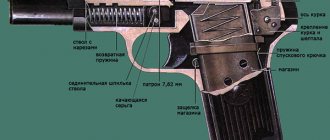

4.1. Loading and unloading a PM pistol

Rice.

36. Loading the magazine with cartridges Fig. 37. Removing cartridges from the magazine To load a pistol at the command “Load” or independently, the shooter must:

- remove the pistol from the holster; remove the magazine from the base of the handle; put the gun in the holster;

- equip the magazine with cartridges, for which, holding the magazine in your left hand (Fig. 36), with your right hand put cartridges into the magazine one after another, while pressing with your thumb until the cartridge goes beyond the upper curved edges of the side walls of the magazine body, push it with the primer close to the rear wall of the magazine body;

- remove the pistol from the holster and insert the magazine into the base of the handle;

- send the cartridge into the chamber of the barrel, to do this, turn off the safety (move the flag down), move the bolt to the rearmost position with your left hand and release it;

- turn on the safety (move the safety flag with the thumb of your right hand so that it covers the red circle) and put the pistol in the holster.

Note. In a combat situation, the pistol must be loaded in advance.

To completely stop shooting

the command “Discharge” is given

. On this command, the shooter must:

- stop pressing the tail of the trigger;

- turn on the fuse;

- unload the gun.

To unload a pistol you need:

- remove the magazine from the base of the handle;

- turn off the fuse (move the flag down);

- remove the cartridge from the chamber, for which, holding the pistol in your right hand by the handle, pull the bolt back with your left hand and release it; lift the cartridge ejected from the chamber from the ground (floor) and wipe it with a rag;

- turn on the fuse;

- put the gun in the holster;

- remove the cartridges from the magazine: taking the magazine in your left hand, with the thumb of your right hand, slide the cartridges one by one forward along the magazine feeder and pick them up with the bark of the same hand (Fig. 37);

- remove the pistol from the holster; insert the magazine into the base of the handle; place the pistol back into the holster and fasten the holster lid.

Rice.

38. Position of the pistol and magazine in the hand upon the command “Weapon - for inspection” At the command “Weapon - for inspection” the shooter must:

- With your left hand, remove the magazine from the base of the pistol handle and place it under the thumb of your right hand in front of the safety (Fig. 38) so that the magazine feeder is 2-3 cm above the bolt;

- after inspecting the weapon, the shooting director takes the magazine in his left hand;

- With the thumb of your right hand, press the shutter stop button and release the shutter;

- by pressing the trigger, perform a control release of the hammer;

- put the fuse in the “safety” position;

- insert the magazine into the base of the handle;

- place the pistol in the holster and fasten the holster lid.

Read full summary Material part of small arms

How to Increase Your Pistol's Reload Speed

Athletes involved in practical shooting know how important a skill is to master the technique of high-speed pistol reloading.

This seemingly simple operation can be worth winning in competitions when the clock is counting down to seconds. In addition, the ability to quickly reload a weapon is also useful for ordinary shooters, it saves time, which they pay for at the shooting range or shooting range. Simple tips on how to quickly reload your pistol were published on thearmorylife.com.

The first step to fast reloading is to properly fit your belt. The most effective placement of a magazine pouch is on the inside of the sternum near the weak hand so that it can quickly slide down onto the magazine in the pouch. This movement requires the least physical effort, and the magazine travels the shortest distance to the weapon.

Photo from thearmorylife.com

The reload itself can be divided into several stages: ejecting the first magazine and removing a new one, bringing the magazine to the pistol for installation, and then regaining grip and aiming. As a quick note, all magazines should be stored on the belt with the bullets facing forward or facing away from you. This greatly simplifies the recharging process.

The magazine must be grasped correctly: the index finger is located along the front edge of the magazine, and the tip of the index finger is located on or just below the first projectile in the magazine. This turns reloading into “pointing” the magazine at the pistol’s magazine well.

Do not bring the magazine to the pistol, holding it only by the base - it will be very difficult for you to accurately hit the shaft on the grip!

To speed up reloading, many athletes use magnetic pouches. To minimize possible damage to the sliding surfaces of the magazine when in contact with magnets, soft leather or felt is glued to the surface of the magnets.

The next prerequisite for speed is how you hold the gun. You won't be able to keep the gun pointed at the target because it will make it too difficult to remove the magazine, so it is best to rotate the muzzle toward your weak hand 90 degrees, almost at chin level, for the most efficient reloading. You should be able to see the magazine well opening.

Determine the optimal meeting point between the magazine and the pistol for you.

To do this, place your weak hand on the magazine pouch and quickly lift it up, as if to reload, and see where the magazine stops and what its general orientation is. Do this several times - the store should stop in the same place each time. It is at this point that you should hold the weapon when reloading.

Over the course of the repetitions, determine which part of the reloading process is most difficult for you and focus on executing it accurately and efficiently, then begin to gradually introduce speed. If equipment breaks down at a certain speed, pay attention to what has changed and work on it. Once static training becomes successful, begin to try the technique while moving - and always be aware of the direction and orientation of the muzzle.

Characteristics of the cartridge

The Makarov ammunition was created taking into account the impossibility of using it with the 9x19 mm Parabellum cartridge. There is a similar foreign-made ammunition called 9x18 mm Ultra. The parameters of the German cartridge are slightly different from the PM. The German company Geko developed it specifically for arming police inspectors. Their main differences:

- sleeve dimensions;

- power;

- bullet caliber.

If the Soviet ammunition has a calibration of 9.27 mm, then the Ultra is 0.27 mm larger. Detailed characteristics:

| Characteristic | Parameter |

| Caliber | 9 mm |

| Cartridge weight | 10 g |

| Charge mass | Circumference – 0.25 g |

| Bullet weight | 6.1 g |

| Chuck length | 25 mm |

| Bullet length | 12.35 mm |

| Case length | 18.1 mm |

| Loading chamber volume | 0.56 cm3 |

| Maximum gas pressure | 118 MPa (1200 kg/cm2) |

| Bullet speed V10, m/s | From 290 to 435 depending on the type and model |

| Specific energy, J/mm2 | From 4.2 to 7.2 |

The penetration indicator depends on the type of projectile. If this is a regular cartridge or a type of rebound action, then the weight of such a bullet will not exceed 6 grams, and armor-piercing ones will weigh at least 7 g. The volume of the temporary pulsating cavity in the gelatin block, which any variant of PM cartridges has, also depends on the modification, and varies from 293 to 495 cm3.

During manufacturing, each ammunition is checked by technologists. The cartridges are packed in special wooden boxes. Each package contains 2560 pieces. The boxes are folded into boxes that are made of iron or galvanized material. Each box must be signed and labeled. The weight of one box of ammunition is 33 kg.

Types and parameters of cartridges

Depending on the modification, PM bullets have different parameters, but they all have a lead core. Bullets are produced by Russian factories. Main manufacturers: Novosibirsk Low-Voltage Equipment Plant, Tula Cartridge Plant, Barnaul Machine Tool Plant, organization in Novosibirsk and Klimov. Main variations of PM ammunition:

- The usual variation is called 57-H-181C. This projectile is manufactured with a brass case.

- SP-7 is an ammunition with an expansive bullet.

- There is ammunition with a PPT tracer bullet (57-T-181);

- The 7N15 includes a metal body and an all-metal armor-piercing bullet.

- Ricochet version - 9x18 PRS gs.

- To sell cartridges abroad, they began to create 9x18 PSV (Hollow Point type).

- Training or sports cartridge brand - 9x18 PSO gzh and 9 UCH gzh.

- Blank ammunition and pistol versions are manufactured, which are most often used by law enforcement agencies at the shooting range.

- Armor-piercing shells that have increased mass of each part and power.

- Expansive cartridge (9 SP7 gzh, 9 SP8 gzh, 9 Ppe gzh, 9x18 RG028 gzh).

The characteristics indicate the average indicator of powder gases. Practical studies have shown that this position varies from 103.9 to 147.1 MPa. The average impulse value is no more than 3 N·s. It is worth considering each type in more detail, because even the same model has different characteristics, depending on which plant produced the ammunition. For example, a 9 mm PM cartridge with a lead core is produced for export by several organizations. The bullet weight varies from 6.1 g to 6.86 g, and the initial speed from 303 m/s to 325 m/s.

Other features:

- An expansive projectile can be produced using polyethylene. Special notches are created on the bullets along the entire rim or they are distinguished by a hexagonal hole.

- The expansive version can be produced with a lighter weight, from 4.1 g. The speed indicator varies from 325 m/s to 420 m/s, and the gas pressure during the trigger release is 122.6 MPa.

- SP-8 is designed for firing when minimal destruction of low-strength barriers is necessary. The speed of this ammunition is 255 m/s, and the gas pressure is 78.5 MPa.

- There is a type of 9mm cartridges with a tracer bullet. This type of projectile is designed to have a psychological effect on the enemy and is capable of adjusting fire. Parameters: ammunition weight - 9.6 g; bullet weight - 5.7 g; initial speed – 300 m/s; the tracing range is no more than 150 m, and the offset range is up to 20 m.

- For armor-piercing bullets, the mass of the bullet is 5.9 g, and the muzzle velocity of the ammunition is at least 435 m/s. The gas pressure is also the highest - from 147.1 MPa.

- The 9x18 PS GS PPO model was created specifically for police officers and military personnel of government agencies.

- 9x18 RG028 gzh - high penetration power.

- 9x18 PRS GS is a special ammunition. It doesn't ricochet like others. Also most often used in law enforcement agencies.

- 9x18 PSV was created specifically for export.

- 9x18 PSO gzh is produced for sport or hunting shooting.

The inert version - 9 UCH GZh - is a training type of ammunition or, as experts say, a training type. If the edges of the cartridge case are pressed into a “star” shape, then the cartridge is blank. The most powerful are armor-piercing cartridges. Their weight reaches 7.4 g. They are created for use in small arms. This type of projectile can penetrate an armored or steel plate of 5 mm at a distance of up to 10 m.

The 9x18 mm PMM cartridge is a new projectile with the 7N16 index. It was created specifically to increase the bullet's penetration ability. It has a significantly increased powder charge and uses a new bullet in the shape of a truncated cone. The speed indicator is up to 410-435 m/s, and the kinetic energy: 485-505 J. The designers created a different form of the cartridge, thereby reducing the likelihood of ricochets. At a distance of up to 20 m, it easily penetrates 3 mm steel sheets. These bullets can only be used in a special weapon with a reinforced design. In such weapons as: PMM, OTs-27, “Bisons” and “Cedars”.

There are also subtypes of almost every option. Some types of cartridges are modernized, while others are redesigned, changing the internal structure of the ammunition.

Operation of pistol parts and mechanisms when firing by self-cocking

40. If shooting is carried out without first cocking the hammer, then when you press the tail of the trigger, the hammer is cocked automatically (Fig. 47). In this case, the cocking lever, having engaged its self-cocking protrusion with the self-cocking tooth of the hammer, cocks the hammer. The trigger, without being cocked (since the sear at the moment of release is raised to the upper position by the protrusion of the cocking lever), breaks away from the self-cocking protrusion of the cocking lever and hits the firing pin; a shot occurs.

Rice. 47. Position of parts and mechanisms of the pistol before firing a self-cocking shot:

1 - shutter; 2 — trigger rod; 3 - ejector; 4 — return spring; 5 — trigger;

6 - store; 7 — mainspring; 8 - trigger; 9 — cocking lever; 10 - sear with spring

Operation of pistol parts and mechanisms after a shot

38. The bolt moves back along with the cartridge due to the pressure of the powder gases on the bottom of the cartridge case. At the beginning of the backward movement (at a length of 3 - 5 mm), the bolt with its protrusion displaces the release protrusion of the cocking lever to the right, thereby disengaging it from the sear (disconnection occurs).

The released sear is pressed against the trigger under the action of a spring: when the trigger turns back to full capacity, the nose of the sear jumps behind the cocking of the trigger and holds it until the next shot.

With further movement of the bolt back, the release protrusion of the cocking lever slides along the groove of the bolt; The cartridge case, held by the ejector in the bolt cup, hits the reflector and is thrown out through a window in the bolt wall.

The feeder delivers the next cartridge and places it in front of the bolt rammer.

The bolt, having reached the rearmost position, returns to the forward position under the action of the return spring; The bolt rammer pushes the next cartridge out of the magazine and sends it into the chamber. When the bolt reaches its extreme forward position and sends the cartridge into the chamber, the ejector hook slides into the annular groove of the sleeve.

The cocking lever rests on the sear (on the side), and its release protrusion is located opposite the recess on the bolt. The pistol is ready for the next shot.

39. To fire the next shot, you must release the tail of the trigger and press it again.

When releasing the tail of the trigger

The trigger rod with the cocking lever moves back under the action of the narrow feather of the mainspring, at the same time the cocking lever moves down and with its cutout goes under the protrusion of the sear.

When you press the tail of the trigger

the cocking lever raises the sear and releases the hammer from the sear again. The next shot occurs.

If the bolt does not reach the extreme forward position (the cartridge is dented), then the release protrusion of the cocking lever will not fit into the recess on the bolt, as a result of which the cocking lever will not engage with the sear and, when the trigger is pressed again, will not turn the sear and will not release the hammer . This eliminates the possibility of a shot if the cartridge is not completely chambered.

PM cartridge - device

This modification of the cartridge is a unitary product. It has a wafer sleeve in the shape of a cylinder. Cartridge parameters: 7.62×25 mm TT. it was developed by the outstanding Russian designer B.V. Semin back in 1951. PM cartridges have a unique design that is not repeated in exact proportions in any other product. Many modern designers take the drawings of these shells as the basis for new developments. Basic moments:

- The sleeve is made of bimetal. It has a standard shell shape.

- The core inside is made of steel, its shape is mushroom-shaped. It is pressed into a lead shell and primer, which contains a powder charge.

- Caliber 9 mm. Ammunition size - 7.62x25 mm TT. Can be used in weapons with a simpler mechanism. Suitable for guns with a blowback action or short barrel stroke.

The first version of this ammunition was created from brass alloys, and the core was made not of steel, but of lead. It is important that the shell was steel. The new modification significantly saves production costs and increases the bullet's penetration ability. Especially if we are not talking about metal targets. The ammunition does not have the ability to penetrate body armor, because when it hits the metal, the shell is destroyed, and the core has a special shape, so it rebounds. The obstacle is not broken through, but characteristic marks may remain on the surface.

back in 1994, it created a special variation of PM cartridges: a 9x18 mm cartridge model with an expansive version of the bullet, which penetrates the target through and does not ricochet. These cartridges have a high power rating and a heavy case. It is 2 grams more than conventional projectiles.

Operation of pistol parts and mechanisms when fired

37. To fire a shot, you must turn off the safety, cock the trigger and press the tail of the trigger with your finger.

When the safety is turned off and the hammer is cocked

the operation of the parts and mechanisms of the pistol occurs as described in Art. 35.

When you press the tail of the trigger with your finger

the trigger rod moves forward, and the cocking lever, connected to the rear end of the trigger rod, rotates on the rear axle of the trigger rod and rises until its cutout rests against the protrusion of the sear; then the cocking lever lifts the sear and disengages it from the cocking hammer. The release protrusion of the cocking lever fits into the bolt recess.

The trigger is released from the sear and, under the action of the wide feather of the mainspring, sharply turns forward on the trunnions and hits the firing pin.

The firing pin moves forward energetically and breaks the cartridge primer with its striker; a shot occurs.

The pressure of the resulting gases forces the bullet out of the barrel; at the same time, the gases press on the walls and bottom of the sleeve. The cartridge case expands and is pressed tightly against the walls of the chamber. The gas pressure at the bottom of the cartridge case is transferred to the bolt, causing it to move backward.