A fuze is an automatic device designed to trigger ammunition. Without it, an explosion is impossible or difficult. During the war years there were a huge number of their varieties and modifications. German fuses were particularly sophisticated and complex. It is impossible to consider all of these devices in this publication, so we will present the most frequently encountered ones at battlefields.

MUV, MUV-2, MUV-3, MUV-4

Fuses MUV, MUV-2, MUV-3, MUV-4 are instantaneous fuses and are used both in mines of a certain design and for the manufacture and detonation of explosive charges mechanically.

The MUV fuse is intended for equipping anti-personnel mines and making homemade mines and surprise mines. It consists of a metal or plastic body, a firing pin, a spring, a pin (T-shaped and P-shaped) and an MD-2 or MD-5M fuse.

Fuse MD-2 and MD-5M

The MUV fuse kit also includes a pin, with which the striker is cocked.

MUV fuse with MD-2 fuse

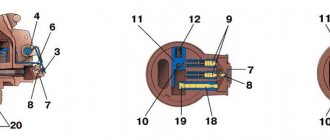

MUV fuse with MD-2 fuse: a-general view; b-section

1-hole for a hairpin; 2-P-shaped combat pin; 3-spring; 4-drummer; 5-body; 6-fuse MD-2

The MUV-2 fuse has the same purpose as the MUV. It differs from the MUV by the presence of a fuse in the form of a plate metal element, which holds the striker in the cocked position for at least 2.5 minutes after the safety pin is removed, which ensures safe installation of the mine.

MUV-2 fuse with MD-5M fuse

MUV-2 fuse with MD-5M fuse

The response time depends significantly on temperature; this must be taken into account when using a fuse, otherwise the mine will not work within the designated time frame, especially at low temperatures.

When cocking the firing pin of the MUV, it is necessary to ensure that the open end of the body is directed away from oneself and away from others in order to avoid injuries in case of accidental failure of the firing pin.

The fuse is screwed into the firing pin body, as a rule, at the mine installation site with the firing pin cocked, with a pin or safety pin inserted into the upper hole of the firing pin.

The MUV-3 fuse differs from the MUV-2 by the presence of a bracket, which increases the force of pulling out the combat pin to 2-6 kg versus 0.5-1.3 kg. The fuse bushing is made of diphlon. Otherwise, it is no fundamentally different from the MUV-2 fuse.

Fuze MUV-3 (unloaded)

MUV-2 and MUV-3 fuses are used to perform tasks behind enemy lines, mainly with a P-shaped pin. In the safe position, the firing pin is held in the cocked state by a safety pin, which is removed when the fuse is installed.

Before using MUV-2 and MUV-3 fuses, it is imperative to remove the cap and check the presence of a metal element, a safety and combat check, and the serviceability of the cutter. The metal element must be located in the slot of the sleeve under the cutter and rest with both ends against the slot of the sleeve.

Fuses with cut metal elements, with dents from the string, as well as with the presence of rust on the string are prohibited from being used. It is prohibited to screw the fuse into the fuse body without checking the presence and correct installation of the safety and combat pins.

The MUV-4 fuse differs in the type of temporary fuse. After the safety pin is pulled out, liquefied rubber begins to flow from cavity to cavity. This system ensures that the time for setting the fuse to the firing position is less dependent on the air temperature.

MUV-4 fuse (unloaded): a - general view; b - section.

1 - cap; 2 - piston; 3 - rod; 4 — chamber with rubber; 5 — MDV body; sleeve; 6 - metal bushing; 7 - balls; 8 — bushing; 9 — safety pin; 10 — combat check; 11 - spring; 12 - drummer; 13 — body; 14 - bracket.

Operating principle: when the striker (12) moves with the rod (3) by 5-8 mm (after the long cocking time has expired), the balls (7) are pushed into the gap between the sleeve (8) and the striker (12). The released firing pin rests against the combat pin (10), when pulled out, under the action of the spring (11), it pierces the igniter primer, causing an explosion of the mine charge.

The procedure for installing fuses in fragmentation mines:

1. Screw the fuse into the fuse body. 2. Install the fuse in the mine. 3. Install the guy wire. 4. Pull out the safety pin. When pulling out the safety pin, the fuse must be held with your hand to prevent the fuse body from breaking.

Forbidden:

1. Use a fuse with mechanical damage and without a safety pin. 2. Remove (neutralize) mines with fuses set to firing position. Fuses MUV, MUV-2 MUV-3, MUV-4 are not sealed and can be used in appropriate conditions on land, without exposure to moisture; It is necessary to protect them from dirt and especially sand.

MUV fuze

I think it will be interesting..

Mine fuze MUV (Historical and technical essay)

The widely known MUV mine fuse. This fuse turns seventy-two years old in 2004. Extremely simple and even primitive, due to its simplicity and primitiveness, like the famous AN-2 aircraft, it survived several wars, its more advanced brothers, and its own modernizations. He continues to remain in service today. Variations of this fuse have spread throughout the world and exist under various indices, produced and used both in Europe and in Africa, Asia, and even crossed the ocean. Of course, it cannot be said that all of its foreign variants are an exact copy of the Soviet MUV fuse, but the fact that they are all direct borrowings is undeniable. Firstly, MUV appeared in the USSR long before something similar appeared anywhere in another country. Secondly, the very first imitations of the MUV were the Finnish tension-action cartridge fuse M40, which appeared in 1940 during the “winter war” and the German fuse Zugzuender 42 (ZZ 42), which appeared only in 1942. Thirdly, in countries that followed their own path of development of mine fuses (USA, England, France) in those years, no fuses closely enough similar to the MUV appeared. Fourthly, MUV borrowing fuses, as a rule, are available in countries that, during and after the Second World War, were in one way or another under significant influence of the Soviet Union. Therefore, this fuse is worth talking about it in more detail and tracing its history. Soon after the end of the Civil War, the outstanding Soviet military engineer D.I. Karbyshev formulated clear provisions regarding mine explosives in general, as part of the obstacle system, and the basic requirements for the design of engineering ammunition, explosive means, mine-explosive equipment and equipment. In particular, this is Karbyshev’s major scientific work “Destruction and Obstacles”, published in 1924. By him and other Soviet military engineers (I.V. Volkov, B.A. Epov, D.V. Chernyshev, B.M. Ulyanov, A.D. Podshivalkin, A.I. Kulchikhin, I.A. Shipilov, V P. Yastrebov and others) developed a fairly clear classification of mines and the basic tactical and technical requirements for them, as well as for their drive devices. Based on these fundamental requirements, the construction of both the engineering mines themselves and the fuses for them began. One of the first Soviet mines, which was developed by 1932 as a product to be manufactured in a factory, was the T-4 anti-tank mine. This mine had a target sensor on top in the form of a pressure board, which, falling down under the influence of the tank caterpillar, forced a special lever mechanism to pull the combat P-shaped pin out of the fuse. The freed drummer hit the primer. The fuse was not an integral part of the mine's design. It was an independent product that was inserted into the mine when preparing it for use. Today we cannot say for sure who exactly proposed the design of the fuse for this mine and whether this fuse was developed specifically for it. We know the name of the mine designer. This is N.N. Simonov. Whether he was also the creator of the fuse remains unclear. The fact is that the fuse was most likely developed as a universal fuse for anti-tank mines. Yes, yes, for anti-tank mines. Our widely known as the MUV anti-personnel mine fuse was born as an anti-tank mine fuse. It was used in anti-tank mines of the thirties and forties T-4, TM-35, TM-39, TMD-40, AKS. The reference book “Partisan's Companion”, published in 1942, describes this fuse, which appeared in 1932 under the name “Simplified UV Fuse”: “A simplified fuse (SV) is a cylinder, inside of which there is a firing pin that pierces the igniter capsule using a spring. The spring comes into action as soon as the safety pin is pulled out.” Of course, this is a very general description of the fuse. Let's look at it in more detail, because... the design principle of the fuse will change little over time. Fuze simplified UV. Its device is extremely simple. It consists of the following parts - sleeve (1), firing pin (2), spring (3), primer holder (4), P-shaped combat pin (5) and safety pin (6). The figure to the right shows the sleeve in partial section. The sleeve was made of copper and was a cylindrical or somewhat cone-shaped tube, closed at one end and having an M10 internal thread at the other end. The diameter of the sleeve at the bottom is 12.3 mm, at the top 10.5 mm. Length 53 mm. At the top there was a rectangular slot for the striker. The striker was made of steel and coated first with copper, and then galvanized or nickel-plated, and was a rectangular long plate 58 mm long. The lower end of the plate was sharpened and a triangular plate with rounded edges was placed horizontally on it. It was diagonally slightly smaller than the inner diameter of the sleeve and acted as a guide for the firing pin and at the same time as a lower stop for the spring. The striker had two holes in its upper part for a combat pin and for a safety pin. Spring made of spring steel, chrome plated. Its lower end rested against the triangular plate of the striker, and its upper end rested against the upper part of the sleeve. A capsule holder, which was a complex-shaped tubular part, was screwed into the sleeve from below. In the upper part, the capsule holder had an external M10 thread. The outer diameter of the primer holder in its upper part was the same as the lower diameter of the sleeve (12.45mm). The outer diameter of the lower part was 8.8 m, and the inner diameter was 8.0-8.4 mm. This made it possible to easily insert a standard KD No. 8 detonator capsule or a fire-conducting (bickford) cord into the capsule holder. A regular KV-11 igniter primer was pressed into the primer holder from above. In the safety position, the firing pin shank protrudes from the cartridge case so that both holes are visible. A P-shaped combat pin is inserted into the lower one, and a safety pin is inserted into the upper one. The spring is in a compressed state. The detonator capsule KD No. 8 is inserted into the primer holder and crimped using a crimp. However, the detonator capsule can simply be inserted into the capsule holder, wrapping it with paper so that it is held tightly enough. The primer holder is returned to the cartridge case. After the fuse is inserted into the mine (horizontally), so that the sharp lower end of the double-armed lever enters the ring of the P-shaped pin, the safety pin is removed. From this moment on, the spring-loaded firing pin is held in place only by the P-shaped combat pin. When pressure is applied to the mine cover and the pressure bolt presses on one end of the double-armed lever, the second, rising, pulls the P-shaped pin out of the fuse and releases the firing pin, which, under the action of the spring, will go forward and puncture the primer. A flash of flame inside the primer holder will cause the detonator cap to explode. It will trigger the main charge of the mine. The HC fuse with a similar explosive mechanism was used in the first Soviet anti-bottom high explosive anti-tank mine AKS. Some time after the HC fuse was adopted, it underwent some modernization. The copper plate striker was replaced with a steel round-shaped striker. Accordingly, the rectangular hole in the upper part of the sleeve was changed to round. The T-4 mine was manufactured in small batches and was used mainly as a test base. In 1935, the first industrially manufactured metal anti-tank anti-track mine TM-35 was adopted into service with the Red Army. This mine used a UV fuse. The same principle of operation of the fuse and, accordingly, the HC fuse was used in the Soviet extended anti-tank mines TM-39 and TMD-40, and in these two mines two HC fuses were used at once. The UV fuze was also used in one of the first Soviet anti-personnel mines. Thus, in particular, its use was envisaged in the anti-personnel mine model 1933. The design of the capsule holder made it possible to use hydrocarbons as an igniter for incendiary tubes, for which the end of the fire-conducting (bickford) cord was inserted into the capsule holder instead of the detonator capsule. With the outbreak of the war with Finland in December 1939, when it turned out that the given conditions required primarily mines capable of stopping Finnish infantrymen, the newly created mines (PMM-5, PMM-6, loop anti-ski mine, lever anti-ski mine) were also used UV fuse. The use of a universal HC fuse turned out to be much more expedient than developing its own specific fuse for each new mine. It could also be used in the manufacture of homemade and improvised mines, including anti-vehicle mines. So the abbreviation UV meant “universal fuse” more than “simplified fuse,” as the creators themselves called it. At the same time, the Finnish war also revealed a very significant drawback of the fuse, namely, the leakage of the primer holder, as a result of which, in conditions of damp swampy soil, melting snow, or even simply due to precipitation, moisture penetrated between it and the detonator capsule and the latter failed . Attempts to seal the junction of the detonator capsule and the primer holder with various available means (tar, electrical tape, resin) did not always give the desired result, and they sharply increased the preparation time for the fuse. The second drawback of the HC fuse was that in all cases the striker was held only by the combat P-shaped pin, and the safety pin played only the role of a backup in case of accidental pulling out of the combat pin. The safety pin, which was not held in place by anything, often fell out of the hole and was lost. This made the fuse dangerous to use. The solution to the problem of tightness lay on the surface and in 1940 the MD-2 fuse appeared, which was a brass (aluminium, steel) sleeve (shown in red in the section in the figure on the left), into which the same KV-prick-action capsule was inserted on top. 11, and below is the usual detonator cap KD No. 8. The latter was crimped onto the bushing and, for greater tightness, the joint was covered with black or red varnish. In the upper part, the bushing had an external M10 thread and a grooved side for ease of use. By the way, in the same year, the industry also mastered the production of detonator caps made of aluminum, as a result of which they began to be produced in two modifications, KD No. 8A and KD No. 8M. Thus, the need for a primer holder disappeared and it ceased to be part of the UV fuse. Note that in the same 1940, P.G. Radkevich and N.P. Ivanov proposed for anti-tank mines a much simpler, more reliable and easy-to-use push-action fuse MV-5, which did not require a rather bulky and complex lever device , which was used in T-4, TM-35, TM-39 and TMD-40 mines with a UV fuse. The new anti-tank mines of the TMB, TM-41 series already used the MV-5 with an MD-2 fuse, and the need for a UV fuse for new industrially produced anti-tank mines disappeared. Also in 1940, the UV fuse itself was modernized. It consisted in the fact that the hole for the combat pin began to be made not round, but elongated, and a copper spacer sleeve was added to the fuse, which was inserted between the combat P-shaped pin and the safety pin. Now in the safety position, the spring-loaded hammer was held in place by a safety pin resting on a spacer sleeve. The latter, in turn, pressed on the combat pin, pressing it against the cartridge case. This ensured reliable retention of both the safety pin and the combat pin. And at the same time, by pulling up the safety pin, and thereby lifting the firing pin, it was possible to easily remove the P-shaped combat pin from the fuse and replace it with a T-shaped one (and vice versa). A T-shaped pin was introduced into the fuze kit so that the fuze could be used as a double action (pull/push) fuze. When the safety pin was pulled out, the firing pin fell down under the action of a spring until the upper part of the slot rested on the combat pin. The fuse was in firing position. The figure on the right shows the position of the firing pin in the safety position (to the right) and at the moment of placing it in the firing position (to the left). The fuze sleeve and bushing are shown in partial section. When put into firing position, the copper bushing usually jumped off the rod, although even if it remained in place, this would not in any way interfere with the operation of the fuse. In addition to the main modernizations, the metal of the sleeve was replaced from copper to brass (later to duralumin or steel with an anti-corrosion coating), as a metal more resistant to oxidation. The drummer began to be made round in cross-section and made of steel. As it turns out over time, making the striker from steel became a mistake. According to the observations of A.V. Bondarev, over time, with the relatively good preservation of the cartridge case itself, the combat pin and the excellent preservation of the spring, the firing pin corroded significantly, as a result of which its size increased and the fuse became inoperative. He also had to encounter these fuses with a round hole in the upper part of the cartridge case, but with a flat firing pin. He came across composite sleeves, for example, a copper sleeve with a tin cap soldered on top for a flat firing pin, or a sleeve soldered from two copper parts. In connection with the modernization, the name of the HC fuse was replaced by MUV. Modernized simplified fuse MUV mod. 1940 Its design differs little from that of the UV fuse. It consists of a brass (sometimes copper) sleeve (1) with an M10 internal thread at the lower open end and a hole for the firing pin at the upper closed end, a steel firing pin (2) with an upper hole for the safety pin and a lower slot for the firing pin, a spring ( 3), a copper spacer sleeve (4), a safety pin (5) and two combat pins - P-shaped and T-shaped (6a and 6b) used depending on the method of using the fuse. On the right is the MUV fuse mod. 1940 in a combat position without a fuse. The outer diameter of the sleeve is 12.3 mm, length 55.6 mm. General data of the MUV fuse: *diameter -12.3 mm; *length of the unloaded fuse is 74mm; *length with MD-2 fuse - 126mm; *total weight without fuse -31 grams; *triggering force with a P-shaped pin is -0.5 - 1 kg, with a T-shaped pin - 2-15 kg. It should be noted that the MD-2 fuse is not included in the MUV fuse kit and is supplied separately. However, the modernized fuse has lost the ability to be used as an igniter for incendiary tubes, which, in the author’s opinion, is a big drawback. The fact is that the problem of reliable ignition of incendiary pipes in our country has not been satisfactorily resolved today. Standard factory-made incendiary tubes ZTP-50, ZTP-150 and ZTP-300 do not solve this problem, because For the most part, sappers in the army have to use incendiary pipes made on the job site, which have to be ignited the old fashioned way - with matches. The MUV fuse, in addition to being used instead of the UV fuse in anti-tank mines TM-35, TM-39 and TMD-40 and anti-personnel mines (PMM-5, PMM-6, loop anti-ski mine, lever anti-ski mine) was intended as a standard fuse (with T -shaped pin) of the new anti-personnel mine PMD-6, adopted for service in 1941 shortly before the start of the war. From the author. Here we are again faced with ambiguity and vagueness in mine terminology. To be precise, the HC fuse should be called a pin-point igniter, because at the output it only gives a boost to the flame and only when combined with the detonator cap KD No. 8 can it be considered a fuse, because at the exit we get an explosion. The situation is the same with the MUV fuse. When it is not combined with the MD-2 fuse, it is just a tension or push action pin mechanism. And only when we screw the fuse into it does it become a fuse, because at the exit we get an explosion. But it is what it is. We will use the terms that were introduced to us by the creators of the fuses and the service instructions. And if we start correcting the terminology, we simply risk completely confusing the reader. The MUV fuse, together with its predecessor UV and the UVG variant, found the widest application during the Great Patriotic War. In addition to the PMD-6 anti-personnel mine and its variations (PMD-6f, PMD-6sh, PMD-7, PMD-7ts, PMD-57, MKF), it was installed in the POMZ-2, which later became a classic mine, which entered service with the Red Army in 1941 , various types of homemade and improvised mines, in the wooden anti-tank mine YaM-5 and its variations (YAM-5k, YaM-5M, YaM-5u, YaM-10) developed and widely used during the war years and in the world’s first anti-tank anti-aircraft cumulative mine LMG (1942). The same fuse was used in the MS-2-2-trap and various impromptu trains. Muv was also used to undermine mines and charges in the controlled version (a sufficiently long twine was tied to the R-shaped check, which with its help was pulled out if necessary). The alloy river mines of the UMK-2, SRM-263 and the planned river mine were also equipped with a fuse of the MUV. He found widespread use in the partisan sabotage war. It is enough to say about the opposite partisan mine, where the steam locomotive, running around the lever associated with the R-shaped combat check of the fuse of the Muv, pulled it out, causing the explosion of the charge of TNT. At the same time, due to a low production culture, in particular, due to the fact that the length of the drummer was not always withstanding for sure, there were times when when removing the safety stud, the fuse occurred. Therefore, the instructions demanded before using the fuse to check whether the drummer would reach the capsule in the combat position of the fuse. However, the manufacture of standard fuses of the MUV soon after the start of the war became difficult, first of all, due to the fact that the manufacture of an elongated slot for a combat check required milling, and milling machines, especially for small parts, were not enough. I had to abandon the elongated slot and make a second drilling hole instead. So the fuse received his simplified version of the 1942 sample. A modernized simplified fuse of MUV. 1942 Outwardly, fuse arr. 1942 It differs from the pre -war option by the absence of an elongated slot under the combat check (instead of it. A hole), the absence of a spacer bushing (it simply did not complete fuses in order to save copper) and the absence of corrugated rolling in the upper part of the fuse, which reduced the production of the fuse per operation. In addition, due to the often arising deficiency of fuses MD-2, fuses of the MUV arr. 1942 Often equipped with a capsulaster from the fuse of UV. This was done so that in the absence of fuses MD-2 in the troops, the fuses of Muv would not be useless. The extinguishing of a spacer bushing set and the transition to a round hole for a combat check instead of elongated significantly increased the danger of a fuse and in 1943 a different version of the combat R-shaped check was proposed. She received a safety 0-shaped ring, which in a safety position was pounced onto the drummer and prevented the random pulling out of the combat check. The safety stud in the fuse with such a check received a different role - to prevent random dropping of the safety ring. The figure on the right shows the safety position of the fuse (to the right) and the combat position (to the left). Unfortunately, this very useful invention was not widely distributed due to the fact that the transfer of the fuse into a combat position now required two actions instead of one (pulling out a safety hairpin and drop the safety ring). The sappers, accustomed to the same action (and often, neglected the safety hairpin), too often forgot to drop the safety ring and the mine did not work when necessary. In the post -war period, this version of the fighting check fuses were not completed. This version of the fuse Muv lasted until the end of the war and then was produced in parallel with the fuse of the arr. 1940 until the mid -seventies. The fuses of the muvs of both samples were packed in wooden boxes in size 55x49x17 cm. The weight of the box is 20 kg. There are four sealed banks in the box. Each bank has 10 cardboard boxes. In each box, there are 5 fuses with T-shaped checks and 5 P-shaped checks separately. Those. There are 200 fuses in the box. The fuses were not equipped with fuse. Simplified fuse Guilsic UVG arr. No. 1. From the very beginning of the war, due to the sharply increased needs of troops in mine-explosive means, the consumption of fuses of UV and Muv has increased so much that the industry could not cope with the tasks of their production. A particularly narrow place in the production of fuses was the production of cartridges and fuses MD-2. The output was found in a return to the fuse of the capsulator capsuretor (especially since the carving fled MD-2 and the capsulenter completely coincided) and in the use of the guilse fuse from the rifle cartridge. 1908. Both shooting rifle sleeves and newly made, but not meeting the requirements of standards were used. At the sleeve, the bottom was sawn with the capsule and the internal thread of the M10 was cut. Otherwise, UVG did not differ from the fuse of UV and could be used both with the fuse MD-2 and with the detonator capsule KD No. 8. The picture on the left shows the UVH fuse with an unscrewed capsulaster capacity (1), with a screwed capsuler and a capsule-deputy deputon of KD No. 8M (2) inserted into it. Nearby for comparisons, the UV fuse is shown (3). Simplified fuse Guilsic UVG arr. No. 2. However, this did not solve the problem until the end. It was required to create a fuse requiring a minimum of machine equipment. A fuse that could be done in the field. Nevertheless, the cutting of two threads (in the sleeve and on the capsuler) and the presence of a complicated part (caps -mount) made it difficult to increase the production of explosives. The output was found in a gills for 180 degrees. The bottom of the sleeve was not sawn off. It was only necessary to drill a hole in the place of the capsule. The smell MD-4, which was a capsule-depetrator KD No. 8 with a capsule of the KV-11 type, put on it on a varnish, but a larger diameter and with an elongated skirt. This fuse MD-4 was inserted into a sleeve of a sleeve. In the picture on the right, the fuse of UVG arr. No. 2, made from the sleeve of the rifle tableton, with the remains of the fuse. Nearby, the reconstruction fell MD-4. Some experts claim that this is the Finnish sleeve, which appeared in the Finns during the winter war (1939-40). We will not argue, especially since, firstly, both the Finns and the Russians in service consisted of the same rifle and the same cartridge, and secondly, mutual borrowing types of weapons and ammunition are so developed in the world, Which sometimes becomes impossible to determine priorities in invention. But the fact remains - the Red Army during the war used the fuses of the UVG of both samples. Well, here are a few images of the Finnish sleeve of M40. The difference between UVG and M40 for an experienced eye is still noticeable. With the end of the Great Patriotic War, the production of fuses of the UV, the UVG of both samples and the fuse MD-4 was discontinued. In service with the army, only a fuse of Muvs was left as a model of 1940 and a model of 1942. It was produced until the beginning or even the mid -seventies, although, of course, its role with the advent of the anti -personnel pressure of the PMN with the built -in fuse in 1949 decreased sharply. The PMD-6 mine and its modification of the PMD-6M, using the fuse of the MUV, although they remained in service, but only as a backup in case of war. Anti -tank mines under the fuse Muv was no longer produced. The PMZ-2 mines used very widely, in the post-war period, was modernized and received the name POMZ-2M. The modernization was that the tide was cut off in the upper part of the case, which was intended to keep the MUV fuse with the fuse MD-2. A hole was drilled in the upper part of the minina housing, in which M10 thread was cut. The fuse, which received the name MD-5M, was screwed into this hole. And already a fuse Muv was screwed onto the fuse. So gradually it was forgotten about the fuses of UV and UVG, who played a very significant role in the Wehrmacht inhibition in his victorious march in Russian expanses. But it would not be bad to remember that the Nazi generals, along with the Russian tall and frosts, were bitterly complained of Russian mines. Here is what the German, General F. von Mellandin writes in his book “The Book Fist of the Wehrmacht” about Soviet mining: the Russian Supreme High Command led combat operations during the Battle of Kursk with great art, skillfully withdrawing its troops and nullified the power of our armies with the help of a complex Systems of minefields and anti -tank barriers ... ... Russians, like no one, knew how to strengthen their phone (anti -tank defense area) with the help of minefields and anti -tank obstacles, as well as mines scattered in disorder between mineral fields. The speed with which the Russians installed mines was amazing. For two to three days they managed to put over 30 thousand minutes. There were times when we had to neutralize up to 40 thousand min. Despite the fact that we advanced into the defense of Russians up to 20 km, minefields were still located around us, and anti -tank defense areas prevented further advancement. In this regard, it should once again emphasize the most skillful disguise of the Russians. Not a single minefield, not a single anti -tank area was able to detect until the first tank was blown up on a mine ...

Sources

1. P.I. Biryukov and others. Textbook. Corps of Engineers. Military publishing house of the USSR Ministry of Defense. Moscow. 1982 2. I.P. Balatsky, F.A. Fominykh. Essay on the history of the Kaliningrad Higher Military Engineering Command Order of Lenin Red Banner School named after. A.A.Zhdanova. Military Publishing House of the USSR Ministry of Defense. 1969 3. Book on Soviet mine-explosive weapons without sending data (without cover and title page). Presumably editions of 1943-44. 4. Kalibernov E.S. Engineer Troops Officer's Handbook. Moscow. Military publishing house. 1989 5. QRDATA II: International Deminer`s Guide to UXO Identification, Recovery and Disposal. 6.Textbook. Military engineering training. Moscow. Military publishing house. 1982 7. Manual on military engineering for the Soviet Army. Moscow. Military publishing house. 1984 8.Engineering ammunition. Materials and Application Guide. Book one. Military publishing house of the USSR Ministry of Defense. Moscow. 1976 9. US Army Field Manual FM 20-32. Mine/Contermine Operations. Headquarters, Department of the Army, Washington, DC, 30 September 1999. Change 22 August 2001. 10. Partisan's Companion. Directory. Young Guard. Moscow. 1942 11. Collection of A.V. Bondarev. 12. Collection of D.I.Gorbovsky. 13. US Army Field Manual FM 5-102. Countermobility. Headquarters, Department of the Army Washington, DC, 14 March 1985. 14. W. Fleischer. Deutsche Landminen 1935-1945. Waffen-Arsenal.Band 164. 15. Website “The Grenade Recognition Manual” (members.shaw.ca/dwlynn/). 16.F.Mellentin. Armored fist of the Wehrmacht. Rusich. Smolensk 1999 information taken from the site Minesweeper..

VZD-3M, VZD-1M

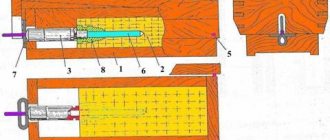

and VZD-1M fuses are intended for loading, respectively, small and medium sticky mines (sticky mines), anti-personnel fragmentation mines of the POMZ-2, POMZ-2M type (trip mines), and can also be used for automatic explosion of explosive charges at expiration of a predetermined period.

The VZD-3M fuse consists of a body with a cover, a striking mechanism with a moderator and an MD-2 or MD-5M fuse. A metal element is used as a moderator. The fuse kit includes metal elements 1, 3, 5, 6, of which 6 are included in the fuse, and the rest are wrapped in a wrapper and placed under the fuse in a cardboard box. The same box contains a table of the timing of their deceleration at different temperatures.

Fuse VZD-3M

VZD-ZM fuse with MD-5M fuse: A - general view B - section.

1 - cover; 2 - cap; 3—metal element; 4 - cutter; 5 - bushing; 6 - check; 7—bushing; 8 - drummer; 9 — rubber ring; 10 - spring; 11 — body 12 — MD-5M fuse

After pulling the pin out of the fuse, the cutter of the impact mechanism, under the action of a spring, begins to cut the metal element. At the end of the cutting, the striker is released and pierces the igniter primer of the MD-2 fuse.

The fuse is not sealed and is not suitable for installation in water, but it is designed to be protected from rain (splashproof).

A fuse installed with a deceleration period of up to 6 hours (at nominal temperature at +20 C) is prohibited from being neutralized. If set for a period of more than 6 hours, it can be neutralized only if no more than 1/3 of the set delay period has passed since its launch.

The VZD-1M fuse consists of a body with a membrane, a cap, a pinning mechanism and an MD-5M fuse. The principle of its operation is similar to the VZD-3M fuse.

Fuse VZD-1M

VZD-1M fuse device: 1 - cover; 2 - cutter; 3 - metal element; 4 - check; 5 - bushing; 6 - threaded bushing; 7 - drummer; 8 — mainspring; 9 — body; 10 — membrane 11 — igniter MD-5M.

VZD-1M is equipped with six replaceable metal elements No. 1, 3, 5, 6, 7 and 8, of which No. 6 is inserted into the fuse, the rest are placed in a bag placed in a case.

The features in handling the fuse are the same as with the VZD-3M, only when installing it in a mine, it is prohibited to screw in the fuse without a safety pin. The pin is removed after the mine is installed on the site.

MD-5, MD-7

Most often used in 45, 57, 76 mm shells. Extremely simple in design. It was screwed into the bottom of the projectile, sealed with a lead gasket and non-drying mastic based on red lead. Has a fixed firing pin. The fuse was made of fairly high quality; its internal parts are made of non-ferrous metals, chrome-plated and, as a rule, do not become corroded after being in the ground for half a century. Operating principle: upon contact with an obstacle, the inertial striker overcomes the 2-3 mm contact of a split thin-walled brass tube. There are no more safety devices. Possible shocks and impacts may bring the firing pin dangerously close to the sensitive igniter primer.

It is possible that accidents that occurred when handling armor-piercing projectiles equipped with MD-5 fuses were caused by irreversible chemical processes in the ignition and detonation device. In pre-war times and in the initial period of the war, a huge number of shells equipped with MD-5 were manufactured. During the war, due to the dangers of handling, this fuze was withdrawn from production, but not removed from service. It was replaced by the MD-7 fuse, which was very similar in appearance and design, which was equipped with additional devices - a striker counterspring and a copper circle covering the igniter primer.

M-1, M-4

Soviet 82 and 50 mm mines with an M-1 fuse are very dangerous, even if they have not gone through the barrel, for some reason they find themselves in a combat platoon. A distinctive feature is an aluminum cylinder under the cap. If a red stripe is visible on it, the mine is armed!

Particularly dangerous are German mines with a Wgr.Z-38 (aluminum) fuse that have passed through the bore and Soviet ones with an MP, M-4, MP-82 (plastic) fuse, which can even be triggered by a side impact. MP-82 differs from MP (MP-4) in having a more durable diaphragm and was intended only for 82 mm fragmentation and smoke mines.

The insert fuses of the RGD-33, RPG 40(41) grenades, the Serdyukov ramrod grenade, and the RGD-43 pose a serious danger. They can be found separately from grenades next to the remains of soldiers and confused with a pencil or other object. If you find suspicious objects of a similar shape, exercise extreme caution!

Explosive means (SV). Part III

(Continued. Beginning in the articles “Means of Explosion (SV). Part I

and

Part II

")

SV stick type

The blasting means described in parts I and II of this article are used mainly when performing demolition work, although in some cases they are also used in engineering mines (for example, EDP-r electric detonators with KPM-1 blasting machines are used to explode MON-50 mines). The SVs described below are used mainly in engineering mines, although they can also be used, if necessary, during normal demolition work.

The main means of explosion here are fuses and igniter caps. In various variations, they are components of ammunition (for example, a regular capsule is part of the design of a cartridge for small arms), components of fuses (for example, an MD-6 fuse is part of the MVM fuse of a TM-46 mine) or they exist separately, attached to the source external influence when equipping ammunition (for example, an MUV fuse can be equipped with an MD-2 or MD5m fuse, which is screwed to the fuse only at the time the mine is installed).

What is common to all fuses and primers is that the actuator (weapon bolt striker, fuse firing pin) causes a mechanical blow (puncture) to the means of explosion (fuse, primer), which causes an explosion of the initiating explosive located inside the fuse, primer. The consequence of the explosion of the initiating explosive is the explosion of the main explosive charge (powder charge of the cartridge).

The standard fuses of the Soviet Army (Russian) are detonator caps KD-MV, M-1, igniter caps KV-11, KV-11m, fuses MD-2, MD-5M, MD-6N, MD-9, MD-10 and a number of others. Let's look at some of them.

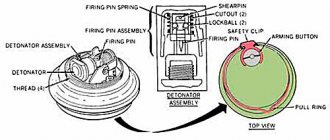

Fuses MD-2 and MD-5M

. Both fuses are metal bushings into which a primer-igniter is pressed on top (similar to a regular rifle primer), and a regular detonator cap No. 8A is pressed into the bottom. The MD-2 fuse has a thread in the upper part of the bushing for screwing to the fuse actuator. The MD-5M fuse also has a thread in the lower part of the bushing for screwing into the mine body, a socket for a TNT block. When the fuse striker strikes the primer, it sends a force of flame into the detonator cap, causing the latter to explode. The fuse of the UZRGM grenade has the same fundamental device, but there is a column of powder placed between the igniter capsule and the detonator capsule, which burns for 3.2-4.2 seconds and only after this time transmits the flame force to the detonator capsule

The remaining service fuses differ only in their size, shape, and body material

Let's look at some universal fuses used in many mines. In general, strictly speaking, a fuse should be called a fuse connected to an actuator and means for actuating the actuator. However, there is no strict terminology here.

Fuzes of the MUV series.

— fuze MUV

. An extremely simple design and extremely reliable fuse, invented back in the First World War and used to this day in many types of mines. It consists of five parts (body, firing pin, spring, firing pin (two options - T-shaped and P-shaped), safety pin (pin). This fuse uses fuses MD-2, MD-5M, MD6N, etc. The figure shows an MUV with an MD-2 fuse screwed into it and a P-shaped pin. Above on the firing pin rod you can see the hole for the safety pin. The fuse is inserted into the mine with the fuse, and a tension wire is attached to the pin. When the wire is pulled, it pulls out of the firing pin P -shaped pin and spring-loaded striker strikes the primer. The T-shaped pin is used when using a fuse as a pressure fuse. However, the fuse turned out to be very insidious and overly sensitive. Other modifications of the fuse, without affecting the essence of the design, differ from each other in devices for increasing the force required for pulling out the pin and safety devices that provide a delay in bringing the fuse into combat mode after pulling out the safety pin.

— fuse MUV-2

. It differs from the MUV in the presence of a temporary fuse, which is a structure made of a wire loop at the end of the firing pin rod and a soft metal plate lying on the body. When the safety pin is pulled out under the influence of a spring, the loop falls on the plate and begins to cut it. Depending on the air temperature, this process lasts from 2 minutes to 59 hours. After cutting the plate, the drummer is held only by the combat pin. This fuse dramatically increased the safety of miners. The picture shows an MUV-2 fuse with an MD-5M fuse. The combat T-shaped pin, the ring of the safety pin and the rubber flap covering the metal element and the loop at the end of the firing pin are clearly visible.

— fuse MUV-3

. It differs from the MUV-2 by the presence of a bracket connected to the pin and hugging the fuse body. The bracket increases the pulling force of the combat pin, which ensures satisfactory sensitivity of the fuse. The picture shows the MUV-3 fuse without a fuse.

— fuse MUV-4

. It differs from its predecessors in the type of temporary fuse. After the safety pin is pulled out, liquefied rubber begins to flow from cavity to cavity. Such a system ensures that the time for setting the fuse to the firing position is less dependent on the air temperature. In the picture, the MUV-4 fuse is without a fuse.

From the author.

Oddly enough, in mine blasting, strict terminology has not yet been developed in the designation of engineering ammunition and explosive means. Thus, the terms “fuse”, “explosive mechanism”, “explosive device”, “actuator” and some others exist with equal rights. Moreover, the same design used in hand grenades is called a “fuse”. Moreover, there is no clear distinction in the use of the terms “mine” and “land mine”. In some cases, a mine with a large explosive charge is called a land mine, in others a controlled mine, in others, a controlled mine with the addition of improvised lethal elements (for example), “stone-throwing land mine”, “incendiary land mine”. Fourthly, it is simply an explosive charge that explodes when the enemy approaches in order to inflict losses on him. With regard to nuclear engineering munitions, in the same instructions on one page the same munition is called a “nuclear mine”, on the other “nuclear landmine”. The only thing that can be said for sure is that in mine blasting the names that are widely used among journalists who are “major specialists” in the mine field (“infernal machine”, “bomb”) are not used.

(Continued. Ended in the article “Means of Explosion (SV). Part IV

»)

Veremeev Yu.G.

What is a playstation move controller used for?

Moves, as they are popularly called, perform two simple options:

- replace dualshock;

- capable of tracking body movement using built-in sensors.

Among other things, compared to a joystick, they weigh much less.

As the developers tell us, these controllers are needed to interact with a virtual reality helmet.

In other words, it’s hardly worth buying a twin pack separately. Moreover, on the market it costs much more than the same dualshock 4. But there are still several games and applications where only these controllers are needed. So far the line-up is meager, but the Japanese have promised to diversify it.

The list of games and entertainment is in the article about the camera, see above. Of course, with the purchase of a VR helmet, it becomes much wider.

For example, Capcom released a version of the Viar of the eighth part of Resident Evil, which I also have a review about. Gamers say that it’s just creepy how scary it gets there.

What are move controllers?

As you know, in the fourth line of Sony PlayStation there is a model that has technologically stepped forward. We are talking about PS4 Pro, where it became possible to immerse yourself in virtual reality.

But you still can’t do without additional gadgets. That's why the company developed a VR helmet and also released an updated camera.

In addition, some games simply won't be worth purchasing if you don't have move controllers.

At their core, these are additional gadgets that allow you to much more accurately calculate the coordination of movement in space using a special sensor.