Any weapon, as you know, is learned in battle. After development, it undergoes practical testing at testing grounds, but the final conclusion about the weapon is still given by consumers, that is, military personnel. Most often, design bureaus, when developing their models, try to take into account the technical requirements put forward by the customer and make the weapon as convenient and high-quality as possible. It happens that after their assessment, the weapon is sent for modification.

So in the early 90s of the last century, the Tula Instrument Design Bureau carried out not just modifications, but a serious alteration of the PP-90 submachine gun. The authors of multiple weapon developments are V.P. Gryazev and A.G. Shipunov created an alternative to this not very successful folding submachine gun. The new version was called the “compact model for concealed carry PP-93.”

The purpose of creating a compact PP-93 APB

In 1993, Russian developers who created the earlier PP-90 submachine gun accepted a new order from the Russian Ministry of Internal Affairs. The design bureau, which was already working on the PP-93 version at that time, was tasked with creating a model of a submachine gun for special operations. The pistol had to be designed so that special forces could use this weapon in a hidden manner, as well as openly. The Ministry of Internal Affairs of the Russian Federation proposed to include the LP-93 laser target designator and the G-PP-93 silencer in the pistol package. All the customer’s wishes were taken into account, and the PP-93 APB was born.

The first test of the PP-93 submachine gun took place during the Chechen events. Soldiers of the Khanty-Mansi special rapid reaction detachment appreciated the combat qualities of the new weapon, and it was subsequently adopted not only by riot police units and the Russian Ministry of Internal Affairs, but also by special operations forces of the Armed Forces of Belarus (SSORB) and Mongolia. At first, samples were produced on which either a laser pointer or a silencer could be installed, but after the wishes of the soldiers, changes were made, as a result of which it became possible to use both a target designator and a silencer at the same time. This allowed special forces soldiers to use weapons in a short range and eliminate the enemy quickly and silently.

general information

The PP-93 is powered by 9x18mm ammunition. A team of engineers from the Tula Instrument Design Bureau under the leadership of A. Shipunov and V. Gryazev worked on the development of the project. The work took place in the department of V. Valuev, who was involved in the creation of the previous generation - PP-90. This generation appealed to the soldiers who took part in combat operations around the world. The management decided to create the 93rd model for operations where concealed carrying of a weapon is not required. The Ministry of Internal Affairs sent technical documentation to Tula, which requested a submachine gun with the ability to install a laser sight and a silencer.

After the design was completed, the 93rd version was named APB. The difference with the PP-90 is large; only a few nodes were the same. This weapon turned out to be a simplified version of the previous generation: the geometry of the parts was changed and the ability to fold the stock was eliminated. The new product has improved quality and balance, making it easy to use in combat conditions.

The first consumers of the PP were SOBR units from Khanty-Mansiysk. They used weapons in clashes with the enemy during the Chechen War. Subsequently, the weapon was used in the following countries:

- Russia - is used by riot police units, the Ministry of Internal Affairs and collection units;

- Belarus - is in service with the MTR detachments of the Republic of Belarus;

- Mongolia - is in service with units operating on missions of high importance.

The first copies made it possible to install either a laser designator or a silencer. The soldiers left a request for the simultaneous installation of two modules. This increased the practicality of the weapon when used in urban environments. With a small combat area (typical for urban conditions), the laser sight allows you to quickly aim the gun at the enemy, and the silencer allows you to silently neutralize the enemy.

Positive aspects in the design of PP-93

If we consider the design of the PP-93 as a converted model of the PP-90, then it must be said that little has been preserved from the previous submachine gun in this model, but this was precisely the advantage that special forces soldiers appreciated. Let us list the positive aspects in the design of the PP-93 APB:

- Compactness of the model. The design of the pistol and its small thickness allow it to be carried concealed;

- Accuracy of sight and high accuracy of combat even when shooting with one hand;

- Quick change of magazine with ammunition due to the convenient design of the magazine latch;

- Possibility of using a silencer and laser sight;

- The use of powerful armor-piercing ammunition 7N25 of 9x18 caliber, piercing 5-mm steel sheets at a distance of 15 m and second-class body armor at a distance of up to 30 m;

- In addition to the mechanical safety, the PP-93 also has an automatic safety, which prevents an accidental shot when the weapon falls to the ground.

Positive design features include the fact that the body and stop of the submachine gun are made of steel. This makes the weapon reliable and provides it with a large working reserve.

Ammunition used

Even when creating the PP-90, engineers understood that the use of 9x18 mm cartridges reduces the effectiveness of the gun. He is not able to penetrate body armor that the enemy may be equipped with. When the creation of PP-93 ammunition began, in relation to modern conditions, it became even more outdated, which reduced its penetrating effect to a minimum.

In Tula they found a solution to this problem - they developed new charges with an armor-piercing bullet, which received the index 7N25. The bullet is made as a semi-jacketed one. The core, made of steel, is exposed. Kinematic energy upon contact with an obstacle is increased due to the reduced bullet weight and increased speed after the shot. This made it possible to penetrate 6B5-12 military body armor at a distance of up to 30 meters and steel sheets 5 millimeters thick at a distance of up to 15 meters.

Disadvantages in the design of the PP-93 submachine gun

As happens when developing high-end weapons, the positive aspects still outweigh the negatives, but shortcomings still happen. In PP-93 they are insignificant, but they are worth mentioning:

- The shoulder rest is poorly fixed, and this affects the accuracy of aiming;

- Inconvenient location of the cocking handle. It is located under the barrel and has the shape of a slider. In order to cock the bolt, you must first recess the handle, and then pull it up and return it to its original position. If you do not follow these rules, you can damage your fingers when returning the handle to its original place after firing;

- The safety pin has an inconvenient flat shape, which makes it difficult to work with gloves.

The recoil of the PP-93 is small, but due to weak fixation during shooting, the bullet leaves the line of sight.

GENERAL PROVISIONS

1.1.

These Recommendations should be used when restoring instrumentation and upgrading existing dam condition monitoring systems.

When developing the Recommendations, the experience of organizing and conducting field observations and studies at a number of domestic dams, as well as foreign experience, was used. The recommendations can be considered as an addition and development of the “Rules for the technical operation of power plants and networks”, SNiP Provisions and other currently valid regulatory documents (SNiP 2.06.06-85, SNiP 2.06.05-84, RD 34.20.501-95).

1.2.

The recommendations are intended for use by the operating personnel of hydroelectric power plants, as well as by engineering, technical and scientific workers involved in assessing the condition of the control equipment, developing and implementing projects for restoring the control equipment and reconstructing systems for monitoring the condition of structures.

1.3.

The goals and objectives of restoring the CIA at operating dams are to bring the composition of the CIA into compliance with the requirements of regulatory documents, as well as ensuring the receipt of information sufficient to assess the condition and behavior of structures.

The Recommendations discuss methods for checking the technical condition of an instrument, assessing the reliability of the information obtained with its help, and selecting equipment to be restored, repaired, or replaced.

1.4.

The goals and objectives of modernizing old control systems at dams are to increase the efficiency of observations, reduce the labor intensity and cost of observations, processing and analysis of observation data.

The Recommendations discuss possible options for modernizing monitoring systems, namely, the wider use of remote equipment, centralization of observations, automation of readings, processing and analysis of observation data, and the creation of automated systems for diagnostic monitoring of structures.

Normative references

1. SNiP 2.06.06-85.

Dams are concrete and reinforced concrete. M.: TSNTP Gosstroy USSR, 1986.

2. SNiP 2.06.05-84.

Dams made of soil materials. M.: TSNTP Gosstroy USSR, 1985.

3. Rules

technical operation of power plants and networks of the Russian Federation: RD 34.20.501-95. 15th edition. M., 1996.

4. Recommendations

according to the methodology for assessing the reliability of main concrete hydraulic structures that have been in operation for more than 25 years and are not equipped (or minimally equipped) with instrumentation: P 61-94/VNIIG. St. Petersburg, 1995.

5. Recommendations

on observations of the stress-strain state of concrete dams: P 100-81/VNIIG. L., 1982.

6. Management

on field observations of deformations of hydraulic structures and their foundations using geodetic methods: P-648/Gidroproekt. M.: Energy, 1980.

Design features of PP-93

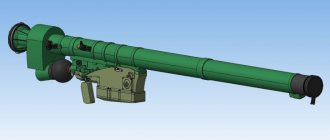

Unlike the design of the PP-90, the model of the PP-93 submachine gun is simple and technologically advanced. The USM is a trigger type, which allows you to shoot in two ways: single and burst. The automation operates on the principle of blowback, like most SMGs.

Box magazine in two versions: double-row for 20 and 30 rounds. In order to get around the problem of the cartridge not entering the chamber, engineers had to bore out the chamber located in the barrel of the pistol. This reduced the risk, but led to the fact that the sleeves began to “inflate”. However, this does not affect the operation of the mechanism as a whole. The cartridge ejection window is located on the right side of the receiver.

The box itself, like the butt, is made of stamped steel, and a handle is attached to its lower front part, into which a magazine with charges is inserted. When firing, the handle is held in place by a spring mechanism. On the left of the muzzle box there is a fuse and at the same time a fire mode translator, which has three positions: “A” – automatic firing (bursts), “O” – single, and “P” – fuse. To put the weapon on safety, you need to move the flag to the middle position.

The sighting mechanism of the weapon consists of a front sight and rear sight. The front sight is protected from damage when shooting from stands. The designers also provided for the possibility of using a laser pointer for better targeting. For stability during operation of the PP-93 and for convenient carrying, the design of the PP-93 provides a folding shoulder rest. When folded, it simply clings with its springy end to a special convexity of the bolt box, also called a stamping.

PREFACE

In accordance with the basic provisions on the diagnostic system for retaining hydraulic structures, the task of operational control of hydraulic structures, in particular concrete and soil dams, is to assess their condition at each stage of operation in order to determine and predict their reliability and identify the need for repair work.

The main goal of operational monitoring of long-term operating structures is to identify signs of their “aging”, leading to a decrease in reliability. A feature of the control of such structures is the reduction in the volume of instrumental observations, especially for the KIA mortgage, due to its gradual natural failure due to the exhaustion of resources and, accordingly, a decrease in the volume of information received.

These Recommendations contain regulation of methods for assessing the condition of the instrumentation and the reliability of observation data, as well as methods for restoring the instrumentation and modernizing control systems on concrete and earthen dams. At the same time, in development and addition to the “Recommendations for the methodology for assessing the reliability of main concrete hydraulic structures that have been in operation for more than 25 years and are not equipped (or minimally equipped) with instrumentation” (P 61-94/VNIIG), the work presents also justifications for optimizing the composition and volume of CIA at long-term operating dams.

It should be noted that the issues of methods for restoring control equipment and modernizing control systems for hydraulic structures have not previously been considered in the regulatory literature.

The recommendations were compiled by JSC NIIES Candidate of Sciences. tech. Sciences Alipov V.V. and at JSC VNIIG im. B.E. Vedeneeva" engineer. Aleksandrovskaya E.K.

| RAO "UES of Russia" | Recommendations for the restoration of KIA and modernization of old control systems at dams | P 93-2001 VNIIG |

| Introduced for the first time | ||

| Submitted JSC "VNIIG" them. B.E. Vedeneeva" | Approved by RAO UES of Russia Letter No. 02-1-031/625 dated 07/03/98. | Effective date: 1st quarter. 2002 |

Performance characteristics of PP-93 APB

- Weapon weight – 1.5 kg without ammunition;

- The trunk is 20 cm long;

- The length of PP-93 is 58.5 cm, and with the folded stop it is 32.5 cm;

- Clip capacity – 20-30 charges.

It is not for nothing that this weapon is called an armor-piercing submachine gun; all charges made specifically for it fly at a speed of 320 m/s and are effective at a distance of 100 m at a rate of fire of up to 800 rounds per minute.

The PP-93 submachine gun, having passed tests not only at the training ground, but also participating in many combat operations, has proven itself to be an excellent military weapon, comfortable both to wear and during use. The fighters' reviews of this weapon are the most flattering, and therefore the PP-93 deserves the title of armor-piercing assistant to special forces soldiers.

RESTORATION OF REMOTE KIA AND MODERNIZATION OF MEANS AND METHODS OF MEASUREMENT

4.1. To assess the condition of various types of remote equipment and identify equipment that is subject to restoration, repair, replacement, it is necessary:

consider observation data for the entire installed remote instrumentation for the entire period of operation, reports of testing the functionality of the equipment, information about the failure of the instrumentation;

carry out a visual inspection of the technical condition of the equipment (except for the mortgage), cable communications, wiring closets, temporary and permanent switches, consoles, etc.;

analyze the results of systematization and generalization of data for all types of observations using remote equipment: pore pressure, soil stresses, local deformations, including the opening of seams and cracks, stresses in reinforcement, etc.

The main attention should be paid to the connection of observation results with changes in external loads (upstream and downstream levels, seismic loads), consistency of observation results using remote equipment with similar results obtained using other types of equipment (filtration, geodetic).

Based on the work carried out, the following conclusions should be drawn:

on the technical condition of the KIA with the identification of equipment that is in a faulty state, indicating the probable causes of failure and a conclusion about the possibility of its restoration or repair;

on the reliability of observation results for each KIA unit;

about the sufficiency of the equipment that has remained operational for generalizing the results of observations and conclusions about the state of structures, as well as the need to preserve that part of the equipment, observations on which have lost their information content due to stabilization of the stress-strain state of structures.

4.2.

Restoration of remote equipment (repair, replacement) is possible only for that part of it that is used in overhead or lowered (into wells) versions. Embedded equipment installed during construction can be restored only if the cause of its failure was damage or breakage of cable communications, and the place of damage is accessible. It should be noted that this type of damage, especially during construction, is one of the most common. In the case of cable restoration, the problem of restoring the KIA numbering arises. To simplify the solution of this problem, during preparation, during installation and further during operation of the equipment, it is necessary to regularly record three parameters for each converter: reading from the recorder; ohmic resistance of the circuit (resistance of the coil and cable); ohmic insulation resistance of the converter and cable.

When the insulation resistance of cable lines is less than 0.4 MOhm, the reliability of the measurement results is called into question, and the results themselves can only be used for qualitative analysis.

The converter number after the cable line has been restored is determined by comparing the values of the listed parameters before and after the cable break. It should be borne in mind that the resistance of the circuit and cable insulation during operation is quite stable, while the reading on the recorder can change with changes in the external load (water pressure, deformation).

In some cases, restoration of failed remote equipment embedded is possible by changing the method of installing the converter. Thus, faulty pore pressure converters in dams made of soil materials or in foundations can be replaced with similar converters, but installed in wells with subsequent plugging. Transducers of linear displacements (strains) embedded in concrete or soil can be replaced by similar transducers installed on the surface near the failed embedded transducer with certain adjustments being made to the measurement results.

4.3.

To modernize the means and methods of remote observations, it is possible to replace a previously installed KIA with a more modern one with increased accuracy and lower measurement errors, and to use multi-component converters.

For information on the use of remote instrumentation instead of equipment with direct readings, see sections 2 and 3.

OPTIMIZATION OF THE COMPOSITION AND VOLUME OF KIA AT LONG-TERM OPERATING DAMS

6.1.

The main parameters that are subject to mandatory control, regardless of the height of the structure and for almost any type of concrete dam, are: settlement and planned displacements of the structure and foundation; condition of temperature-sedimentation joints and joints at the “rock-concrete” contact; crack formation and crack opening; filtration flow rates and pressures in the base and body of the structure and the condition of concrete as a building material [2], (RD 34.20.501-95, P 61-94/VNIIG).

The listed parameters associated with the main design characteristics - stability, strength and water resistance - are the minimum that is necessary to assess the reliability of a concrete structure in long-term operation.

In some cases, on long-term structures it may be necessary to determine, in addition to the listed parameters, deformations or stresses in concrete and reinforcement.

6.2.

Parameters related to indicators included in the design scheme of the static operation of a structure are measured instrumentally during the control process. For this purpose, the structure must be equipped with appropriate instrumentation. In case of absence or failure of the KIA, it must be installed.

6.3.

The number of KIA for measuring controlled parameters at each structure is determined depending on its type, size and individual characteristics. At the same time, this quantity must be sufficient to calculate the main characteristics of the structure: stability, strength, water resistance (RD 34.20.501-95, P 100-81/VNIIG).

6.4.

To measure the total settlement of the dam and its foundation, control height marks are installed, which are part of the high-altitude support network. Marks are laid on the crest of the dam and at the temperature-sedimentation seams, 1 piece each. on each side of the seam (from the upper and lower tails, see Appendix 1).

To measure the settlement of the dam base, hydrostatic levels are installed in the pit closest to the base of the structure, the pipes of which are mounted horizontally at the seams between the sections of the dam and are connected to each other by hoses. The system is filled with liquid. In places where settlement is measured, special side settlement marks are placed above the pipes with holes for installing a portable micrometer in them. The hydrostatic leveling system is tied to the initial benchmarks of the external support network.

6.5.

To measure the absolute planned displacements of the dam, various geodetic methods are used depending on the type of structure and the topography of the site: triangulation, polygonometric survey, site method. Triangulation and polygonometry are among the most complex geodetic methods; the cross-section method is the simplest and most widespread. Triangulation, as a rule, is used in combination with other methods, in particular, the alignment method (an example of the use of triangulation and the alignment method is given in Appendix 2).

The sliding method is usually used in the case of a straight axis of the structure. For measurements, a sighting target is installed on the structure, secured at the ends with support points, which must be stationary. If this is not possible, then the control points should be included in the triangulation networks. Control signs are installed between the control points along the target. By placing a measuring instrument (theodolite, alinometer) on one of the reference points and a fixed mark on the other, the displacement of the target line is measured.

6.6.

To measure the relative planned displacements of the dam and the foundation, forward and reverse plumb lines are used.

Installing straight plumbs on an operating structure presents certain technical difficulties and is practically possible only on arched dams. In such cases, the thread (wire) of the plumb line is fixed on the crest of the dam from the downstream side and passes through the pipe to the base of the structure or to the level at which the weight of the plumb line can be placed (P-648/Gidroproekt).

Reverse plumbs for measuring planned displacements of the base of a structure or coastal rock masses, depending on specific tasks and technical capabilities, can be installed from central galleries and adits, from the open surface at the shores of the dam, etc.

6.7.

The condition of temperature-settlement joints is assessed using surface uniaxial, biaxial and triaxial crack gauges. Instruments on the operating structure can be installed on the seams on the dam crest and in inspection panels at various elevations, in expanded seams and buttress planes.

In addition to instrumental monitoring, the condition of temperature-sedimentation seams is also assessed visually, in particular, based on the analysis of data on filtration through these seams.

To determine the state of the contact weld, linear displacement transducers (LMTS) are used, which are located at those points where the expected opening of the seam is less than the measurement range of the gap gauge. The installation of converters on an operating dam is carried out in wells drilled at the base of the structure from the cementation rubble or the transverse gallery closest to the base of the structure.

The number of converters is determined based on specific conditions and the expected depth of the seam opening.

6.8.

Crack formation in concrete, associated with the second design characteristic - strength, is assessed visually on the operating structure. The tasks of visual inspection include: inspection of open surfaces of the structure, sketching of detected cracks, assessment of the kinetics of their development over time, the appearance of filtration and leaching products. At the same time, measurements of crack opening are also carried out, for which the following are used: a portable magnifying glass with measuring divisions, a caliper with a scale, and an MPB-2 microscope with a division value of 0.05 mm. On the largest cracks, simple gap gauges are installed.

6.9.

Seepage flows and pressures at the base of dams are measured using various types of piezometers and pressure transducers (PDS). The number of measuring points must be sufficient to determine one of the design parameters (backpressure diagram) and for the effectiveness of engineering protection means (cement curtain, drainage, depression). Based on this, the minimum number of contact piezometers in the alignment should not be less than 5 pieces, which are located at points before and after the grouting curtain and drainage and on the downstream side under the base of the downstream wedge of the dam. To evaluate the performance of the grouting curtain, in addition to contact ones, depth piezometers should also be installed. The total number of piezometers is determined at each structure by the need to solve specific problems. An example of placing piezometers at the base of a high concrete dam is presented in Appendix 3.

6.10.

Filtration pressure in the body of the dams (concrete mass and horizontal construction joints) is measured using pore pressure transducers (PCs). At the operating structure, transducers are installed in wells drilled in concrete at one or several marks along the height of the dam. Each horizontal alignment can have from three to six transducers located at various distances from the top edge.

6.11.

Filtration flow through the concrete masonry of the dam (seams, cracks, concrete itself) and its foundation is determined using volumetric water collectors and measured spillways. In this case, the flow rate is measured differentially: by sections (seams, cracks) and base, and then summed up. Measuring weirs are installed in the drainage ditches; an example of their placement is presented in Appendix 4.

6.12.

The condition of concrete as a building material is assessed both instrumentally and visually.

6.12.1. Assessment of the quality of concrete in long-term operating dams is carried out using various methods: testing drilled cores, mechanical methods (Fizdel, Kashkarov hammer, Huber disk, Dushechkin device, etc.), non-destructive testing methods (acoustic, thermal, etc.). In this case, the strength of concrete, its water resistance and frost resistance are determined [3, 4].

6.12.2. Concrete corrosion is assessed based on the results of chemical analyzes of water samples filtered through concrete masonry: seams, cracks, concrete. To compare the content of components in the filtered and source water, samples are taken from the upstream of the structure.

6.12.3 Visual observations of concrete corrosion in long-term operating dams consist of identifying and recording leaching zones, the kinetics of their development, as well as identifying signs of concrete aging (peeling, flaking).

The results of visual monitoring are carried out quarterly and recorded in special observation logs, which include: the date of observation, water levels in the pools, air and water temperatures. Detected damage or defects are plotted on diagrams of individual sections of the structure.

Description[ | ]

70% of the PMM pistol parts are interchangeable with the pistol [2].

The pistol has a reinforced frame and increased bolt weight. The PMM chamber is equipped with spiral grooves, which allows the use of high-impulse 9x18 mm PMM cartridges for firing. When fired, the pressure of the powder gases presses the walls of the case into three grooves on the walls of the chamber, holding the case in the chamber until the bullet leaves the barrel and the pressure decreases, after which the case is extracted and ejected. The maximum pressure in the gun barrel with the new cartridge increased by 15%, which slightly increased recoil.

The magazine cover protrudes slightly forward, which gives support to the palm and can somewhat speed up reloading. The shape of the handle has been changed to a more comfortable one, which has improved the conditions for aiming and shooting offhand from the right hand. The rear end of the handle has a notch for a more secure hold. Changing the retention devices can significantly improve pistol shooting accuracy.

Sights are open type - front sight and rear sight with a slot.

Design flaws[ | ]

Springs in magazines work under overstress, so they quickly lose their elasticity, which leads to delays when shooting. Poor quality plastic material from which the feeder is made can cause cracks and cause wear or breakage of the feeder tooth.[3]

Advantages and disadvantages of the model

pros

Minuses

- A high rate of fire leads to rapid consumption of ammunition in the magazine;

- The accuracy of burst fire leaves much to be desired;

- With an incorrect grip and intense shooting, the arrow can burn;

- The standard ammunition is 9 mm PM, which has low penetration power. There is no possibility of using 9 mm PMM in the regular model. On the other hand, the PP 91 Kedr submachine gun is mainly used against unprotected targets and this drawback is not so critical;

- The silencer unbalances the weapon, and the bolt clicks too loudly when firing.

UPGRADE OF OLD DAM CONTROL SYSTEMS

5.1.

Modernization of old control systems at dams is necessary to increase the efficiency of observations, the objectivity of assessing the condition of the structure, as well as to reduce the labor intensity and cost of observations, processing and analysis of results. The main directions of modernization of old systems: replacement of equipment with direct readings with remote equipment; centralization of observations on one console; automation of observations.

The level of automation is determined on the basis of a technical and economic comparison of options, taking into account the class of structures and the volume of measurements, as well as the design, layout and topological geodetic features of the waterworks:

with the number of converters up to 200 units - the first level of automation - recording of observation data is carried out on temporary consoles on magnetic tape (cards), from which the information is transferred to computer media in office conditions;

when the number of converters is up to 500 units - the second level of automation - collection and registration of measurement data is carried out on computer media from the central console of the system; processing and analysis of measurement data can be carried out directly at the structure using a computer, in a design or research organization;

at large waterworks of classes I and II with the number of converters more than 500 units - the third level of automation - all operations to monitor the condition of structures are automated; the operating programs of such systems may include the following operations: collection according to a given program and primary processing of measurement data; accumulation and storage of measurement data in computer memory; analysis of measurement data according to specified programs and criteria for the condition of the structure; recording the occurrence of anomalous phenomena with the issuance of operational alarms; presentation of observation results in a given form (tables, graphs, diagrams, etc.).

5.2.

If the dam or other structures are located at a large distance from the central console, it is possible to automate observations by installing remote automated switches on such structures with subsequent transmission of observation data to the central console.