Large-caliber machine gun cartridges. 14.5 mm heavy machine gun cartridges

In the mid-1930s, a serious problem unexpectedly arose before the high command of the Red Army. With the adoption of large-caliber DK machine guns, it was not possible to completely solve the problem of infantry fighting enemy tanks. The power of the new heavy machine guns turned out to be completely insufficient to penetrate tank armor, the thickness and quality of which was constantly growing. In this regard, the issue of creating a sufficiently powerful and at the same time simple and relatively cheap type of weapon for the infantry - an anti-tank rifle, which had a number of advantages over anti-tank artillery: light weight, high maneuverability on the battlefield and the possibility of good camouflage in relation to to the area.

The removal from service in 1935 of 37-mm dynamo-rocket anti-tank rifles of the Kurchevsky system, which were in fact the first Soviet hand-held anti-tank grenade launchers, essentially left the Red Army infantry without a reliable means of defense. The danger of this situation was very well understood by many Soviet military commanders, so already in March 1936 a competition was announced for the design of anti-tank rifles. M.?N.?Blum, S.?V.?Vladimirov, S.?A.?Korovin and others took part in it. Until 1938, they presented to the Art Committee of the Main Artillery Directorate of the Red Army 15 samples of anti-tank rifles of various systems and calibers, from 12.7 mm to 37 mm, and with a weight of up to 70 kg. But since there were no sufficiently strict specifications for the new weapons, none of these anti-tank rifles met the army's requirements. And only based on the results of the 1936–1938 competition, the GAU developed the main criteria for an anti-tank rifle that meets all the requirements of modern maneuverable combat. With high service and operational qualities, the PTR was supposed to destroy 20-mm tank armor at distances of up to 500 m. However, the creation of a truly advanced anti-tank weapon was hampered by the lack of a cartridge with high destructive qualities. In 1934–1938, specialists from the small arms research range (NIPSVO) in the village. Shchurovo, Moscow region, created a new model of a 14.5-mm cartridge with an armor-piercing incendiary bullet weight of 64 grams, and a high initial speed of 1012 m/s, which ensured armor penetration of any armored vehicle at that time.

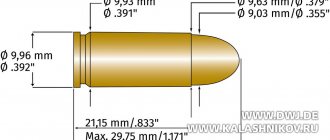

The live cartridge consisted of a cartridge case, a bullet, a powder charge and an igniter primer. The mass of the cartridge was about 200 grams.

The cartridge case has: a body, inside of which a powder charge is placed; the barrel into which the bullet is inserted; a ramp with which the cartridge is fixed in the chamber; a flange (rim) that serves to grip the cartridge case in order to remove the cartridge from the receiver and the spent cartridge case from the chamber by the bolt.

At the bottom of the cartridge case there is a socket for the igniter primer, an anvil on which the igniter primer is broken by the firing pin, and two seed holes through which the flame from the igniter primer is transferred to the powder charge.

The igniter capsule consists of a brass cap with a percussion compound pressed into it and a foil circle covering the percussion compound.

Subsequently, a modified large-caliber cartridge with an armor-piercing incendiary bullet with a steel core B-32 (index 57-BZ-561 and 57-BZ-561 C) and a new cartridge of increased armor penetration with an armor-piercing incendiary bullet BS-41 with a special carbide metal-ceramic carbide core tungsten (index 57-BZ-562) formed the basis on which most Soviet anti-tank rifles were designed.

14.5 mm cartridge with armor-piercing incendiary bullet B-32 mod.

1941 and with a brass sleeve. The new bullet, in addition to the usual cartridge with the B-32 bullet, was adopted by the Red Army in 1941 to fully realize the armor penetration potential of the cartridge. Such a core was much harder and heavier than a steel core. The BS-41 bullet was twice as armor-piercing as the conventional B-32 armor-piercing incendiary bullet, which penetrates a 30-mm armor plate from a normal distance of 500 m. A 14.5-mm BS-41 bullet with a tungsten carbide core pierced a plate of armor steel up to 50 mm thick from a distance of 500 m. In addition to these cartridges, the ammunition of anti-tank rifles also included a cartridge with an armor-piercing incendiary bullet BZ-39. In addition, before the Great Patriotic War in the USSR, work was carried out on the design of a 14.5-mm cartridge with an armor-piercing incendiary chemical bullet BZKh, which was a BS-41 bullet with a capsule filled with tear gas lachrymator (chloroacetophenone), which was supposed to provide a certain impact on the crew when a bullet hits the fighting compartment of an armored vehicle, forcing tank crews to evacuate from a gas-filled vehicle with an intolerable concentration of tear gas outside, under targeted fire from German infantry.

During the Great Patriotic War, 14.5 mm cartridges were used to fire Degtyarev PTRD single-shot anti-tank rifles and Simonov PTRS self-loading repeating anti-tank rifles. The high power of the cartridge and the high penetration ability of the bullet significantly surpassed existing foreign models and again made the idea of creating an anti-tank heavy machine gun promising. Therefore, the 14.5-mm heavy machine gun of the Vladimirov system (KPV) mod. 1944 owes its outstanding firepower, combining the rate of fire of a heavy machine gun with the armor-piercing effect of an anti-tank rifle, to the 14.5 mm cartridge with a bullet weighing 64 grams and an initial speed of 1012 m/s, for which it was created.

14.5-mm cartridge with an armor-piercing incendiary chemical bullet BZH and with a brass sleeve.

The experience of the Great Patriotic War convincingly proved that infantry needs weapons more powerful than large-caliber DShK machine guns to combat light armored targets, machine gun and artillery nests and live enemy force, especially since one of the main elements of the “ammunition-weapon” complex - the 14.5-mm cartridge, used for firing from anti-tank rifles and having a very high penetrating ability, was created even before the war. In 1943, Kovrov KB-2 began designing a machine gun chambered for a 14.5 mm cartridge. The designer of KB-2 S.?V.?Vladimirov began designing a similar machine gun. Together with him, V.?A.?Ryzhkov, A.?I.?Bulanova, P.?P.?Protasov, A.?P.?Finogenov, V.?V.?Kalinin worked on the creation of new weapons. They took as a basis a system of automatic operation that had practically never been used in Soviet automatic weapons—the recoil of the barrel with its short stroke. This decision was facilitated by a thorough study of the latest small arms, including captured German MG.34 machine guns; MG.81; MG.131; MG.151, which successfully used a similar operating principle. The bolt in the Vladimirov machine gun was locked by turning the combat cylinder directly with the barrel coupling using a copier-type accelerator. The feed mechanism is double-sided, slider, designed for the use of metal non-loose machine gun belt for 40 rounds. To compensate for the significant recoil force, the machine gun was equipped with a bolt buffer mounted in the butt plate. The trigger mechanism was designed to conduct only continuous fire. The weapon turned out, despite the use of such a powerful cartridge, to be surprisingly light - only 39.6 kg. However, its combat characteristics were impressive: with a rate of fire of 500–550 rounds/min, the machine gun developed an initial bullet speed of 1030 m/s. When fired at a distance of up to 500 m at an angle of 90 degrees, it penetrated armor 32 mm thick. In 1944, a 14.5-mm machine gun under the designation “KPV-44” (Vladimirov heavy machine gun model 1944) went into small-scale production at the Kovrov plant. The KPV immediately established itself as the most powerful machine gun at that time, with high combat and fairly good service and operational qualities, reliable and trouble-free operation, as well as a very easy-to-maintain and repair model. The KPV-44 was immediately conceived for use not only as an infantry anti-tank machine gun, but also as a very effective air defense weapon for combating enemy aircraft at low altitudes. The machine gun could be mounted on a single wheeled infantry machine, twin and quadruple machine guns, which made it possible to fire in the ground and anti-aircraft position. After many years of refinement, the KPV/KPVT machine guns entered service with the Soviet Army in 1949, first in the infantry version (PKP; SKP), and subsequently in numerous anti-aircraft machine guns (ZPU-1; ZPU-2; ZPU-4) and tank installations. They still serve as machine gun weapons for tanks and armored personnel carriers.

Among other small arms systems, the 14.5 mm Vladimirov heavy machine gun has no equal in firepower on the battlefield. A quadruple anti-aircraft installation of KPV machine guns, with a total rate of fire of 2400 rounds/min, if necessary, transferred to the position for firing at ground targets, can, in a few seconds of dagger fire, turn a three-axle army truck into a flaming destroyed shell, sagging into a dark oily puddle. The muzzle energy of a machine gun is 32,000 J, and a hit to any part of the human body is almost always fatal, and any hit to a limb leads to its separation. This is a legendary weapon, recognizable by its silhouette, by the sound of firing.

To fire the Vladimirov KPV/KPVT machine gun, cartridges with the B-32 armor-piercing incendiary bullet can be used; armor-piercing incendiary bullet BS-41; armor-piercing incendiary tracer bullet BZT and its modernized versions BZT-44, BZT-44 M (with a steel core) (indices 7-BZT-561, 57-BZT-561 S and 57-BZT-561 SM); armor-piercing incendiary-tracer special bullet BST (with a carbide core) (indices 57-BZT-562 and 57-BZT-562 C); with a sighting-incendiary (explosive) bullet ZP (index 57-Z-561 M), instantaneous incendiary bullets MDZ (indexes 57-Z-564 and 57-Z-564 S) and MDZM (index 7-Z-6). In 1989, the BS-41 bullet with a special core was modernized and received the designation BS. It is designed similarly to the 12.7 mm BS armor-piercing incendiary bullet of the 1974 model. Cartridges with different bullets are fired from KPV/KPVT machine guns with the same sight settings.

14.5 mm cartridge with an armor-piercing incendiary tracer bullet BST and a steel case with a phosphate-varnish coating

14.5 mm cartridges with B-32, BS-41, BST, BZT, BZT-44 and BZT-44 bullets M are designed to destroy lightly armored and unarmored ground targets, fire weapons and manpower located behind light shelters at ranges up to 1000 m, vehicles and cargo vehicles - up to 2000 m, and air targets - at altitudes up to 1500 m and at ranges up to 2000 m. Thus, when firing from a KPVT machine gun with cartridges with an armor-piercing incendiary bullet B-32, their penetrating effect is at least 80% when firing at an armor plate 20 mm thick, installed at an angle of 20 degrees to the vertical, at a distance of 300 m, and the incendiary effect - at least 80% on paper soaked in gasoline and covered with an armor plate 20 mm thick, at a distance of 100 m. A cartridge with armor-piercing incendiary tracer bullets BZT and BZT-44 has a penetration effect of at least 80% when firing at an armor plate 20 mm thick , installed at an angle of 20 degrees to the vertical, at a distance of 100 m, and the incendiary effect is at least 80% for gasoline (for BZT-44 M - at least 90%) covered with an armor plate 20 mm thick, at a distance of 100 m.

In addition, cartridges with BZT, BST and ZP bullets are intended for fire adjustment and can be used for target designation. The tracking range of BST and ZP bullets is at least 1500 m, BZT and BZT-44 - at least 2000 m. The BZT-44 M bullet is also used for target designation and fire adjustment with a distance of the beginning of bullet dispersion - at least 2100 m. BS-41 bullets and BST have better armor-piercing ability than B-32 and BZT bullets. When armor-piercing incendiary bullets B-32 and BS-41 hit an obstacle (armor), the core of these bullets pierces the armor, causing damage with fragments formed from the bullet and the pierced armor. When firing at fuel protected by armor, the bullet core pierces the armor; the incendiary composition ignites when a bullet hits the armor; the flame penetrates the hole punched by the core in the armor and ignites the fuel. B-32 and BS-41 bullets also provide ignition of flammable objects and fuel located in thick-walled containers not protected by armor (in tanks, railway tanks, gas tankers, gas storage facilities, etc.) at ranges up to 1500 m.

The BZT and BST bullets have a number of advantages compared to the BS-41 bullet, including greater armor-piercing and incendiary ability, as well as the presence of a tracer. The mechanism of armor-piercing and incendiary action of BZT and BST bullets is the same as that of B-32 and BS-41 bullets. When fired, the ignition composition of the bullet tracer is ignited by the action of powder gases. After the bullet leaves the barrel, the igniter composition ignites the tracer composition, due to the ignition of which a red path is formed during the flight, visible day and night.

14.5-mm cartridge with an incendiary-sighting bullet (explosive) ZP and with a brass sleeve

When fired, when the incendiary bullet ZP is in the barrel bore and receives high acceleration, the oncoming cap, under the influence of inertia force, settles on the firing pin, while the tip of the firing pin pierces the bottom of the advancing cap, due to which the bullet flies out of the barrel with the firing pin cocked. When it encounters an obstacle, the speed of the bullet drops sharply, the firing pin, under the influence of inertial force, continues to move forward and pierces the igniter capsule with its sting, which, when pinned by the firing pin, is triggered and ignites the incendiary composition. The incendiary composition can also ignite due to deformation of the cap and rapid compression of the composition that occurs when the bullet encounters an obstacle. The target is ignited by the flame formed when the incendiary composition of the bullet is ignited. The formation of a path during the flight of ZP bullets occurs in the same way as with BZT and BST bullets.

The 14.5 mm machine gun cartridge with an instantaneous incendiary bullet MDZ is similar to the 12.7 mm machine gun cartridge with an instantaneous incendiary bullet MDZ, but with one belt on the leading part.

Currently, modernized MDZM bullets are produced with a ledge in the leading and tail parts and with a phosphate coating. Cartridges with the MDZ bullet are designed to destroy low-flying air targets (airplanes and helicopters) at distances up to 2000 m, as well as to defeat manpower located behind light shelters, and unarmored combat and auxiliary equipment (tractors, ATGMs, anti-aircraft and missile launchers, vehicles , oil terminals, etc.? etc.). The MDZ bullet, having a high-explosive fragmentation and incendiary effect, ensures the destruction or damage of air targets by fragments or a blast wave, as well as the ignition of flammable liquids located in tanks with wall thicknesses from 2 to 8 mm, at ranges from 100 to 1500 m. When hit MDZ bullets into the barrier explode the explosive material and the resulting fragments, and the blast wave hits the target and ignites the fuel. For a cartridge with an instant-action incendiary bullet MDZ, the incendiary and explosive effect of the bullet when firing at a flammable liquid protected by a 2 mm thick sheet of aluminum alloy grade D16 AM at a distance of up to 1500 m is at least 90%, and for a cartridge with an MDZM bullet the incendiary effect of the bullet when firing at jet fuel TS, TS-1, TS-2 (which powers the engines of ground combat and aircraft vehicles), protected by a 2 mm thick sheet of aluminum alloy D16 AM, at a distance of up to 1500 m it is at least 80%. When an MDZ/MDZM bullet hits the engine, instantaneous ignition of the fuel occurs, because... The flame temperature ranges from 2500 to 3500 degrees (Celsius). The flash from the explosion of MDZ/MDZM bullets is noticeable at a distance of up to 2000 m. A machine gun belt equipped with 14.5 mm cartridges with a modernized MDZ-M instant incendiary bullet with a steel sleeve.

Structurally, the 14.5 mm armor-piercing incendiary bullet B-32 is similar 12.7 mm B-32 bullet, but has one leading belt and ledges in the leading and tail parts. The B-32 armor-piercing incendiary bullet consists of a brass-plated steel shell, a lead jacket, a hardened steel core made of U12 A, U12 XA steel and an incendiary composition. The head of the B-32 bullet is painted black with a red belt.

The BS-41 armor-piercing incendiary bullet consists of a steel bimetallic shell, a lead jacket, a cermet core made of tungsten carbide (RE-8 alloy) and an incendiary composition. The top of the BS-41 bullet is painted black, the rest of its surface up to the edge of the cartridge case is painted red, the igniter primer is coated with black varnish.

The armor-piercing incendiary-tracer bullet BZT consists of a steel brass-plated or bimetallic shell, a lead jacket, a hardened steel core made of steel grades U12 A, U12 XA, an incendiary composition and a tracer cup, inside of which the ignition and tracer compositions are pressed. The head of the BZT bullet is painted purple with a red belt.

The BST armor-piercing incendiary-tracer bullet consists of a brass-plated steel shell, an aluminum jacket, a metal-ceramic core made of VK-8 alloy, an incendiary composition and a tracer cup, inside of which the ignition and tracer compositions are pressed. The top of the BS-41 bullet is painted purple, the rest of its surface up to the edge of the cartridge case is painted red.

14.5-mm cartridges with an incendiary bullet ZP are designed to destroy open ground targets, ignite wooden buildings, haystacks, straw and other flammable objects, fuel located in tanks and tanks unprotected by armor, at ranges up to 1500 m. The ZP bullet has a tracer . The route is red, visible day and night. Tracing range is up to 1500 m. The sighting and incendiary bullet ZP consists of a brass-plated or bimetallic steel shell, a tombak cap, a lead jacket, an incendiary composition, a cup with a striking mechanism and a lead gasket located in it, and a tracer cup, inside of which the ignition and tracer compositions are pressed. The impact mechanism consists of a capsule sleeve with an igniter primer, a running cap that acts as a fuse against premature firing of a bullet, a striker with a sting and a fabric gasket. The top of the ZP bullet is painted red.

The MDZ instant incendiary bullet consists of a brass-plated steel shell, a lead jacket, a glass with an explosive contained in it, a gasket and an explosive device. The top of the MZD bullet is painted red to the edge of the cartridge case.

Due to the presence of igniter caps and detonator caps in ZP and MDZ bullets, as well as soft tombak tips, it is prohibited to remove these cartridges from loaded belts by focusing on metal or hardwood objects. Ammo boxes can serve as a stop for this purpose.

14.5 mm blank cartridge

14.5 mm training cartridges (index 57-N-561-UCH) are intended for training in loading, unloading and firing techniques, as well as for studying the operation of automatic machine guns. They have a sleeve with longitudinal grooves on the body. In training cartridges, the igniter primer is broken (cold), there is no powder charge in the cartridge case, and the bullet is only a bullet casing that does not contain other elements of the bullet.

14.5 mm blank cartridges (index 57-X-561) are designed to simulate combat shooting and consist of a cartridge case with an igniter primer, a powder charge and a cardboard cap. To hold the cap, the muzzle of the cartridge case is slightly compressed.

The greatest shooting efficiency is achieved when using various cartridges interspersed. When firing at air and ground armored targets, it is advisable to alternately use cartridges with B-32, BZT, BS-41 bullets or with BST, B-32 and BZT bullets.

When firing at unarmored ground targets, cartridges with B-32, BZT-44 M and MDZM bullets are used interspersed.

When shooting at air targets, it is necessary to use the following combination of large-caliber cartridges with B-32, BZT-44 M and MDZM bullets.

The ratio of cartridges in a machine gun belt for firing at specified targets is used in accordance with the approved ammunition.

Sergey Monetchikov Photo from the author’s archive

12.7x108 caliber cartridge and bullets for the DShK machine gun and others.

The 12.7x108 cartridge

, which was most widely used during the Second World War for firing from the DShK machine gun, received its name from the first letters of its inventors and has designations all over the world such as - 12.7x108 mm / SAA 9395 / 12.7x108 Russian Rimless /50 Russian Heavy. The letters in its name mean D-Degtyarev, Sh-Shpagin, but there are big disagreements with the letter K - some historians say that it means large-caliber, while others claim that this is the initial letter of the surname Kolesnikov, who is the creator of the wheel drive for this easel machine gun. A large-caliber cartridge for this new type of small arms at that time, equipped with an armor-piercing B-30 bullet with parameters of 12.7x108 mm, was created in 1930 and was designed for use as ammunition for this heavy machine gun and an anti-tank rifle that had not yet been adopted for service . Subsequently, the license to produce such cartridges was sold to Czechoslovakia, Yugoslavia, China, Egypt, Romania and other countries, and the assemblies of different camps of these cartridges can be seen in this photo below, which will open in a large window if you click on it.

Czech ball, Russian AP, Czech API, Chinese API, Yugoslav API, Egyptian API-T, Russian API-T, Yugoslav API-T, Romanian High Pressure Test.

A standard armor-piercing bullet with the B-30 index at a distance of half a kilometer could easily penetrate armor up to 16 mm thick. and it was a serious weapon. DShK

machine gun was used in combat during the Great Patriotic War as a single or twin anti-aircraft gun, such bullets, dangerous for the enemy, ensured end-to-end destruction of enemy aircraft flying at a huge speed for that historical period of 500 km/h at an altitude of up to 2 -x kilometers, or even more.

After its creation before and immediately during WWII, this cartridge was modernized and redesigned several times, and all this was mainly due to the expansion of the range of new bullets for this ammunition and as a result of the work, the capabilities of the machine gun appeared and expanded: Bullets for DShK cartridges.

- T-38 - tracer bullet, completely filled with lead - B-32 - armor-piercing bullet weighing 48 grams, in the middle of which there was a steel core, the main task of which is to destroy openly located targets and those located behind obstacles - BZT-44 - armor-piercing incendiary tracer a bullet weighing 44 grams - for adjusting fire, target designation and the formation of fires.

— BZ-41 – a new armor-piercing incendiary bullet. All cartridges were assembled on the base of a brass sleeve weighing up to 70 grams. There is no information yet about the presence of iron casings. After WWII, the development of this type of cartridge included ammunition equipped with MDZ and BS bullets. The cartridge was equipped with an MDZ bullet, the mass of which reached 43 grams, and had an instantaneous incendiary charge - which was used to combat air targets at low altitude and lightly armored and automotive vehicles.

The cartridge with the BS bullet, which weighed 55 grams, was armor-piercing incendiary, but its core was made of tungsten carbide, which, having penetrated the target, split into a great many small fragments, hitting and setting everything on fire.

This bullet was created in 1972, when everyone began to understand that the armor penetration of the outdated B-32 was no longer enough to reliably destroy armored personnel carriers and infantry fighting vehicles. And in the mid-50s, a special large-caliber cartridge for a 12.7x108 mm sniper rifle was invented. The Soviet government did not spare its people, much less the enemy, and by special order, cartridges with two bullets, known under the index 1SL and 1SLT, were developed, which were armor-piercing incendiary and tracer type of action. Their direct purpose was to fire from a 12.7 caliber heavy machine gun, which was the weapon of combat helicopters. And there were also blank cartridges that were used for training and noise training and some others with different types of bullets.

Cartridge 12.7x108

became quite widespread, since in Soviet times these cartridges were supplied to many countries (mainly the Warsaw Pact), and were also produced under license, for example in China. The total length of the cartridge reached 146.8 mm, the length of the cartridge case was 107.9 mm, the weight of the cartridge, depending on the bullet, was in the range of 124-134 grams, the weight of the powder charge was 16.5 grams. Various large-caliber weapons were developed for this ammunition in Hungary and South Africa.

The 12.7x108 cartridge was used in the following types of weapons in service in the countries of the former USSR, namely: machine guns DShKM - the famous Dashka, Berezina, Utes and Utes-M, ShVAK (USSR), NSVT, as well as sniper rifles and others. —

LARGE-CALIBER CARTRIDGE WITH AN ARMORO-PIERING BULLET Russian patent 2009 according to IPC F42B5/02 F42B12/06

The invention relates to unitary armor-piercing and armor-piercing incendiary type cartridges intended to destroy ground and air lightly armored targets.

A 12.7 mm cartridge is known (see Production of small arms cartridges. Handbook. Part 1. Under the general editorship of Ph.D. N.P. Ageev. Central Research Institute of Information. 1973, pp. 23, 24, fig. 10a , table 4), containing a bullet with an armor-piercing core, fixed in a sleeve in which a propellant powder charge is placed.

This cartridge has the following parameters: bullet weight - 48 g, cartridge charging chamber volume - 20.5 cm3, armor-piercing core diameter - 10.9 mm, ratio of bullet mass to charging chamber volume - 2.36, ratio of cartridge length to bullet length - 2.28, the ratio of the diameter of the armor-piercing core to the caliber of the cartridge is 0.86 (see Album of designs of cartridges for small and large-caliber automatic weapons. N.G. Menshikov. Artillery Order of Lenin, Suvorov Academy of the Red Army. M., 1946, pp. .27, 34, 35).

The disadvantages of this cartridge are the following:

— a relatively short range (100 m) for penetrating an armor plate 20 mm thick, due to the limited volume of the cartridge’s charging chamber, which does not allow placing the required amount of propellant powder charge to increase the speed of the bullet, i.e. to increase the specific kinetic energy of the bullet at the target.

A 14.5 mm cartridge is known (see Production of small arms cartridges. Handbook, part I. Under the general editorship of Ph.D. N.P. Ageev. Central Research Institute of Information. 1973, pp. 23, 24, fig. 11 , table 4), containing a bullet with an armor-piercing core, fixed in a sleeve in which a propellant powder charge is placed.

This cartridge has the following parameters: bullet weight - 64 g, cartridge charging chamber volume - 37 cm3, armor-piercing core diameter - 12.45 mm, ratio of bullet mass to charging chamber volume - 1.73, ratio of cartridge length to bullet length - 2, 27, the ratio of the diameter of the armor-piercing core to the caliber of the cartridge is 0.98 (see Album of designs of cartridges for small and large-caliber automatic weapons. N.G. Menshikov. Artillery Order of Lenin, Suvorov Academy of the Red Army. M., 1946, p. 28 , 36, 37).

This cartridge is more effective compared to the known one, however, it also has relatively low efficiency, since it penetrates an armor plate 20 mm thick at a distance of no more than 300 m. This is due to the fact that the volume of the cartridge’s charging chamber does not allow increasing the amount of propellant powder charge required to increase the speed of a bullet that has a relatively large mass (64 g), in order to increase the specific kinetic energy of the bullet at the target.

This cartridge was taken as a prototype, because has the greatest number of common features with the proposed solution.

The objective of the proposed invention is to increase the efficiency of the cartridge, which consists in increasing the distance of penetration of an armor plate with a thickness of 20 mm by increasing the speed of the bullet, leading to an increase in the specific kinetic energy at the target.

The task is achieved by the fact that in a cartridge containing a bullet with an armor-piercing core fixed in a sleeve and a propellant powder charge placed in the sleeve, the ratio of the mass of the bullet to the volume of the charging chamber of the cartridge is 1.20...1.43, while the ratio of the length of the cartridge to the length of the bullet is 2.30...2.46, and the diameter of the armor-piercing core is selected within 0.82...0.85d, where d is the caliber of the cartridge.

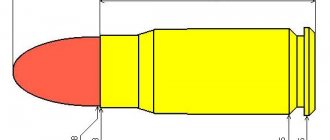

The drawing shows the proposed cartridge.

The cartridge contains a bullet 1 with an armor-piercing core 2, a bottle-type sleeve 3, in which a powder propellant charge 4 and an igniter primer 5 are placed. The volume of the sleeve without the volume of the tail of the bullet located in it forms the charging chamber W.

The cartridge has the following parameters: d=12.7 mm, m=48 g, w=37.0 cm3, d1=10.85 mm, L=153 mm, 1=64.5 mm, where d is the cartridge caliber, m is the mass of the bullet, w is the volume of the cartridge’s charging chamber, d1 is the diameter of the armor-piercing core, L is the length of the cartridge, l is the length of the bullet.

In it, the ratio of the mass of the bullet 1 to the volume of the charging chamber W is 1.20...1.43, while the ratio of the length of the cartridge to the length of the bullet is 2.30...2.46, and the diameter of the armor-piercing core 2 is selected within 0.82...0 .85d, where d is the cartridge caliber, mm.

These ratios were determined as a result of experimental work during firing with 12.7 mm cartridges and are interrelated, since changing any of them leads to a decrease in the efficiency of penetration of armored plates.

If the ratio of the mass of the bullet to the volume of the charging chamber is greater than 1.43, then the amount of powder charge placed in the charging chamber decreases, which leads to a decrease in the speed of the bullet, i.e. to a decrease in the specific kinetic energy of the bullet at the target, and this leads to a decrease in the efficiency of penetrating armored plates.

If the ratio of the bullet mass to the volume of the charging chamber is less than 1.20, then this leads to an increase in the amount of powder charge placed in the charging chamber, which leads to an increase in flight speed, i.e. to an increase in the specific kinetic energy of the bullet at the target, but at the same time the speed loss increases and the efficiency of penetrating armored plates decreases.

If the ratio of the length of the cartridge to the length of the bullet is greater than 2.46, then it is possible for the bullet to break off from the rifling of the weapon's bore.

If this ratio is less than 2.30, then the volume of the charging chamber decreases and the speed of the bullet decreases, and therefore the efficiency of penetrating armored plates.

When the diameter of the armor-piercing core is more than 0.85d, the specific kinetic energy decreases, and hence the penetration of the barrier.

When the diameter of the armor-piercing core is less than 0.82d, the specific kinetic energy increases and the penetration of armor should increase, however, the installation density deteriorates, which is why the bullet can be dismantled in flight.

During experimental firing with 12.7 mm cartridges, an armored plate 20 mm thick was penetrated at a distance of 1000 m.

The cartridge works as follows.

When the igniter capsule 5 is broken, a beam of fire appears (from the activation of the composition), which ignites the powder propellant charge 4. Due to the action of the expanding powder gases, the bullet 1 begins to move along the barrel of the weapon. Thanks to the rational choice of the ratio of the mass of bullet 1 to the volume of the charging chamber W, bullet 1 receives high acceleration when moving along the barrel.

When bullet 1 moves along a trajectory, two main forces act on it: the force of gravity of the earth and the force of air resistance.

The force of gravity of the earth bends the flight path of bullet 1. In the proposed bullet 1, due to the high flight speed, the duration of action of this force is reduced, which means the trajectory has a flatter profile, which increases the range of a direct shot.

The force of air resistance increases the loss of speed.

Reducing the air resistance to the movement of bullet 1 in flight is ensured by a rational choice of the cross-section of bullet 1.

All this ensures that high kinetic energy is maintained in front of the target.

When hitting a target, the main part of the kinetic energy acts on the cross section of the armor-piercing core 2, providing high specific kinetic energy. The cross-section of the armor-piercing core 2 is selected in such a way that, ensuring the density of the bullet mounting, there is a maximum specific kinetic energy, and therefore maximum destruction of the target.

Thus, the advantage of the proposed solution compared to the prototype is the increase in the penetration distance of an armored plate 20 mm thick to 1000 m.

Without which the machine gun will not fire. Part 2

<<< See the first part

Pistol and revolver cartridges

| Top row: pistol cartridges 7.62x25 TT; 5.45x18 MPC; 9×18 PM; 9×18 PMM (7N16); 9x18 PMM with powder bullet; 9x19 Parabellum; 9x21. Bottom row – 9x18 PM (from left to right): with a bimetallic sleeve; with steel sleeve; with a tracer bullet; with expansion bullets |

| Revolver cartridges (from left to right): .42 Smith and Wesson Russian; 7.62x38R Nagan; 12.3x50; 12.3x35; 12.5x40 with lead bullet; 12.5×40 shot; 12.5×40 with steel bullet |

Until recently, military ammunition for short-barreled small arms was not very diverse: a 9-mm cartridge for PM and APS and a rarely used 5.45-mm cartridge for PSM. In paramilitary organizations you can still find the pistol 7.62 mm TT and the revolver 7.62 mm Nagant. Moreover, the multi-billion dollar reserves of 7.62 mm pistol cartridges located in army warehouses prompted the GRAU to the idea of creating modern weapons for them. This cartridge was also mentioned in the competition for a new army pistol. The rapid development of personal protective equipment that has occurred in the last decade has required a very intensive development of this category of ammunition like no other. At the same time, the modernization of old and the development of new ammunition are taking place in parallel. The first is typical for the army, the second for the Ministry of Internal Affairs as a richer customer at the present stage. Apparently, the first sign of this direction was the armor-piercing bullet for the 9 mm PM cartridge, adopted in the 1970s for special units. But the low power of the cartridge required its radical modernization, and in the early 1990s a 9 mm PMM (7N16) cartridge appeared with almost the same bullet mass, but with its initial speed increased by more than 100 m/s due to the use of a new charge. Naturally, such modernization actually means the adoption of a new cartridge, since it requires a change in the design of the weapon. True, old cartridges can be used in new weapons, but not vice versa. The new ammunition's ballistic characteristics are close to 9x19 Para, the standard NATO cartridge for pistols and submachine guns. Apparently, modernization still did not fully satisfy today's conditions. Cartridge developers offer new bullet designs for it, in particular, those made by powder metallurgy. One can only hope that the experience of the German industry will be taken into account, which, solely due to the lack of lead, was forced at the end of World War II to master the production of similar SE bullets, which differ from ordinary ones in ballistics (due to lower density) and high wearability of the weapon barrel. The disadvantages of powder bullets included a very high probability of chipping the warhead during chambering. Weapon designers are increasingly looking towards the 9x19 Para. It is unlikely that the creators of the variants of the already known “Klin” and “Cypress” submachine guns and the new OTs-22 under 9x19 were inspired only by the prospect of exporting their creations.

One of the latest army-funded programs in this area was the development of a powerful 9-mm assault pistol cartridge with a 21 mm (9 x 21) long sleeve, designated RG052. It significantly surpasses all similar ammunition in the world in armor penetration. But the lack of money and production capacity deprived him of his future. Its latest modification, already based on the 9x19 Parabellum cartridge case, the production of which for export first to the USA and then to the Czech Republic was launched at the Tula Cartridge Plant, is inferior in its characteristics to the RG052. Almost all other developments in this area are carried out in the interests of the Ministry of Internal Affairs. And a lot is being done. Army ammunition is being adapted to police needs. The 9-mm PM cartridge has already received at least three semi-jacketed bullets with increased stopping power, prohibited for use in warfare by the Hague Convention, but used by law enforcement forces in almost all countries of the world: SP-7 with a polyethylene plug in the head and two modifications with a hexagonal hole in head part and shell cuts. The entry into service of the Ministry of Internal Affairs of 9-mm submachine guns revived the production of tracer bullets. If the 5.45-mm OTs-23 “Dart” pistol enters service with the police, we should expect the appearance of special bullets (armor-piercing and semi-shell) in this caliber.

Legislative restrictions imposed on ammunition for service weapons, namely: the mandatory discrepancy in caliber and geometry of the cartridge case with those in service and the maximum energy not exceeding 300 J, force the industry to produce a new cartridge. The most likely “contender” is the world-wide Browning cartridge 9×17 Short (9×17 Br.Short) or, according to the American standard, .380 Auto, which the plant in Novosibirsk has begun producing. Although for some reason we adopted the German transcription of the name: 9×17 Kurz.

After half a century of oblivion, revolvers are again in favor. But the relatively low-power 7.62x38R cartridge for the 1895 Nagant revolver, which was produced until recently, clearly does not meet the requirements of today, and in the conditions of the current economic crisis, the development and mass production of our own 9-10 mm caliber revolver cartridge is an almost impossible task. The use of imported ammunition also poses moral and financial problems. There are two ways to design revolvers: for a standard pistol cartridge, or for a new cartridge created using a serial cartridge case with a protruding flange or its blank. The first way has, at first glance, a significant advantage: a single ammunition for pistols and revolvers simplifies supply. But there are many more disadvantages: the complicated design of the drum due to the lack of a protruding flange on the cartridge case, and, most importantly, pistol cartridges are usually much weaker than revolver cartridges of the same caliber, which sharply reduces the effectiveness of the weapon. A clear example of this is the Tula revolver OTs-01 “Cobalt”. A convenient and aesthetic model, but chambered for the 9 mm PM cartridge with all the ensuing disadvantages.

The second path was chosen when creating ammunition based on a 32-caliber hunting cartridge case for the Udar multi-purpose revolver complex at TsNIITochMash. The nomenclature for it includes cartridges with a live bullet with a steel core, with rubber and plastic bullets with a bruising effect, a shot cartridge with dye and light-sound bullets, and a pyro-liquid cartridge with an irritating agent. For the effective operation of such a variety of ammunition with an impressive caliber of 12.5 mm, the last two types also required a relatively long cartridge case - 50 mm, which immediately affected the dimensions and weight of the weapon. Excessive universalization has led to the fact that in a live cartridge, the charge and bullet occupy less than half the volume of the cartridge case. The rejection of the last two types of ammunition allowed Tula gunsmiths to use a shorter cartridge case in their systems: the R-93 revolver developed by KBP uses a cartridge with a sleeve length of 35 mm (12.3 × 35), and TsKIBSOO developed a cartridge with sleeve 40 mm long (12.5×40). The range of KBP ammunition includes cartridges with lead and steel bullets with a plastic shell, rubber bullets either with a bruising effect, or containing a dye for marking and a cartridge with a shot charge. Similar ammunition was developed at TsKIBSOO, but the difference is that the R-93 has a rifled barrel, and the Gnome has a smoothbore. Despite their impressive capabilities - an armor-piercing bullet fired from a Gnome revolver breaks through a Group 4 vest that can withstand a hit from a 7.62 mm machine gun - large-caliber revolvers are very specific weapons due to their size, weight and power. It is no coincidence that even in the United States, where gigantomania regarding small arms has become a national tradition, police officers rarely use the beloved .45 (11.43 mm), preferring the .38 (9 mm).

Large caliber cartridges

| Large-caliber cartridges (from left to right): .50 Vickers (12.7x81), the first domestic heavy machine gun P-5 was made for this cartridge; 13.2x96 Hotchkiss; .50 Colt-Browning (12.7×99); 12.7mm DShK (12.7x108); 12.7 SHVAK (12.7x108R); 14.5×114; 14.5 mm BNS (14.5x147) |

This category traces its history from ammunition to heavy fortress rifles designed to hit protected targets. The first unitary large-caliber cartridge with a metal sleeve and an armor-piercing bullet with a steel core adopted by the Russian army was ammunition for the 8-line (20.3 mm) Han fortress rifle of the 1873 model. With the arrival in the 90s of the 19th century of cartridges with smokeless powder and jacketed bullets, which successfully hit almost all targets for which serf guns were previously intended, the role of the latter in the weapon system decreased to zero. At the beginning of the 20th century, guns were transferred from fortresses to arsenals for storage. The appearance on the battlefields of the First World War of mobile armored vehicles, protected from normal caliber bullets, revived the idea of a heavy gun or a larger caliber machine gun. Taking into account the experience of the past war, in the 1920s all developed countries paid great attention to the development of powerful large-caliber small arms and ammunition. In the USSR, by 1930, a five-line (12.7 mm) cartridge with a wafer sleeve was successfully tested, for which a magazine-fed Degtyarev heavy machine gun (DK) was subsequently developed. But large-scale production of the cartridge began with the adoption of the more advanced DShK machine gun. Therefore, you can find the name of the cartridge: “12.7 mm DShK”, although later many types of weapons were created for it for all branches of the military. The significance of the caliber is due to the fact that the leaders in this field at that time, the USA and Great Britain, adopted half-inch (12.7 mm) machine guns. However, in terms of ballistic characteristics, the domestic cartridge was significantly superior to its Western counterparts. In the 1930s, the cartridge was produced with armor-piercing (B-30), armor-piercing incendiary (B-32), armor-piercing incendiary-tracer (BZT), incendiary-sighting (ZP), sighting (P) and tracer (T) bullets . The latter was produced in extremely limited quantities. At the same time, ShVAK aircraft machine guns were produced with a cartridge with a sleeve that had a protruding flange. It had the same charge and the same bullets as the infantry one. The different design of the cartridge case was explained by the automatic features of the ShVAK machine gun. By the beginning of the Great Patriotic War, the B-30 and P bullets were replaced by the similar in design, but more effective B-32 and ZP, respectively, and the aviation version of the 12.7 mm ShVAK was discontinued due to the transition to the 20 mm caliber cartridge. During the war, a 12.7-mm cartridge with a BS-41 bullet with a metal-ceramic core was produced in small quantities for anti-tank rifles, and an armor-piercing incendiary phosphorus bullet BZF-46 and instantaneous incendiary explosive bullets MD, MDZ- were developed for aircraft machine guns. 46, MDZ-3 and RZTS (version of MDZ-3 with a tracer and self-destruction). The BZT bullet was replaced by the technologically simpler BZT-44.

In the 1950s, with a decrease in the number and types of targets effectively hit by this caliber, the range of manufactured cartridges was reduced to B-32 and BZT-44. In the 1970s, with the adoption of machine guns of the NSV-12.7 family and the aviation YakB-12.7 family, the number of types of bullets also increased. New modifications of armor-piercing incendiary bullets with a metal-ceramic core (BS) and instantaneous incendiary bullets (IMB) have appeared. A two-bullet cartridge was developed specifically for the aircraft machine gun in two modifications: with two armor-piercing incendiary bullets and with the first armor-piercing incendiary and second tracer bullets. It is curious that the design of the B-32 bullet has remained virtually unchanged since the beginning of production to the present day. Today, the cartridge and weapons for it are produced in large quantities abroad, where it is known as “12.7x108”. It also has a new purpose - 12.7 mm heavy sniper rifles have been developed in Russia, Hungary and Belgium. The Novosibirsk plant has begun developing a 12.7 mm sniper cartridge.

From the mid-1930s to the present, the design of the 12.7 mm brass case changed significantly only in 1939, when the small-diameter primer with an inserted anvil was replaced by a more powerful "berdan" type, and the primer socket with one central hole gave way to a regular socket with an anvil and two side seed holes. The old, relatively weak primer required an additional booster charge in the form of a circle of nitro cloth at the bottom of the cartridge case and a cotton wad to prevent powder spillage. A more powerful primer made it possible to get rid of nitro fabric and wad and simplify the technology of loading ammunition. The varnished steel case that was tested was not put into service due to a large percentage of delays in the operation of the weapon's automation. The remaining changes affected only the design of the bullets.

Another, no less famous Soviet large-caliber cartridge 14.5x114 was developed in the mid-1930s, but only entered mass production in 1940. It was intended to destroy armored targets up to light and medium tanks. Until 1944, only anti-tank rifles were produced for it. The nomenclature of bullets also corresponded to the purpose of the weapon: armor-piercing incendiary B-32, BZ-39 and BS-41 (the first and last are similar in design to 12.7 mm bullets). As an experiment, to increase efficiency, a capsule with the irritating substance CAF (chloroacetophenone) was placed in the bottom part of the BS-41 core. The bullet, called “armor-piercing-incendiary-chemical,” after penetrating the armor, created an intolerable concentration of tear gas in the space behind the armor and incapacitated the manpower located there. The Germans used a similar bullet for the 7.92 mm PzB-39 anti-tank rifle.

The increased armoring of tanks undertaken by the warring parties during the war reduced the effectiveness of anti-tank rifles to such an extent that they actually became only a means of fire support on the battlefield. Attempts to increase armor penetration by increasing the charge - the 14.5-mm BNS (high initial velocity) cartridge, obtained by recompressing a 23-mm cartridge case from the VYa-23 gun - did not yield a significant increase in efficiency. However, the ballistics of the 14.5 mm cartridge were suitable not only for fire support and destruction of lightly armored targets, but also for combating air targets at low altitudes. And with the advent of the Vladimirov heavy machine gun at the end of the war, the 14.5-mm armor-piercing incendiary tracer bullet BZT-44 was adopted.

In the 1950s–60s, 14.5 mm machine guns practically replaced 12.7 mm weapons in the USSR ground forces. To solve new problems, 14.5 mm cartridges with ZP and MDZ bullets, structurally similar to 12.7 mm, are being adopted. The BS bullet receives a tracer and becomes a BST. At the same time, the brass sleeve was replaced with a cheaper steel one, coated with green varnish.

In general, the range of small arms ammunition of the Soviet army, which simultaneously included two large-caliber cartridges of equal distribution among troops, differed from the Western one, which had one similar cartridge. Most likely this is due to the different range of tasks that small arms are designed to solve.

In the 1970s, a 15.2-mm machine gun with a high rate of fire chambered in an original cartridge with a brass cylindrical sleeve with an electric capsule sleeve was used to arm some highly specialized aircraft.

See ending >>>

Join our group “Courage 2004”

Share on social networks:

Soviet aviation ammunition

Cartridge 12.7×108 mm

During the war it was used with heavy machine guns DShK and aviation UB.

Bullet diameter, mm: 13.01 Cartridge length, mm: 146.7 Case neck diameter, mm: 13.56 Case length, mm: 108 Case rim diameter, mm: 21.69 Bullet weight, g: 48.2 Cartridge weight , g: 125 Initial speed, m/s: 820

armor-piercing incendiary bullet B-32 for cartridge 12.7*108

The most common cartridge is 12.7x108 with the B-32 bullet. This bullet has a nose painted black with a red stripe, and there are 2 flutes on the bullet itself. It is impossible to disassemble such a bullet, as this will lead to injuries and burns from the ignition of the incendiary composition.

In addition to armor-piercing incendiary bullets (in addition to the B-32 bullet, there are several other types), there are bullets for 12.7 * 108 cartridges containing explosives, and in fact they are more likely to be a small projectile

Instant bullets containing explosives

SHVAK 12.7

ShVAK ” (Shpitalny-Vladimirov, aviation, large-caliber), was adopted Serial production of ShVAK 12.7 machine guns was carried out from 1935 until the adoption of the 20-mm ShVAK cannon in 1936

Cartridges for the DK, DShK and ShVAK machine guns were loaded with identical bullets and differed only in the design of the cartridge case. The only exceptions are early-style cartridges, equipped with bullets without a flute and B-30 bullets with a nickel silver jacket. The ShVAK machine gun cartridge case has a protruding rim of the case. When loading, the rim of the cartridge case rests against the ledge of the barrel hemp. The rim also serves to hook the extractor legs onto it when extracting the spent cartridge case and to ensure the supply of the cartridge. The ShVAK cartridge case is equal in length to the cartridge case of the DK and DShK machine guns, but has one central ignition hole for the Boxer system primer.

Comparative table of characteristics of cartridges 12.7 ShVAK and 12.7 DShK:

20 mm ShVAK

Sh

nutritional -

V

ladimirov

A

aviation

K

large-caliber - Soviet aviation small-caliber automatic gun chambered for 20x99R. Used on the I-153P, I-16, I-185, Yak-1, Yak-7B, LaGG-3, La-5, La-7, Pe-3 aircraft. Turrets with ShVAK were also installed on Pe-8 and Er-2 bombers.

Types of shells for ShVAK 20mm:

OZ

- with a head fuse, 2.8 g of explosive + 3.3 g of incendiary

OST

— with head fuse, 2.8 g explosive + 3.3 g incendiary, tracer

OF

— with a head fuse, 6.7 g HE, explosive, with semi-finished fragments

OFZ

— with a head fuse, 0.8 g of explosive + 3.8 g of incendiary, with semi-finished fragments

BZ

- solid steel core in a soft shell, 2.5 g of incendiary substance, in an aluminum or bakelite ballistic shell

BZT

— like BZ but with a tracer

PU

- explosive mixture in an explosive shell

PUT

— solidly stamped hollow with a reactive mixture in the cavity

ShVAK 20mm aviation gun scattered tape fragments

23mm VYA cartridges

The Volkov-Yartsev-23 cannon was developed for the Il-2 attack aircraft that was being created. Adopted into service in 1941 under the name VYa-23, a total of 64,655 of these guns were produced. The ammunition used is 23x152 mm. with fragmentation incendiary, armor-piercing incendiary, fragmentation incendiary tracer shells. For incendiary fragmentation shells, the membrane or the head of the fuses is painted red.

37 mm NS-37 cartridges

The NS-37 aircraft cannon (short for Nudelman-Suranov) was produced from 1943 to 1945. The Ns-37 used 37x198 mm ammunition. Intended for installation on LaGG-3 and Yak-9T fighters (in the engine cylinder block), Il-2 attack aircraft (in underwing nacelles) and Su-8 (under the fuselage). During the war, 6833 of these guns were produced.

Link from the NS-37 tape:

NS-23 sleeves

In 1943, a new 23 mm cartridge with a reduced charge was developed. Based on the 14.5 mm standard anti-tank cartridge, a new cartridge case was created by re-crimping it to a 23 mm caliber. Together with the new cartridge case, a standard 23-mm projectile weighing 200 grams was used. A tape was also developed specifically for the new NS-23 cartridge. The weight of such a cartridge with a belt link turned out to be almost half the weight of a cartridge with a link of the 23-mm VYA-23 cannon. The design of the NS-23 cannon is similar to that of the NS-37 cannon. On October 10, 1944, the NS-23 cannon and its cartridge were put into service.

About cartridges:

Marking of special cartridges 7.92 Mauser

8×50 R cartridge for the Lebel rifle

Cartridge stamps 7.62*25 TT

Special cartridges 7.62*54R

Marking of cartridge cases of three-line cartridges of early production

Non-standard stamps for 7.92 Mauser cartridges

Marks on cartridges left by weapons

Legendary 7.92x57 Mauser

German cartridge Patrone 318 for the PzB anti-tank rifle

German Unitary cartridge 7.92×57 mm Mauser

CARTRIDGES FOR WEHRMACHT PISTOLS

German armor-piercing bullet with a tungsten core S. mKH