Maintenance of the air gun is carried out regularly: cleaning and lubrication of the main parts. Lack of care for the weapon will lead to malfunctions, and this is an extra expense for the owner. Even if you are not planning to shoot a pistol in the coming year, the appropriate procedures must be carried out at least once during the period.

We will tell you how to care for your pneumatic so that it “doesn’t misfire” and retains its original properties for as long as possible. Using the tips from our website will save air fans from unnecessary expenses on repairs.

Weapon storage

The weapon must be in perfect condition so as not to fail in battle. One of the important points in caring for air guns is its storage.

Need to store:

- away from people, especially children;

- in a case/box/case - they come complete with the weapon, and if not, they can be purchased separately;

- in a prone position - especially applies to rifles, because if you put a rifle in a corner there is a risk that sooner or later someone will bend it;

- not under the bathtub - well, weapons don’t like water;

- not on the balcony - and changing weather conditions;

- in a discharged state - especially applies to gas cylinders, which they like to store from game to game with an equipped cylinder, we also discharge the magazines, there is also no need for excess pressure on the spring.

Cleaning accessories

Cleaning accessories must be of high quality, because the result and operation of the weapon depend on them. There are ready-made kits on sale that include everything you need. You can buy accessories individually, in a single copy or in a set of several pieces.

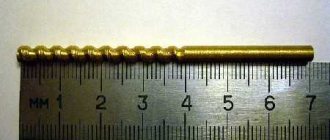

For cleaning you will need a cleaning rod, a metal brush and a powder puff. The remaining oil is removed with a brush; on the contrary, the barrel is lubricated with a cleaning rod. The puff is needed to dry the barrel. You will also need a clean cloth or napkins to wipe the parts of the gun.

The cleaning rod is selected according to size relative to the caliber of the gun. The puff requires replacement; after 20 uses it will no longer absorb moisture. The brush wears out and also needs to be changed periodically.

On-site inspection

Next comes the stage of checking the weapon on site: charging and test shots. Here the operations are different for air rifles and pistols. The main rule is that we act according to the weapon’s passport - everything should be described there: in what order is it correct to load, how to shoot, what to shoot with, etc. We read everything, while reading we ignore the point SHOOTING AT PEOPLE AND ANIMALS IS STRICTLY PROHIBITED. This inscription is apparently highlighted specifically for visually impaired people; hardball players, as a rule, are sighted people, so this rule can be circumvented. During the check, you can also carry out zeroing; with an “oblique” barrel, you will not be welcome on the team (unless on the enemy team).

Cleaning, lubrication and repair of pneumatics

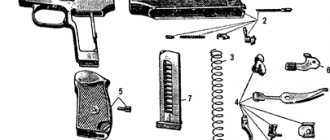

Partial disassembly of the pistol is carried out in accordance with the instructions. The process of cleaning a weapon and lubricating its parts takes place in 3 steps:

- Removing plaque, soot, and dirt.

Using a cleaning rod and a cotton cloth moistened with oil, wipe the barrel bore dry. Purpose: to remove galvanized (lead) plaque, carbon deposits, and other unwanted layers. - USM processing.

The trigger mechanism is lubricated with gun oil. Without disassembling (except if required), you need to apply a couple of drops to the moving parts. The procedure ends with blank shots. - Elimination of excess oil.

Use a cleaning rod to remove excess grease. You cannot wipe it dry, otherwise there will be no thin protective film that protects the metal from rust.

Complete disassembly is performed if the gun needs to be repaired.

Home prevention

After shooting, the following operations are carried out:

- basic manual disassembly (removal of magazine, muffler, stock, etc.) and wiping/cleaning;

- After a certain round (500-1500 shots, indicated in the weapon’s passport), it is necessary to clean and lubricate the barrel and trigger mechanism. Rifled barrels get more dirty than smooth barrels. The essence of cleaning is to work with a cleaning rod and a brush (do not kill the cuts), then wipe with something until it is completely clean, and at the end add a little oil (do not overdo it). For cleaning the USM, read the instructions. You may have to work with a screwdriver.

- Here we fix all the problems fixed during the game and send the weapon for storage.

Of course, caring for an air pistol and caring for an air rifle are different, but in general, operations can be carried out according to the proposed instructions, specifying the details for a specific weapon. Let's keep our pneumatics in order, so that they don't let us down in battle.

Cleaning process

Before starting work, the weapon must be inspected. Identify traces of rust, possible cracks on metal parts, loosening of screws, chips formed on the stock, damage to the sight devices. If the weapon is wet, remove the moisture with a napkin or absorbent cloth.

To be able to clean the gun, you need to partially disassemble it. Cleaning is done using special products containing kerosene. After applying the product, you need to clean everything with a brush. It removes lead deposits and makes surfaces smooth. Then use a cleaning rod to clean out dirt, tiny shavings and kerosene residues. You need to clean carefully, without making sudden movements, so that scratches do not remain on the surfaces. Use a powder puff and a rag to wipe all parts dry.

Storage and transportation of short barrels

Proper storage conditions for an air pistol will extend its service life, eliminate corrosion and leakage of gun lubricant from the barrel bore:

- Room.

Dry, with a stable positive temperature of no higher than 25 degrees. The room where the weapon will be stored must be darkened - do not allow direct sunlight to hit the device. Excessive humidity and temperature changes negatively affect the metal. - Gun position.

Pneumatics can be stored in 2 positions - vertical (muzzle up) and horizontal (on a flat surface). Leakage of weapon lubricant from the barrel is excluded. - Exception of galvanizing.

Short-barreled pneumatics cannot be stored in a firing position. It is worth making sure that there is no ball in the barrel. If you store a weapon with a loaded projectile for a long time, a zinc coating will form in the barrel bore. During repeated use, the cost of the shot may be failure of the product.

In order not to violate the Federal Law of the Russian Federation “On Weapons”, if the pistol has a power of more than 7.5 Joules, you will have to buy and install a gun safe.

The same applies to transportation issues. You can carry pneumatic guns to the shooting site only in a purse, case or case. The pistol must be unloaded. You cannot freely carry the device in your hands, especially in crowded places (events, public transport), much less shoot.

Carrying CO2 airguns in a personal vehicle is permitted. The unit must also be unloaded and in a bag, case or case in a visible place. In both cases, you need to have the product passport with you. A license, permit, sports passport or hunter's ticket will be required additionally if the power of the pistol exceeds 7.5 Joules.

Maintaining your gun keeps it in working condition for many years.

The procedure for cleaning and lubricating weapon parts prevents the formation of unwanted deposits and improves shooting results. October 19, 2022

What breakdowns most often have to be repaired?

The causes of pneumatic problems are individual. One owner fires many shots every day, another stores the weapon incorrectly, and a third does not carry out preventative cleaning on time. Dried seals and gaskets not only impair the operation of the gun, but completely disable the main working mechanisms.

The service center encounters the following problems every day:

- The gun doesn't fire. It is necessary to check the operation of the valve, the pressure injection system, and check the tightness when ready to fire.

- Impossible to hit target. Diagnostics will be required to determine the cause. Often it is enough to perform zeroing in a workshop.

- Can't insert bullet. If the ammunition is chosen correctly, the mechanism may become completely dirty and require cleaning.

- After the fall, the weapon stopped working. Without disassembly, the master will not be able to tell how to repair the weapon in this case.

- The trigger broke. The trigger mechanism was under excessive load, the weapon needs to be comprehensively diagnosed.

- The range and speed of the bullet have changed. In this case, the pneumatic gun will not hit the target, each time showing a different height of impact.

Despite the abundance of different breakdowns, it is not difficult to find the problem. To do this, the technician performs diagnostics, disassembles the device and inspects the main parts. Already at the stage of identifying the breakdown, it will be possible to find out the exact price of repair work. Owners often bring in old guns that are in full working order. They just need to be re-opened, lubricated and set up for further work.

How to lubricate an air rifle

What exactly should I lubricate with?

Can you tell me the name? I think I understand what you mean. But do you also need grease inside the “working” space? And in general, what is the composition and where can I buy it? Can you be more specific?

The most easily accessible is CV joint-4. It comes in small tubes at any auto parts kiosk. And at the gas station.

Do you have castor oil, would it work?

I don't find anything funny, I feel sorry for things. It’s good at least it’s not Weirauch in this case, for example. The question, of course, is the ability to self-learn, but what’s surprising is that in the information age, people can’t help but google it. Timan at one time also smeared Gama with sunflower, but then he had real problems with the Internet, and now he gets calls from all over the country about steering with rifles

Well, castor oil is not sunflower oil at all. The flash point is high, which allows it to be used in motors. The debate about synthetics or castor oil is still raging. Well, if the PPP compressor is sometimes lubricated with synthetics, castor oil is definitely no worse in this sense.

It may thicken over time, but I have never encountered it in such a way that it polymerizes like sunflower.

But CV joint-4 is better, yes.

I’m used to trusting this store and its employees, so I only read the instructions on the bottle by accident and at home. And there, in black and gold, firstly, “Do not use for lubricating electrical contacts,” and secondly, a whole ode about how great it is to lubricate various mechanisms with this oil. If the manufacturers themselves write this, it is not surprising that the consumer burns with silicone every now and then. I just don’t understand, but it’s not suitable for electrics, if it’s really silicone - the same silicone Liqui-Moly from the same store is taken for exactly this purpose and it says about wiring, and high-voltage, and not about low-voltage. Hez, maybe this is a vague warning against splashing onto sparking contacts due to the presence of butane in the aerosol.

Gosh, I beg you! How much does it cost to write the letters you need on the label? Necessary instead of unnecessary. The employee will do it for a fee. Without any conspiracies and economic comparisons between efforts and results.

yes, the very word “silicone” fascinates some, they also proudly say that they lubricated it with silicone and not some kind of shit

Strange. The main component is mineral oil. And it’s no good!?

quote: Originally written by gnom: But the rear belt of the piston must be lubricated with any grease, at least lithol.

To what extent is this a necessary condition for it to be consistent? Always (after preliminary complete removal, a little less than two cars, and degreasing, just in case), I usually took a domestic weapons-grade neutral (“Berkut” or something like that). I smeared the cuff along the edge, a little behind the piston, a little more on the spring, trigger and other mechanics. I didn't seem to notice any problems. For about three years, instead of the domestic neutral one, I’ve been using ballistol, and experimenting a little with Nanoprotect. Did I do something wrong?

Composition: 100ml. Vaseline oil + 25 ml. kerosene + 20 ml. turpentine.

I just bought the components yesterday.

Why do they need to smear the TRUNKS?

By “barrels” I meant weapons in general. quote: Originally posted by Non-Fuzzist: Kerosene and turpentine, as we understand, are not the best option for a model diesel engine, which is the PPP.

But diesel almost never happened. Only at the beginning, the first shots are 10. And this is with such and such a composition. Hmmm, a mystery though.

quote: Originally posted by Non-Fluffy: It is “poor” in lubricating properties. And over time it forms a film, i.e. it polymerizes. TO

You will need to thoroughly disassemble your Di to see what has polymerized there over the course of more than three years. So, with incomplete disassembly, everything seems to be fine. It seems that everything is blurred and there is no film.

quote: Originally posted by Non-Fuzzist: just above is an example with a photo of silicone aerosol lubricant

I'm not even talking about silicone. And everything seems to be clear with him.

At most BPPs, absolutely any oil is enough, even a simple industrial oil, which, by the way, is all sorts of “wood grouse”, “special weapons oil”, etc. But if you take rifles like Norika, Hatsan and others with idiotic cocking kinematics, it is better to use grease at the rear, because The conditions there are very, very harsh.

quote: . Just don’t want to smear something on the engine barrels. I don't know why.

It is worth remembering that motor oil manufacturers are international giant corporations, with billions of dollars in revenue, their own research institutes, unique technologies, and so on. It's not even funny to compare them with. All this “special” mixture that we are used to “smearing trunks” with is the cheapest, basic mineral oil, and even diluted with solvents for better fluidity.. Comparing it with motor oil is like a station cheburek with a Prague restaurant..

quote: Originally posted by gnom: It is worth remembering that motor oil manufacturers are international giant corporations, with billions in revenue, their own research institutes, unique technologies and so on.

I remember about their research institutes. And about their technology too. And also about their love for all kinds of additives, which raises some concerns. Because I'm not a chemist. quote: Originally posted by gnom: All this “special” mixture that we are used to “smearing trunks” with is the cheapest, basic mineral oil

Is it really as bad as it sounds?! But in theory there should be a minimum of any additional goodness in the oil.

quote: Originally posted by gnom: Comparing it with motor oil is like comparing a station cheburek with a Prague restaurant..

More like a station cheburek with McDonald's. The Prague restaurant does not have its own research institute, but McDonald's does.

And by the way, one more point. If we use motor synthetics to lubricate the compressor and CV joint-4 (mineral water with a lithium thickener) for the rear part of the piston, won’t we get the reaction that is notorious to many motorists at the output?

The main thing is that the oil requirements, for our purposes, allow us to choose from many options. For me personally, I’ll probably prefer the good old neutral (Since ballistol is no good. I really don’t understand why. Yeah, I’ll take it on faith. ). After all, before experimenting with ballistol, I used it for 20 years. ICHH no problems were observed. Well, I’ll buy Shrus-4 for difficult cases, of course. Well, maybe I’ll experiment a little with Nanoprotect. The truth is that working with him gives me two feelings. On the one hand, in the form of a spray - convenient. But some kind of “sticky” infection. After it, purely from tactile sensations, it is unpleasant to finger the mechanism. But these are purely my cockroaches.

The only thing left to figure out is what to do with the leather cuffs. Something tells me that their lubrication must be approached even more subtly. Yesterday I read a lot about this topic and re-lubricated my spring pistol with neutral. I don’t understand whether it’s a little more oil or something. Today (when more than 50 shots are fired) a white “fog” flies out of the barrel. I look down the barrel, but there doesn’t seem to be any smoke. I suspect that the problem lies in the properties of the cuff material. Namely, in the ability to absorb excess oil, and in the absence of a tight fit to the cylinder walls during the reverse stroke. When it was smeared with ballistol, only the first ten shots saw such crap. Or is it better not to bother with this leather at all, and to make a polymer cuff on the knees from something suitable?

Washing bullets

The service life of the weapon and the accuracy of the battle are also affected by the quality of the ballistic projectile used for firing. In order for the bullet to have a minimum negative impact on the barrel and lubrication at the moment of firing, you will need to use high-quality bullets. However, buying expensive foreign ammunition can be too expensive. Therefore, we recommend purchasing our domestic bullets, loved by many pneumatic gun owners for cheap, but at the same time washing them before use:

- Pour the entire box of bullets into a glass or plastic container and fill them with kerosene or diesel fuel. We leave them in this position for half an hour so that all the leaded deposits formed during the manufacturing and storage process are completely removed.

- We drain the oil products (reusing kerosene is not recommended), and then dry the bullets in the sun or in a warm room. If time is precious, then just as in the case of a rifle, we use a hairdryer.

- Place the bullets in a clean container and fill them with hot water. Add a small amount of dishwashing detergent or laundry soap. We thoroughly wash the bullets, stirring them in the solution by hand.

- We pour the soap solution into the sink, and place the bullets in an even layer on newspaper to dry naturally. After a few hours, the cartridges can be loaded into a clean, oiled rifle.

Clean bullets not only do not stick to your hands and do not leave a black residue, but also practically do not provoke the appearance of soot at the moment of firing. Thanks to this, the need for frequent maintenance of the rifle disappears, and its service life increases significantly.

Is it worth cleaning imported bullets? In fact, this procedure will never be superfluous. However, this only applies to simple ammunition, without any internal fillers or tips.