Today, many who buy an air rifle or pistol don’t even think about the fact that it needs to be cleaned, some clean it but not as needed, let’s see what proper cleaning of pneumatics is.

The barrel of a rifle, especially if it is a magnum class rifle, is very quickly covered with lead, usually lead dust or microscopic pieces of a bullet. What the cleanliness of the barrel affects is practically nothing up to a certain limit, but at one point the accuracy begins to drop and you can forget about accurate shooting.

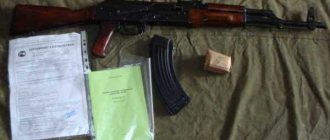

The number of rounds for a rifle after which it needs to be cleaned is different for each model, depending on the bullets used and the power of the rifle, but as a rule it is worth cleaning after 100 - 150 shots. Also, many rifles, and even Izhevsk rifles, have a choke constriction and it is on this that the main lead is applied.

Many people usually use inexpensive cleaning kits that can be bought at any store that sells weapons and equipment. This set includes a three-arm cleaning rod in a plastic braid, a brass brush, a nylon brush and a velvet cloth. You can use such a set somewhere in nature when you need to clean the barrel not too much. For complete home cleaning, it is better to buy a meter-long, non-removable cleaning rod that has a plastic braid.

There are also those who clean an air rifle with a steel cleaning rod that comes with domestic rifles - you shouldn’t do that! After several such cleanings, you will definitely damage the rifling of the barrel.

Proper cleaning for many consists of running a nylon brush several times along the barrel and, if you’re lucky, with some kind of oil. This is far from “proper cleaning of pneumatics”!

To understand how much lead remains in the barrel after such cleaning, you can do a small experiment:

Rub the edge of the barrel with a pencil and then try to wipe it off with oil, you can rub for a very long time after that, take regular cotton wool and rub the barrel, the cotton wool will become completely black. Now you can imagine how much lead remains in the barrel.

after that, take regular cotton wool and rub the barrel, the cotton wool will become completely black. Now you can imagine how much lead remains in the barrel.

Some kits include the correct wiper with which you can actually completely clean the barrel of a rifle, but alas, not all kits have it.

Correct visher

As a rule, really high-quality products can be found at gun shows. As an option, some stores sell a set of patches with holes for a special holder. The holder is sold there. You can buy it too. It’s not cheap, and cleaning with a visher in the form of a corkscrew will still turn out no worse.

Well, okay, we have a cleaning rod with a visor, now we can move on to the cleaning procedure itself.

When to clean air guns

Lead bullets are used in rifled weapons. The projectile passes through the barrel channel, fitting tightly into the rifling. As a result of friction, soft metal particles are retained in the barrel, accumulating there after each shot. In addition, the higher the muzzle energy of the pneumatic, the more “garbage” there is – the more the bullet is sharpened. “Leading” is the name of this process.

Lead usually “settles” in the breech. If there is a NSC (narrowing of the muzzle), then the picture is similar here. “Air” samples that have polygonal rifling in the barrel bore are resistant to lead.

The lead plating process is influenced not only by the power of the weapon, but also by the quality of the projectiles. The latter should be washed - this method will help keep the barrel clean.

The culprit of contamination may be the trunk itself, or rather the quality of its material. Some manufacturers use soft metals with a low percentage of carbon in their composition. The peculiarity of such steel is corrosion, the appearance of which on a weapon, even in small quantities, can damage the device. This is why it is important to pay frequent attention to the condition of the weapon.

More often, the barrels of gas-cylinder models (using CO2) suffer from corrosion. After firing from such pneumatics, cooling occurs, and then condensation forms. Typically, the cans are filled with undrained carbon dioxide. In fact, the projectile expels CO2 and water.

A spring-piston rifle can become contaminated by piston lubricant. An effect occurs that is observed during the operation of a diesel engine. The air is sharply compressed, causing the lubricant to ignite. The result is that combustion products clog the channel. The degree of contamination is high, as if from gunpowder soot.

(Hunter Magazine, No. 36/1/2011)

Along with the usual firearms, pneumatics are also used in hunting small animals. In the modern world, pneumatics are one of the most common types of small arms. The operation of pneumatics is based on the principle of throwing a bullet using compressed gas. This principle is common both for the first guns of Gutter (Fig. 1), A. Dolep (Fig. 2), B. Girardoni (Fig. 3) and for the latest developments, Crosman, Diana, GAMO, Hatsan (Fig. 4- 9) etc.

Fig.1. Air gun sample 1590 g

Rice. 2. Andreas Dolep's air gun with an under-barrel cylinder (1695)

Fig.3. Air gun of Bartolomeo Girardoni (1779)

Fig.4. Air compression rifle MP-532 (Izhevsk Mechanical Plant).

Fig.5. MP-573 air rifle (Izhevsk Mechanical Plant).

Fig.6. Air multi-compression rifle Crosman 2100

Fig.7. Air spring-piston rifle Diana PANTHER 31

Fig.8. Air spring-piston rifle Gamo Shadow Sport Fig.9. Air spring-piston rifle Hatsan 135

The use of compressed gas power in most airgun designs leads to certain nuances in care. Particular attention must be paid to lubrication and cleaning of the mechanisms and pneumatic barrel. If the weapon has just been purchased or has been in storage for a long time, it must be re-preserved before being lubricated during commissioning.

Depreservation Often new air rifles contain a preservative lubricant, the purpose of which is to protect metal parts from destructive corrosive atmospheric factors during storage. The working and performance-preservative properties of these preservatives are usually not specified in the accompanying documentation and are unknown to users, therefore it is advisable to re-preserve the weapon. It is recommended to remove the preservative (re-preservation) with a soft, dry cloth that does not leave lint. In some cases, solvents such as gasoline, white spirit or acetone can be used to dissolve and facilitate removal of the preservative. However, when using solvents, you must avoid getting them into the cylinder, which is especially true for gasoline, since its residues are difficult to remove (gasoline has a wide boiling point). When using acetone, it is worth remembering its ability to dissolve varnish (for example, on a wooden stock), as well as some paints and plastics.

Lubrication The selection of optimal lubricants, as well as the process of lubrication of pneumatics, differs significantly from the same for firearms. This is primarily due to significant differences in the technology of firing a shot with firearms and pneumatic weapons of various systems. In general terms, several types of lubricants can be recommended for pneumatics, namely: - Lubricant with a high flash point for lubricating metal surfaces on which high air pressure develops (for example, piston, cylinder, cuff of spring-piston pneumatics). — Lubricant with good adhesion to metal for locks, springs and pneumatic mechanisms. — Considering the frequent shooting of pneumatics on the street, a special lubricant with high anti-corrosion properties may also be useful for coating the external surfaces of the barrel, receiver, front sight, sighting rib, etc. in contact with the atmosphere.

Lubrication process The selection and application of working lubricant depends on the type of air gun. Among pneumatic weapons, spring-piston systems are the most demanding for proper lubrication. It is recommended to lubricate “fracture” parts operating under atmospheric pressure conditions, which instantly develop high speeds and also stop instantly (springs, latches, etc.) with a lubricant that has high adhesion to the metal. In this case, the lubricant does not necessarily have to be consistent or have high kinematic viscosity, since at certain moments, cohesive forces (interaction between the lubricant layers) can prevail over adhesion, which will lead to separation of the lubricant layer under the influence of inertia. And yet, as practice shows, LITOL-24 and CIATIM greases can be used for this purpose. Liquid lubricants used for high-speed friction units must contain a significant concentration of special additives that increase the “stickiness” of the oil to the metal, as well as its anti-corrosion and anti-friction ability. Among such oils are KRM, Neutral and gun oil Poliform, Ballistol, etc. (See Okhotnik magazine No. 34, 2010). Lubrication of the “fracture” spring is usually carried out through the hole in the cylinder by applying 10-15 drops of liquid oil or heated grease using a syringe or oil can. A special approach to lubrication requires: a piston-cylinder friction pair, a cuff (in fractures), an exhaust valve (in compression and PCP rifles) since these units are responsible for the development of high air pressure, or rather a mixture of air with lubricant vapor. It is clear that such areas cannot be lubricated with oils with a low flash point (less than 150-180 °C), since the concentration of flammable vapors above the surface of such oils is sufficient for detonation when they are compressed with air. Detonation or the so-called “diesel effect,” despite its external effectiveness (flame and roar), destroys the cuff and bypass seals, and also deforms the mainspring, which can burst as a result of a wave of coil collisions passing through it after a sharp impact from the explosive front. To lubricate the piston-cylinder friction unit, as well as to fill the micro-gaps between the cuff and the walls of the discharge chamber, we can recommend silicone-organic oils, the ignition temperature of which is almost independent of viscosity and is limited by the temperature of their decomposition to organic combustible components. Typically, 3-5 drops of PMS or DC siloxane liquid are needed to lubricate these components. At the same time, excessively exceeding the minimum amount of siloxane fluid required for lubrication or its use in very powerful rifles can lead to the gradual decomposition of the silicon-organic components of the lubricant to fine-crystalline silicon oxide (or simply sand), which will negatively affect the lubricated system. An alternative to siloxane lubricants are special mineral and synthetic oils with high ignition temperatures (more than 260 °C), which are characterized by high viscosity and, unlike siloxane lubricants, have greater anti-corrosion ability. After lubricating the cylinder, to evenly distribute the lubricant over the inner surface of the cylinder, it is necessary to fire a dozen shots. A CO2 pneumatic equipped with a cylinder of liquid carbon dioxide does not produce a “diesel effect” when using any lubricant, since carbon dioxide does not support the combustion of organic vapors. In such systems, the rubber seals of the carbon dioxide dispenser neck require periodic lubrication. It is recommended to lubricate them (with any of the lubricants listed) after removing the weapon from storage, as well as after each shooting. This recommendation also applies to other weapons that use compressed or liquefied gas containers. Moreover, the main requirement for lubrication of such systems is the complete absence of water. It is also a good idea to lubricate CO2 pneumatic barrels after shooting with oils with high water-displacing and anti-corrosion properties. (For example, neutral oil Poliform). The latest recommendations are related to the fact that any gas, at the time of expansion, greatly reduces the ambient temperature, while condensing moisture in the barrel of the weapon. It is clear that the presence of condensate in the barrel does not have a positive effect on its ballistic properties and in the future can lead to the appearance of rust. To reduce wear and make operation easier, the cocking lever and the CO2 cylinder tightening screws are lubricated. Also, the trigger mechanisms of all these types of pneumatics require a very small amount of lubrication. Considering the complexity and not always complete accessibility of the friction surfaces of the trigger mechanism, it is advisable to lubricate it with highly penetrating anti-corrosion oils (Poliform, Gunex, Ballistol, Brunox, etc.) at intervals of 1500-2000 shots. For economic reasons, rust-resistant types of steel are used to manufacture the bulk of air guns. Therefore, even the blued surface of the barrel, receiver, trigger and other metal parts of air guns often need anti-corrosion lubricant. To prevent rust, both oils containing anti-corrosion additives and special inhibited protective water-displacing compounds can be used. Examples of oils with high anti-corrosion characteristics can be: NG-203B, Gun oil Poliform, KRM, Brunox, Ballistol. Oils that do not contain anti-corrosion additives (I-12A, I-20A, spindle oil, transformer oil, etc.) are not advisable to use for this purpose. Before treating external metal surfaces with anti-corrosion agents, you must ensure that there is no dust or dirt. The oil is applied carefully, e.g. with a gauze swab, so that its excess does not fall on the cuff or other parts in contact with high pressure. If the pneumatic is not stored, after some time (from 30 minutes to 5 hours) the oil is removed with a clean cloth. Among the protective water-displacing agents, the following are known: short-acting agents “WD-40”, preservative “Hado” and long-term agent “to protect metal from corrosion Poliform”. Unlike oils, protective water-displacing agents, having a high penetrating ability, leave a very thin film on the metal surface, which after 2-3 days is almost unnoticeable to the touch. Before use, these products must be shaken and applied evenly to metal surfaces. It is recommended to apply the protective agent Poliform before dripping, but again so that it does not get on the cuff. After 4-7 days, an anti-corrosion film is formed on the metal treated with Poliform, which is less noticeable to the touch than a layer of oil, but more effective. Most air gun barrels become dirty when fired, which is a completely normal process. Contamination often manifests itself as the appearance and gradual increase in the number of separations from the main group of hits. The rate of contamination depends on the material of the bullets (which also almost always contain factory dust), the speed of their flight, the number of rifling in the barrel and the material from which it was made. Among all air guns, the most susceptible to contamination are rifled spring-piston rifles that fire lead bullets. At the moment of firing, the rifling of the barrel (Fig. 10) cuts into the bullet, taking on some of the metal. At the same time, the amount of material left by the bullet in the rifling increases with increasing rifle power. Medium-power pneumatic barrels (bullet speed up to 200 m/s) become dirty after an average of 250-300 shots. High-power pneumatics require cleaning after 40-60 shots (in some cases after 20 shots)

Rice. 10 Muzzle of an air rifle barrel

The barrels of some rifles (Gamo 1250, Diana 46, 48, 52, 54, 350) have a pressure (up to 2 cm starting from the muzzle), which is largely leaded. This part of the barrel needs to be cleaned more often (preferably immediately after shooting). The barrels of powerful spring-piston rifles (Gamo 1250, Diana 350) mostly become dirty from the breech (10-20 centimeters), where the bullet receives maximum acceleration, while the length of the contamination increases with the number of shots. In barrels manufactured with low precision (for example, in some Izhevsk rifles such as IZH-60 and MP-512), it is not recommended to completely remove the lead, as this may sharply reduce the accuracy. In such rifles, after 300-500 shots you only need to run one or two dry patches, removing excess dust and dirt. It is recommended to clean air guns from residues of lead, copper, plastic or rubber bullets either with a special brush made from materials whose hardness is lower than steel (plastic, brass) or with a tight rag patch. At the same time, the patch material should not leave lint (for this reason, it is not advisable to use cotton wool and cotton swabs). The issue of using liquids and products to help clean air gun barrels is quite controversial. Definitely: for these purposes you cannot use most of the special cleaning compounds (RFS, robla, alkaline oil, etc.) that are widely used to care for firearms whose barrels are made of more resistant steel and have a chrome coating. It is more acceptable to use non-corrosive steel oils, which contain, in addition to base oil, detergent and dispersant components. Despite the fairly wide range of oils presented on the Ukrainian market, the user rarely receives objective information from the manufacturer about the properties of a particular product. Having discarded advertising cries about versatility and effectiveness, we decided to verify in practice the cleaning properties of the oils provided on the market regarding the lead formation that forms in the barrel of air rifles. For testing, oils of different price categories were taken, namely: regular industrial oil I-20A, which does not contain any additives, Ruzhes oil, gun wood grouse oil - RZh, Ballistol, Gunex2000, Brunox, gun oil Poliform, neutral oil Poliform. The shooting was carried out from rifles: IZH-38 (bullet speed 110 m/s) and Hatsan-125 (bullet speed 280 m/s). After 50 shots, tight gauze patches soaked in the test oil were passed through the barrel at intervals of 2-3 minutes. We measured the number of contaminated patches until a clean one came out. Also, to ensure the superiority of one oil over another, additional patches were passed. After completing the study of each oil, in order to remove its residues, patches soaked in acetone and dry patches were driven through the barrel. The test results are shown in the table. As expected, industrial oil that does not contain additives has the worst cleaning potential. Rouges oil and gun wood grouse-RZh oil are characterized by slightly better cleaning properties, but they still cannot boast of ideal cleaning properties, since even after a clean patch moistened with these agents comes out, other oils draw out the contamination. The remaining products have approximately the same cleaning potential: 4-5 patches moistened with neutral Poliform oil, as well as Ballistol and Brunox oils, Gunex-2000, and 2-3 with Poliform gun oil. It is quite interesting that Poliform Gun Oil showed the ability to somewhat clean the barrel after applying patches with Ballistol and Brunox, while Gunex-2000 did not show such a property. Taking into account the small amount of time between cleanings, the tests carried out revealed precisely the dispersing properties of the oils, i.e. the ability to hold the maximum amount of dust per unit volume (on one patch). In practice, cleaning usually takes place after more shooting, which leads to some “foiling” of the lead flakes and their rolling into the walls of the barrel. In this case, the effectiveness of cleaning will also be influenced by the detergent properties of the oils (the determining property is the ability to remove dirt), as well as the shooter’s skill in handling the brush.

Table.

Comparison of cleaning properties of oils Oil

| The required number of oil patches to clean a rifle | ||

| IZH-38 (40 rounds) | Hatsan-125 (30 rounds) | |

| I-20A | 11 | 14 |

| Rouges | 9 | 10 |

| RJ | 6 | 8 |

| Brunox | 5 | 6 |

| Ballistol | 4 | 5 |

| Neutral Poliform | 4 | 5 |

| Gun Poliform | 3 | 3 |

| Gunex2000 | 3 | 5 |

After cleaning, airgun users may still be advised to leave a small (invisible to the eye) amount of lubricant in the barrel. This is achieved by running an oiled and then wrung out gauze patch. The presence of a thin film of oil on the rifling significantly reduces scoring on the surface of the bullet, as a result of which it spins more easily, leaving less lead in the bore, and has higher penetration power.

Frequency of the procedure

Large manufacturing companies, as a rule, leave recommendations on the frequency of cleaning of air guns. Standard - after shooting 100 - 200 bullets. Experienced rifle users do not count, but clean when they realize it is necessary.

You can navigate by the accuracy - a sharp decrease in the indicator, as well as (property of PPP) by the haze escaping from the muzzle, or sparks. These negative factors aggressively affect the entire mechanics of the rifle and cuff. A high degree of clogging of the weapon will lead to damage to the trigger mechanism (trigger mechanism) due to the arbitrary movement of the piston to the rear position.

Advantages and disadvantages of pneumatics

The main advantages that determine the advisability of choosing such a weapon for the purpose of self-defense are:

- Sufficient lethality of the shot.

- No license required upon purchase.

But despite these advantages, there are also some disadvantages:

- First of all, the impact of a ball that is fired from such a weapon cannot cause severe harm to health unless it is shot directly into the eye, for example. At least as strong as expected of him. If the attacker is wearing sufficiently thick clothing, the blow will be almost imperceptible to him.

- And the reliability of such weapons is not always at its best. The gas cartridge is replaceable and can lose its charge even when the pneumatic gun is not used.

- Loses its effectiveness at low temperatures. This is due to the fact that the gas pressure drops as the temperature decreases, and therefore the force of the impact too.

That is why you should not blindly trust this technique, but rely more on your own strength and common sense.

Important rules for cleaning pneumatics

It is important to lubricate the pneumatic barrel periodically, but only when it is clean. Before you begin the procedure, you should know important cleaning rules. The points must be fulfilled by weapon owners:

- Consistency . As stated earlier, serious companies give recommendations on the frequency of canal cleaning activities, depending on the model of weapon. If the product’s operating instructions do not contain this information, the user can use the “golden rule” - after shooting, maintenance follows. It doesn’t matter how many shots were fired, because even 1 projectile ejected from a lubricated channel has already left carbon deposits that need to be removed.

- The right tools . You can remove carbon deposits from the channel with a plastic or bronze brush. The materials are soft, so the inside of the barrel will not be scratched. The downside of these options is that they are not suitable for removing lead plaque. You will inevitably have to use a hard brush - steel or brass. Cleaning with such a tool should be carried out as a last resort, because for a rifle it is a “painful” procedure.

- Use of chemistry . A beginner is confident that he can easily remove old gun oil. In reality, the process is labor-intensive. Even soap and hot water will not completely remove the remaining oil. Using an alkali or kerosene based composition will solve the problem. However, after manipulation, the barrel must be thoroughly rinsed under running water and dishwashing detergent. If this is not done, the kerosene residue will corrode the new layer of oil.

These are just 3 key rules for properly cleaning the air vent. The procedure must be performed carefully and thoroughly. 5-10 minutes is not enough to completely remove dirt. It is worth noting that the better the procedure, the longer the service life of the rifle.

How to clean

The most powerful and best air pistols, rating 2021

Now that all the necessary tools are at hand, you can begin the process of cleaning the weapon. In fact, the process is not much different from that applied to firearms. However, in the case of pneumatics, everything happens much faster. Here is the algorithm of actions to follow:

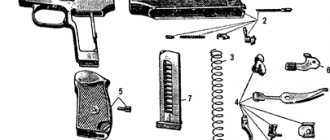

We carry out incomplete disassembly of weapons

This is important to do in order to carry out better cleaning. If you do not know how to disassemble your air pistol, then refer to the instruction manual that comes with the weapon. We use a kerosene-based chemical to remove carbon deposits or galvanized oil.

It is important not to overdo it, since excess kerosene is quite difficult to remove using conventional means. Also use that part of the cleaning rod assembly that is not intended to be lubricated (residues of kerosene will eat away the lubricant). After the barrel has been treated with chemicals, it is necessary to go over it with a plastic or metal brush (depending on the degree of contamination of the weapon). Also, be sure to keep an eye on the condition of this tool, as it will wear out over time and become unusable. We wash the barrel in soapy water or with dishwasher detergent (AOS, Fary). This must be done in order to remove any remaining kerosene, and also to easily remove the shavings that formed during the cleaning process. Don’t be afraid to go under the water with a cleaning rod to make sure everything is clean. Dry the barrel near a heating radiator or in any warm room. As soon as the trunk is visually dry, it is necessary to remove those particles of water that are hidden very far away. To do this, use a puff (soft version for rifled barrels) or rags (rough material for smooth-bore weapons).

That's all, all that remains is to re-lubricate the pistol with gun oil, after which you can use the weapon. We remind you that a clean barrel is the key to the health and long service life of your pneumatics. In addition, if the bullet experiences minimal resistance at the moment of firing, this will significantly increase the combat characteristics of the pistol.

What funds will be required

The best solution would be to purchase a ready-made set of tools for cleaning rifles and pistols. It usually consists of a bronze brush and a cleaning rod. Additionally, other materials may be needed:

- A nylon brush is effective for cleaning rifled and smooth trunks. And it costs less on the market than its bronze counterpart. The only downside is a large number of shavings after using it.

- Cotton fabric must be thin, clean and dry. Special materials are sold on the shelves of weapons stores - they can also be used. If this is not possible, you can tear up an old T-shirt.

- Acetone liquid is a worthy replacement for the alkaline composition. It dries instantly, but the chemical composition is more economical in price.

Of course, the best weapon lubricant is Ballistol. Suitable for all types of air guns. Budget or professional device – it doesn’t matter. The oil is sold in aerosol form.

Budget treatment of the pistol valve mechanism

It is imperative to lubricate the CO2 pneumatic valves to ensure their normal functioning and extend their service life.

There are 2 solutions:

- purchasing a can of silicone lubricant;

- disassembling and processing the mechanism manually.

Yes, they sell carbon dioxide canisters with oil inside. It is enough to shoot it - the valve is processed. The downside is the high price per piece. The most uneconomical option. A cheap but inconvenient solution is to disassemble the mechanism and lubricate it manually. However, it can be made easier.

Lifehack:

- Take a medical syringe with a thin needle and fill it with weapons-grade liquid.

- Insert the needle into the outlet valve - enter the composition.

- The mechanism has been processed.

Important . Some models of Baikal brand pistols have a filter that must be removed, otherwise lubrication will not be possible. In addition, the element is useless - it interferes with the movement of CO2.

Step-by-step cleaning of a rifle barrel

The cleaning process is as follows:

- removal of lead residues;

- degreasing;

- drying;

- oil lubrication.

It will take a lot of effort to remove lead plaque. An adult man can do it without any problems - naturally, a bronze brush is used. Only this non-ferrous metal is capable of removing lead without significantly damaging the channel. Using Ballistol the user washes away lead residue and reduces friction.

If a spring-piston “air” with a side or under-barrel cocking lever is being cleaned, you should look at the bypass to see if oil drops, lead or bronze shavings can get into the hole. Otherwise, when making the first shot, you will most likely need to clean it again.

Degreasing the barrel is the next step after removing lead deposits. Here the user removes dirty oil - with impurities of bronze and lead. Degreasing with gasoline or other flammable substances is unacceptable. Acetone can be used. The result is that there are no flammable vapors in the barrel.

The bypass hole is closed before the degreasing procedure. It is better to use a nylon brush for the procedure. You need to be careful when choosing a tool - it must be resistant to acetone, otherwise the channel will be covered with a polymer layer.

You can skip the degreasing step, but use drying. It is enough to use pieces of dry cotton fabric or cotton pads. It is better to dry with a visher - a special ramrod attachment. The addition is bronze, with a screw groove. A thin strip of the selected material is inserted into the latter. Drying is completed when no oil or other traces remain.

The last stage is to lubricate the barrel with a thin layer. This will allow the pellet to move easily through the channel. For rifles, the main thing is to choose the correct proportion and thickness of the oil - it is allowed only in liquid form. If Ballistol is not applied in a thin layer, the rifle's accuracy will suffer.

Features of cleaning different models

The most unpretentious models are those that use CO2. Any mechanical dirt is simply blown out of them. However, the presence of moisture in the cylinder and the effect of its condensation during firing make the barrel lubrication procedure mandatory. The same requirement also applies to models with pre-pumping or with a multi-spring, into the reservoir of which air is pumped from the street.

In spring-mechanical rifles, it is imperative to protect the bypass hole from lubricants and solvents getting into it. The best way to “kill” such a rifle is to drop oil, diesel fuel, acetone, and gasoline into the compressor (in order of increasing strength of the diesel effect).

External lubrication is required for all models. Lubricate the hinges and locking parts in the “breaks” and charging levers, apply protective lubricant to the valves of air containers. It would be a good idea to drop some liquid “spindle” oil under the trigger.

Do I need to wash the bullets?

The service life also depends on the cleanliness of the bullets. The washing procedure is relevant for Russian-made shells, which are loved by most air gun owners for their affordability.

The bullet washing process consists of the following steps:

- Lead bullets are poured into a separate container. Next, fill in diesel fuel or kerosene, which will remove foreign particles and galvanizing from the shells.

- Drain the flammable substance and empty all the bullets from the container - dry well. It is allowed to reuse kerosene or diesel fuel, but only 3 times.

- Dried ammunition is placed in a clean glass or other container and filled with soapy water. You can replace it with any dishwashing detergent - this option is better, because it effectively removes traces of petroleum products, and the bullets will be flawless.

- A hair dryer will help speed up the drying process of bullets. But before shooting, you need to make sure that the bullets are thoroughly dry, otherwise plaque will form in the barrel bore.

The advantage of clean bullets is that they do not stick to your fingers, and there is no oil film (a characteristic feature of all lead analogues). After shooting the “air”: there is almost no soot, good accuracy of fire from long distances (the deviation of the projectile along the flight path is minimal or absent).

Preparing the gun for use

If you think that an air gun can be used immediately after purchasing it in a store, you are deeply mistaken. Most manufacturers immerse weapons in a special preservative lubricant, which increases shelf life, but cannot be used for shooting (the accuracy of the fire will be too low, and soot will begin to form much faster). Therefore, after purchase, it is recommended to first carry out the depreservation procedure:

- We carry out partial disassembly of the weapon (according to the same scheme as in the case of cleaning and lubrication).

- Remove all preservative liquid using a powder puff with a cleaning rod or a rag.

- We thoroughly degrease not only the barrel, but also all metal parts.

- We wash the barrel using a soap solution (water + any detergent).

- We apply new oil to the barrel, for example, the popular Balistol in the form of a spray.

- We use a special silicone liquid to lubricate small parts (such as the trigger).

- We assemble the weapon, carefully placing all the parts in place.

After this, you will also need to check how well the pistol is shot. Unfortunately, many sellers in gun stores deliberately reset the factory settings so that customers turn to them for help. However, in order to zero the front and rear sights, it is not at all necessary to have great knowledge and experience. It’s enough just to follow certain instructions and recommendations from professionals:

We find a suitable place for shooting. It is best, of course, to give preference to a shooting range, since there the wind or air humidity will not affect the bullet. However, if going to such an establishment is not possible, wait for a clear, windless day, and then go outside the city into a forest or some open field where there are no people. Prepare a comfortable position for yourself. To make zeroing a pistol as effective as possible, it is best to use a special locking machine. However, not everyone has such a device. As an alternative, a sandbag that adapts to the shape of the weapon is a good idea. We fire several test shots from a distance of 5 meters. The best point to aim at is the bottom of the black circle on the target.

It's important to place all your shots in one spot to get a feel for how much spread the gun has. If the accuracy of the battle is good, then the shooting position has been chosen conveniently. Once you have made a few test shots, you can begin to adjust the position of the front sight using the two drums located on the rear sight (they adjust the vertical and horizontal)

After that, we take a few more shots and look at how the result has changed.

Also, during zeroing, try not to rush anywhere, adjusting only one position per stage (vertical or horizontal), otherwise it’s easy to get confused in your own calculations. It is also worth increasing the distance to the target gradually, otherwise the spread may turn out to be too large with the next increase in the distance.

Self-blueing

Burnishing is a procedure for applying an oxide film to a metal surface to protect the metal from corrosion. That is, applying bluing to the barrel extends the life of the part. The black protective film wears off over time and is re-blued.

The process looks like this:

- The pneumatics are not completely disassembled.

- The barrel is separated from the rifle, cleaned and dried.

- Placed in sodium nitrous compound.

- Wait for the composition to boil.

- The part is left to soak for 7 minutes.

- The barrel is immersed in cold water.

- The black coating on the steel is smeared with an onion head.

- The blued part is washed and dried.

- Lubricate the part with gun oil.

Blueing adds aesthetics to pneumatics. At the owner's request, other parts of the weapon can be treated in this way, for example, the trigger, if there was corrosion on it.

Step by step cleaning

Now that you know more about the basic cleaning rules, it’s time to move on to the maintenance procedure itself. It is best to carry out the work according to a certain algorithm of actions so that cleaning is as effective as possible.

Step 1

Removing lead plaque. It is recommended to use a plastic cleaning rod or a bronze brush for this purpose, so as not to leave scratches on the rifled barrel. The carbon deposits are removed quite easily, so you don’t have to put in any serious effort. Hand movements should be smooth and leisurely.

Step 2

Degreasing the barrel. This procedure is carried out using special alkaline compounds, sold in almost every gun store, or gasoline. The chemical is applied to the same plastic cleaning rod in an even layer. Don't overdo it with the lye, otherwise it will be difficult to clean.

Step 3

Drying weapons. Before you begin lubrication, it is necessary to thoroughly dry the cleaned and chemically treated barrel. To do this, you need to place the rifle on a horizontal surface in a room where there is dry, warm air. For example, you can simply put the rifle on the floor near the radiator for 12 hours.

Step 4

Rifle lubrication. To carry out this procedure, you will have to acquire a high-quality mineral composition (best from an imported manufacturer). The oil should be applied in two stages in a thin layer. If too much smoke comes out during the test shot, you will need to remove some of the compound using a cleaning rod.

Recommendations for storing and caring for an air rifle

Storage of air guns also affects their service life. Owners without experience often put their units in the wrong place for storage purposes.

Basic rules that all users of the “aircraft” must follow:

- There should be no high humidity in the room, and an even temperature should be maintained. The main thing to remember is that air guns can withstand negative values without problems, but high values have a negative effect (freeze is better than heat).

- The rifle is positioned in the correct position - the barrel “looks” upward. This way the lubricant will not flow out of the channel.

- If you have a gun case, it is recommended to use it. It serves as additional protection for the barrel from contamination.

- After a long period of inactivity, the rifle must be cleaned and lubricated with gun oil, only then should it be fired. Failure to comply with this rule will result in product failure.

- The packaging for the bullets closes tightly, which prevents moisture from getting inside. Otherwise, condensation will form, which will ruin the projectiles.

What about air pistols?

Features of zeroing a rifle with an optical sight

Zeroing a rifle with an optical sight has its own characteristics. This procedure should be started from a minimum distance. Subsequently, it will gradually increase so that the result obtained is as objective as possible.

Zeroing an air rifle with an optical sight:

During zeroing, you should select an aiming point through an open sight and fix the weapon before firing. Then you need to bring the crosshairs to the point where the rifle is pointed with an open sight. This can be done by using an adjustment drum. And after that the first test shot is carried out.

The essence of the whole process is to bring the crosshairs of the sight to the point of impact of the bullet. When the desired result is achieved, you should gradually increase the existing distance and repeat the entire procedure.

In this article you can learn how to make an air gun. We use available tools that can be found in any home. Review of the Stechkin air pistol model Gletcher APS - read more. Characteristics, features, modification with the Blowback function, partial disassembly of the pistol.

About storing an air pistol

Improper storage of an air pistol will most likely lead to frequent clogging of the barrel with copper-plated bullets. To prevent trouble, you should choose the right place for the weapon and remember important storage rules:

- The pistol is not exposed to direct sunlight.

- The room is dry, and the air temperature does not exceed +25 degrees.

- The gun is positioned with the barrel up or in a horizontal position, but tilting is unacceptable, otherwise oil leakage cannot be avoided.

- The pistol should be stored unloaded.

If possible, it is recommended to purchase a gun safe.

Tools and cleaning products

For basic care of an air rifle you will need the following minimum set:

We also recommend reading:

Budget spinning reels Riobi Exiya Features of crucian carp killer gear and how to make such equipment Diagram of how to learn how to tie a hook to a fishing line Features of fishing with a retractable leash, selection of gear and installation

- Ramrod.

- Cleaning rod attachments.

- Cleaning agent.

- Lubrication.

If you have a choice, then it is better to choose a non-removable cleaning rod. Three-element “Chinese” products are not very convenient to use, they deteriorate faster and can cause irreparable damage to the bore and the cut of the barrel. The ramrod rod must be covered in plastic braiding. You can make it yourself using heat shrink tubing.

Cleaning rod attachments are brushes made of various materials. The minimum set should consist of at least two such devices - plastic and fabric. For more thorough cleaning, you will also need a brush with brass bristles.

As a cleaning agent, acetone is considered the most acceptable option. You should not use gasoline for these purposes, as its vapors will detonate when fired, causing damage to the weapon.

Cleanliness is the key to long service life of pneumatics

Regular cleaning of the air vent allows you to:

- maintain optimal accuracy and accuracy of fire;

- increase service life;

- save money on repairs.

If you don't clean the rifle out of the box, your shooting performance will begin to gradually decline. The reason is the accumulation of lead particles in the bore. The popular name for the process is “lead”. More plaque is produced in magnum class spring-piston rifles. Carbon deposits also accumulate in the channel as a result of the “diesel effect”: ignition of weapon lubricant.

The type of barrel is important. Channels with conventional rifling become clogged more often than polygonal ones. An interesting fact: the degree of “lead” decreases as the number of grooves increases. Barrels with 6-14 screw recesses are installed on serial "air" barrels, but more often with average parameters.

Another reason for rapid channel blockage is the use of low quality bullets. It is strictly forbidden to use homemade or spent ammunition, as it will damage the rifle. It is impossible to reduce the contamination of rifled weapons by changing the type of ammunition. Copper-plated bullets leave a residue and wear down grooves. Suitable for smoothbore pistols and rifles only.

Gas cylinders, PCP and multi-compression devices require care. CO2 models are less demanding: most of the debris is blown out of the barrel channel. But avoiding cleaning will lead to condensation and then rust.

Caring for air guns is necessary to prevent mechanism failure

It is important to perform the steps correctly so as not to damage the device