointed out the rigidity of the seats, the short length of the canvas belts intended for tying up personnel (a kind of analogue of modern car seat belts), and the unsuccessful design of their buckles. The testers wore budenovki, which clung to the awning, which, as about.

In general, despite a bunch of manufacturing defects, it was recognized that before the STZ-5 Komsomolets transport tractors enter the army, they can be used to transport divisional artillery guns (excluding 152-mm guns model 09/30), but without limbers .

The need was also noted for creating a trailed cart for transporting shots behind the Komsomolets tractor, the weight of which with cargo should not exceed 1.5 tons. Such special single-axle trailers were manufactured and tested. The production of trailers, which differed in design, was carried out at several enterprises.