Regular eight-groove rifling on the left and octagonal polygonal rifling on the right.

Polygonal rifling

(/pəlɪɡənəl/ pə-LIG-ə-nəl) is a type of rifling gun barrel where the traditional sharp "lands and grooves" are replaced by less pronounced "hills and valleys" so the bore has a polygonal (usually hexagonal or octagonal) cross-sectional profile.

Italian firearms manufacturer Sabatti SPA issued a press release on September 7, 2022 for a more modern design that describes a special type of non-angled polygonal rifling with rounded dimples called multi-beam rifling

.

Polygonal flutes with more edges have finer angles, which provide a better gas seal in relatively large diameter holes. For example, in pre-Gen 5 Glock pistols, octagonal rifling is used in the large diameter .45 ACP bore, which has an 11.23 mm (0.442 in) diameter, as it resembles a circle more closely than the hexagonal rifling used in the smaller diameter holes. [1]

History[edit]

Left

: rifled mountain gun of the French La Hitte system "Canon de montagne de 4 modèle 1859

Le Pétulant

".

Caliber: 86 mm. Length: 0.82 m. Weight: 101 kg (208 kg with trolley). Ammunition: 4 kg shell. Right image

:

Le Pétulant

(detail).

Although polygonal rifling had existed since the early days of rifled barrels, it had fallen out of use by the time the first cordite cartridges were introduced, largely due to manufacturing problems and poor compatibility with the new, more erosive smokeless powder ammunition at the time.

The polygonal barrel principle was proposed in 1853 by Sir Joseph Whitworth, a prominent British engineer and entrepreneur. Whitworth experimented with cannons using twisted hexagonal barrels instead of the traditional round rifled barrels, and patented the design in 1854. In 1856, the concept was demonstrated in a series of experiments using brass howitzers. However, the British military rejected Whitworth's polygonal designs. Whitworth subsequently adopted the small arms concept, believing that polygonal rifling could be used to create a more accurate rifled musket, replacing the Pattern 1853 Enfield.

During the American Civil War, the polygon-rifled Whitworth rifle was successfully used by Confederate States Army marksmen (known as Whitworth Sharpshooters) to terrorize Union Army gun crews. The muzzle-loading inch rifle was often called the "Sniper" due to its high accuracy compared to other rifled rifles of its era (far superior to the breechloading Sharps rifle used by the Union Army), and is considered one of the earliest examples of a sniper rifle. Whitworth's snipers killed several high-ranking Union officers. Major General John Sedgwick, who was mortally wounded at 1,000 yards (910 m) during the Battle of Spotsylvania Courthouse.

The last service rifles to use polygonal rifling were the British Lee-Metford rifle, named after Metford's patent rifling; and the Japanese Arisaka rifles, designed by Colonel Arisaka and Colonel Nambu. The Lee-Metford rifle proved to malfunction after switching to erosive cordite proving too much for the smooth and shallow Metford rifling, which was designed to reduce barrel fouling for black powder ammunition. When the Metford rifling design was abandoned, the Lee-Metford became the Lee-Enfield rifle in favor of Enfield-style rifling, which had deep rifling for longer life. On the other hand, Arisakas were widely produced for the Imperial Japanese Army from 1897 to 1945 without undue problems with rifling erosion, as the Japanese used higher quality non-erosive propellant.

During World War II, polygonal rifling reappeared in the German MG 42 general purpose machine guns as a result of the cold hammer forging process developed by German engineers before the war. This process addressed the need to produce large quantities of stronger barrels in less time than those produced by traditional methods [2], as the MG 42's notoriously high rate of fire tended to quickly overheat the barrel and thus required frequent barrel replacements. The MG 42's successor, the Rheinmetall MG 3 machine gun, can also have polygonal rifling.

Heckler & Koch was the first manufacturer to use polygonal rifling in modern small arms such as the G3A3 battle rifle and several semi-automatic hunting rifles such as the HK SL7. [3] Today this method is used by companies such as Tanfoglio, Heckler & Koch, Glock (Gen 1-4), Magnum Research, Česká Zbrojovka, Kahr Arms, Walther and Israel Weapon Industries. Polygonal rifling is usually found only in pistol barrels and is less common in rifles; however, some extremely high-precision rifles like the Heckler & Koch PSG1 and its Pakistani variant PSR-90, and the sniper rifle use the LaRue Tactical Stealth system.

The term "polygonal rifling" is quite generic, and different manufacturers use different polygonal rifling profiles. H&K, CZ and Glock use polygonal internal thread rifling similar to the bore shown above on the right. This type has a smaller bore area than the male polygonal rifling type developed and used by Lothar Walter. Other companies, such as Noveske (Pac Nor) and LWRC, use rifling more like conventional rifling, with both sides of each land being sloped but having a flat top and defined angles; this type of rifling is more similar to slanted ground rifling than polygonal rifling.

Barrel rifling. Non-standard cuts, sizes, equipment, tips. Part 1.

https://telete.in/joinchat/AAAAAEMI5d95ioeDWw36gQ

Materiel. What affects the combat characteristics of a barrel?

Barrel length: This is the most important factor when developing or upgrading any weapon. The length of the barrel is primarily dictated by the class of weapon, the laws of physics and common sense.

In simple terms, we can say: if you are planning a barrel for a pistol cartridge with a length of less than 50mm, for an intermediate (automatic) cartridge with a length of less than 150mm, for a rifle cartridge with a length of less than 200mm, you don’t have to read this materiel. With such a short length, either a simple smooth barrel or a perfectly calculated rifled barrel will show plus or minus equally bad accuracy, making it possible to hit only a chest figure target at a distance of up to 20m. Moreover, a barrel of this length will reduce the muzzle energy of the cartridge by 30 percent, because the powder charge simply will not have time to burn out completely in the barrel.

You can put a 200-300mm long barrel on a pistol, you can radically increase its combat characteristics, especially range, but the pistol will turn into another class of weapon - a carbine, and it will no longer be possible to carry it covertly.

You can lengthen the barrel until the bullet begins to slow down in the barrel, but such a barrel cannot be made even in a factory, because its length will be tens of meters, and problems often arise with shortening the barrel. If a short-barreled weapon usually “survives” a shortening of an already short barrel by 10-15%, then a long-barreled weapon, designed for either a pistol or an intermediate/rifle cartridge, does not like this very much, and you may have to change the pitch of the rifling.

Rifling pitch:

The rifling pitch (twist) is the distance at which the rifling (and the bullet passing along the bore) make one full revolution. In the USSR or Russian system it is indicated in length in millimeters, in the Western (NATO) system: in one turn per number of inches. The first rule in calculating twist: it is not the caliber of the bullet, but its length. A longer bullet needs a shorter (faster) rifling pitch, a shorter bullet needs a longer (slower) twist. A longer bullet loses axial rotation much faster than a short one.

The rifling pitch at different arms factories and companies is calculated using formulas that they keep secret. Ready-made, publicly available rifling steps can be found in the description of a specific weapon, but if you are making a custom one, you will have to really strain your brains.

Important! Contrary to popular belief, the pitch of the rifling affects not only the bullet and its fighting qualities, it also affects the recoil impulse, the pressure in the barrel and chamber, and the load on the barrel walls. The bullet in the barrel is sealed, pressing into the fields and twisting along the rifling.

As for the smooth barrel, it has a slightly different principle: in a smooth-bore weapon, the wad is responsible for obturation, and a homemade smooth barrel for a rifled weapon is made with an average diameter between the diameter of the barrel along the fields and along the rifling, this is necessary for obturation.

Short-barreled (pistol): Used in all pistols and revolvers, also in submachine guns. Such weapons use relatively weak pistol cartridges and have a relatively small margin of safety of the main components for the sake of compactness. The bullets in pistol cartridges are relatively heavy, large in caliber, but short in length. It is not difficult to spin such a bullet to a stable state.

Example: Colt M1911 .45ACP has a rifling pitch of 400mm. PP MAC-10 .45ACP - 510mm. Beretta 92FS has a rifling pitch with a barrel of 125mm - 250mm, the MP-5 submachine gun has a rifling pitch of 1:10 (also 250mm).

If you are making a barrel with a length of 50mm to 150mm, the pistol cartridge and rifling pitch are your choice. What is written below is relevant only for intermediate and rifle cartridges and weapons with a large margin of safety, from a “large” PP (for example PPSh) to a rifle with any bolt locking system.

Military (Universal): Military weapons use different cartridges. These are mainly varieties of PS bullets, with a steel core, lead jacket and copper jacket. They are about 30 percent lighter than standard civilian ones. Various bullets with increased penetration (PP) have massive cores made of hardened steel. Armor-piercing bullets are usually the lightest, do not have a lead jacket at all, have a strong core made of some hard metal and a hard and thick copper shell so that the core does not fly out on its own. In some cases, elongated heavy bullets are also used - subsonic cartridges or cartridges with a reduced initial velocity (SV). With such a “choice” of ammunition, it is very difficult to select the desired twist, so the rifling pitch on military weapons is chosen either by making a compromise or by choosing the most commonly used cartridge.

Example: few people know that the M16 and M16A1 are the deadliest of the AR-Series rifles. The barrel twist of 356mm and 305mm did not twist even the relatively light bullets of the M193 cartridge and, as a result, the bullet began to tumble when it hit the biotarget. This resulted in terrible injuries and minimal survival rates. A side effect of this slow twist is very strong ricochet and lack of range. This is where the myth of the “Dum-Dum” bullet was born, “a specially designed bullet with an offset thread”) in a pistol that can cause the barrel to rupture from excessive load!

In a full-size PP: the initial speed will decrease, the impulse and recoil will increase. The rate of fire will increase (for PP on a blowback), the load on key components and parts will increase. The SMG will lose range, penetration and muzzle energy. Lead bullets will correspondingly be torn off the rifling. If the barrel is thick enough, then the shot will not rupture it, but there is a high risk of the bullet getting stuck in the barrel and when firing in bursts, this is also fraught with rupture.

In weapons chambered for intermediate and rifle cartridges (rifle, assault rifle): such weapons have a very large margin of safety, but also considerable cartridge power and strong pressure in the chamber. Such a weapon already has a fast rifling pitch, about one and a half turns per barrel. Some samples have two or more turns (SVD since 1975 and the Tiger-240mm carbine with a rifled barrel length of 550mm). When the twist is twisted, there will be a decrease in the initial speed and a decrease in the aiming range, and there will also be a load on the lugs. Case ruptures and sticking of the case to the chamber (and separation of the “back” of the case) are possible.

A practical example: the author was given the task of restoring the AKS-74U mock-up and converting it to 7.62x39 caliber. The author used as a source a scrap of a PKM machine gun barrel (a barrel written off for disposal with a torn chamber), with a rifling pitch of 240mm. What a surprise it was when, at a distance of 200 meters, it was not possible to achieve a stable hit of the bullet on the target! Not a single adjustment to the range led to any result; the impression was that the bullet was flying anywhere, but not at the target. And from the Aksinya 5.45 you can safely hit a tall target at a distance of 300 meters or more.

AKSU rifling pitch 5.45 - 160mm. We calculate using the Greenhill formula:

(150 * 7.92^2) / 26.8 = 351mm - very different from the factory AKM rifling pitch. Well, there were no intermediate cartridges in the 19th century.

(180 * 5.6^2) / 25.5 = 221mm - which is close to the factory pitch of the AK-74 rifling.

The author also tried other formulas, but nothing produced a rifling pitch similar to the factory one in the AK 7.62. Unless the late Kalashnikov knows what formulas he used. Perhaps a certified specialist would have calculated the exact pitch of the rifling using formulas, but the self-taught one decided to compromise.

The author took a different path: the method of scientific poking. I found out that the rifling pitch of the AKS-74U is exactly 20% less than the rifling pitch of the AK-74. The AKM and AK-74 barrels are the same length, the bullet length is similar.

Total we have: 240-20% = 192mm. This is the appropriate rifling pitch. Based on this and other experiments, the author realized that if a bullet in a weapon chambered for an intermediate or rifle cartridge makes one full revolution in the barrel, you can forget about accuracy and range. After changing the barrel to a homemade one with a pitch of plus or minus 190mm, the machine gun began to hit the chest target at 200m, albeit adjusted for range. Automation also began to work more confidently.

Problems associated with the barrel and their elimination:

Insufficient accuracy at long range: the rifling pitch is slower than necessary - replace the barrel with a smaller (faster pitch). Tested with lighter bullets.

Insufficient accuracy at any distance: Absence or poor quality of the muzzle chamfer, the bullet comes off the rifling unevenly and loses stability - make a high-quality muzzle chamfer. There may also be a bell in the barrel, which occurs if you are too zealous with emery honing and mix up the edges during turning; this is a defect and can only be cured by replacing the barrel. This is if the bullet does not break off the rifling.

Bullets falling off the rifling: This is when “irons” appear on the target, bullets arriving sideways. Many reasons:

Poor bullet quality: This applies to homemade or shot bullets. Try other bullets to complete the picture.

Powder Too Fast: Applies to homemade ammo. For example, construction powder (stroyak) has a very fast burning rate and even a shell bullet, receiving such a “kick in the ass”, can become deformed and fall off the rifling. It should not be confused with a “large weight” and should be adjusted downward; it is the gunpowder that needs to be replaced with a slower one.

The barrel is down in caliber: if the caliber of the barrel is either in the margins or in the rifling, it’s “squandered”. Comparable to a worn bore. It can only be treated by replacement.

Let's move from theory to practice. Non-standard (non-classical) profile (type) of barrel rifling:

In addition to the classic rectangular rifling known to everyone who has ever held a rifled weapon in their hands, various manufacturers of rifled barrels use non-standard barrel rifling. Some companies highlight their barrels as a business card, another takes care of the owner so that it is easier for him to clean, a third strives to reduce the load on the barrel in order to make it thinner. Do-it-yourselfers first do what is available to them according to their capabilities, then, having studied the classics, having acquired at least hobby equipment, they try to make a copy that is in no way inferior to the factory one, and sometimes even superior to the factory models in terms of performance characteristics and practicality.

I repeat: Important! The type, type, number and direction of rifling do not affect combat characteristics in any way, provided that the caliber, dimensions, rifling pitch and parameters (for example, length) are observed. To put it simply, a PM barrel cut with twelve cannon-type rifling will shoot neither better nor worse than the factory four-rifled one. A correct homemade barrel with classic rifling installed on a Glock will also not work worse than an Austrian factory-made one with polygonal rifling.

Also, rifling is not divided into “pistol, rifle and machine gun”. The profile and type of rifling is chosen by the manufacturer according to a patent, and by the homemaker according to his taste and preference.

Everything described will be shown on experimental pieces 30-35mm long.

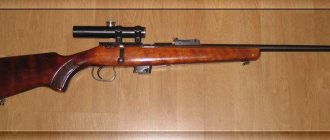

Gun rifling:

Cannon or artillery rifling consists of narrow rifling and narrow fields in large quantities. In industry, it is used for cutting barrels of rifled guns and other artillery, due to its large size and caliber. Among small arms, such rifling is found only in one sample, the Special Carbine KS-23, the barrels of which were rumored to be made from the barrels of obsolete 23mm caliber aircraft guns. The method of cutting a trunk is planing.

In homemade projects, such cutting is used mainly by novice gunsmiths due to the fact that it is done without the use of any factory equipment, literally on the knee, and when making broaching and cutting, serious metalworking skills are not required and there is a minimal chance of error. In fact, this is the easiest way to make a rifled barrel. It's very simple to do and it's almost impossible to screw it up. There is only one difficulty here: finding a suitable source tool for making a broach with a suitable sharpening angle, usually a spiral reamer, a countersink, or even a drill (Nikola made his broach from a drill). It makes no sense to make a broach for cannon rifling from scratch; it would be better to make one for classic rifling. Another undoubted advantage of this cutting is that it can be produced on a thin-walled workpiece, where it is impossible to carry out high-quality mandrel cutting.

A similar method of planing has already been described by the respected Nikola , but still I will write my experience - so to speak, for the complete collection.

For work we will need:

- Drill, vise, hammer, pushers

- Micrometer or electronic caliper

- Diamond files

- Dremmel with abrasive diamond bits

- Reamer-blank and barrel blank

Step 1: Finding the source for transferring

We measure the normal and the angle we need with a protractor for clarity and look for a tool. It is better to search at metal collection sites or flea markets where they sell Soviet stockpiles of tools; you often come across a lot of interesting things there. Most of the standard factory tools have a twist that is much larger than we need, but very often we come across something non-standard, often outdated, but with the angle we need.

Here is a photo of a non-standard f8mm reamer purchased about 10 years ago, the angle allows you to make a six-rifle broach of 7.62mm caliber with classic rifling.

Step 2: Making a broach

Having set it with minimal runout, we clamp our source tool into a drill and use a diamond tool to draw out the configuration. Unlike a two-fin reamer for the production of classic rifling, the configuration here can be any, the main thing is to make the pilot part longer than the caliber and with a diameter as close as possible to the caliber of the barrel blank, the cutting part 1-1.5 mm long, the diameter of the working part in the desired caliber according to the rifling and the backing , without which the broach will cut very poorly. You don’t have to worry about symmetry when processing in a drill; it turns out just like on a lathe - if you align the part with minimal runout.

We sharpen the back of the head.

In the photo there is a mandrel broach. This is not know-how at all, but just a mistake. Made many years ago, during the era of mandrel research. The author did not sharpen it, and so it works as it should.

Step 3: Planing the Gun Rifling

We prepare the form, lubricate it and plan it with a hammer. We punch the broach once - we get six riflings. With such a small width, the bullet can be torn off. We put a broach between the grooves and go through it again. 12 cuts is what we need.

As you can see in the photo, the wall of the barrel is very thin, about 1mm. The twist is faster than the factory one; it is suitable for a heavy but soft lead bullet with the original barrel length of a PM pistol.

Polygonal cutting "Stealth"

Another relatively simple cut. The advantage of this rifling is that it is almost invisible in the light, and it is more reminiscent of a Lancaster drill than mandrel rifling. With all this, such cutting, if the dimensions and pitch are observed, works no worse than the classical one, it has been tested. However, its invisibility is its disadvantage. It is very difficult to convince, for example, a buyer that the barrel is not smooth but rifled. This property can be useful for those who do not have a lathe in their household and are forced to turn to the appropriate specialists, because such cutting will be the easiest to disguise - it is enough to “crap” the inside of the barrel with something. The configuration of such a cut is something like this:

Shown in four-rifle version. Narrow, rounded and shallow rims and wide rifling.

The author did not see such a cut in the factory version, and he got it not as a result of some experiments, but completely by accident. Making a mandrel for this kind of cutting is also very simple - just like for a classic one. This result is obtained if a classic mandrel is sanded from a larger to a smaller caliber (for example, from 9.32 PM under Luger 9.08) - the edges collapse.

For work we will need:

- Classic mandrel or everything you need to make it

- Sandpaper set P200-400-600

- Drill, vice

- Hammer, pushers, barrel blank

Step 1: Making a “classic” mandrel

We make a completely “classic” mandrel, skipping the grinding stage. We leave the allowance the same as for polishing classics. We make the angle of the grooves half a degree larger than the specified one so that the twist turns out correct, because such a mandrel is susceptible to pulling off. If there is a damaged/rolled/cut-out mandrel of a larger caliber available, we can safely regrind it.

Important! On a rounded or polygonal mandrel, grinding is done strictly after making the cutting grooves; in a classic mandrel, exactly the opposite!

Step 2: Sanding

We grind the unpolished “classic” mandrel to the same dimensions as the correct classic one. It is better to grind both straight and reverse. Soft sandpaper will help. The grain and pitch are the same as on the classics. After grinding, the mandrel is ready.

In this case, a damaged mandrel (with an incorrect groove angle) was ground from 9.32 to 9.08. The general manufacturing principle is already clear.

Stealth mandrel:

We are preparing the form. Since our mandrel will push through the barrel bore minimally, to reduce the bullet’s axial friction, it needs to be made with a larger diameter - almost the diameter of the bullet. Lazy people can go through the axial for PM with an unsharpened 9mm reamer, according to the principle of a smooth barrel. When mandreling, the mandrel goes very easily, literally flying by with a whistle.

Here's the result:

Can you see the rifling?

And they are there.

The twist turned out to be very long due to an error in the source code. Those interested can enlarge the photo and see the cuts, because They are difficult to see even in cross-section.

Polygonal cutting "Glock"

In fact, they are not entirely polygonal. Rather, it is an ordinary classic with rounded corners. They are found in the barrels of pistols from the Austrian company Glock (meaning the native Austrian Glock barrel; there are a lot of manufacturers of custom Glock barrels, the rifling may differ) and some other foreign pistols. According to rumors, Glock uses such rifling to reduce bullet friction and barrel load, but this has not been practically confirmed. The main advantage of this type of cutting is, first of all, that the rifling is easier to clean, and the mandrel for them is a little easier to make, but it takes experience, a steadier hand and more patience to accurately observe the dimensions, especially on the inner diameter (inside the grooves) of the mandrel.

The sketch has an error in scaling, but the principle of rifling itself is correct. The usual classics, but instead of straight edges of the rifling and fields, they are rounded.

Polygonal or hexagonal rifling - hexagon

Making a Glock mandrel

The Glock mandrel is made according to the principle of a classic mandrel, with the same configuration and from the same available material - a bearing roller. The only difference is in the processing of the grooves and the grinding of the mandrel itself. An example shown is the 9.02 Luger/Parabellum.

For work we will need:

- Drill, vice

- Diamond needle file set

- Dremmel with diamond and abrasive attachments

- Measuring tool: micrometer or electronic caliper, protractor

- Sandpaper set P200-400-600

- Hammer, pushers and barrel blank

Step 1: Derivation of geometry Everything here is the same as on a regular, classic Dorn, described in the Dorn article. Allowances for grinding are the same.

Step 2: Marking and making grooves

We mark the mandrel in any available way for the required number of riflings (how to do this is described in the article Dorn).

The grooves of the Glock mandrel are sawed at the desired angle with a round thin diamond file, measuring periodically. The strictness of the internal diameter is not very important, at least not more than one and a half to two dozen more than the internal F of the barrel along the margins, otherwise the chamfer from a round needle file that forms rounded margins may not work - and semi-polygonal rifling will result.

Dorn looks like an unpolished classic.

Step 3: Sanding

We clamp the almost finished mandrel into a drill and sand it with soft wet sandpaper, bringing it to the final dimensions. It’s not necessary, but it’s advisable to grind back and forth, ten seconds forward, ten seconds in reverse. Grinding will fill the edges of the mandrel, making the rifling formers round, which is what is needed for the desired cutting.

The final touch - Important! In literally five movements back and forth, we file each groove with a round diamond file. This is necessary to restore the chamfer on the field formers, otherwise it may not catch and result in a “stealth” cutting.

Glock mandrel profile:

We prepare the form in the same dimensions as for classic cutting, apply a protective coating and finish it. The mandrel is a little harder than with classic cutting, but it can be punched through with a hammer without any problems. Shustovka, if desired, is done in the same way as with classic cutting.

To be continued.

Even more information on DEEPWEB. Communication on DEEPWEB (chat). Sports betting with DeepBet and the office where it is profitable to place them. Paid training courses are free. Money solves everything

Benefits[edit]

Hexagonal polygonal rifling.

Proponents of polygonal rifling claim a number of advantages. These include:

- Without compromising the thickness of the barrel in the area of each groove, as with traditional rifling, as well as less sensitivity to barrel failure due to stress concentration.

- Providing a better gas seal around the projectile, as polygonal holes have smaller, smoother edges with slightly less bore area, resulting in a more efficient seal of combustion gases trapped behind the bullet,[4] slightly greater (consistency) muzzle velocity and slightly increased accuracy. [1]

- Less deformation of the bullet, resulting in less frictional resistance as the bullet moves through the barrel, which helps increase the muzzle velocity of the bullet. The absence of sharp deformation of the bullet surface (rifling) also reduces resistance in flight.

- Reduces copper or lead buildup inside the barrel, as there are no sharp rifling edges to "cut" into the bullet's surface, and no pronounced corners that can accumulate contaminants that are difficult to clean, making maintenance easier. Reducing contamination also theoretically results in a simpler "copper equilibrium" profile, which is potentially beneficial for accuracy.

- Increased barrel service life, since thermomechanical loads on the corrugations are distributed over a larger area, which means they wear out less over time.

However, precision target pistols, such as those used by Bullseye and IHMSA, almost universally use traditional rifling, just like target rifles. The debate among target shooters is almost always between rifled barrels and buttonguns, as the traditional rifled style dominates. Polygonal rifled barrels are used competitively in action pistol shooting such as MAOSP and IPSC competitions.

Part of the difference may be that most polygonal rifling is produced by stamping the barrel with a hammer around a mandrel that has a reverse rifling imprint. Hammer and forge machines are extremely expensive, not available to gunsmiths (unless they buy pre-rifled blanks), and are therefore usually only used for barrel production by large companies. The main advantage of the hammer forging process is that it can produce the rifling, chamber, and counterbored barrel contour in one step. Hammer forging, first used for rifling in Germany in 1939, remained popular in Europe but was only later adopted by gunsmiths in the United States. The hammer forging process creates a lot of stress in the barrel, which must be relieved through careful heat treatment - a process that is less necessary for a traditional cut or button cut barrel. Because of the potential for residual stress causing accuracy problems, shooters in the United States tend to avoid hammer forged barrels, and this limits them to the type of rifling available. From a practical standpoint, any accuracy problems resulting from residual stresses during hammer forging are extremely unlikely to be a problem on a defensive or service pistol or a typical hunting rifle.

Forensic examination of firearms[edit]

Polygonal rifling does not allow a firearms examiner to measure the width of ground and groove impressions under a microscope (called a "ballistic fingerprint") because the polygonal ridges have a rounded profile instead of well-defined rectangular edges, causing minor surface deformation. The FBI GRC file lists the groove and groove width for this firearm as 0.000. However, it should be noted that forensic identification of firearms [in court cases, etc.] is based on microscopic examination of tool marks on the surface of the bore, created during the manufacturing process and altered by dragging body armor onto it. same surface. Thus, the barrel surface of an individual firearm is always unique. [5]

Lead bullets and polygonal rifling[edit]

| This section may contain original research . |

Austrian firearms manufacturer Glock advises bare lead bullets (i.e. without casings) in their polygonal rifled barrels, which has led to widespread belief that polygonal rifling will not be compatible with lead bullets. Firearms expert and barrel maker, the late Gale McMillan, also commented that lead bullets and polygonal rifling are not a good combination. Neither H&K nor Kahr explicitly recommend against using lead bullets in their polygonal rifled barrels, suggesting there may have been an additional factor in Glock's warning. Kar warns that lead bullets can cause additional contamination [6] and recommends paying special attention to cleaning after use. Although H&K does not insist on a brass jacket, at least one well-documented disastrous incident involving an H&K pistol [7] may be related to this issue. Moreover, Dave Spaulding, a well-known gun columnist, reported in an issue of Handguns Magazine

February/March 2008 that when he asked H&K about their polygonal rifling barrels, they commented: “In their experience, polygonal rifling does not suit lead. higher speed than conventional slicing.”

One suggestion that "an additional factor associated with the Glock warning" may be that Glock barrels have a fairly sharp transition between the chamber and the rifling, and this area (known as the "throat") is prone to lead accumulation if not lead bullets are used. This buildup can result in an inability to fully return to battery, causing the gun to fire if the case is not properly supported by the chamber and the breech is not completely locked, resulting in a potentially dangerous case failure. However, since this abrupt transition occurs on most autopistols, this assumption is of limited value. A sharp transition or "ridge" at the front of the chamber is required for cartridge clearance in most auto pistols.

Another possible explanation is that there are different "flavors" of polygon rifles, and perhaps Glock's particular style of polygonal rifling may be more prone to lead fouling than the particular styles used in H&K and Kahr barrels. [ citation needed

]

"Leading" is the buildup of lead in the bore that occurs in almost all firearms that fire lead bullets at high velocities. These lead deposits must be cleaned regularly, otherwise the barrel will gradually become narrower, resulting in higher than normal pressure in the barrel. In extreme cases, increased pump pressure can reduce the strength of the barrel material and lead to catastrophic failure, causing the gun to explode in the shooter's hand, causing serious injury.

Polygonal future of "Vepr"

Again in Vyatskie Polyany.

I had the opportunity to visit Vyatskie Polyany at very different times, but each time I paid attention to the vitality of the Vyatskie-Polyansky Machine-Building Plant, whose structural division of Hammer Weapons LLC produces the well-known Vepris and Snipes.

In my opinion, one way or another, the main secret of perseverance is in a location remote from large industrial centers, which affects the mentality of people living and working here. After all, it is the caution and prudence of the factory workers for the past 25 years that has been the key to maintaining a viable weapons production, which is based on the production cycle of the Kalashnikov light machine gun (RPK74M).

Employees of the experimental development laboratory of Molot Weapon LLC, headed by Pyotr Mokrushin (second from left)

It would seem that the value of 50-year-old technologies is great, but what about the modern understanding of labor productivity? So no one says that preservation is the same as the absence of changes, which I was convinced of when I visited the plant in May, where I looked at the workshops, talked with the designers, and tried out some models of weapons in the shooting range.

At the end of the 80s of the last century, the manufacturing technology of Kalashnikov assault rifles and machine guns could safely be called a close-to-ideal standard in terms of large and very large-scale mass production, when the annual production volumes of assault rifles in Izhevsk amounted to hundreds of thousands, and light machine guns were made in Vyatskie Polyany several tens of thousands. Production was so optimized that even with the obvious comprehensive superiority of some new technology, the risks of unbalancing the process, which had been established with filigree precision, sometimes stopped the implementers at the level of the idea. Opportunities to change something appeared in the mid-90s, when the volume of government procurement failed and the conveyor practically stopped. But these were times of lack of money and survival, not the best for implementing plans for the reorganization of production facilities.

Executive Director of Molot Weapon LLC Roman Bukarev (right) discusses production issues in one of the enterprise’s workshops

Times have changed and changes have begun. In Izhevsk, in accordance with the status and capabilities of the Kalashnikov concern, they are truly global in nature, and in Vyatskie Polyany the process of restructuring production in a modern way is developing according to a long-term plan, which is directly dependent on the results of the current activities of Molot Weapon LLC.

Accordingly, the reorganization and re-equipment of production is carried out in stages, depending on the importance of the existing problems and the money allocated for reforms.

Of course, first of all, this concerns the transfer of the production of complex parts from a step-by-step cycle to machining centers. In addition, the focus is on the energy efficiency of all processes, reducing the amount of manual labor in general, intra-shop logistics and other criteria usual for this type of reform. I think that KALASHNIKOV readers are less interested in man-hours, kilocalories and lux than the weapons themselves, so I’ll move on to news about hardware.

Firstly, I will immediately admit that in the design bureau and at the shooting range they showed me some products that it is too early to talk about publicly, but my acquaintance with which will certainly be reflected in future publications. Secondly, in reality there were only one or two public new products, but they are all of an applied nature and relate to real projects that are available to consumers now or in the near future.

Executive Director of Molot Weapon LLC Roman Bukarev at the shooting range with a sports "Vepr"

First and most importantly, the testing of the Vepr with a polygonal barrel has been completed. I’m not sure that the audience of “KALASHNIKOV” needs to be explained what it is, but still, for those who have not come across this term before, I will explain that a barrel is called polygonal, in the channel profile of which there are no fields, rifling and combat edges in the usual sense. On the cut of such a trunk, we will see a polygonal-shaped channel without sharp transitions from plane to plane (in this case, plane is a relative concept), twisted along the length in the same way as in the case of a regular trunk.

Due to the absence of pronounced combat edges, the polygonal profile of the barrel ensures its greater survivability, simplifies the cleaning process and is better suited to certain types of ammunition, both with an excessively hard surface and, conversely, more plastic ones. Of course, the last statement is not applicable for simplified typing and requires clarification in each specific case. In addition, the polygonal profile is perfectly suited for mass production using rotary forging and simplifies the process of applying chrome plating. In general - some advantages. Just like in that cemetery...

The improved Vepr-12 Sport with a folding shank for an AR-shaped stock was produced in a pilot batch. The model being prepared for serial production will differ from the one shown in the photo with a different handguard and a few more details.

In short-barreled weapons, polygonal barrels are used in millions of copies. The best example is Glock. And in long-barreled weapons, “polygonals” are still hampered by limited omnivorousness from the point of view of reliable stabilization of various bullets at high pressures and speeds.

If we look at the problem more narrowly, then not everything is simple with the “plunging” of a bullet into rifling that does not exist in this case, and intermediate ballistics studies this problem. In the USSR, the last “entry” into “polygons” occurred during work with a 6-mm rifle and a machine gun. The designers didn’t like something and shelved the topic.

In terms of civilian weapons, absolute categories and some shortcomings can be completely neglected by offering the client a polygonal chrome-plated barrel - almost eternal and incredibly easy to maintain.

Leading specialist of the advertising service of Hammer Weapon LLC Irina Kopanitsa shoots from VPO-148. Seventy copies with butts of various types are already waiting for transport from wholesalers in the warehouse

In general, everything is simple - finished with a polygonal trunk. I got it at the shooting range with almost 10,000 rounds fired with a bulk “Barnaul” with a bimetallic shell. Before shooting, I assumed that an accuracy of about 10 cm (a cross-section of 4 shots per 100 m) would be quite satisfactory for such a “lived” barrel, but in fact it immediately became clear that the carbine could do more and in the illustration you see the results of 10 shots.

Shooting was carried out from a sitting position from a rest using mechanical sighting devices. One of my hits was “lost” in a hole from 12 gauge, and if you don’t take into account the gap to the right, then the diameter is less than 70 mm! Even for the new Vepr-308/BPZ complex, this is not a satisfactory, but an excellent result, and with all the nuances of what is happening, it is clear that the Hammer Weapon is moving in the right direction and nothing will prevent the appearance of polygonal Veprs on the shelves of Russian weapons stores.

Results of firing from the Vepr-308 carbine with a polygonal barrel. 100 m, 10 shots, mechanical sight, fired about 10,000 shots into the carbine. Polygonal "Vepri" have already been certified and will go on sale in July-August

We also shot from a modernized 12-gauge Bekas with a new gas engine, which makes it possible to use a magazine extension. The gun is equipped with a new stock, an extended magazine and will be sold both in a combined version with two barrels and in a traditional hunting version. There is a provision for mounting a picatini rail on the receiver and a diopter sight for working with a short bullet barrel, with which, by the way, I tested the gun with a bullet at a distance of 100 m.

It must be said that some factory workers doubted the advisability of such an experiment, but I, knowing the capabilities of the Techkreem cartridges with the original Brenneke bullet, was confident in the result. But I didn’t take into account that the cartridges were prepared with a “magnum” bullet with a 40-gram bullet and corresponding recoil, which was poorly absorbed by a thin summer shirt (the temperature was about +30°C). To be honest, six shots were not a pleasure for me, but the result was obtained - four hits landed in a circle with a diameter of 20 cm, two bullets flew six or seven centimeters to the right and left. For 100 m and coarse - the diopter is excellent, especially taking into account the “magnum”, for which you should prepare from the point of view of clothing. The group lay 25-30 centimeters below the center of the target, on which I placed the front sight of the sighting device.

Sales Director of Molot Oruzhie LLC Vladimir Kislov (right) takes part in a conversation about configuration options for the modernized Bekas.

The gun is decent, utilitarian and versatile. The new box took root with him like family. I think that it turned out to be a worthy competitor to the MP-155.

Another expected new product is the VPO-148 chambered for the 5.45-mm domestic machine gun cartridge (5.45×39). This model, in modern fashion, is maximally “picatinized” and is equipped with a heavy barrel with a developed muzzle device. For lovers of military style and cheap cartridges, this is what you need. It remains to be seen what application IPSC shooters will find for this new product.

Well, that’s all, actually, for now. “Everything” means a small part of the information that I brought from Vyatskiye Polyany. I will prepare a detailed story about the modernization of production a little later, after the completion of the current stage of assembling carbines. Then, closer to autumn, the time will come to reveal the cards regarding another new product prepared by Hammer Weapon LLC for hunters - the news from Vyatskie Polyany is not over yet.

The first batch of modernized 12-gauge Bekas of 100 pcs. is already ready and waiting for accompanying documents for shipment to the retail chain

Links[edit]

- ^ ab History of the barrel Archived April 20, 2010 at the Wayback Machine

- ↑

Barrels and Bullets: Regular and Polygon Rifle, Dennis Cantrell, 06/08/2010 - SL7 Polygonlauf, Vielflächenlauf by Lutz Möller (German)

- ↑

Peter Alan Kasler - Glock: The New Wave of Combat Pistols, page 138 - "National Institute of Justice Firearms Examiner Training".

- "Q&A: Pistol Kar". thegunzone.com. 2007. Retrieved May 13, 2009.

- "Learning About Shooting, No. 01... Why not shoot lead bullets through a barrel with polygonal rifling (Invalid link 2017-05-28)". April 2002. Archived from the original on 2008-10-10. Retrieved May 13, 2009.

Recommendations

- ^ a b

History of the barrel Archived 2010-04-20 on the Wayback Machine - Barrels and Bullets: Regular Rifle vs Polygonal, Dennis Cantrell, 06/08/2010

- SL7 Polygonlauf, Vielflächenlauf by Lutz Möller (German)

- Peter Alan Kasler - Glock: The New Wave of Combat Pistols, page 138

- “National Institute of Justice Firearms Specialist Training.”

- "Questions and answers: Kar pistol." thegunzone.com. 2007. Retrieved 2009-05-13.

- "Shooting Training, #01...Why not shoot lead bullets through a polygonal rifling barrel (Invalid link 5/28/2017)." April 2002. Archived from the original on 2008-10-10. Retrieved 2009-05-13.