PCP pneumatics - definition and principle of operation

Pre-Charged Pneumatic or PCP pneumatics

stands for this - a weapon that fires compressed air from a tank. The container is filled by pre-pumping (pump) up to 300 bar. Depending on the volume of air in the cylinder, modern models can fire up to 110-120 shots without refilling.

The advantage of PCP rifles and pistols over their spring-piston counterparts is that reloading is performed with a bolt (biathlon type), and not with a cocking lever (breaking).

Design

PSP weapons were used by rangers from Austria in battles against Napoleon's army. In history, the samples are known as Girardoni - multi-shot air rifles. The creator, Bartolomeo Girardoni, presented his invention to Joseph II in 1779. The Austrian Archduke was delighted. Mass production began.

Interesting fact:

Girardoni's drawings were kept secret.

Modern PCP models are not structurally very different from their predecessors. Consists of the following parts:

- compressed air tank;

- trigger mechanism (trigger mechanism) - similar to gas-cylinder types of pneumatics;

- trunk;

- reducer (pressure stabilizer);

- adjusting screws (to control pressure, power).

The last two points are new technological solutions. The first models of rifles were produced with direct flow.

Air rifles and their device for the amateur

The main components of the gun are:

1. Stock (stock). That part for which the pneumatic is held. It can be made of plastic, wood, or made to order.

2. Barrel. That part along the rifling of which the bullet passes, picking up speed. They come in different lengths, with different numbers of grooves. The accuracy and accuracy of the hit depends on them.

3. Trigger. Click on it and it fires. It's simple.

4. Fuse. Something without which you cannot buy air guns on the territory of the Republic of Belarus. Can be automatic or manual.

5. Rear sight and front sight. There is always a fly. It is thanks to it that you can aim at the desired point to hit. But manufacturers may not install a rear sight, but not just like that, but so that you buy an optical sight and get great pleasure from using the pneumatic gun.

It is these few components that you will find in every Gamo, IZH, Daisy and other air rifle with the naked eye. The problem is that inside the pneumatics there is a complex mechanism, a lot of parts hidden from the consumer’s eye. They are subject to wear and tear and may require replacement in the future. But here everything is not so simple. There are zips for pneumatics, which are considered consumables, and there are very complex parts, the installation of which will require the intervention of specialists.

Weapon calibers with pre-pumping

In Russian gun stores, PSP is presented in 4 calibers:

- 4.5 mm is the standard for an air gun, but pre-pumped models are rarely found with this barrel diameter;

- 5.5 mm - suitable for hunting small game, sport shooting, and also has a high lethality, but low persistence (low projectile weight);

- 6.35 mm – used by hunters to hunt ungulates and predatory animals. Working distance – from 100 m;

- 7.62 mm – high lethality, stopping effect.

Important.

Federal Law No. 150 “On Weapons” allows for aerial hunting of squirrels, hazel grouse, doves, and ravens. However, in the Russian Federation it is prohibited to use pneumatic weapons with a muzzle energy of more than 25 J. Weapons are registered with the internal affairs bodies at the place of registration.

PCP rifle design

The Girardoni multi-shot PCP rifle was in service with the Austrian rangers who fought against Napoleon's soldiers. Since then, its design has not undergone significant changes.

The PCP air rifle consists of elements, including:

- high pressure tank;

- barrel locked with a simple sliding bolt;

- a trigger mechanism responsible for controlling the valve;

- gearbox (modern innovation);

- screws that allow you to adjust the pressure in the gearbox and the speed on the shock group (also a modern addition).

The appearance of a gearbox is especially significant. The first rifles were straight-through.

Direct flow or gearbox?

For direct-flow weapons, maximum pressure is ensured when the cylinder is full at the moment of firing. It falls as the volume of gas in the tank decreases, and the speed of the bullet’s departure decreases accordingly.

After the first powerful shots, the pressure will gradually decrease to non-working, and the bullet simply will not be able to fly out of the barrel.

The gearbox scheme involves collecting gas in a storage chamber, which explains the ejection of a bullet with specified speed and pressure. Gas is consumed economically and efficiently.

Straight-through systems have their own advantages that make such rifles popular:

- Straight-through - the most powerful air rifles. The storage chamber of geared models is not capable of providing pressure for a 12.7 mm caliber bullet.

- A gear unit is more complex than a direct-flow system. It requires special maintenance and increases the cost of the weapon.

- With a strong decrease in gear pressure, the stability of the shot jumps. The gearbox leaks primarily during sudden temperature fluctuations.

These characteristics determine the choice of weapon. Geared rifles are suitable for sports in order to place bullets as accurately as possible at decent distances. An inexpensive, unpretentious and practical model with direct flow is suitable for hunting.

Calibers of PCP weapons

PCP weapons, and especially PCP Kruger rifles, have a large selection of calibers. In Russia the most common are:

- 4.5 mm. This caliber is rare and is used for recreational and sport shooting. Distance up to 50m

- 5.5 mm. Suitable for hunting small game (small birds, rodents) and sport. It has a low bullet weight (up to 2.5 grams), good penetration ability and low flatness. Long range shots will require rangefinders and careful elevation adjustments. Distance up to 70m.

- 6.35 mm. Suitable for hunting predators and small ungulates. Distance up to 100m.

- 7.62 mm. In terms of their characteristics, such rifles are close to small-caliber firearms. They have a strong stopping effect due to the greater mass of the bullet. Distance up to 150-200m.

Hunting with air guns in Russia is allowed for crow, hazel grouse, and squirrel. The power of rifles should not exceed 25 J, weapons must be registered.

Classic layout or bullpup

The bullpup system involves the location of the trigger in front of the magazine and bolt group. In the case of pneumatics, all the main disadvantages of this system are leveled out:

- The shooter's shot does not stun;

- there is no need to think through the mechanisms for extracting cartridges;

- the high-pressure reservoir balances the center of gravity shifted to the butt.

Accurate, compact and powerful weapons are easy to transport and comfortable to shoot in confined spaces (even from a car).

Rifles with a classic layout have their own characteristics. The following are considered particularly significant:

- quick jump;

- the ability to reload without changing the fold and without taking your eyes off the sight;

- long sight line length.

The advantages of PCP rifles with a classic layout include lower weight, which is explained by the absence of a supporting rail.

Refueling PCP weapons

The tank should be filled with gas to the pressure permitted by the manufacturer. This can be done using various devices:

- Hand pump. To create a pressure of 150-200 bar it takes 15 minutes; getting 300 bar is problematic.

- Compressor. Requires electricity, works faster than pumps. When operated at the limit, it fails, and pumping the tank to a pressure of 300 bar requires maximum load.

- HP cylinder and filling station. Allows you to redirect the weapon in a couple of minutes and to any pressure, completely silently and not only with air, but also with nitrogen.

The disadvantage of the latter method is the need to refill the cylinder itself. This can be done at a fire station or at a diving station.

Advantages and disadvantages of PSP

Devices with pre-pumping have an advantage over PPP:

- Not subject to registration with the Department of Internal Affairs.

The low power of PCP pneumatics makes it affordable for purchase by adult citizens. Despite exceeding the caliber of 4.5 mm, manufacturers underestimate the characteristics by introducing design changes. The owner can easily, if he has the skills and tools, increase the power of the weapon, but this is a violation of Russian law. Fortunately, manufacturers took care of this point, placing parts in the box with pneumatics to strengthen and weaken the structure. - Multi-charge.

There are PCPs on the market that can fire a series of up to 14 bullets. There are single-shot models. - Stable power of shots.

With one fill you can shoot up to 65 bullets without a significant drop in pressure. The reservoir is sealed and retains the pressurized air with a block valve. The latest PSP models are equipped with clutches that regulate the pressure of incoming air. The design features of the injection system ensure that the power of the weapon is always stable, even after long-term shooting without refueling. To pump the tank, pumps up to 3200 bar are used. - High precision shooting.

Only PCPs have this quality. The reasons are low returns, the use of the latest technologies when assembling weapons (the process is complex). The combination of excellent accuracy and muzzle velocity makes it possible to use 4.5 mm rifles for hunting. - Long-term operation.

Structural simplicity, low wear of moving parts, increase the service life of the PSP. The tanks are always sealed, and the barrel is easy to replace with a new one, if necessary.

Pneumatics with pre-inflated air are not ideal - there are disadvantages:

- Expensive.

To become the owner of an optimal PCP rifle, you will need a budget of 50,000 - 100,000 rubles. In addition, the price difference in gun stores can reach up to 15,000. Full equipment only increases the price tag. - Long time to fill the tank.

If an air cylinder is used, the operation will be quick. But you have to pay for speed, and an easy way to avoid costs is to inflate the balloon with a pump. Free, but long - 100 “jocks” will not please anyone. - Storage nuances.

The PCP weapon and the full cylinder must be located separately. Ignoring the rule will lead to condensation, which means corrosion. The compression tube will become unusable.

Considering the inconvenience of using pneumatics with an air cylinder, it is still superior to spring-piston systems:

- accuracy of shots;

- build quality;

- compactness;

- low weight.

PCP air guns are all about versatility. The device is suitable for everyone: hunters, athletes, amateurs. The high cost is compensated by quality.

Tips for a pneumatic builder (using the example of co2-pcp)

Preface.

Quite a few airgunners have at least once thought about creating their own pneumatics or, at a minimum, completely tuning existing models. I'm not an exception.

The idea of “collective farming” does not appeal to me, as a perfectionist, so I immediately plunged into the development of complex structures of such a level that it would be possible to almost put production on stream. To make the pneumatics of your dreams, without exaggeration.

And so, full of ideas and desires. Borrow other people's developments and existing schemes, modify or invent something of your own. What's next?…

And then learn the materiel, because we are professionals)))

Here everything goes according to the principle, “The further into the forest, the thicker the wolves.”

It took a long time to look for explanations for some points, but something was on the surface, but the main thing is that the deeper you try to understand the processes of development and manufacturing of a full-fledged, for example, rifle, the more new details and points emerge that also require study and clarifications...

I have already studied many points for myself, but the inconvenience for me was the fragmentation of the data. I had to sit for more than one night looking for manuals and instructions...

In this article I will try to analyze as many nuances of pneumatic construction as possible using the example of Co2 rifles, so that in the future other home-made people will not feel like lonely pioneers in an unknown direction...

The article will not be detailed instructions with drawings and diagrams, but will serve as a good guide, an action plan, and will help organize at least some of the questions (and answers) in your head.

What is co2-rsr? Why?

Co2-рср, as a class, is almost not widespread in Russia. The principle is identical to the classic PCP - a refillable tank (removable or not), only carbon dioxide is used instead of air. Accordingly, refueling is not done with a pump or high-pressure cylinder, but with a fire extinguisher or carbon dioxide cylinder.

Why this particular class? Everything is simple, spring-piston systems are an order of magnitude simpler, gas-cylinder systems with disposable cartridges differ only in the absence of a refillable tank, and PCP, although it has differences, for the most part works on the same principle.

Trunk.

Almost the first difficulty that arises when building a homemade pneumatic is the barrel. This is one of the most expensive parts in a rifle. Where is the son-in-law? Which?

It is impossible to make a rifled barrel yourself; the technology for its production is very complex. A smooth barrel of great length and precise caliber is also not easy to obtain.

A smooth barrel is a tube, and any tube, unlike a rifled barrel, can be made. By the way, on the Hansa there is a master who can make smooth stems of sufficient length, his nickname is Peter.

But I’ll look at the rifled barrels in more detail.

1) Donor.

One of the relatively simple and cheap options is to borrow a barrel from a donor rifle. The Izhevsk Mechanical Plant became an excellent assistant in this matter. His rifles are inexpensive and numerous. At any flea market, you can buy a used rifle in poor condition, but with a live barrel, for a thousand or fifteen hundred.

Then you will only need to give it to a familiar turner or process it yourself for the necessary fastening.

The disadvantage is that when buying a donor rifle, you cannot count on high quality and good condition of the barrel. Lottery. It may turn out to be ideal, or maybe with nail-killed rifling.

When choosing a barrel from a donor, you automatically limit yourself in caliber - only 4.5mm.

2) Liner.

Also a relatively inexpensive option is a thin-walled barrel from Crosman rifles. Such a barrel has already been processed and is ready for installation, with only one “but” - the installation will be exactly like the Crossman, or it will still have to be modified. Buying such a stem can cost 3000 rubles.

The advantage over the donor barrel from IZH is the choice of lengths up to 610mm and at least some variety in calibers - 4.5mm and 5.5mm.

Disadvantages include vague, shallow cuts.

3) Form.

What is a form? A blank is a blank of a barrel, a homogeneous tube with rifling, without chamfers, without fasteners. Such a detail, in fact, is not yet a complete detail, because necessarily requires processing and finishing before installation.

Advantages - high quality of rifling and the entire barrel as a whole, variety of calibers from 4.5mm to 12.7mm. The form is the choice of professionals)))

And now the fly in the ointment. The price of one unprocessed form starts from 5 thousand rubles for the simplest, short and small-caliber, and up to 30-40 thousand rubles. for the coolest and rarest.

On average, you will have to pay 7-10 thousand rubles for a normal form, depending on the caliber.

Another difficulty is processing. A high-quality form made of good steel also requires appropriate processing equipment; fortunately, many sellers of forms also specialize in processing forms to meet customer requirements. Naturally, you will also have to pay for processing.

When choosing a form, the question may arise about some additional parameters, such as twist and the presence/absence of a choke.

Twist is the pitch of the rifling, the distance over which the rifling (and the bullet, accordingly) makes one full revolution.

The most common twist in pneumatics is about 450mm. In reality, the twist is adjusted relative to the length of the bullet. The longer the bullet, the shorter the rifling pitch. But, since mere mortals do not have the opportunity to order a barrel with a twist precisely matched to the customer’s bullets, this parameter can be omitted; all blanks for pneumatic needs have a normal average twist.

The exception is, perhaps, large-caliber rifles, which often use bullets much more similar to firearms (long) than to pneumatic ones. In this case, the twist needs to be shorter.

Chock. I’ve seen this reaction from many people: “Chock? This is a narrowing muzzle attachment for hunting smoothbore rifles. Why the choke on the pneuma? The truth is that choke in air rifles is not that uncommon.

It is believed that the choke in a rifled pneumatic barrel compresses the bullet at the exit and stabilizes the sausage acquired by it during its movement along the main part of the channel. (c) Gosha-kun, guns.ru

For reference, the FX company (a large manufacturer of PCP rifles) practices the production of smooth air barrels with something like a rifled choke at the end. And practice has shown that there is no noticeable deterioration in the accuracy and accuracy of rifles.

Storage tank.

We finished the trunks. The next important element in the rifle is the reservoir.

There are two main types of rubbers - removable and stationary. The former allow you to have several filled tanks on hand at once or quickly change the rifle’s power supply from co2 to air, if the safety margins of other elements of the rifle allow this. The latter can be larger in volume and hidden deep in the rifle body. The advantage of a non-removable reservoir is that it does not have to be removed from the rifle for refilling.

The main materials for making tanks are steel and D16T duralumin. The strength of duralumin, with less weight compared to steel, is enough for a 2.5 mm thick wall to withstand compressed air pressure of more than 200 atmospheres.

The tank itself is a seamless steel or duralumin pipe with two plugs at the ends. In the case of a stationary cutter, one of the plugs can be a valve or a receiver.

Surprisingly, the number of shots from one refill depends on the volume of the tank. With volume, everything is relatively simple - the more, the better, within reasonable limits (rifle dimensions, appearance).

But there are some additional points when calculating the tank that will not be superfluous.

To understand tanks, you need to understand the gas used. Since we started to consider assembling a CO2 rifle, let’s take carbon dioxide gas.

The pressure of carbon dioxide, as is known, very strongly depends on the ambient temperature; the rifle cannot be overcooled, nor can it be overheated. In the first case, the rifle will simply lose a lot of performance, in the second, it may even explode with dire consequences.

Here is an approximate dependence of CO2 pressure on temperature:

0 C - 27 bar; 20 C - 58 bar; 30 C - 70 bar; 40 C - 105 bar; 60 C - 170 bar.

Remembering the school physics course, “C” is degrees Celsius, and “bar” is a unit of pressure measurement, approximately equal to one technical atmosphere (AT = 1 kgf/cm).

The optimal temperature is 20-25 degrees, a higher temperature rapidly increases the pressure to a dangerous level (critical pressure CO2 ~ 72 atm, a higher temperature transforms the gas into the state of a supercritical liquid - a state in which the difference between the liquid and gas phases disappears).

1 liter of liquid carbon dioxide produces 505 liters of carbon dioxide upon evaporation. This information will allow you to roughly calculate the number of shots from one tank fill, knowing the volume of the evaporation chamber and the rezik itself.

But you should not rush to calculate these parameters from 100% of the tank volume, since it is far from completely filled with the liquid phase of co2. This directly concerns the process of filling the tank.

The carbon dioxide tank is refilled from a fire extinguisher or from a large industrial cylinder.

To ensure that not only gas, but also a liquid phase flows into the rezik when filling, the donor cylinder must be turned upside down, then when the valve is opened, liquid carbon dioxide will flow into the tank.

In the case of a fire extinguisher, such problems are not required; the fire extinguisher has a tube in the body from the valve downwards, thanks to which the liquid enters before the gas.

Optimal refilling conditions are from a cylinder at room temperature into a very cool tank. This will allow the liquid phase to flow more efficiently. In this case, the removable tank has the advantage of being able to be placed in the freezer. A rifle with a non-removable tank will not have to be completely filled.

When pouring into a container at room temperature, you can fill it with the liquid phase to no more than 50%. When filling a frozen tank, you can physically fill 70% or even more, BUT:

ATTENTION!!! You cannot fill the tank with more than 70% liquid phase (0.7 kg of CO2 per 1 liter of volume). When refilling with cooling of the tank, be sure to weigh the reel before and after refilling. If you fill more than 70% of the liquid phase, then when the tank warms up, the CO2 will expand and can rupture the tank. As experienced people say, the tank will not have enough safety margin.

Now about durability. As is known, reservoirs in PCP pneumatics undergo hydraulic testing (water is pumped under pressure 1.5 times greater than the approximate operating pressure). Without such pressure testing, the tank is simply deadly, a time bomb.

So, pressure testing for the co2 tank is also necessary, although not so obligatory. You can make a tank with a large safety margin (for example, with a wall thickness like an air tank) and hope that you don’t have any leaks (which are also revealed by crimping). If you do pressure testing, you need to remember that for co2 it is done not 1.5 times the working pressure, but 2.5 times, i.e. about 175 at.

I would not recommend anyone to do crimping on their own, although you need to learn, but at least you will need to devote maximum attention and time to this. I think there is no need to tell you what dangers a tank that explodes during testing entails. Although water reduces the degree of danger compared to air, it is still an EXPLOSION! TB, TB and more TB.

Regarding my development of the rifle, I decided to avoid crimping, as a complex and not critical process for co2, but, as a conscious designer, I introduced a simple system of protection against exceeding operating pressure into the project.

Well, “trust, but verify”, no one forbids (and many recommend) installing a pressure gauge on the tank or evaporation chamber. This will not only allow you to control the pressure for safety purposes, but also monitor the presence of the liquid phase in the tank, i.e. Know when the tank needs to be refilled.

As far as the tank is concerned, everything seems to be...

Evaporation chamber (dispenser) and valve.

Not the most difficult part from a development point of view. Rather, the valve is complex not in calculations, but in implementation due to the possible presence of small or tricky parts.

The whole essence of the calculations comes down to ensuring that there is enough gas in the evaporation chamber for the design power, and the valve provides the necessary throughput for efficient use of the chamber volume.

It is important to provide for the location of the chamber or channel to it from the reservoir so that only gas, without the liquid phase, enters the evaporation chamber.

Unfortunately, I can’t tell you many details about the volume of the evaporation chamber, because... At the moment I don’t have all the necessary information myself.

Hansa users have repeatedly mentioned a certain program from master Ignat, which allows many calculations regarding the volumes of evaporation chambers and pneumatic compressors to be made in order to achieve the desired indicators.

https://www.iguns.ru/index.htm - Ignat’s website, where there is this program and a lot of other interesting content.

I will give just an example of the characteristics of the evaporation chamber to have at least some idea:

For a speed of 240 m/s for a bullet weighing 0.62 grams (18 J), a dispenser volume of about 12 cm3 is needed.

By the way, about speeds. You should not try to squeeze speeds exceeding 240 m/s out of co2 pneumatics, this is impossible. The explanation is quite simple, 240 m/s is the approximate speed of sound with carbon dioxide, and it is very difficult to exceed this indicator (read as “almost impossible”).

This limitation in speed has created the misconception that co2 is for toys that are not capable of high power. This is a strong misconception. In my article (of 3 parts) about large-caliber co2 guns ( -HERE- ) I have already demonstrated that carbon dioxide should not be underestimated.

Yes, you cannot get a speed higher than 240 m/s, but speed, as you know, is a variable parameter, depending on the weight of the projectile. The constant parameter is the energy of the shot. Thus, having “rested” during acceleration of the CO2 rifle against the “ceiling” of 240 m/s, you only need to increase the weight of the projectile. At a speed of 240 m/s, a 0.62 g bullet will give 18 J, and a 0.8 g bullet at the same speed will have an energy of 23 J.

At some point you will have to increase the caliber, because... By constantly increasing the weight of a bullet within the same caliber, we will be forced to lengthen the bullet, and this is not good, as we found out in the section about barrels and their twists. A long bullet will need a different pitch of rifling, and the gas will no longer transfer its energy to the bullet as efficiently.

Regarding the valve, I will say the obvious, the faster the valve releases gas, the better. But as the valve capacity increases, its dimensions increase significantly. The valve that provides enough gas to fire something large-caliber has monstrous proportions. Fortunately, in large-caliber rifles all other elements match the valve.

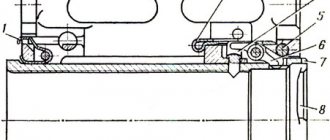

Rammer bolt.

Everyone knows why the rammer needs a bolt function - so that when fired, the rammer is not pushed in the opposite direction from the bullet. I don’t even have much to say here. Just like in a car showroom or somewhere else, there is a list of options and you just need to select the ones you want:

Type of locking - classic bolt (by turning the bolt) and biathlon (lever) or some rarities, such as locking the barrel with a rotary bypass block.

Type of rammer - with a narrow spout, or tubular, or without a rammer at all.

Type of cocking USM - simultaneously with the bolt (when retracted/when returned) or a separate cocking handle for the striker.

The same thing with the receiver - the work is exclusively design. You can have a box for a single charge, you can provide for the installation of a magazine, you can come up with something else.

Trigger mechanism.

I can’t say that there is nothing complicated here, but the work is again on creativity. There are many schemes and layouts of various triggers; in the simplest, the trigger itself performs the sear function; in complex ones, the number of intermediate sears can reach 4-5.

It all comes down to making the descent easy, short and predictable.

The trigger force depends on the difference in the lengths of the trigger and sear levers, as well as the stiffness and number of springs.

The length of the trigger stroke partly depends on this. The shorter the descent, the tougher it is (in equal conditions). It is to get rid of this dependence that additional sears are introduced into the trigger circuit. The easiest trigger is in those schemes where the trigger plays the role of a locking stop. Pressing such a hook releases the sears and they themselves, under the action of their springs or the striker spring, release this same striker.

Some craftsmen are so keen on easing the trigger that the trigger begins to be pressed simply under its own weight if the rifle is pointed vertically upward. This is already too much.

Predictability of the trigger is no less important for an accurate shot than the force or length of the stroke of the SK. It’s good if the trigger is easy, but just before the firing pin is released, the force increases noticeably, then you can accurately select the free stroke and feel that right now there will be a shot. This is achieved, for example, by a slightly more complicated shape of the trigger lever, which interacts with the sear. Due to the curved shape of this lever (or the presence of an adjusting screw that simulates a kink), before the sear is brought to the shot, the ratio of the levers changes, increasing the force.

There are also USM designs called “self-openers”. Such systems do not have a striker, and the valve opens itself under the influence of gas pressure when it (the valve) is “released” by the sear.

The advantage of such a system is easy release, the absence of unnecessary vibrations produced by the striker and somewhat smaller dimensions.

The disadvantage is some complexity and the need to somehow cut off the released gas from the main reservoir. Otherwise - one refill per shot.

Materials.

Nowadays, almost everything can be found. To make a rifle from scratch you will need the following materials:

A variety of steels for a variety of parts.

Dural D16T – pipes, rods, bars. Durable and lightweight material.

Brass. It has relatively low friction when interacting with steel. Often used in valve bodies, etc.

RTI – rubber bands of all types. There are a number of companies that provide rubber bands of absolutely all sizes to order, either individually or by the carload.

Polyurethane. For over-cylinder gaskets, etc. Tenacious and durable.

Hardwood. Let's add nobility to our product by giving it a beautiful wooden stock.

ABS plastic. 3D printing technology is spreading at tremendous speed. This needs to be used. With very high strength and good resistance to temperatures, it has a low price and is easy to process/manufacture parts of any shape and size.

That seems to be all. This knowledge is quite enough to design a working scheme and implement it.

Then it's just a matter of invention, drawing skills and manufacturing of parts.

03 September 2014

Reducer or direct flow

The principle of direct flow of PCP pneumatics is simple. The devices demonstrate maximum power if the tank is full. With each shot, the pressure and initial velocity of the projectile rapidly drops. The volume of air in the cylinder may not be enough to push the bullet out.

PCP with gearbox – new generation models. Compressed air is collected in a storage chamber, which allows the shooter to control its flow. The pressure in the cylinder drops slowly, and the initial speed is stable.

Direct-flow rifles will not lose user interest, as they are endowed with advantages:

- power exceeds gear systems;

- structural simplicity reduces the cost of pneumatics, no special maintenance is required;

- shots are stable and do not jump, unlike geared weapons, where a sharp drop in pressure has the opposite effect.

Geared systems are ideal for sport shooting, where it is important to accurately place projectiles on target from a long distance. It is better for a hunter to choose a straight-flow rifle, which is unpretentious, powerful and low in price.

Shall we pump it up? Review of hand pumps for PCP pneumatics

Everyone is well aware of the proverb: “You can’t catch a fish out of a pond without effort.” It fully applies to shooting sports. For example, this is well known to those who have fully inflated a compressed air cylinder at least once using a hand pump. Here you have to work hard. The editors of DWJ magazine reviewed several models of hand pumps from well-known manufacturers.

All sports shooters using gas-cylinder pneumatic weapons know: after a couple of hundred shots, even rifle cylinders no longer have enough pressure. It’s good if you have a spare cylinder with a suitable thread at your disposal. But this is not always the case in small shooting clubs. Therefore, many shooters have a container of compressed air at home for personal use. However, sooner or later the compressed air in it runs out. And this often happens just when it is necessary to fill a cylinder for your air gun with compressed air for an upcoming competition or training. If the shooter wants to refill his large cylinder, he needs to load it into the car and take it to the nearest gun store. It is possible that you will be asked to leave the cylinder for inspection. Then you will have to pay for checking and subsequent filling of the cylinder with compressed air.

Hand pump. Advantages and disadvantages

It's good if the shooter has a hand pump. It is always ready for use and transportation; it cannot be emptied like a cylinder. Unfortunately, the hand pump has one significant drawback, as indicated by its name: to pump air into the cylinder, the shooter will have to make an effort, and a considerable one at that. To pump an empty cylinder to a pressure of 200 bar, it will be necessary to make 50 to 60 strokes. Each move is accompanied by bending the legs at the knees. However, this does not frighten those who consider squats as an exercise in the morning exercises that they do every day.

To use a hand pump, step on the base with both feet, lift and forcefully lower the handle to its lowest position.

Meanwhile, the process of pumping a cylinder has one peculiarity: the greater the filling (that is, the closer the pressure gauge needle approaches the 200 bar mark), the greater the force that must be applied to pump air. And this is directly related to the increase in applied muscular force, which is very significant at the final stage of pumping air: when the pressure gauge needle approaches 200 bar, the applied force is approximately 40 kg.

Exploitation

Hand pumps were provided to the German edition of DWJ magazine by the companies ahg-Anschuetz and Gehmann. The pumps are delivered to customers practically assembled in appropriate packaging. The buyer can only attach the base, which, however, is quite easy to do using the included tool. In principle, the only information of interest in the supplied operating instructions is about the residual pressure release screw. The purpose of this screw (for the hand pumps provided to the editors of DWJ magazine, located in the front part of the body) does not even approximately correspond to its name. It must be screwed down when the cylinder is screwed onto the adapter. Otherwise, the remaining compressed air will be released from the cylinder, and to achieve the required pressure when pumping, you will have to make 20–30 more strokes.

To make maximum use of one stroke (stroke) when pumping air, it is recommended to grasp both parts of the handle with both hands and slowly, using the same force, lower it down until it stops. In this case, injection occurs in a quiet mode; there are no pressure drops during air injection.

Due to the fact that when using a hand pump, air from the environment is pumped into the cylinder, rust may subsequently form in the cylinder. To eliminate this phenomenon, a desiccant is installed in the pumps.

Gehmann models

In general, all Gehmann pumps are characterized by low operating costs and a long service life, which is associated with a continuous lubrication system using a special product pumped in at the factory. According to the manufacturer, the expected service life of pump wear parts is five to seven years. There is no need for additional lubrication of the seals. The built-in metal-ceramic filter absorbs suspended particles in the pumped air, almost completely purifying it. In the event of a breakdown, the owner of the hand pump can at any time contact the repair shop located at the Gehmann location in Karlsruhe and which has all the necessary spare parts at a very reasonable price.

Of all the hand pumps tested by the German editors of DWJ magazine, the Gehmann M220 model was the simplest and cheapest (pictured on the left). It costs 169.00 euros and fully meets the usual requirements. The Gehmann model M100 (pictured in the center) has a knurled screw on the handle, with which it is possible to switch from a three-piston air injection system to a four-piston one and vice versa. One pump model from the English manufacturer Hill is also sold by Walther (pictured on the right). It is designed for cylinders for air guns with an air pressure of 300 bar (recommended retail price for the pump is 395.00 euros)

The Gehmann M220 model is the simplest and cheapest manual Murrr pump with a recommended retail price of 169.00 euros. The M100 model costs 19.00 euros more. This is explained by the fact that this pump, instead of a three-piston one, has a four-piston air injection system. It is turned on by turning the thumbscrew and allows you to pump a larger volume of air into the cylinder in one stroke. Then, for example, when the pressure in the cylinder reaches 150 Bar, the screw can be turned in the opposite direction and the three-piston system can be turned on. At the same time, to pump air to a pressure of 200 Bar, you will have to exert significantly less effort. In one stroke, the productivity of a pump with a four-piston system is 300 cm3, while for a pump with a three-piston system it is 210 cm3.

The operating mode of both pump models is similar. They have the same processing. After pumping air into the cylinder, to remove moisture from the pump body, it is necessary to briefly open the residual pressure release screw. Then you should disconnect the compressed air cylinder from the threaded adapter. The adapter itself can be left screwed to the pump.

Anschuetz model

As for the operation and design of the hand pump sold by ahg-Anschuetz (a distributor of the English manufacturer Hill), they are almost completely consistent with those described above. However, unlike the blue pumps of its competitor, the MK 4 model not only has a different color (black), but also has a performance of 231 cm3 per stroke. Hill's patented dry air filter removes up to 90% of the moisture contained in the air pumped into the cylinder.

The M 4 model sold by Anschuetz impresses with its good handle with a soft rubber coating. An optional dry air filter installed on the right side of the pump removes almost all moisture contained in the air pumped into the cylinder.

Compared to other models, the rubber-coated handle is much softer, which makes working with the pump much more comfortable. Model MK 4 costs 214.00 euros, and a pump with a dry air filter is 35.00 euros more expensive. Hill provides a lifetime warranty on its pump.

An optional filter for removing moisture from the pumped air is sold in vacuum packaging

Of course, the choice of a specific model is a matter of taste for each buyer. All hand pumps provided by the editors of DWJ magazine have successfully passed tests.

Timo Lechner, translation by Victor Nazarov

Popular PCP rifle models

The AirSoft-RUS online store presents the best models of PCP rifles from Russian and foreign manufacturers. It is worth highlighting one sample each, of different calibers, combining high performance and reasonable price.

Baikal MP-555KS 03

Model MP-555 KS 03

from the Russian brand Baikal - this is quality, reliability, uniqueness. The price tag of 16,800 rubles (note: all prices are current as of the date of publication of the article) makes it the most affordable for fans of PCP-type pneumatics. Ideal for training and sports competitions.

Caliber 4.5 mm. MP-555 KS is a modernized version of another rifle – MP-553K. The device has become more ergonomic. Equipped with a rifled barrel for lead bullets weighing up to 0.45 g. The removable magazine is protected against falling and has a capacity of 5 rounds. The reservoir is also removable - volume 200 bar. Without refueling you can fire up to 100 shots. The butt and stock are made of impact-resistant plastic, which lightens the overall weight of the rifle.

Other features:

- initial bullet speed – 140 m/s;

- single shooting;

- protection against double chambering of a bullet is provided;

- adjustable diopter, USM.

Excellent PSP weapon up to 3 J, which according to the legislation of the Russian Federation is considered a product structurally similar to a weapon. Sold freely.

Hatsan FLASH QE

Model FLASH QE

from the Turkish manufacturer of inexpensive, reliable pneumatics - Hatsan. It will cost only 32,990 rubles. The rifle is suitable for training, sports, and small game hunting.

Caliber 5.5 mm. Hatsan FLASH QE is equipped with a rifled barrel, as well as a moderator that reduces the sound of a shot by 2 times. Capacious clip-drum for 12 lead bullets. The rifle is tactical and lightweight, since the butt and stock are made of plastic. The total weight is 2.68 kg with a length of the “air” of 107.5 cm.

Other features:

- high initial speed – 295 m/s;

- single shooting mode;

- the presence of Picatinny rails for installing optics, under-barrel accessories (LCC, flashlight).

A beautiful rifle with a pre-pumping system, in black design.

Hatsan FLASH W

FLASH W

– another weapon model from Hatsan. True, the caliber is already 6.35 mm, and the price is almost the same as FLASH QE - 33,950 rubles. Suitable for practical, recreational shooting.

The rifle is rifled, made of impact-resistant wood. At the same time, the mass of the device is only 2.5 kg, thanks to its compactness - 91.5 cm. The drum magazine is designed for 10 lead shells.

Other notes:

- high starting bullet speed – 265 m/s;

- conducting single shooting;

- Built-in Picatinny rails for installing sights and under-barrel accessories.

Users of the AirSoft-RUS site choose FLASH W for its elegant appearance, practicality, technical characteristics, and price tag.

Brief conclusion on the topic

PCP rifles and pistols bypass PPP in many respects. The price tag is high, but the owner can strengthen the device to the limit. The main thing is not to violate Federal Law No. 150 “On Weapons”: making changes to the design is punishable.

Is it worth buying PCP weapons that cost more than 50,000 rubles?

Definitely. Turkish rifles demonstrate power and accuracy, but in terms of build quality they are inferior to their German counterparts. It all depends on the financial capabilities of the aerial fan. The listed weapon models are reliable and perform well. It is important to remember that proper, periodic care of the device will ensure its long-term operation. October 19, 2022