The Maxim machine gun is the first automatic weapon in history that uses the removal of powder gases to fire and reload a cartridge. The developed Maxim machine gun, the design and operating principle of which turned out to be so successful that from the second half of the 19th century to the present, this heavy machine gun is still in service in the modern world. Having all kinds of modifications and calibers, the principle of shooting remains unchanged.

Machine gun Maxim SHP

History of the Maxim machine gun

- 1873 – production of the first model of the Maxim machine gun;

- Autumn 1882 - final development of machine gun drawings;

- 1883—1895 – many patents have been issued for these weapons;

- 1888 – the first demonstration of the product in Russia;

- 1898 - the first mass use of a machine gun by British troops in Sudan;

- 1899 – the first successful version was manufactured for the British 7.7 mm cartridge;

- May 1899 - the first batch of machine guns manufactured in Britain was delivered to St. Petersburg;

- 1901 – adopted into service in the Russian Army;

- May 1904 – start of production at the Tula Arms Plant;

- 1910 – development of a Russian model;

- 1930 - new modernization of the Soviet machine gun;

- 1931 - production of a quadruple anti-aircraft gun began.

Who created

Hiram Stevens was a famous inventor. His inventions are known in various fields. Creating a machine gun was his long-time dream.

The world's first Gatling machine gun, which had from 6 to 10 barrels, was effective at that time, but was heavy and inconvenient to use. It was necessary to turn the barrel rotation knob with one hand, and with the other to direct the fire towards the enemy.

The first Gatling gun

Stevens came up with a more advanced weapon, in which he was the first to use recoil energy to automatically reload and fire a cartridge.

However, American gunsmiths refused to introduce the machine gun into production, citing complexity and high cost. The required high precision processing of machine gun parts required the involvement of many qualified specialists. The cost of one copy, at that time, was comparable to the cost of a steam locomotive.

Machine gun author Hiram Stevens Maxim

Hiram Stevens emigrated to England, where he did a lot of marketing work among the leadership of countries and the military elite. He found interested entrepreneurs in the production of these weapons.

To attract more attention to his creation, he used such a trick - in the documents he corrected the rate of fire indicator from 600 to 666 , allegedly emphasizing that this was a “devilish” weapon. Despite the indignation of churches and pacifists, the inventor ensured that the leading powers began to buy the machine gun.

See also the article Collimator sights and operating principles

Nathan Rothschild undertook to finance the project. Apparently, the world's behind-the-scenes elite was already planning the massacre.

Lord Nathan (Nathaniel) Mayer Rothschild, who financed the production of Maxim

History of production development

The first customer of several copies was Kaiser Wilhelm, who personally tested the machine gun.

The inventor brought a machine gun to Russia, from which Tsar Alexander III fired. Russia ordered 12 units chambered for the Berdan rifle (10.67 mm). Subsequently, the barrels were converted to the caliber of the Mosin rifle (7.62 mm). In total, during the period 1897-1904, Russia purchased 291 units.

The production license was sold to Germany, America and Russia.

Since the time the machine gun received Russian citizenship, it has undergone a number of modernizations at the Tula Arms Plant.

In the history of the Maxim machine gun, there are many names written about who invented this type of weapon.

Changes introduced in the Russian version of the combat product:

- sighting device changed;

- the receiver mechanism was redesigned for a new cartridge;

- the hole in the muzzle sleeve has been expanded;

- the carriage was replaced with a Sokolov wheeled machine;

- the size of the armor shield has been reduced;

- Ammo boxes have been changed;

- a folding butt pad is installed;

- the fuse was moved to the trigger area, which speeded up the firing process;

- added return spring tension indicator;

- the sight has been changed with an enlarged scale;

- a separate firing pin is introduced to the firing pin;

- for long-range shooting, a heavy bullet and an optical sight were introduced;

- The water casing is reinforced with longitudinal corrugation.

Tula gunsmith Tokarev

To provide the army with machine guns chambered for the domestic cartridge, in the 20s of the last century our designers tried to develop their own models of automatic weapons. Based on the Maxim machine gun, Tula gunsmith F.V. Tokarev undertook to solve this problem. He was the first to invent the Maxim machine gun.

He created the MT model, a light machine gun of the Maxim-Tokarev system, which had a wooden butt and air cooling. However, the weight remained high.

It had some advantages over foreign analogues, and was put into service in 1925.

MT machine gun

In 1923, another inventor of the Maxim machine gun appeared. On the basic design by gunsmith I.N. Kolesnikov created the Maxim-Kolesnikov machine gun. It was distinguished by its original pistol grip.

See also the article KPVT machine gun and its design

MK machine gun

Both products were subjected to field tests, according to the results of which MT received the advantage. In 1925, its mass production began, which ceased in 1927.

Dekhtyarev's new heavy machine gun, which was hastily adopted in those years, turned out to be unreliable. In order to provide the army with weapons, industry is forced to return to the production of Maxim, which was manufactured in Izhevsk and Tula until the end of the Great Patriotic War.

Machine gun "Maxim" model 1910

The Maxim machine gun of the 1910 model was a modernized version of the machine gun of the 1905 model. Its serial production was carried out at the Imperial Tula Arms Factory (ITOZ) from May 1905 under license (England). The main role in finalizing the systems of both Maxim models and putting machine guns into production belonged to Guard Colonel Tretyakov and senior class master Pastukhov, who served at ITOZ. The essence of the modernization, which was carried out in 1909, was to create a lighter machine gun. Some parts made of bronze (barrel casing, receiver, handles, etc.) were replaced with steel ones. The sight, parts of the casing and box, the trigger rod, and the butt plate were also changed. The first two machine guns modernized by Tula gunsmiths were submitted for testing on June 15, 1909 (where they became competitors of the new Vickers machine gun). After appropriate modifications, the Tula “light” machine gun was adopted for service, giving it the designation “Maxim heavy machine gun of the 1910 model” with a field wheeled machine gun of Colonel Sokolov. Serial production of the new modification of the Maxim and the machine began in 1911. The machine gun of the 1910 model was indeed significantly improved compared to the prototype, primarily in technological terms, but it is hardly correct to say that “Russian technicians created, in fact, a new machine gun,” which is established in Russian literature.

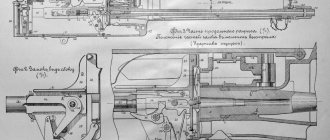

The machine gun consisted of: barrel; a frame that included a locking mechanism, a drum, a handle and a chain; bolt (lock) with impact mechanism, combat cylinder, lifting and locking levers; trigger pull; box (riveted) with a hinged lid; butt plate with safety catch, trigger lever and control handles; return spring with casing (box); a receiver having a tape feeding mechanism; barrel casing with sleeve and steam outlet tube, drain and fill holes; sighting devices; muzzle

The automatic system implemented a barrel recoil scheme with a short stroke. The barrel bore was locked by a system consisting of two articulated levers. The connecting rod (front lever) was connected to the bolt with a flat hinge, and the crank (rear lever) was also hinged at the rear of the frame, that is, the frame was the receiver. At the right end of the bloodworm axis there was a swinging handle, at the left there was an eccentric (drum) with a Gall chain, which was connected to the return spring. The return spring was mounted in a separate box located on the left wall of the Maxima box. The lock was equipped with a drummer with a double-leaf mainspring. The combat cylinder, which had grips to hold the cartridge case, slid vertically in the grooves of the lock and had a hole for the firing pin to pass through, so the shot could only be fired if the cylinder was in a certain position. The drummer cocked his ankle. At the same time, the upper safety release captured him. The ankle, with its combat platoon, stood on the lower descent. The trigger lever, which had a finger button, was placed between the control handles and was held in place by a safety lock. A canvas cartridge strip was inserted into the transverse window of the receiver on the right. The tape nests were separated by metal plates fastened with rivets. In this case, the rivets were placed with a slight interference fit, which made it possible to firmly hold the cartridge in the socket. The cartridge box was installed separately from the machine gun. For reliable operation of the feed, the second number supported the tape with his hands in the correct position. The weight of the canvas tape was 1.1 kg. The cutout wall of the left frame of the receiver frame activated the feed mechanism. On the first Maxim machine guns of the 1910 model, a reel was installed on the box, designed to direct the canvas tape to the receiver. Later the coil was moved to the shield.

1 - fuse, 2 - sight, 3 - lock, 4 - filler plug, 5 - casing, 6 - steam exhaust device, 7 - front sight, 8 - muzzle, 9 - cartridge outlet tube, 10 - barrel, 11 - water, 12 - pourer plug, 13 - cap, steam outlet, 15 - return spring, 16 - release lever, 17 - handle, 18 - receiver.

The shot was fired from a closed bolt. It was necessary to lift the safety and press the trigger lever. At the same time, the trigger rod moved back, pulling the tail of the lower trigger, which released the ankle. The firing pin passed through the hole in the cylinder, breaking the cartridge primer. The lock, under the influence of recoil, tried to move back, transferring pressure to the crank and connecting rod. The crank and connecting rod formed an angle, the apex of which was facing upward, and rested against the protrusions of the frame with their hinge. The barrel and frame with the lock moved backwards. After the movable system had traveled about 20 millimeters, the handle ran onto the fixed roller of the box and rose, turning the crank down. As a result, the lever system straightened and the lock was pressed more closely to the bore. After the bullet had ejected, the powder gases entered the muzzle, pressing on the front section of the barrel, and the moving system received an additional impulse. The design of the Russian-style muzzle was developed by Zhukov and finalized by Pastukhov. The barrel, moving back, opened transverse holes in the muzzle, through which excess powder gases were discharged. By turning, the handle caused the levers to fold down and move away from the lock barrel. In this case, the handle acted as an accelerator of the lock, transferring to it the kinetic energy of recoil and braking the frame and barrel. The lock cylinder, holding the spent cartridge case by the rim, removed it from the chamber. When lowering the connecting rod, the tube of the locking levers pressed on the tail of the ankle, which, turning, cocked the striker. The lifting levers lifted the larva, capturing the next cartridge from the receiver window (the window was longitudinal). During the further movement of the system backwards, curved leaf springs located on the inside of the box lid lowered the cylinder. Simultaneously with this cranked lever, the slider of the feed mechanism was moved to the right. The slider's fingers jumped for the next cartridge. When the handle was turned, the chain wound around the drum, stretching the return spring. The weight of the barrel was 2.105 kilograms, the moving system - 4.368 kilograms. The rear stroke length of the barrel was 26 millimeters, the lock relative to the barrel was up to 95 millimeters. Coordination of the movement of the lock and the barrel was achieved by adjusting the tension of the return spring.

Operation of the automatic system of the Maxim machine gun

At the end of the rotation, the handle hit the roller with its short shoulder and began a reverse rotation (early samples of the Maxim machine gun had a separate spring for this). The moving system moved forward under the action of the return spring. The lock sent the cartridge into the chamber, and the spent cartridge was sent into the cartridge outlet tube, from where it was pushed out during the next cycle. The crank lever shifted the slide to the left, and it advanced the next cartridge to the receiver window. When turning the crank and connecting rod, the tail of the safety release was raised by the tube of the locking levers. When the combat larva stood opposite the striker with its hole, the upper trigger released the firing pin and, if the trigger lever was pressed, a shot was fired.

The machine gun consisted of 368 parts. The maximum gas pressure in the barrel was about 2850 kg/sq.cm, and the average was about 1276 kg/sq.cm. During training, a blank firing bushing was used, which was screwed into the muzzle. When the mainspring broke, the debris was removed through the bottom of the box. The Maxim machine gun of the 1910 model had a rack-mounted sight mounted on the lid of the box. On the rack there was an aiming bar, which had divisions for aiming at range. On the transverse tube of the clamp, divisions were marked along which the rear sight was installed. The front sight of a triangular cross-section was inserted into a groove on the casing. The length of the aiming line was 911 millimeters. The height of the front sight above the axis of the bore was 102.5 millimeters, so the accuracy of the casing had a great influence on accuracy. The sight was set to a range of up to 3.2 thousand steps (2270 meters), but the effective range did not exceed 1.5 thousand meters. The capacity of the casing was about 4.5 liters. Some machine guns had casings with longitudinal fins, which increased rigidity and increased the cooling surface, but fins were abandoned in favor of simplifying production. Canvas or rubber hoses used in some armies to vent steam into the atmosphere or into a condenser canister were used in the Russian army only in armored installations.

Armored trains were heavily armed with machine guns. Russian armored train of the Hunhuz type in Galicia, 1916. Both Maxim and captured Schwarzlose machine guns were used to arm such armored trains.

With the help of a crank mechanism, smooth and almost shockless operation of the automation was ensured. The use of a power supply system drive from the frame was rational from the point of view of uniform distribution of recoil energy. The Maxim system had high survivability and reliability, which ensured its exceptional longevity. Despite the fact that the external position of the handle was dangerous for the crew, it facilitated the assessment of the condition, as well as the determination and elimination of delays in firing. The production of a machine gun was quite complex and required not only high-quality steel and skilled workers, but also numerous special equipment. Some equipment was also required for assembly and initial running-in of the units. Sokolov's machine, which he developed with the participation of Platonov, a master of the St. Petersburg gun factory, consisted of a frame with a trunk, wheels and a table. The rim and spokes of the wheels were made of oak, the tire was made of steel, and the nuts and bushings were made of bronze. The table carried a clamp-type swivel with a clamp, fine and coarse vertical aiming mechanisms, as well as a shield. The machine gun was attached to the swivel by the front eyes of the box. The lower eye connected the machine gun and the head of the lifting mechanism. Rough vertical alignment was carried out by moving the table along the arcs of the frame. In the first version of the machine, the frame had two foldable legs, a seat, and a roller at the end of the trunk. This design made it possible to fire from two positions and roll the machine gun by the strap. When carried, the legs folded back and the trunk forward. Later, the front legs, roller and seat were eliminated, and a small opener was strengthened at the end of the trunk. These changes led to the fact that the maximum elevation angle decreased to 18 degrees (from 27), and the declination to 19 degrees (from 56); shooting was carried out only from a prone position. The mass of a 6.5-mm shield measuring 505x400 millimeters was 8.0 kilograms (with a reel guiding the tape - 8.8 kilograms). It was believed that the shield would protect the machine gun crew from rifle bullets at a distance of over 50 meters. Although the convenience of a wheeled machine even on slightly rough terrain is questionable, in our country the addiction to them lasted a long time.

Installation of Maxim machine guns in the turrets of the Austin armored car built at the Putilov plant

Before the complete “victory” of Sokolov’s machines in Russia, several installations were used with the Maxim machine gun. The field and fortress wheeled carriages were removed from service before 1914, but the Vickers tripods of the 1904, 1909 and 1910 models remained. The Vickers tripod of the 1904 model had a mass of 21 kilograms, the height of the firing line was 710 millimeters, the vertical guidance angle was from -20 to +15 degrees, the horizontal guidance was 45 degrees, its modification of the 1909 model, which had a new lifting mechanism, had a mass of 32 kilograms , vertical guidance angle - from 15 to +16 degrees, horizontal guidance - 52 degrees. The 1910 model tripod had a mass of 39 kilograms, the mass of the shield 534x400 millimeters was 7.4 kilograms, the vertical aiming angle was from -25 to +20 degrees, horizontal - 52 degrees, and occupied three fixed positions at the position. In 1915, the Kolesnikov system, which was easier to manufacture and lighter, was added to the Maxim machine gun. This machine was produced by the Petrograd gun factory, Kyiv, Bryansk and Petrograd arsenals. The Izhevsk and Sormovo factories were engaged in the production of shields. Kolesnikov’s machine had a tubular boom with a coulter and rope loops instead of handles, 305 mm oak wheels with steel tires and hubs and bronze bushings, horizontal and vertical guidance mechanisms, and a shield mount. The disadvantage of the design was that the axis of the barrel bore was too high relative to the axes of the wheel travel and the vertical guidance mechanism. This increased dispersion during shooting. The mass of the machine was 30.7 kilograms, a 7-millimeter shield measuring 498×388 millimeters was 8.2 kilograms, the vertical guidance angle was from -25 to +32 degrees, and the horizontal guidance was 80 degrees. The machine consisted of 166 parts, including knitting needles. During the war, the machine gun and machine gun were painted in a protective color.

To save money during the training of machine gunners, instead of live cartridges, manufactured cartridges with a reduced powder charge were used. A box of live ammunition intended for machine guns was marked with the letter “P” before being sent to the troops. A large number of proposals were received from foreign companies and domestic inventors regarding sights, as well as devices for conducting “hidden” firing from machine guns. The latter consisted of a periscope sight mounted on the parapet of the trench and an additional trigger lever. Such sights were tested, but not a single sample was accepted for service. The pressing problem of firing at air targets has given rise to many different options for improvised anti-aircraft installations among the troops. For Sokolov’s machine, for example, they developed a stand with a clip for anti-aircraft shooting. In the fall of 1915, master Kolesnikov made a tripod “machine gun mount for firing at aircraft.” The machine, developed in the workshops of the Rifle Range, provided large elevation angles and all-round fire, aiming was free, a clamp was used to fire “at the point,” and a butt could be attached. Titular adviser Fedorov presented an anti-aircraft gun, easily made from scrap materials. The machine gun was mounted on it with a Sokolov machine gun. This installation made it possible to fire at vertical guidance angles from +30 to +90 degrees. The 5th Department of Artcom decided to send descriptions of these installations to the troops, transferring them from “procurement” to their own discretion. The standard anti-aircraft machine gun mount was never transferred to the Russian Army. Lieutenant General Kabakov, inspector of the rifle unit in the army, on October 11, 1913, in a note to the Aeronautical Unit of the GUGSH, gave recommendations for converting the Maxim machine guns into aviation ones - although these recommendations were not implemented, however, five years later, similar changes were made by the Germans to the MG machine gun. 08/18.

The procedure for unloading the Maxim machine gun, model 1910: Press your fingers at the bottom of the receiver tray on the right side to remove the tape. Pull it back twice and then release the cocking handle located on the right side of the box. Using a pencil or other object suitable for this purpose, make sure that there is no cartridge or cartridge case in the under-barrel front tube. Raise the safety and press the release lever. The procedure for partial disassembly of a 1910 model Maxim heavy machine gun with a Sokolov machine gun: 1. Before disassembling, pour the coolant out of the casing. Separate the shield from the machine. To do this: loosen the nut of the connecting bolt; the tail of the bolt head is turned upward to a horizontal position; the shield is removed upwards. 2. Open the box lid by pushing the clasp forward with your thumbs. 3. The lock is removed. To do this: send the handle forward with your right hand until it stops; With your left hand you take the frame of the lock and lift it up a little; smoothly lowering the handle, the lock rises from the box; the lock turns and is removed from the connecting rod. 4. The firing pin is lowered to release the mainspring. To do this, it is necessary: holding the combat cylinder in the uppermost position, press the tube of the locking levers to the platform; release the hammer from the upper descent; by pressing on the tail of the lower trigger, smoothly release the firing pin. 5. The receiver is taken with both hands and pulled out upward. 6. The box with the return spring is separated. To do this, the box is moved forward so that the hooks come off the box spikes, after which the drum chain is removed from the return spring hook. 7. The butt plate extends. To do this, you need to squeeze the head of the split pin with your fingers, pulling it to the side; push the butt plate up by holding its handles with both hands (if it is difficult to extend the butt plate, you can use a special lever device). 8. Fold the handle forward, grasping the roller and the bolt, pull the right bolt to the right, grasping the left bolt from both sides from behind and pull it out. 9. The frame with the barrel is removed. To do this: the connecting rod will rise and rest on the crank; grab the handle with your right hand, fixing it (do not let it turn), grab the drum with your left hand, push the frame back; clasp the barrel and the extended end of the left frame with your left hand; remove the frame with the barrel from the box. 10. The barrel is separated from the frame. To do this: with your left hand grasping the end of the left frame and the barrel, with your right hand the right frame is moved to the side and removed from the barrel axle; after this the left frame is removed. 11. The trigger rod is removed. To do this, the rod is applied to itself, lifted upward by the end and removed from the box. 12. By turning to the right, the cap is removed from the muzzle; the bushing is unscrewed from the muzzle using two keys; The muzzle is unscrewed with a drill key. The procedure for assembling a machine gun: 1. The rod is inserted into the box. Its hole is put on a spike in the bottom of the box, while the rod spike is inserted into the hole in the bottom of the box; the thrust moves forward all the way. 2. The barrel and frame are connected: take the barrel with the rear oil seal wound on it in your left hand (the number should be turned upward) and put the frame frame on the barrel axles - the left one, and then the right one. 3. Insert the barrel and frame: place the connecting rod on the crank; carefully slide the barrel into the casing and the frame into the box. 4. Lift the handle to insert the right latch; push in the left one. 5. Insert the butt plate. To do this, hold the buttplate by the handles and slide it onto the box slats using the grooves. In this case, it is necessary that the thrust be in the forward extreme position. Insert a pin on the right side. 6. Attach a box with a return spring. To do this, it is necessary to position the tension screw knob vertically; put the handle in place and put the drum chain on the hook of the spring (the spring is circled from below); holding the machine gun, move the box forward and place the box hooks on the box spikes. 7. Insert the receiver. To do this, the receiver is inserted with grooves into the upper cutouts of the box; The slider should be in the left position. 8. Screw in the muzzle. Wind the front seal onto the muzzle end of the barrel, screw the bushing into the muzzle, insert the muzzle into the hole in the casing, and then screw the muzzle. 9. Place a lock in the box. To do this, the connecting rod is raised, and the firing pin is cocked. After this, holding the lock with its horns forward and the combat cylinder upward, put the tube of the lock levers onto the connecting rod until it stops, turn the lock and place it in the box; While holding the lock, send the handle forward and release it. The lock should fit into the grooves of the frame ribs with its pad. 10. Close the box lid. 11. Raise the safety, press the release lever. 12. Place the cap on the muzzle. Technical characteristics of the Maxim heavy machine gun, model 1905. Cartridge – 7.62 mm model 1891 (7.62×53); The weight of the machine gun “body” (without coolant) is 28.25 kg; The length of the machine gun “body” is 1086 mm; Barrel length – 720 mm; Initial bullet speed – 617 m/s; Sighting range – 2000 steps (1422 m); Rate of fire – 500-600 rounds/min; Combat rate of fire – 250-300 per minute; Belt capacity – 250 rounds. Technical characteristics of the Maxim heavy machine gun, model 1910: Cartridge – 62 mm model 1908 (7.62×53); The weight of the machine gun “body” (without coolant) is 18.43 kg; The length of the machine gun “body” is 1067 mm; Barrel length – 720 mm; Initial bullet speed – 665 m/s; Rifling – 4 right-hand; Rifling stroke length – 240 mm; Initial bullet speed – 865 m/s; Sighting range – 3200 steps (2270 m); The longest firing range is 3900 m; The maximum flight range of a bullet is 5000 m; Direct shot range – 390 m; Rate of fire – 600 rounds/min; Combat rate of fire – 250-300 rounds/min; Belt capacity – 250 rounds; Weight of the loaded belt – 7.29 kg; Tape length – 6060 mm. Technical characteristics of the Sokolov machine: Weight with shield – 43.5 kg; Vertical guidance angle – from -19 to +18 degrees; Horizontal guidance angle – 70 degrees; The height of the firing line is about 500 mm; The greatest length of the machine gun with the machine is 1350 mm; Stroke width – 505 mm; The distance from the center of gravity to the coulter is 745 mm.

Based on materials: S. Fedoseev - Machine guns in the First World War.

Additionally: A lot of information at the link https://warbook.info/item/pulemet-maksima-maksim-1910-30-goda

Combat use

The British first used a machine gun on the battlefield during the battle against the Mahdi's superior army in Sudan. An army of thousands, armed with muskets, was defeated in a short period. The results of this massacre showed that the tactics of field battles must change radically. This fact was confirmed by the events that took place on the battlefields of the 20th century.

Changes in troop tactics after the introduction of the machine gun:

- the infantry went deeper into the trenches;

- the cavalry ceased to exist;

- line attacks stopped;

- gun volleys are a thing of the past.

The first samples were equipped with heavy gun carriages and resembled a cannon. They were classified as artillery and used for the defense of fortresses and fortified positions.

Hiram Stevens with the first sample on the carriage

Classic image of a Maxim machine gun

The first large-scale use of the machine gun in the 20th century occurred between Russia and Japan in May 1904 in the defense of Port Arthur. Both sides used them as miniature artillery, opening fire from the rear, over the heads of their soldiers, at enemy positions. The same version of the Maxim weapon was used during the 1st World War.

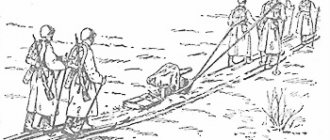

After a number of modifications, the sample acquired the well-known classic appearance on a frame with wheels. This option was more mobile; it was used not only in defense, but also in attack. The weight of the weapon changed from 244 to 65 kg.

The machine gun was mounted on spring carts.

As well as armored cars, armored trains and ships. It was also used in anti-aircraft artillery.

During the Civil War, the cart was used effectively against infantry and cavalry. Nestor Makhno was the first to use the tactics of fighting on carts.

Maxim on a cart

With the advent of armored vehicles and tanks in the army, carts lost their role, and the legendary machine gun continued its life.

Armored car with a Maximov machine gun

Russian invention - motorized machine gun

The machine gun was widely used during the Civil and Great Patriotic Wars. The last large-scale use of these weapons was during the Sino-Soviet conflict on Damansky Island in 1969.

Currently, the machine gun is used by units of the Ukrainian Armed Forces in the civil conflict in the South-East of Ukraine.

A Right Sector fighter and a Maximka machine gun at a firing position near Donetsk

Cavalry Killer

From the first examples of use, the Maxim heavy machine gun had a great influence on combat tactics. The military actions of the British in suppressing uprisings in the African colonies and the Russo-Japanese War showed the futility of massive infantry attacks against machine gun fire.

The military armies of different countries, who in the past had uniforms of bright colors, changed into modest khaki, less noticeable in a machine gun sight. Maxim’s invention forced armies to bury themselves in the ground, largely predetermining the emergence of the concept of “trench warfare.”

He forced the mounted army units to dismount and put an end to cavalry as the main type of troops. When attacking with lava, machine guns mowed down people and horses almost completely.

Although it was the use of spring carts with machine guns mounted on them that gave birth to a new type of mobile fire weapon. The legendary cart became a symbol of Budyonny’s First Cavalry Army and the units under the command of Father Makhno.

How the Maxim machine gun works - TTX

| Weight with machine, kg | 64,3 |

| Body weight with barrel, kg | 20,3 |

| Length, mm | 1067 |

| Barrel length, mm | 721 |

| Cartridge, mm | 7.62x54 |

| Combat rate of fire, rpm | 250-300 |

| Maximum rate of fire, rpm | 600 |

| Initial bullet speed, m/sec | 855 |

| Number of shots | 200/250 in tape |

| Barrel diameter | 7.62x54 mm, 4 grooves |

| Sighting range, m | 2300 |

| Maximum sighting range, m | 3800 |

| Effective sighting range, m | 600 |

| Stroke width, mm | 505 |

| Type of ammunition: | canvas or metal cartridge belt for 250 |

| Work principles: | gas outlet, crank locking |

| Machine gun crew | 3 people |

Technical and tactical characteristics

The 1910/1930 model machine gun met the Great Patriotic War as part of the Red Army. Attempts to replace it with similar weapons of the Degtyarev system failed, and the Maxim machine gun, the characteristics of which became obsolete in the early 40s, began to be produced in large quantities again. The production of new machine guns of the Maxim system was finally stopped in 1945.

| Caliber | 7.62 mm |

| Weight in firing position | 66 kg |

| Machine gun body weight | 20.3 kg |

| Belt weight with 250 rounds | 10.3 kg |

| Initial bullet speed | 800 m/s |

| Rate of fire | 600 rpm |

| Combat rate of fire | 250-300 rpm |

| Sighting range | 3000 m |

| Bullet range | 5000 m |

In different countries of Europe, several varieties of heavy machine guns of the Maxim system were designed and produced: the English Vickers, the German MG-08 and MG-11, etc. Some of them were used as manual ones, there were also large-caliber versions, they were installed on ships and aircraft.

Maxim machine gun: design and principle of operation

Design

General design of the Maxim machine gun

Atlas of drawings 1906

General view drawing

General view in section

Cross section and drawings of the internal mechanism

Drawing of the spring, lock fork, connecting rod and handle

Drawings of lifting mechanism parts

Images and drawings of the supporting structure

From the drawings presented above, we can conclude that the machine gun mechanisms are highly complex.

How does the Maxim machine gun work?

Loading

- Thread the cartridge belt into the receiver;

Maxim machine gun operating principle

- Move the handle to the front and rear positions. At the same time, the belt with cartridges will move, and the first cartridge will stand opposite the lock (A). The lock moves forward and captures the cartridge (B);

Maxim machine gun operating principle

- Repeatedly vigorously move the handle back and forth. When the handle moves forward, the lock removes the cartridge from the belt (B). When the handle moves to its original position, the cartridge enters the barrel bore, the tape moves onto one cartridge, which again captures the lock (G). The machine gun is ready to fire;

How does the Maxim

Shooting

- The design of the Maxim machine gun is such that when you press the trigger, a shot is fired. Under the influence of powder gases, the lock with a new cartridge and spent cartridge case moves backward (A). The handle automatically goes forward (B);

Maxim machine gun, shooting

- The cartridge and cartridge case move downwards, and under the influence of the return spring, the lock moves forward, the cartridge is inserted into the bore, and the spent cartridge case is inserted into the cartridge case ejection tube (B), which pushes out the previous cartridge case. Another shot is fired (D). The next cartridge is captured, the lock moves back, and the process repeats;

Maxim machine gun, shooting

Instead of a preface

“Memorandum from the chief of supplies of the Red Army and Navy D. P. Oskin to the chief of staff of the Red Army M. N. Tukhachevsky on the production capabilities of strengthening infantry weapons”

September 26, 1925

Top secret.

The Presidium of the Council for the Preparation of the Red Army, at a meeting on July 10, 1925 (Minutes No. 11), adopted a resolution to strengthen the infantry armament. I fully agree with the need to strengthen armaments, and I believe that each measure is valuable only to the extent that it is actually feasible. Therefore, I find it necessary to indicate in the attached calculations the amount of funds required and the existing production capabilities of the industry that will have to be faced when implementing the resolution adopted by the Presidium of the Council.

In all calculations, the initial data is a three-year period for rearmament and the existing option and staff.

- Light machine guns (in a platoon).

The need is 21,605. In the future, when replacing heavy machine guns, the need will increase to 28,930. We have up to 7.5 thousand foreign machine guns of various systems, which are wearing out, with a dwindling supply of cartridges. It is necessary to switch to a Russian 3-line light machine gun.

- Light machine gun (in company).

Requirement—32,295. I consider it necessary to use existing heavy machine guns. There are 23.9 thousand. There are 10.6 thousand missing.

- Heavy machine gun (in the battalion).

The need is 1280. There is no sample of a gun or a projectile, there is no free factory for production. There is no need to introduce this year if there are heavy machine guns in companies and guns in battalions. For now, design the type and receive prototypes only in 1926/27, and start production from 1927/28.

The main machine guns of the Red Army in 1924, from left to right: Maxim machine gun, Lewis Mk. I; Chauchat Mle 1915; Madsen.

Basics of machine gunning in Interbellum. Following the results of the Great War, the military, for the most part, came to the conclusion that the machine gun is an extremely important factor in strengthening the infantry and should be present not only in the battalion, but also in the company and platoon. Moreover, having agreed that the heavy machine gun in its existing form fully satisfies the requirements for battalion reinforcement equipment, and the light machine guns (or, in other words, submachine guns) that appeared during the war are good as maneuverable weapons for squads and platoons, then with samples of company machine guns there was no general uniformity. The role of company machine guns was intended for both “light mounted” machine guns, capable of firing from a bipod, and not just from lightweight machine guns, and light machine guns using light tripod mounted machines. The wishes of a certain number of theorists about the use of large-caliber machine guns as battalion ones, in order to enable infantry to fight enemy armored vehicles without attracting additional forces and to distance the range of opening fire on enemy infantry, remained, by and large, wishes. Since large-caliber machine guns turned out to be too heavy for the battalion, and the armor of the tanks was slowly becoming thicker than at the end of the Great War. And large-caliber machine guns began to appear in battalions only during the next war, and then mainly as a means of air defense.

The British first tried on Lewis and then Bren for the role of company machine guns, that is, they took the path of creating light machine guns for light machine guns. The French, Poles, and Finns decided that a company machine gun should be the same as a battalion machine gun. The Americans at first also followed the same path, but realizing the severity of the Browning M1917, they soon adopted the new M1919 for the role of a company machine gun - an air-cooled version of the Browning M1917 heavy machine gun with a lighter machine gun. By the mid-30s of the last century, the Germans created a single machine gun (MG.34), used in a platoon unit on a bipod, and in a company and battalion unit - on a machine gun, while the machine gun could be removed from the machine and used with a bipod without any additional actions.

The Red Army used heavy machine guns as company machine guns - at first it was a very heavy Maxim, then it was replaced by the SG-43. But in 1946, a special company machine gun, the RP-46, was adopted for service, which was a modification of the DP light machine gun for belt feeding and with a heavier barrel. Thus, at the end of the Great Patriotic War in the USSR, the formation of the image of machine gun weapons, which was dreamed of back in the 20s of the last century, was completed.

Advantages and disadvantages of the Maxim machine gun

Advantages

- high rate of fire;

- good accuracy of fire;

- high reliability and durability;

- the ability to fire in long bursts;

- large ammunition load;

- presence of armor protection;

- comfortable ergonomics when shooting.

Flaws

- short effective firing range;

- how much does a Maxim machine gun weigh?

- low maneuverability;

- high profile, making camouflage difficult and making the machine gunner an easy target;

- complexity of the design, making disassembly and assembly difficult;

- high cost and difficulty in production;

- low efficiency when water is scarce;

- combat crew of 3 people.

Operating countries

| A country | Usage |

| Bulgaria | Austro-Hungarian and Russian designs |

| Great Britain | Own production |

| German Empire | Own production |

| Greece | Purchase for your own 6.5x54 mm cartridge |

| Kingdom of Italy | Purchase |

| Serbia | Manufactured in Germany chambered for 7x57 mm |

| Ottoman Empire | 220 pcs., purchase |

| Russian empire | Own production |

| Romania | Purchase chambered for 6.5x53 mm |

| USSR | Own production |

| Montenegro | Purchase from Germany chambered for 7.62x54 |

| Finland | Own production |

| Switzerland | Own production |

| Ukraine | There are about 35,000 pieces in MO storage. |

Cultural use

This great invention of murder has become the hero of many folklore works of the world. Poems and songs were dedicated to him. His image was described in many works of literature and cinema. Films about the Civil War and the 2nd World War could not do without him.

Art films

- Chapaev;

- Officers;

- Brother 2.

Songs

- Two maxims;

- Maxim machine gun.

Many documentaries have been filmed.

Documentary video

Video about the Maxim machine gun - device

Today, civilian models of the machine gun are available for public sale. Many models have been developed for collectors, construction sets and toys made from various materials from metal to cardboard.