Warrior of the Red Army, believe in the power of your military equipment, keep cool in moments of danger, never part with your weapon, fight the enemy to the last opportunity!

I. GENERAL INFORMATION

The 37-mm mortar (Fig. 1) is a smooth-bore mounted fire weapon and is designated as an individual weapon for a fighter to engage manpower and suppress enemy firing points.

| Rice. 1. 37 mm mortar in firing position |

In the stowed position, the mortar is a shovel, the handle of which is the barrel. In this position, the mortar can be used for various kinds of trench-earth work (Fig. 2) like an ordinary small sapper shovel (self-digging, digging trenches, etc.). When shooting, the shovel serves as a base plate. The shovel is made of special armor steel, which is not pierced by bullets, so it can be used as a shield to protect against bullets and shrapnel.

| Rice. 2. Using a 37mm mortar as a shovel |

In the stowed position, the mortar is carried on a belt pouch. The mortar fires fragmentation mines, which are carried by the soldier in a special bandoleer with shoulder straps. The bandolier is worn around the torso. The mortar has the following main characteristics: 1. The longest firing range is about 250 m. 2. The shortest firing range is about 60 m Note: The design allows for a shorter range, but firing at a range of less than 60 m in the open terrain is not recommended due to the danger of hitting friendly fighters with shrapnel. 3. The weight of the mortar is about 1.5 kg. 4. The angle of horizontal firing without changing the position of the plate is about ±12°.

II. MORTAR DEVICE

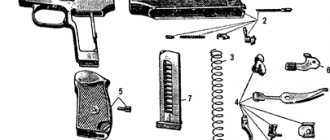

The mortar (Fig. 3) consists of three main parts: a barrel, a shovel—a base plate, and a bipod with a plug.

| Rice. 3. Construction of a 37 mm mortar |

The barrel serves to direct the flight of the mine towards the target when fired. In the muzzle, the barrel has a small bell for ease of inserting mines when loading. The barrel tube is tightly connected to the breech , which serves as the bottom of the barrel. is pressed into the breech , onto which the capsule of the mine's expelling cartridge is pinned. The tail part of the breech ends in a ball heel , which serves to articulate the barrel with the shovel (plate). The barrel and shovel in the articulated joint are made one-piece. To connect the barrel with the shovel in a traveling manner, there is a rotating ring . To protect your hands from burns when shooting, there is a canvas movable sleeve . The shovel (base plate) serves to support the mortar into the ground when fired and transmit the recoil force to the ground. The bipod serves to support the barrel into the ground when firing, which increases the stability of the barrel and improves shooting accuracy. The bipod in the stowed position is placed in the mortar barrel with the lyric facing towards the breech of the barrel; from the muzzle, the barrel is closed with a plug. Before shooting, the bipod is connected to the barrel using a spring lyric.

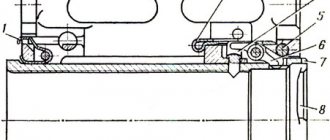

III. CARTRIDGE PIECE DEVICE

The bandolier (Fig. 4) is a canvas belt with sockets in the form of loops, in which iron cases for mines are fixed. The bandolier has an iron loop and hook for fastening it when putting it around the body and a shoulder strap to prevent the bandolier from sliding down. The mines are inserted into the bandoleer with the tail down, and the mine is held in the case from falling down by the annular roll of the case, and at the top by a spring. When the mine is correctly positioned in the case, the fuse head should not protrude from the top edge of the case.

| Rice. 4. Bandolier |

To remove the mine from the case, you need to push it from the bottom up, resting your fingers on the wings of the stabilizer; in this case, you must not press the primer of the tail cartridge . As soon as the mine passes through the spring and its fuse comes out of the case, it can be taken by the fuse and removed upwards from the case.

IV. TRANSITION I3 FROM MARKING POSITION TO COMBAT POSITION AND BACK

To move from the traveling position to the combat position, you must: 1. Unfasten the belt bag (case) for the mortar and remove the mortar from the bag loop. 2. Open a trench for the slab with an inclination forward towards the target; Make the ditch tilt about 30°. 3. Hold the mortar with one hand by the barrel with the shovel up and the back part away from you. 4. With the other hand, turn the breech ring to the right (as indicated by the arrow on the ring) half a turn. 5. Move the trunk away from the shovel.

| Rice. 5. Carrying a mortar and bandolier on a hike |

6. Place the mortar with the back of the slab in the ditch (with the blade of the shovel up), lightly rub the shovel onto the ditch (moving the shovel down and up). 7. Remove the barrel plug with the bipod and attach the bipod to the barrel. 8. Point the barrel at the target and rest the bipod on the ground. The mortar is ready to fire. The transition to a combat position is carried out very quickly with appropriate training. To move from a combat position to a traveling position, you must: 1. Remove the bipod from the barrel and insert it into the barrel, closing it with a plug. 2. Remove the mortar from the ditch and fold it into the shovel position (put the breech in the guide hole of the shovel); in this case, you need to ensure that the edges of the hole fit into the cut out part of the collar under the ring. 3. Turn the ring to the left as far as possible, tightening it more securely (against the direction of the arrow). 4. Place the mortar in the belt case with the barrel down and fasten the case (Fig. 5).

V. SHOOTING FROM A MORTAR

1. Firing from a 37-mm mortar can be carried out at the following targets: a) at enemy personnel located in open positions or behind cover (ravine, trench, building, pit, bushes, etc.); b) according to the calculation of machine guns, mortars, guns 2. The firing position for the mortar must be chosen such that you can camouflage well and hide from the fire of rifles, machine guns and machine guns (in a shell crater, in a ditch, behind a stone, etc. , Fig. 6). 3. The mortar is aimed at the target without the help of sighting devices. Therefore, when shooting, it is necessary to proceed from the following conditions: the greatest range is obtained at an elevation angle of 45°. It is not recommended to shoot at smaller angles, as frequent misfires will occur. As the angle increases (more than 45°), the range decreases. 4. Changing the elevation angle is done by rearranging the bipod: to increase the angle, the bipod rests on the ground closer to the mortar; to decrease - further from the mortar.

| Rice. 6. 37 mm mortar in position |

5. When shooting, the barrel must be held with the left hand at all times, and for stability, the elbow of the hand must be rested on the ground (Fig. 6 and 7). 6. Correction of aiming is carried out after observing the results of the first shot; when flying, you need to increase the elevation angle; if undershot, reduce the elevation angle. Lateral aiming is corrected by turning the barrel in the desired direction. 7. The mortar can be fired from a prone position or from a kneeling position. The most convenient way is to shoot from a prone position (Fig. 7). 8. To fire a shot after aiming, you need to take the mine out of the case with your right hand and lower it into the barrel with the tail part until the centering thickening, after which you release the mine and move your hand down or to the side. Loading a mortar is completely safe.

| Rice. 7. Prone shooting position |

9. If it misfires, you must carefully tip the mortar over - lift the breech with your right hand, and catch the mortar with your left hand as it exits the barrel. Don't let the mine fall to the ground, make sure that the mine doesn't hit your hand with the fuse head as it exits the barrel. If the breech of the barrel is raised and the mine begins to slide towards the muzzle, then it is impossible to lower the barrel in the opposite direction, since the mine may again impale itself on the firing pin, which will cause a shot. 10. You can fire a mortar without using a bipod. In this case, resting the elbow of your left hand on the ground and clasping the barrel with your hand, give the required elevation angles and lateral aiming. Such shooting, like shooting with a bipod, is very effective. 11. There are usually no malfunctions of the mortar when firing. If they are detected (breakage of rivets of the linings and plate, deflection of the plate, etc.), it is necessary to repair the mortar on your own or send it to a workshop. 12. When shooting, make sure that the mine does not hit the cover (branches, etc.), otherwise it will explode before reaching the target.

VI. MINE DEVICE

A 37-mm fragmentation mine is delivered to military units fully equipped and ready for firing (Fig.

| Rice. 8. General view of the 37 mm mine |

The mine consists of three main parts (Fig. 9) 1) the body , which is filled with explosive; 2) fuse , which is screwed into the head of the body; 3) an ejector cartridge with a charge, which is inserted into the stabilizer tube. For a fully equipped, serviceable mine: 1. The fuse must be screwed in, and the fuse membrane must not be pressed through. If the membrane is pressed through, then the mine cannot be fired - there will be failures of the fuse or ruptures of the mine in the mortar barrel.

| Rice. 9. Section of a 37 mm mine |

2. The ejector cartridge is inserted into the stabilizer tube and fully seated. If the cartridge is not chambered, then it is necessary to press the fingers of both hands on the edges of the bottom of the cartridge case to chamber the cartridge. Do not press on the cartridge primer, as the charge may ignite. Before firing, the grease must be wiped off the mine. You cannot shoot with a greased mine - there will be misfires and undershoots.

VII. CARE AND SAVING OF THE MORTAR

Before firing, the mortar barrel must be wiped dry to remove grease, sand and dust. You cannot fire a mortar with a lubricated and dirty barrel - there will be frequent misfires and undershooting of the mines. After firing, the mortar must be cleaned. To clean, you need to use the bipod as a banner, wrapping rags on the bipod.

Courtesy of Konstantin Vikhornov - website Search Team "Wormwood"

Modern mortars. Part 1

The M224 LWCMS 60mm mortar system is carried by a crew of four.

This standard weapon of the Army Infantry and Marine Corps is designed to provide fire support to small maneuver units with high-explosive fragmentation, illumination and smoke mines. Mortars are part of field artillery. They are designed for mounted firing at hidden targets, as well as for the destruction of field fortifications, and differ from cannons that fire at targets with direct fire along a low flat trajectory, and howitzers, which usually fire at hidden targets that are not visible from the firing position along a mounted trajectory .

The mortar fires its ammunition (mine) along a high trajectory, which allows it to hit targets behind hills, in narrow streets, in ravines and trenches; the latter fighting quality made it particularly useful in the trench warfare of the First World War. The mortar can be a very simple system: simply throw a shell down the barrel and fire as fast as a soldier can throw rounds down the barrel (20 rounds per minute; it's quite possible to throw every three seconds). Plus, mortar systems can be carried by crews, a light mortar can weigh up to 23 kg, and even ready-to-fire heavy towed mortars weigh 150 kg, which is not in favor of, for example, the 155-mm light howitzer M777 from BAE Systems, which weighs 4200 kg. In addition, the range of light mortars can reach 3.5 km, and the latest heavy systems can reach 10 km.

The mortar appeared as a siege weapon that could be fired over fortress walls to destroy the guns and destroy the structures behind them. Following the reappearance of mortars in World War I, this class of artillery became widespread during World War II, where it played an extremely important, although often underappreciated, role in many combat episodes. For example, Wehrmacht doctrine considered mortars as the main means of fire support for infantry, while “barrel” artillery was reserved for “main attacks.” The mortar began as a small unit's "pocket" artillery - a role that it broadly continues to play today.

Modern mortars fall into three categories: light mortars (typically 60 mm) used at the platoon and company level, medium mortars (81 mm for Western models or 82 mm for Russian and Chinese) used at the company or battalion level, and 120 mm battalion-level mortars, also used in artillery units. The trend is for battalion-level dismounted infantry to be armed with 81mm mortars, while mechanized units are typically armed with vehicle-mounted 120mm mortars. Modern mortars are lighter, fire further, and have greater accuracy and lethality than the systems that were deployed 15 years ago. All this is thanks to the widespread use of new alloys and composite materials in the manufacture of mortar barrels and base plates, automation and digitalization of fire control and progress in fuses and mortar ammunition. These innovations have increased the mortar's capabilities in performing direct fire support missions, despite the changing dynamics of ground combat with its large extent, heterogeneous operations and asymmetry. The obvious conclusion is that under these conditions, the importance of the mortar as a weapon system increases for the combat commander, as well as its contribution to the outcome of the battle.

High mobility is one of the main tactical advantages of the mechanized Stryker units of the US Army. The ability to immediately return indirect fire is critical to maintaining the maneuver advantage of these units.

Light mortars

Which weapons are most suitable as standard weapons for a unit at a particular level are determined by two main factors. First, how does it fit into the combat responsibilities of a unit at this level? In particular, does it correspond to interests and range of tasks? Second, is it compatible with the units' ability to deploy the system, that is, can they move and maintain it? While the advantage of having a longer-range weapon is obvious, if too many soldiers are needed to carry it or its components, it may not be practical. The difficulty of moving a heavy system and providing sufficient ammunition can negate the value of the increased range. A balance needs to be achieved. Most armies around the world agree that the 60mm mortar is the best choice for a light infantry company. The US Army's FM7-90 mortar combat manual states: "The advantage of the 60mm mortar... lies in its immediate response to the company commander's orders and the speed with which it can go into action."

The US Army and Marine Corps are armed with the M224 LWCMS (Lightweight Company Mortar System) light mortar system with an effective fire range of 70 meters to 3500 meters. A weapon's minimum range is just as important as its maximum, as it determines how close in front of friendly forces it can fire. This can be critical to thwarting an attack that threatens to overwhelm one's own positions, or to deter an enemy attempting to close in on allied positions without returning artillery fire. The M224 mortar and its 20 percent lighter variant, the M224A1, are supplied by General Dynamics Ordnance and Tactical Systems (GDOTS). This family of mortars fires high explosive, smoke (white and red phosphorus), illumination (visible and infrared) and practical mines. In turn, Saab offers its M1061 MAPAM (Multi-Purpose Anti-Personnel Anti-Materiel) mortar ammunition, which can be used with the M224/A1 mortar and fired at a smaller distance from friendly forces thanks to its controlled scattering of fragments; in addition, it is capable of penetrating the most vulnerable spot of an armored vehicle - the roof, and detonating inside it with a delay.

Another light infantry 60-mm mortar under the designation M6 Mortar is produced by the Austrian company Hirtenberger. In addition to the Austrian army, it was adopted by the British army and marines under the designation M6-895 (895 barrel length in mm), the maximum range of which is 3800 meters. In the case of the British, the previous concept, according to which the light mortar was excluded in favor of the hand grenade launcher, was completely changed. However, combat experience during the British invasion of Afghanistan in 2001–2013 allowed us to appreciate the advantages of a light mortar, which forced us to reconsider plans to replace it. A tripod-mounted automatic grenade launcher (AG) is also sometimes considered as a replacement for a light mortar. However, the characteristics of the projectile trajectory of the AG are closer to the mounted fire of a howitzer. In the case of AG, this makes it difficult to fire on reverse slopes. In addition, they do not have such a diverse range of ammunition.

Mortar M6 Mortar of the Austrian company Hirtenberger

One of the features of the 60 mm mortar is that, although greater accuracy and range are achieved when mounted on a bipod and using the horizontal and vertical guidance mechanism, it allows visual aiming and hand-held fire and thereby quickly hit targets. Taking this aspect into account, DSG Technology has developed an ultra-light 60mm iMortar mortar for small units. With a mass of 5.5 kg and a length of 900 mm with an integrated aiming system, it is well suited for a small combat group, as evidenced by its short range of 1.2 km.

Ultralight 60-mm mortar iMortar

The American army adopted the 120-mm Elbit Soltam smoothbore mortar, which in the ground version with a bipod was designated M120; this mortar is used at the battalion level

Towed 120mm heavy mortars have been adopted by the US Marine Corps because they can be easily transported by helicopter. The EFSS self-propelled expeditionary fire support system includes a 120 mm TDA rifled mortar and a light Growler tractor

Medium mortars

The 81 mm caliber (actually 81.4 mm) is the most common in Western armies, while the 82 mm caliber is typical of Russian and Chinese weapons. Although 82 mm mortars were common in the Soviet army during World War II, they were subsequently replaced by 120 mm mortars in most units. The exception was the transportable, towed and self-propelled smooth-bore mortar 2B9 "Cornflower" of 82 mm caliber on a wheeled chassis, which was put into service in 1970 and used during the Afghan War in 1979–1989. It is also still in service with the Russian Airborne Forces. Unlike traditional mortars, this mortar fires either single shots or in automatic mode using four-round magazines. The range of the mortar, capable of firing high-explosive fragmentation, smoke, illumination and armor-piercing shells, is 4270 meters. The Chinese army is armed with the Type 67, a modernized Soviet regimental mortar PM-41, which was adopted back in 1941. This mortar was widely used in the Vietnam War.

Smooth-bore mortar 2B9 "Vasilek" 82 mm caliber

The United States has used advanced technologies to improve its 81-mm mortars, of which the newest is the M252 model weighing 42.3 kg. It is the standard weapon of the battalion level of the Army light infantry units, and has also been adopted by the Marine Corps. This 81 mm mortar was also installed on a modernized version of the M113 armored personnel carrier, designated M125; The mortar was fired through an open hatch on the roof of the hull. It is also installed on the Marine Corps LAV-M Mortar and transported on the M1129 Styker mortar carrier (main armament is a 120 mm mortar), where it is removed from the vehicle for firing. The M252 has a range of 5,608 meters when firing all types of 81mm ammunition.

The Mo 81 LLR mortar (Leger Long Renforce - light long reinforced) developed by the French company Thales is in service with the French and Irish armies and is offered with a shortened barrel 1.1 meters long (Leger Couf) and with an extended barrel 1.5 meters long (Leger long ). The standard range is 3100 meters, but when firing extended range mines it increases to 5600 meters. The French company Nexter supplies mortar ammunition through its subsidiary Mecar, which produces several types, such as the 155 mm MPM (Metric Precision Munition) with a maximum range of 40 km. Nexter has also developed and prepared for production on the basis of its armored combat vehicle VBCI (Vehicule Blinde de Combat d'Infanterie) a 120-mm mobile mortar system, which is ordered but not yet purchased by the French army.

Mo 81 LLR mortar manufactured by the French company Thales

All 81mm shells are feathered (with stabilizing planes), and the most common type is high-explosive fragmentation. The adoption of multi-mode fuses for high-explosive fragmentation mines allows the crew to easily select the detonation mode of the projectile immediately before firing. Such fuses, such as the M734, can be installed in several modes: impact, delayed (allows you to break through a roof or shelter) or remote (detonated in the air over a target with scattering of fragments over a large area). For example, the temporary fuse of an illumination mine is installed in such a way that the lighting mixture is ignited in the housing lowered over the target by parachute and burns for 50-60 seconds with a brightness of 525,000 candles. The lighting composition can be equipped either to create illumination in the visible range or in the infrared. Smoke shells are filled with red phosphorus granules, which are ignited to produce a thick smoke screen. Another filler in mortar shells, white phosphorus, instantly creates a smoke screen, reducing visibility in the visible and infrared spectrum. It burns hot and can cause burns, but its instant action makes it ideal for marking targets.

Elbit's SPEAR mortar system has low recoil forces when firing, which allows it to be installed on light tactical vehicles. The system installed on the pickup truck has already been tested by American special forces in Afghanistan

“Made with us” and on Yandex.Zen

The simplicity of the design and use of the mortar, combined with good fighting qualities, quickly ensured that this type of weapon became widespread. More than a hundred years have passed since the advent of mortars. During this time, they maintained their popularity and continued to improve.

Now the development of new mortar systems continues in several countries, including Russia, where the Nizhny Novgorod Central Research Institute “Burevestnik” . Work to improve old mortars and create new ones concerns mainly two areas of the battalion level - weapons of 82 and 120 millimeters caliber.

First of all, it is worth noting the modernization of the 2S12 “Sani” complex with the index 2S12A. Adopted into service in 1981, the 2S12 system consists of a 2B11 mortar, a wheeled vehicle and a towing vehicle. The mortar itself has undergone major changes. The main element of modernization of the 2B11 mortar is a new base plate and the system for connecting it to the barrel. Previously, the barrel could only swing in one plane. Thanks to the use of a new base plate with a hinge, the updated mortar can also be aimed horizontally. This allows the fire to be transferred to another target without turning the heavy base plate. In addition, 2B11 received a number of new tools and capabilities.

The updated firing mechanism can be quickly and easily removed; disassembling the mortar is not required. On a special additional carriage stand there is a unit for attaching a sight, making it possible to aim the entire battery using only one sighting device. In addition, the updated “Sleigh” kit includes devices that allow you to quickly and easily align the sight, as well as fire at night.

120 mm mortar 2B11

Transport vehicle on Ural chassis 43206-0651

Wheel travel 2L81

In order to maintain maximum unification with the original 2S12 complex, the modernization did not affect the main part of its units. For this reason, the firing range and accuracy remained at the same level. As before, the Sleigh can fire conventional mines at a distance of up to 7,100 meters. When using guided KM-8 “Gran”, the range of hitting targets increases to nine kilometers. During the modernization, 2S12A received a new towing vehicle. Now this is a Ural-43206 truck or an MT-LB tractor. Transportation of a wheeled mortar can be carried out either by simple towing, or in the back of a truck or on the roof of a tracked vehicle. For loading, transport vehicles are equipped with a quick-release ramp of a tray design and a winch.

The updated composition of the complex’s equipment ensures a faster transfer of the complex from traveling to combat mode and vice versa, including by the forces of a reduced crew. Another project for modernizing an old mortar is called 2B24 and is a further development of the 2B14-1 “Tray” project. Due to its dimensions and weight, the 82-mm gun can be transported disassembled by a crew of four people.

The 2B24 design mainly differs from its predecessor in the length of the barrel. This innovation made it possible to significantly increase the maximum firing range; it is now equal to six kilometers. The 2B24 mortar can fire all available 82mm mines. In addition, during its development, a high-explosive fragmentation mine of increased power 3-O-26 was created.

Like the mortar of the 2S12A complex, the 2B24 has a new joint between the barrel and the base plate, which allows firing at targets in any direction, just by turning the barrel and rearranging the carriage supports. The permissible rate of fire of the gun increased to more than twenty rounds per minute. To ensure an acceptable temperature regime of the barrel and to avoid its deformation, there is a radiator fin on the breech.

Mortar 2B14 “Tray”

Being portable, the 2B24 mortar can be disassembled into three main units, which are packed into packs. One fighter carries the barrel, the second carries the base plate, and the third carries the two-legged carriage and sight. The fourth crew number carries a special backpack-pack for ammunition. Without any changes in design, the 2B24 mortar can be converted from portable to self-propelled. To do this, using a special mounting kit, the mortar is installed in the troop compartment of an MT-LB armored tractor. This complex was called 2K32 “Virgin”.

It is noteworthy that the 2F510-2 mounting kit allows you to quickly remove the mortar from it and use it in a portable version. The ammunition load of the 2K32 combat vehicle is 84 mines. Of particular interest is the 82mm 2B25 Gall mortar. First of all, attention is attracted by the dimensions of this weapon. With a significant caliber, when disassembled it fits into just one container. The Gall crew consists of two people, one of whom carries the mortar itself, and the second carries the ammunition for it. Despite its small size, the 2B25 can fire at targets at ranges from 100 to 1200 meters.

However, the most interesting element of the complex is the new 3BO35 fragmentation mine. The main innovation in its design is the original shank with a propellant charge. Inside the shank there is not only a charge, but also a cylindrical piston. Before firing, the mine is placed in the mortar barrel, after which the firing mechanism ignites the propellant charge. The powder gases, expanding, push the piston out of the shank, which, in turn, rests on the tile of the firing mechanism and throws the mine out of the barrel. Having reached the extreme position, the piston gets stuck inside the shank and does not allow the powder gases to escape, due to which the sound of a 2B25 shot is only a few quiet pops and clicks.

Mortar 2B25 "Gall"

The 2B25 Gall silent mortar was first presented last year at the MILEX-2011 exhibition in Minsk. At the same time it became known that serial production of the mortar had already begun. There is information about the continuation of work to improve the Galla in order to increase the firing range. However, even without any changes, the 2B25 mortar is the world's first serial silent mortar with a powder charge for throwing ammunition. Despite the fact that all the main nuances of the mortar design have long been invented and “polished”, the development of such systems still continues. The development of this area primarily concerns measures to improve the range and accuracy of fire, as well as lightening the design. The creation and use of adjustable ammunition is also considered a promising way to improve mortar systems.

As for special designs like the silent 2B25, this is rather a special tool for special units, but not a weapon for a mass army. At the same time, not enough time has passed since the beginning of the use of “Galla” (if any) and it is not yet possible to draw conclusions about the prospects of the entire direction.

Perhaps in the future mortars will be created that combine the combat qualities of the updated 2B11 and the silent 2B25, and these weapons will begin to be supplied to the troops in large quantities. These are just guesses for now, but what the mortar of the future will look like can only be said in a few years, when specialists from the Burevestnik Central Research Institute show their new developments.

Melee monsters: what modern mortars are capable of

A mortar is an artillery gun with a short (less than 15 caliber) barrel, designed for mounted firing. Its properties are indispensable in close confrontations with the enemy, when artillery support is required literally a few meters from their positions.

Modern mortars have the widest range of combat qualities. These include significant ammunition power, high rate of fire, and relatively low weight (for some models). And the simplicity of the device and use, along with constant readiness for work without special training, make it possible to teach the use of these weapons in a short time.

Alexey Egorov will tell you about the development of mortar weapons in the modern Russian army and what mortarmen can do in real combat in the next episode of the “Military Acceptance” program on the Zvezda TV channel. A field test of mortars of different calibers will be arranged, the most powerful of the modern domestic 120-mm mortars will be tested for accuracy, and a silent-firing mortar will be demonstrated. Viewers will also see a retro mortar - a mortar from the times of Peter I, which still not only shoots, but also hits targets.

Legacy of Peter the Great

In fact, the mortar guns that appeared under Peter I can be considered the prototype of the mortar. The name of the mortar comes from the French word meaning “mortar”, since this weapon turned out to be very similar in shape. The mortar could fire at enemy fortresses or field fortifications with mounted fire. But the Russian officer Leonid Gobyato is considered to be the inventor of the mortar itself.

During the defense of Port Arthur, being in the position of battery commander, he realized the capabilities of a mortar cannon to fire mounted fire at closely located enemy trenches. Later, the officer, together with a group of assistants, proposed a project for a mine with a stabilizer, and used naval gun barrels mounted on wheeled carriages, or even metal pipes attached to wooden blocks as a throwing apparatus for it. They became the prototype of the future new type of weapon.

The largest caliber of man-portable mortars in service with the modern Russian army is the 120mm 2B11. Its maximum firing range is 7.1 km. Knowing the coordinates of the aiming point and target, you can calculate the direction of the mortar and raise it to the desired height at the desired angle. Sights and protractors are designed for this: it is with their help that “shooting from closed firing positions” is ensured. The mortar is equipped with a plate that provides all-round firing without reinstalling the plate; it allows firing from hard and frozen soils without preparing a firing position. The time to occupy a firing position is 1.5-2 minutes for this 210-kilogram weapon, and fire can be fired at a speed of 15 rounds per minute.

"Burevestnik" mortar production

This powerful weapon is produced in Nizhny Novgorod, at the Burevestnik Central Research Institute. At one time, the enterprise was created by order of the Minister of Defense Industry of the USSR as the head structure for cannon artillery weapons of the Ground Forces and the Navy. Over 40 years of practical activity, the institute has carried out more than four hundred research and development work, manufactured and presented to the customer a number of samples of field artillery, as well as means of maintaining and supporting artillery weapons. Today, JSC Central Research Institute Burevestnik is part of the special equipment division of OJSC Research and Production Corporation Uralvagonzavod.

According to senior engineer of the military representative office Ivan Sychev, after assembling the mortar, pre-firing checks and post-firing stationary tests are carried out. And after passing the test at the stand, the mortar will be tested in real combat conditions. Each gun is tested with three shots for accuracy and accuracy. After firing tests, the mortar barrel is cleaned automatically to remove carbon deposits, after which the internal diameter of the barrel is measured. If everything is in order, the weapon is preserved, packaged and sent to the customer.

–

Today, Russian gunsmiths are working on a completely new and unique mortar model. This weapon is intended for special forces performing tasks behind enemy lines. The weight of such a weapon does not exceed 13 kg - and this is in the combat position together with the base plate! The design feature of the weapon lies not only in the fact that its plate is made of aluminum alloy, but also in the central location of the shock absorber, which gives greater stability when shooting. But the most important thing is that the mortar fires silent mines! In the long “tail” of such ammunition there is a piston that pushes the mine out of the barrel without making unnecessary sounds.

Motorized mortar

The speed of changing positions for mortar men is a matter of life and death. Based on the mine's flight path, the enemy can determine the place from which they are being fired at and return fire with fire. In order not to die, the mortar crew must change their deployment point every 6-10 shots. This speed can be achieved using ATVs.

A mortar with ammunition fits perfectly in the trunk of the latest military all-terrain vehicle, which will also cover any off-road terrain. Naturally, the use of such a mobile base implies small parameters of the weapon itself. But size does not affect its power. Created on the same Burevestnik, the 2B24 82-mm mortar fires at a range of up to six km, provides a rate of fire of 20 rounds per minute, and the transportable ammunition load can be 48 rounds. The crew of the gun is two servicemen who bring the mortar into firing position in 30 seconds. It remains to add the technical data of the all-terrain vehicle itself (its brand is PM 500 4x6). Maximum speed – 80 km/h, fuel range – 200 km.

As told at the Burevestnik Central Research Institute, not long ago a completely new modification of the mortar weighing 33 kilograms was tested here. The designers managed to achieve low weight through the use of new alloys. For example, the base plate of a classic 82-mm mortar weighs 16 kg, while the new one, made of titanium, weighs only nine. Such weapons are also suitable for transportation on an ATV.

These "Sleighs" drive themselves

The future of “mortar construction” lies in the creation of new ammunition. A new generation 82-mm mine has already been developed, which flies further, hits more accurately, and is more powerful in charge than standard ammunition. The new mine has the ability to regulate the firing range by using additional powder charges - “mounts”.

The capabilities of mortars to “illuminate” the battlefield are also in demand. For this, the same principle of mounted firing is extremely convenient: illumination mines are equipped with a time delay and, when falling, provide long-term illumination of a given area.

The mortarmen also have so-called smoke mines in their arsenal. The special chemical composition they contain creates smoke screens that deprive the enemy of the ability to navigate the terrain.

Today, modernized 2S12A “Sani” mortar systems are coming into service in formations and military units. As reported at the headquarters of the Ground Forces, supplies are being implemented within the framework of the State Defense Order in the interests of all military districts. The updated Sani mortars are transported by a new Ural transport vehicle of the Motovoz family with a high-power diesel engine and an electric winch for loading the mortar. This weapon has shown high effectiveness in the fight against illegal armed groups in mountainous areas. The new 120-mm mortar also received a new base plate with a hinge, allowing horizontal guidance without turning the heavy support.

Author: Dmitry Sergeev Photo of the Russian Ministry of Defense / JSC Central Research Institute Burevestnik

World of mobile mortars

The 81-mm Expal Eimos mortar system is installed on the rear platform of the vehicle;

it recently achieved its first commercial success with an unnamed country / Photo: militaryphotos.net Indirect fire remains a key element of the battlefield when events take a turn for the worse, its infantry support capabilities are vital as new rules of engagement rarely allow for preemptive fire from closed positions in order to “prepare a bridgehead.” The range of artillery systems is constantly increasing, surpassing the 40 km mark, not to mention the accuracy due to guided munitions and increased mobility due to installation on vehicles.

The disadvantage of these relatively new solutions is that there are few models available on the market, and their protection does not improve mobility. Additionally, since they are primarily deployed from forward operating bases, their range allows them to reach most of their area of responsibility, but the angle of engagement imposed by ballistics does not always allow them to cover targets located adjacent to natural and man-made terrain features, such as hills , buildings, etc. “And that’s where the mortars come in.” With a shorter range for indirect fire, these weapons are clearly the weapon of choice for close-in support of combat units. Not only can a mortar easily fire at high angles to cover close and hidden targets, but its on-target time is much faster than that of artillery unless the latter is working directly for the combat unit.

Mobile mortars, mounted on tracked or wheeled chassis, are lighter and more mobile than large-caliber artillery (with some exceptions of 105 mm guns), and medium caliber guns, such as 81 mm guns, can be easily mounted on the chassis of light armored vehicles, which naturally increases the level of logistics unification.

In Eastern Europe, self-propelled howitzer-mortars already existed during the Cold War, such as the wheeled 2S9 Nona-S or the tracked 2S31 Vienna, the latter purchased by Azerbaijan in 2013. In the West, Patria has developed two 120-mm turret systems, the double-barrel Amos, which is in service in Finland and Sweden, and the single-barrel Nemo. The Amos tower weighs about 4.5 tons, the Nemo tower is about a third of this weight.

Single-barrel turret mortar Nemo produced by the Finnish company Patria during combat training. The Amos double-barreled mortar is in service with Finland and Sweden / Photo: www.armyrecognition.com

As with most kinetic systems, the mortar these days also has strict accuracy requirements. Although its inherent characteristics make it susceptible to crosswinds (the higher the angle, the longer the trajectory, and the greater the altitude, the greater the wind effect), guided mortar munitions were eventually developed that also reduce the risk of consequential casualties. Comprehensive firing data provided by forward observers and even infantrymen using target acquisition systems of varying cost, weight and characteristics also helps improve the accuracy and effectiveness of mortars.

As for the calibers 120 mm and 81 mm, they, with their significant impact at the end of the trajectory, remain the “tone setters” in general units (smart ammunition is also available), while calibers 60 mm and less are mainly used by light infantry and special units for direct support with high-explosive fragmentation shells. Illuminated mines have also been widely used in recent combat missions, as they have a terrifying effect on opponents when they are hiding in the dark in open areas.

The Polish company Huta Stalowa Wola has developed the RAK 120 turret mortar system, chosen by Poland for installation on its Rosomak 8x8 vehicles, but also offered for installation on a tracked chassis / Photo: www.hsw

Tower solutions from Poland

By presenting its RAK 120 turret-mounted mortar system on the Marder tracked infantry fighting vehicle at the national defense exhibition in Kielce in September 2013, the Polish company Huta Stalowa Wola (HSW) clearly showed its readiness to vigorously promote it on the international market (currently Rheinmetall Defense's Marder on the secondary market market is attracting significant interest around the world). Although Poland recently selected this mortar and is due to receive the first eight systems mounted on the Rosomak chassis (Polish-built Patria AMV 8x8), few technical details have been disclosed by HSW at this time. The welded steel armor turret provides protection in accordance with the 1st level of NATO standard STANAG 4569 and is armed with a smooth-bore 120/25 mm breech-loading mortar. All drives are electric, vertical guidance angles range from +80° to -3°, the turret rotates 360° and, accordingly, the horizontal guidance angles are the same. The RAK 120 is equipped with an automatic loading system that allows it to achieve a rate of fire of 10 rounds per minute. Ready ammunition is placed in a 20-round magazine located in the rear niche of the turret. They are loaded manually by the crew through two holes in the rear of the turret from the ammunition located in the vehicle (40 of them are stored on the left side of the aft compartment). The RAK 120 mortar is fully automatic, so the vehicle can be operated by two people (driver and commander), the commander controls all functions from his seat via a human-machine interface.

The RAK 120 is equipped with an integrated operational control system and fire control system, as well as an INS/GPS navigation system integrated with an odometer. Firing can be carried out in a fully automatic mode, the data for firing is called up to the computer through the operational control system, the control system issues the coordinates of the target and the required number of ammunition for firing. However, the commander, using a joystick, can control vertical and horizontal angles and can perform a combat mission in semi-automatic mode, since the mortar has a reserve manual branch. In indirect fire mode, the RAK 120 can reach ranges of 8 km with standard projectiles and 12 km with extended range projectiles, and it is also capable of engaging targets at a distance of 500 meters when firing direct fire. Automatic loading and fire control systems allow you to fire in MRSI mode (simultaneous impact of several projectiles; the angle of the barrel changes and all projectiles fired over a certain time interval arrive at the target at the same time), which significantly increases the lethality of the system. A company of eight wheeled mortar systems, divided into four squads, was reportedly deployed. Each contains two Rosomak-RAK 120 complexes and one Rosomak command post; in addition, a reconnaissance section with four light armored vehicles, a supply section with a truck for transporting ammunition and a headquarters unit with two Rosomak command posts.

Rifled mortar from France

Based on the success of its 120 RT towed mortar (in service with France and many other countries, including the United States, where the French mortar is used as the basis of the Marine Corps fire support system), TDA, part of the Thales group, developed a self-loading version, designated 2R2M (then there is a Recoiling Rifled Mounted Mortar - a sliding rifled one mounted on a machine). The goal of this work was to ensure that wheeled tracked and wheeled vehicles weighing from 10 to 15 tons could fire a mortar without structural modifications to the vehicle. The 2R2M uses a rifled barrel from the 120 RT, which is integrated with a 300 mm stroke recoil hydraulic system that has an efficiency of more than 75 percent. The mortar has a mass of about 1500 kg, is installed on a rotating base, which rotates ±220°, the elevation angles range from 42° (in the stowed position with the roof hatches closed) to 85°. Vertical and horizontal guidance is carried out using a joystick; the system has a navigation unit and a fire control system that displays firing data on the commander and gunner displays. The semi-automatic loading mechanism allows you to fire from 6 to 10 minutes per minute. The amount of ammunition carried depends on the overall configuration of the vehicle, but is usually 40 rounds. They can be of two types: standard with a range of 8.1 km or rocket-propelled with a range of 13 km.

The Turkish company FNSS has developed several mortar transporters based on the M113 chassis, such as the ACV-15 and ACV-19. In the photo, a Saudi M113A4 vehicle with a 120-mm 2R2M rifled mortar from TDA is being tested / Photo: www.armyrecognition.com

The 2R2M became the basis for various development programs, including the US Marine Corps Dragon Fire I program. The French complex is currently being supplied to a number of foreign customers on various chassis. In a self-propelled configuration, the 2R2M can engage targets for one minute and then immediately leave the firing position. FNSS installed this system on its ACV-19 tracked chassis (modification M113A4), an unspecified number of which were delivered to Saudi Arabia and 8 vehicles were ordered by Malaysia. The second batch of 2R2M mortars is being manufactured for Malaysia; they will be installed on the AV-8 8x8 BMP mortar carrier variant developed by FNSS and Deftech (this combination is at the prototype stage). At the end of 2013, the Italian company Iveco Oto Melara Consortium produced the first batch of 12 Freccia 8x8 machines with 2R2M installed (the machine is in the very last stage of acceptance testing). The mortar was also supposed to be installed on the Dardo tracked infantry fighting vehicle, but, apparently, this program was stopped due to financial difficulties. The Sultanate of Oman purchased six systems that were installed on VAB wheeled armored vehicles from Renault Trucks Defense, while the Saudi Army installed an undisclosed number of systems on upgraded M113 armored personnel carriers. Not yet entered into service in its homeland of France, the 2R2M mortar system should be the weapon of choice for the Mepac mortar carrier variant of the Vеhicule Blindе MultiRoles (VBMR) machine, which will replace the VAB as part of the French Army's Scorpion program.

Spanish medium caliber self-propelled mortar

At the end of March 2014, the Spanish company Expal announced that it had received the first contract for its 81-mm Eimos (Expal Integrated Mortar System) mortar from an unnamed customer for an undisclosed number of vehicles, although in this case the Middle and Far East seem likely markets. According to the company, Eimos has been tested in four countries, one customer plus two considered potential customers plus a potential customer in the near future. The contract includes command and control systems and the Shepherd forward surveillance UAV.

The Eimos 81mm mortar is a "flexible platform" that significantly reduces recoil forces, allowing it to be mounted on lightweight Humvees, such as Urovesa's Vamtac 4x4 for the aforementioned first customer. The system consists of a long-range 81 mm Expal mortar coupled to a hydraulic recoil system with a maximum recoil stroke of 300 mm, which, according to the company, reduces recoil forces by 90 percent. Two electric motors carry out horizontal and vertical guidance, the data for firing is provided by the control system, this allows you to fire the first shot 10 seconds after setting the car on the handbrake.

In the past, the company offered Eimos with two levels of accuracy, but Expal is now only marketing the first-row variant with a GPS/INS navigation system that guarantees accuracy of less than two meters, with guidance accuracy improving from 4 minutes to 2 minutes in elevation and azimuth. The 81 mm mortar provides a maximum range of 6.9 km, but can be replaced by a 60 mm mortar in less than three minutes, the smaller caliber weapon has a range of 4.9 km. The mass of the entire system depends on the configuration, but remains less than 500 kg, the mass and recoil forces do not require any modification, or at least minimal modification to the vehicle’s suspension; The diameter of the base plate is 780 mm. In the basic 81-mm configuration installed on the Vamtac platform, the Eimos complex can transport up to 52 rounds in two stacks of 26 each on the right and left of the platform (see first photo of the article)

In order to simplify and reduce the cost of the system, loading is done manually; six finished projectiles are placed on a turntable. In order to reduce the sensor-to-shooter interval, Expal has developed Techfire (Technological Firepower), a computer system that collects data from existing assets (compatible with all communication systems). Three levels of computer control are available, the Elite Tablet and Elite Mini-Tablet, which can be used as ballistic computers on board mortar systems or as a platoon commander's computer for fire coordination. The small PDA can also be used as a forward surveillance computer or ballistic computer for lighter systems. Expal has also developed what it calls an “unmanned forward observer.” The minidrone with electric drives was named Shepherd (shepherd); its shape resembles a bird in order to attract less attention to itself. The device has a wingspan of 1.65 meters and a length of 0.85 meters, the body is made of Kevlar and epoxy resin, and its wings are three-piece. The Shepherd UAV has a maximum take-off weight of 2.8 kg and a flight duration of one hour with a flight range of 20 km. Its sensor package includes a high-precision CCD camera capable of operating at 0.01 lux illumination, although an optional thermal imager can be installed, either in place of the day camera or as an addition to it. The Shepherd's speed ranges from 30 to 42 knots, with a patrol speed of 32 knots at an altitude of 20 to 300 meters above the ground. The ceiling is 4000 meters and the maximum launch altitude is 2500 meters. Company sources confirmed that Expal is in talks with the Spanish military; this system is being considered not only by the ground forces, but also by the Spanish Marine Corps.

ATK received a contract for precision-guided munitions in 2010. Less than a year later, at the beginning of 2011, shells were delivered to Afghanistan / Photo: www.atk.com

USA: comprehensive development

In the United States, the military is looking to upgrade fixed-mounted mortars rather than vehicle-mounted models. They did a great job deploying nine Stryker Brigade Combat Teams, which received a total of 324 120mm Mistral RMS6-L systems mounted on General Dynamics M1129/M1252 Stryker mortar carriers. Elbit currently guarantees Mistral after-sales service. Elbit is the original manufacturer of the mortar after purchasing Soltam.

The XM-905 stationary mortar system came out like this: the RMS6-L was taken from Stryker armored personnel carriers and installed on a rotating platform. This mortar only has manual loading. It was used in Afghanistan by special forces to protect forward operating bases / Photo: www.pica.army.mil

A byproduct of this effort was the XM-905 mortar, a response to a "joint joint operational requirement" issued by the commander of Multinational Special Operations Task Force Afghanistan, which identified a gap in basic defense capabilities. In the XM-905 complex, the RMS6-L mortar is mounted on a round base plate with three openers and supports. The electric motor rotates the plate 360° for azimuth guidance, electric drives allow for elevation guidance; all drives are connected to the control system in order to minimize targeting time. Only loading remains manual; the operator’s position is located on a rotating plate. Mistral was awarded the contract in March 2013, and 20 systems were pre-deployed in Afghanistan by a dedicated technical team to protect forward bases. The entire complex was called the Automated Mortar Protection System (automatic protection system using mortars) and replaced the improved mortar target acquisition system I-Emtas (Improved Enhanced Mortar Target Acquisition System). The Emtas system itself was deployed in Afghanistan (10 systems) during Operation Enduring Freedom.

The Americans are also modernizing existing infantry mortar systems, mainly to reduce weight. Benet Labs, part of the Watervliet Arsenal, is currently working to improve the performance of the M120A1 heavy smoothbore mortar. A new bipod was developed in order to move the control system from the barrel to the bipod and reduce external influences and thereby increase accuracy. Also in development are a new base that provides better stability while reducing manufacturing costs, and a new barrel that can withstand higher pressures, allowing for longer range ammunition. All these improvements, carried out at the Watervliet plant, will increase accuracy by 25 percent and reduce weight by 16 percent. Full qualification of the modernized 120-mm mortar will be carried out in 2015. The lab is also working on medium and light mortars, although details have not yet been revealed. Work is also underway at the Picatinny Arsenal plant, where the lightweight 81-mm M252A1 mortar is being developed. This system will weigh 13 percent less than the original M252.

In order to increase the accuracy of the 60-mm mortar, especially when firing hand-held, the Americans developed a new fire control system, based on the control system for 40-mm grenade launchers / Photo: www2.l-3com

In the light mortar space, the US Marine Corps (USMC) is developing a new fire control unit for its 60mm mortar based on the Ballistic Sight Module Enhanced (BSMe) system originally developed by TechSolutions and L-3 Warrior systems for hand grenade launchers. The work is funded by the Naval Research Office and conducted by the USMC Experimental Center in collaboration with industry. The unit is attached to the top of the barrel and has a built-in red dot sight with automatic brightness adjustment for precise aiming in the daytime, built-in infrared lasers for guidance and illumination for precise targeting in low light conditions, and ballistic tables for different types of ammunition. The standard sighting unit, weighing less than 30 grams, has a maximum laser sighting range of 2000 meters. Specifications for the new variant are not available; although, it is possible that its sighting range can reach the maximum mortar range of 3500 meters. The new system provides much higher accuracy, especially when M224 or M224A1 mortars are used as hand-held systems. The tests were so successful that some prototypes were already deployed on theaters in December 2013. In addition, the M224 series mortars received a new thermally insulated strap to protect the user's hands, providing better portability. The problem associated with the clunking of the old sling mount was eliminated with the adoption of the new mount, thus reducing the risk of detecting the shooter's position by noise.

US troops received precision mortar bombs in the spring of 2011, when the XM395 munition was first deployed to Afghanistan. The new projectile was developed by ATK under the guidance of the Ammunition Program Execution Office as part of the APMI (Accelerated Precision Mortar Initiative) program. The XM395 is based on the body of the M9933/34 mine, in front there is a fuse with a high-precision guidance kit (taken from 155 mm artillery shells), an EPIAFS interface (Enhanced Portable Inductive Artillery Fuze Setter) and front control rudders that allow you to aim the projectile on target; while at the rear, folding stabilizers are installed to ensure stability in flight and an M47 combat charge. Target coordinates are loaded via the Precision Lightweight Universal Mortar Setter; The system at maximum range has a CEP of 10 meters. In April 2010, ATK was awarded a contract worth $13.8 million for 5,480 rounds. The first shells were delivered and deployed to units at the beginning of 2011. The contract also included 156 XM701 inductive fuze setters mated to the M32 Light Mortar Ballistic Computer. This ammunition was initially deployed only with the M120 towed smoothbore mortar, and in the spring of 2012 it was also cleared for use with M121 mortars on Stryker transporters.

An artistic representation of ATK's proposed solution for the US Marine Corps Precision Extended Range Munition program. In this application, ATK has teamed up with GD-OTS and TDA. Raytheon, together with the Israeli company IMI, is the second contender for the Precision Extended Range Munition application / Photo: www.shephardmedia.com

The US Marine Corps is currently studying the Perm, an extended range 120mm round for its Expeditionary Fire Support System based on the M327 rifled mortar. The threshold requirements for a mortar round are: range of 16 km, COE of 20 meters and lethality of 80 percent compared to the current M1101 high-explosive fragmentation mine. The actual characteristics are 20 km in range, CEP of 10 meters and the same lethality as the current high-explosive fragmentation mine. This can be achieved by controlling projectile fragmentation. Two teams are vying for this contract: ATK (the winner of the APMI program) in collaboration with General Dynamics Ordnance and Tactical Systems, and the second team is the French TDA with Raytheon in cooperation with the Israeli firm Israel Military Industries.

The ATK team's solution combines the company's fuze, already used in the XM395, with the "energy" subsystems of the company's extended-range rifled mortar from GD-OTS. TDA contributes its expertise in rifled mortars, while Raytheon is developing rear-folding cross-shaped wings located in the projectile body. According to Raytheon, the projectile will have a CEP of 5 meters at a maximum range of 16 km, but when controlled, it can be aimed at a target with a 5° offset in order to “deceive” enemy return fire. In September 2013, Raytheon announced the successful completion of the first two series of Guide to Hit tests. Tests confirmed that after launch, the nose rudders and tail stabilizers deployed and the projectile entered the stage of stable flight. They also confirmed that the projectile could have the expected range and impact angle. In the summer of 2014, both ATK and Raytheon will provide 42 rounds for evaluation firing as part of the demonstration phase of their initial Perm contract. Following completion of the demonstration by the end of 2015, the ILC will evaluate the results for compliance with the requirements. In 2016, the Corps is expected to issue a request for proposals for a full and open competitive acquisition program.

Several more developments are expected in the US; The Army Weapons Research Center's portfolio includes programs such as the 120 mm guided fragmentation mine, the precision 81 mm light force mortar, the automatic 81 mm direct/indirect fire mortar, and research into extended range munition technology.

Elbit recently acquired Soltam, whose 120-mm Cardom mortar system is installed on Stryker mortar carriers of the American army / Photo:

www .defense-update.com

Israel: cooperation around the world

Previously, in the context of American Army mortars, the Cardom self-propelled recoil mortar from Elbit Systems/Soltam was mentioned. This system weighs less than 700 kg and can accept an 81 mm mortar. It rotates 360 degrees, has a rate of fire of up to 16 rounds per minute at a maximum range of 7000 meters and can fire Multiple Round Simultaneous Impact.

In February 2014, Israel Military Industries announced that its GPS-guided GMM mortar round was being qualified by the Israeli Army. Fully compatible with existing 120-mm mortars, the GMM projectile can be fired at a range of 7 to 9 km, depending on the mortar, with a CEP of 0 to 10 meters at any range. Guidance is provided by nose wings mounted in the projectile body and a connection to the Pure Heart GPS/navigation control unit. A semi-active laser version of this projectile with a laser seeker in the nose could also be developed.

Israel Military Industry's 120mm Guided Mortar Munition guided mortar projectile and its programmable system. GMM is currently qualifying in the Israeli army / Photo: www.imi-israel.com

European trends

According to calculations of the German army, the 81-mm caliber is more effective when firing at infantry. This is based on the assumption that in a time interval more projectiles impact the target almost simultaneously, this increases the effect of surprise, and the target can be destroyed virtually within 20 seconds. Taking into account the impact of a high-explosive 60-mm mine, the 81-mm caliber has an efficiency coefficient of 2.4, and the 120-mm caliber has a coefficient of 7.7. This means that, given the total round weight, number of weapon systems, and system weight, the 81mm mortar wins the bet. This is one of the reasons why the Bundeswehr abandoned the 120mm in favor of the 81mm, a procurement program expected in the coming years. 120mm infantry mortars should remain in service until 2016. As for the single mortar system based on Wiesel-2, consisting of eight mortar transporters, two command posts and four Mungo ammunition transports, it should be transferred from the infantry to the artillery in 2015.

Another army moving to the 81mm only option is the British Army. After the Afghan company, it was decided to remove the 60-mm Hirtenberger mortars on a commando bipod from service in order to reduce costs; The obsolete L16A2 thus remains the only mortar in service with infantry units. Some improvements are due to be made to this mortar, although new upgraded ammunition with increased lethality against buildings, armor and materiel may become available in the near future.

Italy retains not only 120 mm mortars in service, but also introduces new 81 mm Expal M-86 or M-98 mortars. 120 mm mortars are assigned to the regiment level, 81 mm mortars provide the company with indirect fire support, leaving 60 mm weapons to the platoon level. At the end of 2011, Italy signed a contract worth 20 million euros with Expal, which provides for the supply of 371 mortars, an undisclosed number of ammunition of various variants and ballistic computers developed by Expace.

One of the armies went against the “81 mm trend.” The Dutch recently decided to replace their L16s with lighter 60mm mortars. The tender for the supply of 75 systems, including ammunition, will begin at the end of 2015.

At the Idex 2013 exhibition, the Singaporean Srams on board the RG31 vehicle was shown as part of the Agrab Mk1 mobile mortar system, created by the Emirati International Golden Group together with Denel / Photo: www. defesaglobal.wordpress.com

Light platform from Singapore

In 2007, Singapore Technologies received the first export order for its 120 mm Super Rapid Advanced Mortar System (Srams) smoothbore mortar. Deliveries will continue throughout 2014, although the number of systems and the customer remain unnamed. The mortar has a recoil force of only 26 tons when firing maximum power charges. Given this and its curb weight of less than 1200 kg, it can be installed on light Humvee class vehicles. The STK mortar has a semi-automatic loading system; it allows you to achieve a rate of fire of 10 rounds per minute. The Srams barrel length is 1800 mm, when firing extended range ammunition the maximum range is 9 km. The Singapore Army installed it on the Bronco tracked all-terrain vehicle, and the first export order was received in 2007.

Orders have not yet been received for the Bighorn mortar system from Ruag Defense, installed on the FNSS ACV300 vehicle / Photo: www.mdc.idv.tw

Although the Emirati company International Golden Group (IGG) has not confirmed this, it is likely that Srams should be the basis of the Agreb Mk1 system, a mobile complex based on the RG31 chassis from BAE Systems. At IDEX 2011, another order for 72 Agrab Mk2 complexes was announced. The main difference lies in the vehicle, the new version of the mobile mortars is based on the RG31 Mk6E MPV, while the previous version was based on the Mk5 vehicle. Agrab is equipped with an Arachnida fire control system from Denel Land Systems and a FIN3110 GPS/INS navigation system from Selex ES. The first ten Agrab Mk2s were installed on vehicles in South Africa, the remaining 62 mortar systems were installed at the IGG plant in the United Arab Emirates.

Armada International June/July 2014

– S. 16 – 26, translation by Vyacheslav Merzlyakova

Mortars and recoilless rifles | USSR

37-mm mortar-shovel Dyakonov. Model 1938

The 37 mm mortar-shovel is a hybrid of a small sapper shovel and a small-caliber mortar. The handle of the shovel was a mortar barrel 520 mm long, and the blade of the shovel played the role of a base plate and was made of armor steel. An additional support was used as a bipod, attached to the upper part of the mortar barrel. The mortar was equipped with fragmentation mines, which were carried by the shooter in a special bandoleer with shoulder straps. There were no sighting devices, so shooting was carried out by eye. The mortar was used throughout 1939-1942. Captured mortars served in Germany under the designation “3.7-cm Spatengranatwerfer 161(r)”. By the beginning of the war, at least 16 thousand mortars were in service. Mortar performance characteristics: caliber – 37 mm; weight – 2.4 kg; mortar mine weight – 500 g; maximum firing range – 250 m, minimum – 60 m; initial mine speed - 70 m/s; rate of fire – up to 30 rounds per minute; calculation – 1 person.

Company mortar model 1938/40/41.

50-mm company mortars mod. 1938, 1940 and 1941 They are a smooth-bore rigid system with an imaginary triangle diagram. The mortar was constantly improved in terms of weight reduction and firing safety, which was reflected by changes in its designation over the years. The ammunition consisted of a six-feather fragmentation steel mine and a four-feather fragmentation cast iron mine. The mortars captured by the Wehrmacht were used under the designation “5-cm Granatwerfer 205/1/2/3(r)”. A total of 166.3 thousand mortars were fired. Mortar performance characteristics: caliber – 50 mm; weight – 9 – 12 kg, length – 780 mm; barrel length – 553 mm; mine weight - 850 g; initial speed – 95 m/s; rate of fire - 32 rounds per minute; firing range – 100 – 800 m; calculation - 2 people.

82-mm battalion mortar combat crew

82-mm battalion mortar model 1936

82-mm battalion mortar model 1937

Mortar model 1936/37/41/43. was developed on the basis of the Stokes-Brandt mortar and put into service in 1936. Its design was made according to a rigid design (without recoil devices) and consisted of a barrel, a two-legged carriage, a base plate and sighting devices. To fire a shot, the mine was lowered with a stabilizer (tail) into the muzzle of the barrel. The 1937 model mortar differed from its predecessor in having a more rigid round base plate with a side cut. In addition, the design of the two-legged carriage was changed, in particular, the stroke of the shock absorber spring was increased and the sight mount was improved. The 1941 model mortar differed from previous models in its simplified manufacturing technology. The 1943 model mortar was a modernized version of the model. 1941 and featured a modified design of the biped, wheel and trailer mount. Mortars and ammunition were transported on horse-drawn carts or on vehicles available to the troops. In mountain rifle and cavalry units, mortars and ammunition were transported on horse-drawn packs. For short distances on the march (up to 10-15 km), as well as when changing firing positions, mortars and mines were carried by crews on special human packs. For firing from mortars of all types, six- and ten-feather fragmentation mines were used, as well as smoke and propaganda mines. A total of 168.3 thousand mortars were fired. Mortar performance characteristics: caliber – 82 mm; weight in combat position - 56 - 62.7 kg; mine weight - 3.6 kg; initial mine speed - 211 m/s; rate of fire - 25 rounds per minute; The minimum firing range is 100 m, the maximum is 3 km.

107-mm mountain pack mortar mod. 1938

The mortar was put into service in 1939, but serial production of mines for it was established only at the beginning of 1941. The mortar barrel consisted of a pipe and a screw-on breech. The shot was fired in two ways: by the action of the firing mechanism of the firing device, which was cocked after loading the mortar; hard self-piercing of the mine when lowering it into the bore. The biped is connected to the mortar barrel through a spring shock absorber. The base plate was a round stamped all-welded structure. The mortar had an unsprung wheel drive, consisting of a frame, two wheels and a box for spare parts. The mortar was transported in 13 packs. A total of 6.6 thousand mortars were fired. Mortar performance characteristics: caliber – 107 mm; trunk length – 1.7 m; ground clearance – 450 mm; weight in stowed position - 850 kg, in stowed position - 170 kg; projectile weight - 7.9 kg; rate of fire - 6-16 rounds per minute; initial mine speed - 156 - 302 m/s, minimum firing range - 700 m, maximum - 6.3 km; transportation speed on the highway is 40 km/h.

120-mm regimental mortar mod. 1938

120-mm regimental mortar mod. 1943

The mortar was developed on the basis of the French “120-mm Mle1935” (Brandt) and was produced since 1939. It had an attached wheel drive for towing by horses or a truck at a speed not exceeding 18 km/h when driving on cobblestones, and at speeds up to 35 km/h when driving on the highway. The shot was fired by piercing the capsule under the weight of the mine, or using a trigger mechanism - for safety purposes when firing powerful charges. The charge was placed in the shank of the mine; to increase the range, there were additional charges in fabric caps, manually attached to the shank. After the start of the war, the 1941 model was mass produced, simplified and without wheels and a front end. In 1943, the 1943 model mortar was adopted for service. The barrel design was simplified, which made it possible to replace a broken firing pin without disassembling the mortar. A double-loading safety device was installed on the muzzle. The mortar's ammunition included: high-explosive fragmentation, high-explosive, incendiary, smoke and illumination mines. During the war, 44.3 thousand mortars were fired. Mortar performance characteristics: caliber – 120 mm; weight – 280 kg; ground clearance - 370 mm; trunk length – 1.8 m; mine weight - 16 kg; initial speed – 272 m/s; firing range – 6 km; rate of fire - 15 rounds per minute; transition time from traveling to combat position - 2 - 3 minutes; transportation speed on the highway is 35 km/h.

Mortar model 1943 MT-13

The MT-13 mortar was put into service in 1944 and was a smooth-bore rigid system on a rigid (without recoil devices) carriage with a wheeled, sprung ride. The lifting and balancing mechanisms and sighting devices were mounted on the carriage. The problem of transporting the mortar was solved in a new way: it was attached to the tractor with a barrel on which a special pivot foot was attached. Loading was carried out from the breech, for which a swinging barrel was used, which was brought to a horizontal position at the time of loading.

Mortar MT-13

After opening the bolt, a tray was hung on the axle axis of the barrel wedge, onto which the crew laid the mine and manually sent it into the barrel bore.

After the mine was sent into the barrel, it returned to the firing position under the influence of its weight. This also automatically eliminated double charging. The main ammunition, a 12-point 160-mm high-explosive mine F-852, weighed 40.8 kg and contained 7.7 kg of explosives. The fundamental difference between the MT-13 mortar round and all other domestic mortars was the short sleeve into which the mine stabilizer was inserted. The sleeve was introduced to seal off the powder gases during firing. During the war, 798 mortars were fired. Mortar performance characteristics: caliber – 160 mm; trunk length – 3 m; weight – 1.2 t; initial speed – 140-245 m/s; mine weight - 41 kg; rate of fire - 10 rounds per minute; firing range: minimum – 630 m, maximum – 5 km; transportation speed on the highway is 50 km/h. Share to: