Less armor, more mobility

A gradual increase in the combat weight of new tanks is an absolutely normal and logical phenomenon. The mass increases, first of all, due to the strengthening of the armor, the thickness of which, for example, during the Second World War increased several times. However, there was a case during this war when the designers deliberately sacrificed armor. This happened with the Soviet KV-1s tank, the creation of which was largely a forced measure taken to solve serious problems with the reliability of the KV-1. This vehicle left a very noticeable mark on the history of Soviet tank building. The KV-1s appeared as a result of a certain change in the views of Soviet military leaders on the use of heavy tanks. Mobility began to play an increasingly important role. The new tank was created not only by lightening the design of the KV-1: it also contained new technical solutions. What is the history of the creation of the KV-1s

and why was his path to a major series so difficult?

Fighting excess weight

The problems of the KV-1 tank, which clearly manifested themselves at the beginning of 1942, were largely inherent in its design from the beginning. The fact is that a certain margin of safety in the chassis of any tank is limited. If during the modernization process, which makes the car heavier, you exceed it, then problems with reliability will be guaranteed. In the case of the KV-1, it is worth recalling that it was originally designed as a tank with a combat weight of 40 tons. The production tank of the 1940 model had a combat weight of 42.5–43 tons, and that was just the beginning. In 1941, its combat weight reached first 46 and then 47.5 tons.

The situation worsened when, in the fall of 1941, instead of welded towers, the Chelyabinsk Tractor Plant (ChTZ, later ChKZ) began to install cast towers. They were thicker than welded ones, and the tolerance level turned out to be such that cases of exceeding the established mass were not at all rare. Of course, this directly affected the combat weight of the KV-1, which reached 50 tons.

But such an excess of combat mass in the future could not be the last. The fact is that the Soviet military leaders considered the KV-1 tank, if not yesterday, then at least a temporary solution. Do not forget that since the spring of 1941, the KV-3 heavy tank became a priority, which, by the way, was also considered as a temporary solution. Instead, it was later planned to launch either the KV-4 or KV-5 into production. After the start of the Great Patriotic War, work on the KV-4 and KV-5 was stopped. As for the KV-3, its production was still supposed to be launched at ChKZ.

By the end of 1941, it became clear that these plans were clearly unrealistic, so a new idea emerged - by modernizing the KV-1 to a level close to the KV-3. The thickness of its armor was going to be increased to 120 mm in the frontal part (this thickness was indicated, in particular, when discussing the KV-7 assault tank). As a result, the tank became equal in protection to the KV-3. At the very end of 1941, work began on the U-12 85 mm artillery system. If successful, the Soviet Tiger should have been born; at least the protection, armament and weight characteristics of these tanks would have been very similar.

KV-1 No. 10033 during testing in February 1942. It turned out that installing a more powerful engine did not produce a noticeable positive effect. A more serious modernization of the machine was required

But the real history of the development of the KV-1 took a completely different scenario. The increase in combat weight led to the fact that the tank's mobility decreased significantly. And the changed situation on the fronts required not so much strengthening of protection as increased mobility. Complaints began to come from active units. This did not go unnoticed by the State Defense Committee (GKO). On the evening of January 24, 1942, during a telephone conversation between Stalin and Deputy People's Commissar of the Tank Industry I.M. Zaltsman raised the topic of the KV-1.

There were several ways to solve the problem of decreased mobility. To begin with, it was planned to increase the power of the V-2K engine to 700 horsepower. The solution is quite logical, but not sufficient. The decrease in mobility was also expressed in a decrease in the ability to overcome snow barriers, which was directly stated by the head of the Soviet state:

«The T-34 tank walks well in deep snow, like a swallow flies, the KV is bad.”

Stalin pointed out another way to solve the problem of mobility - reducing the combat weight of the KV-1.

First of all, ChKZ took the path of boosting the engine, while at the same time slightly altering the chassis. In February 1942, three KV-1 tanks entered testing. One of them, No. 25818, was serial and was used as a standard. The second, with serial number 6728, received drive wheels with a reduced number of teeth. In addition, the final drive gear ratios were changed. Finally, the tank with serial number 10033, in addition to changes similar to those of tank No. 6728, received a V-2KF engine, boosted to 650 hp, as well as a Nastenko pneumatic regulator.

Tests revealed that the tank with a boosted engine had the lowest average speed. Overheating of the engine became a constant companion of this tank; the changes made to its design could not improve the situation in any particular way. It turned out that simply boosting the engine did not provide any benefits. Based on the test results, changes to the chassis were approved (but they were never put into production). In addition, it was pointed out that the cooling system needs to be redesigned.

GKO Resolution No. 1331 of February 23, 1942, which was the first to help reduce the combat weight of the KV-1

In March 1942, another no less serious problem, which also had long-standing roots, fully manifested itself. The initial KV project offered 3 transmission options, with the mock-up committee choosing a 3-speed planetary transmission developed by students of the Military Academy of Mechanization and Motorization (VAMM). Two options with a manual gearbox were considered as backup. From the boxes developed by Shashmurin and Alekseev, they chose the second one; it was this option that was realized in metal, and then put into production. Alekseev’s checkpoint was based on the proposal of N.L. Dukhov, which, in turn, was a development of the design of the gearbox of the heavy tank SMK-1. As for the planetary transmission, it has always found itself in promising projects. Also, modernized manual gearboxes, which were tested, for example, on the T-220 tank, were also transferred to the future. Worked on new models of checkpoint N.F. Shashmurin.

As for the KV-1, problems with its gearbox began during testing of the first prototype. During the run on September 25, 1939, the tank overcame a ravine, after which noise appeared in the gearbox, the cause of which was damage to a tooth on the idler gear and a bent reverse shaft. The box made itself felt during factory tests in November 1939, and problems with the on-board clutches were added to this. Problems with the gearbox were revealed one after another: during factory tests of the U-7 tank in August 1940, more than a dozen gearbox defects were recorded.

In addition to the increase in the mass of the tank, in the fall of 1941 there were additional problems associated with the evacuation of enterprises and the transition to simplified manufacturing technologies for individual components and parts. For example, since October 1941, the design of the clutches was simplified: ferodo linings were removed from their working surface. The result has become more frequent cases of friction clutches overheating, metal deposits on the working surfaces and failure of the entire mechanism. The quality of manufacturing of gearboxes has also decreased, which has further impacted reliability.

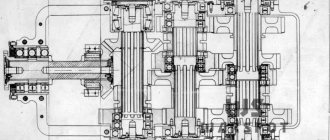

Gearbox “group 21–212”, developed by N.F. Shashmurin. It became one of the most important elements of the future KV-1s

The investigation into gearboxes began at ChKZ back in January 1942. Thunder struck at the very beginning of March 1942. For various reasons, 22 KV-1 tanks from the armored formations of the Crimean Front failed. The incident became known for the reason that the Deputy People's Commissar of Defense, Army Commissar 1st Rank L.Z. personally intervened in the matter. Mehlis. Lev Zakharovich demanded that new checkpoints be urgently sent for repairs, and also that Zh.Ya be sent to the front. Kotina. On March 6, a meeting of military representatives was held dedicated to the operation, repair and identification of defective vehicles. During the meeting, a truly shocking figure was announced - the share of gearboxes with defects reached 40%!

Even before the start of this trial, GKO resolution No. 1331 of February 23, 1942 was issued, according to which the weight of the KV-1 should be reduced by 1.3 tons. On the same day, GKO decree No. 1332 was issued, according to which, from April 1, 1942, the thickness of the walls of the cast tower was reduced to 90–100 mm. Further reduction in weight was also provided for by GKO Decree No. 1334, according to which the weight of the KV-1 was to be reduced to 45 - 45.5 tons by reducing the thickness of the armor. It was also planned to increase the power of tank engines, among which, by the way, there was also a high percentage of defective ones, to 650 hp.

Scheme of operation of the checkpoint “group 21–212”

But in the current situation, even all these measures were clearly not enough. On March 20, 1942, GKO decree No. 1472 was issued, which obligated to improve the quality of engines and gearboxes installed on the KV-1. At the same time, the question of modernizing the gearbox and creating new models was raised. In fact, only the item on improving the quality of gearboxes and engines was completed, but work on new models was slow. The first 8-speed gearboxes entered testing in April 1942, but their introduction into production tanks was delayed.

The acceleration of work on new checkpoints began only after a meeting with the participation of Stalin, which took place on June 5, 1942. This meeting became, in its way, the starting point for the transition from KV-1 to KV-1s. The first tank with this index, the same one on which the 8-speed gearbox was tested, was first tested in April 1942. At the same time, it differed not in its lightweight design, but in its more powerful engine. Now the ChKZ team was faced with the task of creating a deeply modernized KV-1, which was supposed to become more reliable, faster, but lose the main trump card of a heavy tank - powerful armor. The results of the meeting were formalized in the form of GKO Resolution No. 1878 “On the improvement of KV tanks,” signed on June 5, 1942.

Relief with modernization

Changes in the design of the new tank were not limited to just lightening the design and introducing a new gearbox. There are many other complaints about the KV-1. One of the significant disadvantages of the KV-1 was the operation of the cooling system. It constantly overheated, which affected the average speed of the tank. The viewing devices in the turret had an insufficient level of visibility, and there were especially many complaints about the commander’s position. It should be noted that the problem of visibility from the KV-1 commander’s seat began to be solved at the beginning of 1941. When designing the experimental heavy tank T-150, it was planned to install a commander's cupola, and it was also supposed to be installed on the heavy tank T-222 (modernization of the KV-1). For a number of reasons, the commander's cupola never appeared on the KV-1, and now the opportunity has arisen to introduce it as part of a more serious overall modernization.

Upgraded radiators, thanks to which it was possible to establish normal temperature conditions for the engine

One of the most important components of the modernized tank was the 8-speed gearbox. To be on the safe side, in the spring of 1942, two gearbox options were developed. The checkpoint “group 12–21” was created by engineer Marishkin. The gearbox along with the V-2KF engine was installed on a tank with serial number 10279, which was officially called KV-1s. In fact, it was an ordinary KV-1, modernized accordingly. The tank was equipped with water radiators of the KV-3 type, and an oil radiator from the R-ZET aircraft. The second checkpoint, known as “group 21–212,” was developed by N.F. Shashmurin. This gearbox was installed on the second sample KV-1s No. 10334. It had a standard cooling system with additional water radiators, and the oil radiator was similarly redesigned.

Tests began on the 20th of April 1942. By that time, experimental work was carried out by a specially organized plant No. 100. Based on the test results, it turned out that the “group 21–212” gearbox designed by Shashmurin was more reliable, and it was this that was chosen. The design of the gearbox was finally approved in mid-June 1942.

A stamp from a drawing of the KV-1s hull, which clearly shows the time when work on the vehicle began. The signature in the “senior machine engineer” column belongs to M.F. Balzhi, who led work on a number of Soviet heavy tanks

In addition to the new gearbox, the tank received a new main clutch with four ferodo discs, gearbox control drives, a fan, and a Vortox air filter (introduced on the KV-1 of the last editions), later replaced by a more efficient Cyclone. Separately, it is worth mentioning the redesigned cooling system. To test it, tests were carried out in Tashkent in July 1942. A new cooling system, which included new plate radiators, as well as a fan with stamped blades and a number of improvements, was installed in KV-1 No. 10663. Based on the results of the tests, in which three tanks with different cooling systems took part, it was tank 10663 that proved itself to be the best. However, with one significant caveat - although it was the last to boil, it also boiled. This happened after 7–15 minutes when driving in 4th gear. When operating in other modes, the temperature was normal.

KV-1s hull design. In general, it repeated the configuration of the KV-1, but had a number of changes

In parallel with the testing of the modernized units, the development of the tank itself continued, which, like the experimental April vehicles, received the designation KV-1s. According to GKO decree No. 1878, the combat weight of the tank was reduced to 42.5 tons. M.F. was appointed senior engineer of the machine. Balzhi, led the topic by N.L. Dukhov, the general management of the project was carried out by Zh.Ya. Kotin. L.E. also worked on the tank. Sychev, G.A. Mikhailov, A.N. Sternin, G.A. Seregin, A.N. Baran and a number of other SKB-2 engineers. The engineers of plant No. 100 A.S. were directly involved in the tank. Ermolaev and N.M. Sinev, I.A. provided great help. Blagonravov, a teacher at the Military Academy of Mechanization and Motorization, who worked on the topic of tank transmissions.

KV-1s turret diagram. It had many similarities with both the KV-13 turret and the T-34 turret

The day after the GKO resolution was signed, development of the KV-1s hull began. Preliminary work was completed by mid-June, and final approval took place at the end of July. In general, the hull design turned out to be similar to the KV-1 hull design, but there were also changes. For starters, the thickness of the armor has noticeably decreased. The screens in the frontal part of the hull were abandoned, and the thickness of the lower frontal sheet was reduced to 60 mm. The thickness of the sides and stern of the hull was reduced to the same thickness. A small gain in weight was achieved by bevelling the roof of the transmission compartment.

The KV-1s became the second Soviet tank after the T-50 to receive a commander's cupola.

The tower has undergone much more changes. Here it is more correct to say that it was built practically from scratch. It turned out to have little in common with the previous design. The new turret turned out to be much more similar to the one that was designed in the spring of 1942 for the promising KV-13 heavy tank. The senior engineer of this machine, the design of which began in March, was N.V. Zeits. This tank is often classified as a medium tank, but from the very beginning it was designed as a heavy one. There are certain nuances with its name: as the KV-13 it passed through SKB-2, but at plant No. 100 it was called IS-1. The first preliminary developments for the KV-13 were ready by June 1942, work on the project was approved, but due to the urgency of the KV-1s program, the development of the KV-13 slowed down.

However, the turret developed for the KV-13 (in turn, created under the influence of the T-34 turret) formed the basis for the turret for the KV-1s. Of course, it had to be greatly altered, since the KV-13 turret was a two-man turret. However, the general concept of the tower fit perfectly into the requirements described in GKO Decree No. 1878.

Visibility diagram of the KV-1s. There were some problems with blind spots in the frontal area, but at the same time, compared to the KV-1, visibility improved noticeably

A more rational form made it possible to reduce the dimensions, compared to the KV-1 turret, while maintaining sufficient internal volume. As required by the task, a commander's cupola was installed in the tower. The commander's position was moved to the rear left corner of the turret, and the installation of the rear machine gun was also moved there. One significant drawback migrated from the KV-1 turret to the new one - it had only one hatch. There was no hatch in the commander's cupola; it was a strange solution, but these were the types of designs that were developed for Soviet tanks in 1941–42.

KV-1s chassis No. 15002, lightweight support rollers are clearly visible

The deadlines specified in the GKO resolution were only partially met. By July 27, two prototypes of the KV-1s were manufactured, with serial numbers 15001 and 15002. The timing was greatly influenced by GKO Decree No. 1958 of July 3, 1942. According to him, production of the T-34 was organized at ChKZ in August. As a result, it was necessary to abandon not only plans for the production of the S-10 tractor, but also to significantly slow down the KV-1s and KV-13 programs. Due to the launch of the T-34, which was much needed by the troops, the production of the KV-1 was greatly reduced. There were even prerequisites for the complete removal of the KV-1 from production for the sake of the T-34, but things did not come to such a radical measure.

Tracks with a width of 608 mm, which were developed for the KV-1s

Another major difference between the KV-1s and the KV-1 was the chassis. Its change was also partly prescribed in the GKO resolution. For the lightweight tank, a new 608 mm wide track with characteristic “bevels” was developed. The engineers of SKB-2 and plant No. 100 did not stop there: they redesigned the balancers, support rollers, sloths, and a new lightweight design support roller was designed.

KV-1s with serial number 15004 during comparative tests while driving along the swampy shore of Lake Sineglazovo near Chelyabinsk. August 1942

There were certain concerns regarding the reliability of the new chassis, especially the tracks. For this reason, tanks 15001 and 15002 were slightly different from each other. Externally, these tanks can be distinguished by the fastening of the handrails on the turret: on the 15001 they were welded to the roof, and on the 15002 to the sides. Initially, however, there was one more difference: while the 15002 tank was equipped with tracks with narrow tracks, the 15001 had regular tracks with a width of 700 mm, which were used on the KV-1. The difference in weight between the complete set of old and new tracks was 200 kilograms.

In August, cross-country ability tests were carried out on the swampy shore of Lake Sineglazovo, located 18 kilometers from Chelyabinsk. They included the KV-1s 15001 with a wide track, the KV-1s 15004 with a narrow track, the KV-1 10033 with a wide track and the KV-1 11021 with a narrow track. The KV-1s 15004 covered the distance the fastest. Despite the fact that additional tests were required, the decision in favor of narrow tracks was made.

KV-1s 15001 after replacing the caterpillar tracks with “narrow” tracks. The main difference is clearly visible - handrails welded to the roof of the tower

The main load during the tests fell on the second prototype, 15002. This should not be surprising, since it was the second prototype that fully corresponded to the KV-1S, which was supposed to be launched into series. The first prototype also did not stand idle: after testing the tracks for cross-country ability, the vehicle was “changed” to 608 mm wide tracks, after which various elements were also tested on it.

The same tank is on the back left. The design of the installation of the rear machine gun in the turret is clearly visible

The first stage of field tests of the KV-1s 15002 took place on July 28, 1942. During its course, the car reached an average speed of 22.5 km/h. Sea trials on the highway continued until August 5, during which time the car covered 761 kilometers along the Ufa Highway. On August 26, tests were carried out at maximum speed, during which time another 40 kilometers were covered. The tank reached speeds of up to 43 km/h, which was quite a decent figure for a combat vehicle weighing 42.5 tons. Fuel consumption was 250–280 liters per 100 kilometers.

Much more important was another indicator - reliability. On August 4, the tank completed a 200-kilometer march, during which not a single malfunction was recorded. The day before, minor problems with the clutches were discovered, which were quickly corrected at the factory.

KV-1s 15002 during factory tests, end of July 1942

No less important were the tests on the Chudinovsky tract, during which the tank covered 553 kilometers. On August 9, the KV-1s covered 300 kilometers along a country road at an average speed of 20 km/h, and this was the signal that the car could be put into mass production. When driving on a country road, the tank consumed, depending on conditions, 200–350 liters of fuel per 100 kilometers. The tank traveled another 673 kilometers through the swampy area near Lake Sineglazovo, consuming 300–350 liters per 100 kilometers and showing an average speed of 15.5 km/h. The gearbox and cooling system worked fine. Thus, the reliability requirements were met.

KV-1s 15001 during testing, winter 1942–43. A new caterpillar track with tracks 650 mm wide is being tested on the tank. New tow hooks are clearly visible; they later appeared on 15002

The shooting was also quite successful. During tests of the gun's rate of fire, the crew donned movement-restricting winter clothing, and even with this, they managed to achieve a rate of fire of 6 rounds per minute. Thus, the reduction in the size of the turret did not affect the convenience of working in the fighting compartment.

KV-1s 15002 during warranty tests, winter 1943. The tank has new caterpillar tracks and upgraded road wheels

At the end of the tests, both prototypes of the KV-1s became a kind of running test benches. Various components and assemblies were tested on the tanks, in particular, new tracks and modernized road wheels. The most turbulent was the fate of tank 15002, which later turned first into the first prototype of the KV-85, and then into the experimental KV-122 tank. This car has survived to this day and now stands on a pedestal in Avtovo in St. Petersburg.

Metamorphoses of a difficult period

Putting the KV-1s into serial production turned out to be a very difficult task. Zaltsman, who was appointed to the post of People's Commissar of the Tank Industry instead of V.A. Malyshev, received the priority task of urgently launching serial production of the T-34 at ChKZ. Malyshev was removed from his post precisely for disrupting plans to produce the T-34 at tank factories. After this, is it any wonder that Isaac Moiseevich set the task of producing the T-34 at ChKZ above the interests of the “native” tank for his plant. Despite this, by the 20th of August, assembly of the first KV-1s began. Thus, the GKO requirement to switch to “HF with commander’s cupolas” by September 1 was fulfilled.

Assembly of the KV-1s at ChKZ, September 1942. It is clearly visible that the tanks have road wheels from the KV-1, and there are no handrails on their hulls and turrets

The very first production KV-1s almost completely copied the 15002 tank, with the exception of those points that needed to be corrected based on the test results. However, these tanks were still different inside. The fact is that, according to GKO decree No. 1878, the first 25 KV-1s were supposed to be produced with 5-speed gearboxes. In fact, at least 39 of them were built (this number also includes several KV-1s). Externally, these tanks are indistinguishable from cars with 8-speed gearboxes.

But from the end of August, cars began to roll off the assembly line that were clearly different from the second prototype. Due to the high percentage of casting defects, ChKZ was forced to install rollers from the KV-1 on the KV-1s instead of lightweight road wheels. This raised the combat weight by 390 kilograms. Malyshev, who remained in the State Defense Committee after his demotion, was informed about this on August 19 from the Main Automotive and Armored Directorate of the Red Army (GABTU KA). In addition, as of September, handrails were no longer installed on tanks. In total, 34 KV-1s were produced in August, and 176 in September.

The support roller, which was developed in August-September 1942 on the basis of the KV-13 support roller. Due to problems with quality and durability, it did not last long in the series.

Problems with the road wheels forced SKB-2 to develop road wheels of a different design. They didn’t invent a bicycle: the support roller developed for the KV-13 was taken as a basis. Despite the fact that work on the KV-13 was officially frozen, in fact, individual components of the promising tank not only continued to be designed, but were even tested. Just in July-August 1942, KV-13 rollers were tested on one of the KV-1s. Having redesigned the support roller, they began installing it on the KV-1S in the fall of 1942.

Text of GKO resolution No. 2420, which legalized the production of KV-1s with KV-1 hulls

Much bigger troubles began in the fall of 1942. They were also associated with the production of the T-34. By October, the Ural Heavy Engineering Plant (UZTM), one of two suppliers of hulls and turrets for the KV, was completely reoriented to hull production for the T-34. As a result, plant No. 200 remained the only supplier of HF housings, which could not quickly cope with the sharply increased load. The available reserve of hulls for the KV-1 helped us get out of this situation.

One of the KV-1s with the body of the KV-1. Tank from the 9th Guards Heavy Tank Regiment, spring 1943

On October 15, 1942, Molotov signed GKO Resolution No. 2420, which legalized the production of one hundred KV-1s with hulls from the KV-1. Such tanks were manufactured from the second half of October to the beginning of November 1942. In reality, less than a hundred such “centaurs” were produced: ChKZ was well aware that the increased combat weight would negatively affect reliability, so at the first opportunity they were replaced with KV-1s hulls. A total of 70 KV-1s with hulls from the KV-1 were produced, which were sent to the 9th, 10th and 12th Guards Heavy Tank Regiments, as well as to the Ulyanovsk Tank School.

A damaged KV-1s with a KV-1 hull, northwestern front, February 1943. Most likely the tank is from the 12th Guards Heavy Tank Regiment

Despite the fact that the number of KV-1s with KV-1 hulls was small, they did not disappear without a trace. These tanks were captured both by Soviet photojournalists and in photographs of German soldiers. One of these tanks, presumably from the 12th Guards Heavy Tank Regiment, has survived to this day. This car sank in early 1943. In 1998, a tank raised from a swamp was installed on a pedestal in the village of Parfino, Staro-Russian district, Novgorod region. It has the same road wheels that were developed on the basis of the KV-1s rollers. The car also has early tracks with “beveled” edges. The very first version of the KV-1s road wheel has also survived to this day. It can be seen on KV-1 No. 43666, which is on display at the Central Museum of the Armed Forces of the Russian Federation.

The author thanks Sergei Oreshin (Moscow) and Igor Zheltov (Moscow) for their assistance in preparing this material.

Sources:

- Materials of RGAE;

- Materials of TsAMO RF;

- Materials of RGASPI;

- Materials from the archive of Sergei Oreshin;

- ChTZ museum archive materials;

- Materials from the archive of Gennady Malyshev;

- Photo archive of the author

Tank design and protection

Some experts consider the KV-1 tank to be a milestone in world tank building, because some technical discoveries were subsequently used in many other models. These are a diesel engine, projectile-proof armor, individual torsion bar suspension, division of the armored hull into sections: combat, control and engine-transmission.

The tank crew is more protected in such conditions. The driver and gunner-radio operator are located in the control compartment, the remaining crew members are in the combat compartment, both of them are separated from the engine compartment.

The armor protection of the hull and turret - welded armor plates with a thickness of 80, 40, 30, 20 mm - withstood hits of 37 and 50 mm from standard Wehrmacht anti-tank guns. It was not always sufficient for protection against larger calibers - the German 88 mm Flak 18/36 anti-aircraft gun became one of the main means of combating this Soviet tank.

KV-7 – three-gun version of the KV-1

Its design was original, but obviously unsuccessful. It was planned to install three 76-mm ZiS-5 cannons in the tank's turret. But with this installation, the tower could no longer rotate. The result was not a classic tank, but a self-propelled artillery mount - self-propelled guns.

However, in practice this idea was not realized either. It was decided to leave one 76-mm cannon and additionally install two 45-mm 20K cannons.

Six crew members were required to control and fire a self-propelled gun with three guns. Prototypes were assembled that showed good results during factory tests. But the military rejected the vehicle because they did not understand why self-propelled guns needed three guns aimed at one point at once.

By the way, some armies around the world are now armed with self-propelled guns with coaxial guns. Even in our country it was planned to make the Coalition self-propelled guns double-barreled.

KV-8 became a flamethrower

In parallel with the work on the KV-7, the KV-8 flamethrower tank was being finalized, work on which began even before the start of the war - in the spring of 1941. It was planned to install the ATO-41 system as a flamethrower. The flamethrowing range with a standard mixture of fuel oil and kerosene was 60-70 meters, and with a viscous mixture - up to 110 meters. The weapon could fire both single shots and bursts of 4-5 volleys every 3 seconds, the one-time consumption of the mixture was approximately 10 liters.

“Katyusha”: The main secrets of the legendary weapon of Victory

However, the ATO-41 system did not fit into the KV-1 turret - the dimensions of the 76-mm F-32 gun got in the way. It was decided to replace it with a more compact 45 mm gun. To hide the weakness of the new gun from the enemy, a decorative casing-pipe was put on the gun, which created the appearance of a 76-mm caliber gun.

As a result, the KV-8 was able to accommodate the ATO-41 flamethrower, the ammunition of which included 107 ignition cartridges and 5 tanks with a combustible mixture - 2 in the turret, 1 in the fighting compartment and 2 in the transmission compartment. The total volume of the tanks was 960 liters. The car had to be serviced by a crew of four people.

In 1942, a significantly improved model of the flamethrower appeared - “ATO-42”. They also began to install it on a more advanced and faster modification - the KV-1S. Flamethrower tanks entered service.

A total of 102 KV-8 tanks and 25 KV-8S tanks were produced during the war years. These vehicles performed well in various battles. Including in the battle for Stalingrad. Flamethrower tanks did not become widespread, but they made their contribution to the overall Victory. In addition, at that time no army had such combat vehicles created on the basis of heavy tanks.

Heavy tank KV-1. The birth of a heavyweight.

Initially, design work on projects for new heavy-class vehicles took place within the framework of the multi-turret tank concept. The situation changed after the arrival of the head of the design bureau. Kirov, who at that time was engaged in the design of the two-turret heavy tank SMK, a group of graduates of VAAM named after. Stalin for pre-graduation practice.

They were entrusted with the design of a heavy single-turret breakthrough tank, with armament similar to the SMK, but of less weight. A. Eromolaev and L. Sychov were appointed heads of the diploma project. Under their general guidance, the graduates completed the project at a fairly high level. This gave the plant director the opportunity at a meeting of the Defense Committee to propose the production of a prototype of a single-turret tank for testing.

I. Zaltsman’s proposal was supported and on 02.27.39, the Defense Committee approved the technical specifications for the new single-turret heavy tank. The abandonment of the two-turret design made it possible to reduce the overall length of the tank, and due to the freed up mass reserve, increase its armor to seventy-five millimeters, which made it invulnerable to the 75-mm BS. The new tank was assigned the KV index (Klim Voroshilov).

The power plant of the KV heavy tank was designed in versions using the V-2F diesel engine (600 hp) and the M-17F carburetor engine with a power of 660 hp. Two copies of the gearbox were also provided. A planetary gearbox similar to that installed in the Skoda light tank (the components and mechanisms of which were unauthorizedly studied during its display in the USSR) and a conventional one, similar to the gearbox of the T-28 tank.

Armament: 76-mm and 45-mm cannons, a heavy-caliber DK machine gun and two rifle-caliber diesel engines. N. Dukhov was appointed responsible for the project. At the design stage, it was decided to abandon the installation of a carburetor engine and a planetary gearbox. They also abandoned the installation of a heavy machine gun in the turret.

The prototype of the KV tank was completed on August 31, 1939, and in September the tank entered in-plant testing. After eliminating the discovered design flaws, on September 5 the KV heavy tank went to Kubinka, where it participated in a joint display of samples of military equipment.

After returning to the plant, the second stage of in-plant testing began. At the end of 1939, the KV's mileage was 485 km, of which 230 km on the highway and 125 km on the country road. During the tests, 20 different engine and transmission defects were identified. Immediately after the start of the Finnish War, a prototype of the KV heavy tank was sent for front-line testing as part of a heavy tank company. In addition to the KV, the company included experimental SMK and T-100 vehicles. The Finnish PTA was unable to cope with the KV's armor. The day after the baptism of fire, the head of the Council of People's Commissars, V. Molotov, signed the order of the Defense Committee, according to which the KV was officially accepted into service.

Surviving copies

In total, to this day, about 10 KV-1 tanks and a number of copies of its various modifications have been preserved in different countries of the world.

In Russia, KV-1 and KV-2 tanks can be seen in the Central Museum of the Armed Forces in Moscow, and an experienced KV-1s with an 85-mm gun can be seen in the Kubinka Tank Museum (Moscow region). As monuments, KV-1 was installed in the village of Ropsha (KV-1), at the memorial in the village. Maryino (near the city of Kirovsk, Leningrad region, 2 KV-1 tanks and 1 KV-1s tank) and the village of Parfino, Novgorod region (KV-1 with a KV-1s turret). The KV-85 tank (a further development of the KV-1s) was installed in St. Petersburg near the station. metro station "Avtovo". The turret of the KV-1 tank, converted into a firing point, is installed in the Sestroretsky Frontier exhibition complex, the city of Sestroretsk (Resort district of St. Petersburg).

The Finnish Tank Museum Parola displays two KV-1s captured by the Nazis and handed over to their Finnish ally - a shielded tank with an F-32 cannon and a tank with a ZIS-5 cannon and a cast turret (both with Finnish markings and swastikas). The KV-1 with the F-32 cannon is in the tank museum in Saumur (France). The KV-1 with a cast turret is located at the Aberdeen Proving Ground in the USA. And another KV-1 with a cast turret is on display at the Bovington Tank Museum (UK).

In the spring of 2011, another “Klim Voroshilov” was discovered at the bottom of the Neva in the Kirov district of the Leningrad region, which drowned during the battle for the “Nevsky Piglet” in 1941, and on November 16, 2011 it was raised to the surface. The operation was carried out by soldiers of the 90th separate special search battalion of the Western Military District together with employees of the Museum of the Battle of Leningrad. KV-1 near Nevsky Piglet.

Using the experience of others

During the Soviet period, they tried not to mention this, because the country of the Soviets was the first in everything. This “leavened patriotism” is to the detriment of historical truth. Yes, we didn’t invent the tank... Yes, our designers used the experience of others. And what's wrong with that?

Were purchased:

- A sample of the light English tank "Vickers - 6 tons" with a production license.

- 15 MkII tanks, English-made.

- Several Carden-Lloyd MkVI wedges and a license for the production of this model.

- Two TZ tanks without turrets and weapons in the USA from engineer and inventor J.W. Christie is the author of the original chassis for the armored vehicle.

All these acquisitions were used in one way or another in the development of domestic tank models. On the basis of the English wedge, the T-27 wedge was created and put into mass production, which was in service with the Red Army even in the first months of the war.

When creating the T-26 tank, which in the pre-war years was the main one for the Red Army, the achievements, important components and assemblies of the Vickers - 6 tons combat vehicle were largely used. And the original chassis, invented by Christie, was first used on tanks of the BT family, and then on thirty-fours.

Interesting Facts

- The crew of the KV tank near the city of Raseiniai (in Lithuania) in June 1941 held back for 24 hours the Kampfgruppe (combat group) of the 6th Panzer Division of W. Kempf, equipped mainly with light Czech tanks Pz.35(t). This battle was described by the commander of the 6th motorized infantry brigade of the division, E. Rous. During the battle on June 24, one of the KVs turned left and took a position on the road parallel to the direction of advance of Kampfgruppe Seckendorf, finding itself behind Kampfgruppe Routh. This episode became the basis for the legend about the entire 4th German Panzer Group of Colonel General Gepner being stopped by one KV. The combat log of the 11th Tank Regiment of the 6th Panzer Division reads: “The Kampfgruppe Routh bridgehead was held. Before noon, as a reserve, the reinforced company and the headquarters of the 65th tank battalion were pulled back along the left route to the crossroads northeast of Raseiny. Meanwhile, a Russian heavy tank blocked the communications of Kampfgruppe Routh. Because of this, communication with Kampfgruppe Routh was interrupted for the entire afternoon and subsequent night. The 8.8 Flac battery was sent by the commander to fight this tank. But her actions were as unsuccessful as the 10.5 cm batteries, which fired according to the instructions of the forward observer. In addition, the attempt of the assault group of sappers to blow up the tank failed. It was impossible to approach the tank due to heavy machine gun fire." The lone KV in question fought against Kampfgruppe Seckedorf. After a night raid by sappers, which only scratched the tank, they attacked it a second time with the help of an 88-mm anti-aircraft gun. A group of 35(t) tanks distracted the KV with its movement, and the 8.8 cm FlaK crew scored six hits on the tank.

- Z. K. Slyusarenko describes the battle of the KV under the command of Lieutenant Kakhkhar Khushvakov from the 1st heavy tank battalion of the 19th tank regiment of the 10th tank division. Since the checkpoint failed, the tank, at the request of the crew, was left as a camouflaged firing point near Staro-Konstantinov (Southwestern Front). The tankers fought the enemy for two days. They set fire to two German tanks, three fuel tanks, and killed many Nazis. The Nazis doused the bodies of the dead hero tankers with gasoline and burned them.

- It was on the KV that senior lieutenant Zinoviy Kolobanov (1st Tank Division) fought, in one battle on August 20, 1941 (post-war journalism erroneously mentioned the date August 19) near Gatchina (Krasnogvardeysk) who destroyed 22 German tanks and two anti-tank guns, and Lieutenant Semyon Konovalov (15th Tank Brigade) - 16 tanks and 2 enemy armored vehicles.

- At the beginning of the war, the KV-1 tank received the nickname “Gespenst” (translated from German as ghost) among the Germans prone to mysticism, since the shells of the standard 37-mm Wehrmacht anti-tank gun most often did not even leave dents on its armor.

- The original version of the text of the famous song “Tanks rumbled on the field...” contains the lines: “Farewell, dear Marusya, And you, KV, my brother...”

KV-1 tank engine

The KV-1 was equipped with a four-stroke V-shaped 12-cylinder diesel engine V-2K with a power of 500 hp. With. (382 kW) at 1800 rpm, subsequently, due to the general increase in the mass of the tank after installing heavier cast turrets, screens and eliminating the shavings of the edges of the armor plates, the engine power was increased to 600 hp. With. (441 kW). Starting the engine was ensured by an ST-700 starter with a power of 15 hp. With. (11 kW) or compressed air from two 5-liter tanks in the fighting compartment of the vehicle. The KV-1 had a dense layout, in which the main fuel tanks with a volume of 600-615 liters were located in both the combat and engine compartments. In the second half of 1941, due to a shortage of V-2K diesel engines, which were then produced only at plant No. 75 in Kharkov (in the fall of that year, the process of evacuating the plant to the Urals began), KV-1 tanks were produced with four-stroke V-shaped 12- M-17T cylinder carburetor engines with a power of 500 hp. With. In the spring of 1942, a decree was issued to convert all KV-1 tanks in service with M-17T engines back to V-2K diesel engines - the evacuated plant No. 75 established their production in sufficient quantities at the new location.

KV-13 - a machine that was a hundred years ahead of its time

It’s hard to believe, but already from the beginning of 1942 in Chelyabinsk they tried to create armored vehicles with diesel-electric power plants, a kind of diesel locomotives on tracks.

The explosion of a rare Russian aerial bomb was shown on video

The KV-13 project itself was original in all respects. In terms of weight it was supposed to correspond to a medium tank, and in terms of armor protection - to a heavy one. In practice, this was realized after the war - in the T-54 tank. The first prototype of the KV-13 was made in the spring of 1942, then it was further refined and even radically redesigned.

In June 1944, an order was issued by the State Defense Committee and the People's Commissariat of the Tank Industry, which marked the beginning of practical work on creating a tank with an electromechanical transmission. Work has begun on “Object 253”. The base was the KV-13 tank.

The electric transmission, as expected, was supposed to provide higher mobility of the combat vehicle and improve its throttle response and controllability.

The basis of the power plant of “Object 253” was the V-12U diesel engine with a power of 700 hp. It was connected to the main generator DK-305A. The electrical systems of the promising tank included another generator, SG-1A. The task of this three-phase generator was to generate current to power the diesel cooling fans and traction motors, as well as to power the battery charging unit. To power the excitation circuits of the SG-1A and DK-305A generators, as well as to supply power to other units, the tank received two G-73 DC generators.

Military trick: how 375 Red Army soldiers defeated more than 4 thousand Basmachi

To move the “Object 253”, traction electric motors DK-302A and DK-302B with a power of 164 kW were used, transmitting torque to the drive wheels through final drives. It was proposed to change the power of the engines by adjusting the current in the excitation winding of the main generator.

The design ideas seemed quite feasible. Alas, the element base and the general technological level of the domestic industry of that time were far from being at the highest level. The electric transmission turned out to be functional, but too large in size and heavy. Thus, the total mass of all electric transmission units reached 3850 kg, while the purely mechanical transmission of the IS-2 tank weighed 980 kg. And the total weight of “Object 253” reached 54 tons.

It was clear that the “electric tank” would not reach series production. But the speed of implementation of completely breakthrough ideas is amazing. Development of “Object 253” began in June 1944, and construction of the prototype tank was completed in November of the same year. The prototype tank traveled about 10 km and stopped due to electrical equipment failure. The stop became eternal. Even the fact that the “electric tank” was given the name IS-6 did not save the project.

Russian tanks were and remain the best in the world

Designers returned to the idea of tanks with an electromechanical power plant throughout the second half of the 20th century. Nothing succeeded. It is quite possible that only fourth-generation tanks will become truly electric in the middle of the 21st century.

And the symbol of the tank builders of the Kirov plant became the heavy IS-2 - a real tank of Victory in the Great Patriotic War. Unfortunately, it was developed by a little-known engineer Nikolai Fedorovich Shashmurin. He did not seek fame, he was always in the shadow of the officially great tank designers - Kotin and Dukhov. But it was Shashmurin who was the workhorse, thanks to whose efforts the truly best heavy tanks of the Soviet Union appeared.