KamAZ-53501 is an all-wheel drive three-axle truck produced by the Kama Automobile Plant from 2003 to the present. This truck is a representative of the Mustang military family, but in addition to military tasks, it often performs many civilian ones.

Excellent all-terrain qualities allow it to be used in difficult areas. Basically, the KamAZ-53501 truck is intended for transporting any cargo, including weapons. It has an onboard platform with a removable awning frame. There are folding benches inside, which also allows you to carry passengers. But in addition to this, the car chassis can be equipped with specialized add-ons, such as launchers, closed bodies, KUNGs and much more.

To increase functionality, the truck was equipped with a towing device, thanks to which various types of trailers can be used.

Story

Specialists at the Kama Automobile Plant began developing special trucks designed to perform army tasks back in the days of the Soviet Union.

In 1987, a government decree was issued that prompted the plant to create a new family of trucks. This family was given the name “Mustang”, and the models included in it differed from their civilian versions in higher cross-country ability and endurance.

At that time, the main army versions were ZIL vehicles, but the Kremenchug Automobile Plant also had many military modifications. However, the equipment was characterized by high fuel consumption. In addition, gasoline power units were used under the hood, which was unprofitable from an economic point of view. As a result, the USSR Ministry of Defense was given the task of developing new army equipment. Almost immediately, the Kama Automobile Plant began work. Following the assignment, a new family was developed with high unification of components and assemblies, possessing:

- Powerful diesel power plants;

- Maximum load capacity from 4600 to 10000 kilograms;

- Ability to use trailers with a total weight of up to 12,000 kilograms;

- Increased cross-country ability;

- Increased resistance to harsh conditions, including extreme temperatures and mountain passes above 4600 meters.

In addition, trucks are highly versatile, since instead of a standard on-board platform they can be equipped with a variety of other specialized add-ons, which can include military equipment, weapons, any stations and much more.

The first few prototypes of the new family were presented in the 1990s. In 1995, a pilot batch consisting of three models, differing in wheel configuration: 4x4, 6x6 and 8x8, rolled off the assembly line of the Kama Automobile Plant.

One of the first was a truck with the factory designation KamAZ-5350. Its platform later served to create a modified version, which received the KamAZ-53501 index. The modification was introduced in 2003, and thanks to its excellent performance and technical characteristics, it continues to be produced to this day.

KamAZ 5350 - army "Mustang"

Over the more than forty-year history of the Kama Automobile Plant, 32 car models were created and mass-produced in its design bureaus and workshops. And how many modifications, successful or not, have been proposed by the auto giant’s engineers and designers over the years.

Since the launch of the KamAZ conveyor, more than two million trucks have rolled off it. Among them is the 5350 model, in the presentation of which any reference book emphasizes: KamAZ 5350 Mustang is a car created in 1998 for use in the armed forces, now successfully used in civilian life...

Content

Modifications

In addition to the standard version, various modified versions of the KamAZ-53501 truck were developed, including:

Self-loader

In 2007, the “Multilift” system was adopted, which underwent various tests over the course of two years. The presence of such a system allows the vehicle to transport large military containers. Containers can contain any type of cargo, from ordinary bulk materials to military equipment.

The KamAZ-53501 truck, which has this system, was additionally equipped with a self-loader. This modification was assigned the factory index LDS-7927. The model is capable of transporting heavy containers with their further unloading, as well as towing various types of trailers. And all this in off-road conditions.

Excavator

The car's chassis was slightly shortened. An excavator unit developed by the Ivanovo plant was installed on it. Compared to conventional excavators, this modification is less efficient. However, it is intended primarily not for large-scale construction, but for various military tasks associated with digging trenches and pits. Due to its excellent maneuverability and high speed of movement, this modification is popular in many army units.

In addition to earth-moving equipment, the vehicle was equipped with a more economical power plant made by German Deutz, which also runs on diesel fuel. In one hour of operation, this engine consumes about 12 liters of fuel.

Armored truck

This modification has a significantly modified cabin, which immediately sets it apart from other models. The cabin design uses reliable sixth class armor protection to ensure increased safety. The glasses were equipped with powerful metal frames connected by bolts. Inside there are three seats and high-quality thermal insulation and sound insulation. The crew's personal small arms are placed in a special shield. Special armored panels were also installed on the cabin floor.

The car specializes in transporting personnel. For this purpose, a special superstructure was installed on the chassis, represented by an armored module. It also meets the sixth protection class, like the cabin itself. There are several different variations, but the version called “Bear” is the most widely used. The armored module of the truck is equipped with row seats that are installed along the side walls. The walls of the structure are equipped with loopholes for firing. The roof has several special hatches that provide emergency evacuation.

Separate heating and ventilation systems are used for the cabin and for the module itself. Communication with the driver is carried out using a stationary intercom.

Crane installation

For loading and unloading any heavy cargo, a special modification was developed, equipped with a crane installation. The crane was provided by the Klintsovsky Truck Crane Plant. The main features of KamAZ-53501 in this version are the ability to operate without the use of support stands. This was achieved thanks to the heavy chassis of the car. But the supports are still present in the structure.

The designers equipped the crane installation with an additional brake. This is necessary to increase safety during operation, since the modification most often unloads various explosives. This version is operated by two people, one of whom is the driver, and the second is the operator of the crane itself. Special intercoms were used for communication.

KS-45719-7M

The KS-45719-7M truck crane is a “military truck crane” with a lifting capacity of 16 tons, mounted on a KamAZ-53501 base chassis.

This unusual machine is ideal for both standard loading and unloading, construction and installation work, and for solving non-standard tasks of increased complexity. Especially when you have to deal with dangerous goods. And it doesn’t matter where you have to work - at stationary facilities or in the field, far from “civilization.”

The special design of the crane ensures operation without supports. And it can even move with a load on the hook of the main boom, which can also be used in front of the base chassis cabin. The departure angle has been increased to 25°.

A three-section telescopic boom with a bent profile 23 meters long, made of high-strength Weldox steel from the world-famous Swedish company SSAB, provides the new product with compactness and maneuverability when moving, a wide working area and a high height of cargo movement during operation. All load-bearing structures of the crane are as lightweight as possible and have high strength indicators. The crane mechanisms have an individual drive with independent control from hydraulic motors and hydraulic cylinders.

The hydraulic system allows you to easily and smoothly control crane mechanisms with a wide range of speed control for working operations.

High safety when working with dangerous goods is ensured by double brakes on the telescoping, lifting and reach adjustment mechanisms.

A whole range of modern instruments and devices are responsible for the safety of the new product, including a crane load limiter with a digital indication of operating parameters on the display, which includes a built-in device for recording characteristics (analogous to a “black box” in airplanes) and a crane protection module when working near Power lines.

Main settings

| Load capacity, t: | 16 t. |

| Boom length: | 23 m |

| Chassis: | KamAZ-53501 |

Specifications

| Characteristic | Meaning |

| Maximum load capacity of midi, t | 16,0 |

| Load capacity of midi at maximum reach, t | 6,8 |

| Maximum load moment, tm (kNm) | 740(74,0) |

| Maximum lifting height, m | 9,1-23,5 |

| Lifting height at maximum reach, m | 4,1 |

| The maximum lowering depth with a single rope reeving when working with a boom is 9.1 m at a reach of 5.4 m. | 40,0 |

| Reach at maximum load capacity, m | 4,0 |

| Reach, maximum, m | |

| - b) “worker” (with a load on a hook) | 7,5 |

| Minimum reach, m | 1,9 |

| Maximum load weight with which the boom can be telescoped, t: | 6,0 |

| Base, m | 4,9 |

| Track, m: | |

| - front wheels | 2,05 |

| — rear wheels (between the middles of the double slopes) | 2,05 |

| Outrigger base, m | 4,3 |

| Distance between outriggers, m: | 5,8 |

| Rear clearance, m | 2,65 |

| Turning radius, m | 12,0 |

| Overall dimensions of the crane (length x width x height), m | 11.0x2.55x3.80 |

| Movement speeds: | |

| — transport crane (under its own power), m/s (km/h) | 5-60 |

| — transport crane in tow, m/s (km/h) | 1,4-11,1(5-60) |

| — crane with jib transport (under its own power), m/s (km/h) | — |

| Speed of the boom section telescoping mechanism (boom section extension and retraction), m/s (m/min), | 0,25(15) |

| Turning mechanism speed (rotation frequency), rad/s (rpm): | |

| - the smallest, no more | 0,100(0,3) |

| - largest, with load, no less | 0,199(2,5) |

| - largest with jib and load, no more | 0,52(0,5) |

| Rotation angle, rad (°) | 6,28(360) |

| Weight of the crane and its main parts, t: | |

| — structural weight of the crane in transport position | 20,55 |

| - counterweight mass | 0,4 |

| - arrow mass | 3,26 |

| — weight of the crane installation | 12,23 |

| - weight of the jib | 0,55 |

veris39.ru

Cabin

The KamAZ-53501 truck is equipped with an all-metal cabover two-door cab located above the power unit. Depending on the version of the truck, the cab can have one of two colors, namely orange (for civilian versions) and khaki (for military versions). In addition, several versions of the design itself are offered, where there is a high or low roof, as well as a sleeping place (but not used everywhere).

In appearance and interior, this is the same old-style cabin, developed back in the 1970s. There are no significant changes here, mostly there are only minor improvements. The cabin is equipped with two or three seats and a special compartment in which the crew can store special equipment and weapons.

There is a hatch on the roof, usually round in shape. It is designed for firing and emergency evacuation. In addition, this element is often used to improve cabin ventilation.

When operating in harsh temperature conditions, a comfortable climate in the cabin is ensured by a liquid heating system connected to the engine cooling system.

Some military modifications are distinguished by reliable sixth class armor protection. The cabin of these versions has an armored capsule with a reinforced base and hinged armor panels. The standard windshield has been replaced with multi-layer bulletproof glass block. The same was done with the side windows. The fuel tank, power unit crankcase, and batteries are also equipped with armored panels.

The level of comfort, as for military equipment, is quite acceptable. The interior has thermal insulation and sound insulation materials, so the interior is not too noisy during operation.

The cab structure is fixed to the frame by two front hinge joints and two rear sprung supports, which slightly smooth out road irregularities. There are also locking mechanisms and a hydraulic lifting mechanism, which allows, in case of engine maintenance or repair, to tilt the cabin forward and lock it in this position.

Cooling radiator (KAMAZ)

Let's consider all the main components of the cooling system separately. Let's start with what first catches your eye - the radiator.

The cooling system (KAMAZ 5320) includes a 3- or 4-row cooling radiator. It is made according to the classic type and represents:

- the lower tank, to which the outlet pipe fits;

- a central system of tubes arranged in several rows;

- upper tank with inlet pipe.

Radiator mounting is three-point. It is secured on both sides with brackets, which in turn are connected to the frame side members through shock-absorbing elements. The lower radiator mount is connected to cross member No. 1 of the frame.

A special feature of the radiator structure (KAMAZ) is the presence of blinds. This is a mechanical system of metal plates that blocks access to air flow through the radiator. The blinds are controlled by a simple cable drive directly from the cabin. If the handle is pulled out, the blinds are closed; otherwise, the blinds are open. Thanks to this, the engine warms up faster in the cold season.

Loading platform

In the standard version, the KamAZ-53501 truck has an open metal cargo platform, inherited from the KamAZ-5350 model. The platform is equipped with three folding sides and can be supplemented with folding benches, allowing you to transport personnel in addition to cargo.

The height of each side is 750 millimeters. The entire platform structure is 5430 mm long and 2470 mm wide.

Among the standard equipment of this cargo platform, it should also be noted that there is a removable awning frame. Depending on the modification, other types of superstructures can be installed on the chassis, including truck cranes, excavators, any weapons and armored multifunctional modules that provide the ability to fire fire from the inside.

Calculation of fuel consumption rates for KAMAZ dump trucks

Today we can say for sure that the KamAZ 5350 has become one of the most popular and sought-after SUVs in the entire history of the domestic and global automotive industry. Also, during the classes, military personnel will practice maneuvering techniques on a high-speed highway, passing a route as part of a convoy at the maximum and minimum permissible speeds, and master the secrets of driving on mountain serpentines with large slopes and sharp turns.

Specifications

Engine

Since this model is a modified version of the KamAZ-5350 truck, many design solutions and units were borrowed. This also applies to engines. The KamAZ-53501 model is equipped with the following power units:

KamAZ-740.30-260. It is an eight-cylinder power plant with a V-shaped cylinder arrangement, running on diesel fuel. This engine is equipped from the factory with a turbocharging system, supplemented by subsequent cooling of the charge air. The first versions of the engine complied with Euro-2 environmental requirements, but over time it was brought to the Euro-3 level.

Characteristics of KamAZ-740.30-260:

- Working volume – 10.86 l;

- Maximum power – 260 hp;

- Cylinder diameter – 120 mm;

- Piston stroke – 120 mm;

- The compression ratio in the combustion chamber is 16.5;

- Maximum torque – 1079 N.m. (at 1300 rpm);

- Cooling is liquid.

Dimensions of KamAZ-740.30-260:

- Length – 1194 mm;

- Width – 908 mm;

- Height – 1050 mm.

KamAZ-740.622-280. It is a diesel eight-cylinder engine with a V-shaped cylinder arrangement. Like the previous unit, this engine is turbocharged with intermediate cooling of the charged air, which has a positive effect on its power performance. However, unlike the previous one, KamAZ-740.622-280 meets Euro-4 environmental requirements.

Characteristics of KamAZ-740.622-280:

- Working volume – 11.76 l;

- Maximum power – 280 hp;

- Cylinder diameter – 120 mm;

- Piston stroke – 130 mm;

- The compression ratio in the combustion chamber is 17.9;

- Maximum torque – 1177 N.m. (at 1300 rpm);

- Cooling is liquid.

Dimensions of KamAZ-740.622-280:

- Length – 1260 mm;

- Width – 930 mm;

- Height – 1045 mm.

KamAZ-740.662-300. It is an eight-cylinder diesel engine with a V-shaped cylinder arrangement. The unit is equipped with a turbocharger with intermediate cooling of the charged air. It is worth noting that this engine is a modification of the previous one and therefore it is very similar to it. However, it produces a little more power. As for environmental friendliness, it meets Euro 4 requirements

Characteristics of KamAZ-740.662-300:

- Working volume – 11.76 l;

- Maximum power – 300 hp;

- Cylinder diameter – 120 mm;

- Piston stroke – 130 mm;

- The compression ratio in the combustion chamber is 17.9;

- Maximum torque – 1275 N.m. (at 1300 rpm);

- Cooling is liquid.

Dimensions of KamAZ-740.662-300:

- Length – 1260 mm;

- Width – 930 mm;

- Height – 1045 mm.

Cummins ISBe6.7 E5 285. A small number of modifications were equipped with this imported engine. It has six in-line cylinders, a turbocharging system, a charge air intercooler and an electronically controlled CommonRail fuel system.

Characteristics of Cummins ISBe6.7 E5 285:

- Working volume – 11.76 l;

- Maximum power – 280 hp;

- Cylinder diameter – 107 mm;

- Piston stroke – 124 mm;

- The compression ratio in the combustion chamber is 17.3;

- Maximum torque – 1007 N.m. (at 1300 rpm);

- Cooling is liquid.

Dimensions of Cummins ISBe6.7 E5 285:

- Length – 1070 mm;

- Width – 715 mm;

- Height – 840 mm.

Thermostats and pipes

The cooling system pipes (KAMAZ) must be under good supervision. If the connection is leaking, there is a possibility of losing a large amount of coolant and overheating the engine. Particular attention should be paid to the connection points of the pipes at the radiator, water pump and thermostats.

The cooling system thermostats are responsible for controlling the flow of antifreeze. When the temperature of the liquid rises to 800C, it is redirected to the radiator, that is, the circulation begins to go in a “big circle”. In this case, part of the flow continues to flow in a “small circle”. And only at a temperature of 930C does the “small circle” valve close completely, and all the coolant begins to flow through the engine radiator.

Operational resource

The cars of the first years of production used engines designed for 450 thousand kilometers, after which a major overhaul was required. Later, the same engines began to be used on trucks, but already modified, which are capable of covering 800 thousand kilometers before a major overhaul. Scheduled maintenance intervals range from 20 thousand to 45 thousand kilometers on average.

As for the imported Cummins ISBe6.7 E5 285 power plant, it also has an operational life of 800 thousand kilometers before major overhaul. Servicing of this engine is required every 20-50 thousand kilometers, depending on operating conditions.

checkpoint

The transmission system of this model includes a nine-speed manual gearbox ZF 9S1310, provided by the German manufacturer. It has the following gear ratios:

- 1-9.48;

- 2-6.58;

- 3-4.68;

- 4-3.48;

- 5-2.62;

- 6-1.89;

- 7-1.35;

- 8-1.00;

- 9-0.75;

- ZX-8.97.

The main gear has a gear ratio of 5.94.

This gearbox is equipped with a diaphragm, single-plate clutch MFZ 430 from the manufacturer ZF&SACHS. The clutch has a hydraulic release drive and a pneumatic booster.

In addition, the truck's transmission has a two-speed transfer case, which provides it with all-wheel drive. From it, torque is transmitted to the drive axles via cardan shafts. The rear bogie axles are connected to each other by another small shaft. For greater cross-country ability, lockable cross-wheel and center differentials were used on the bridges, activated by a special button from the cab.

Brake system

A dual-circuit pneumatic braking system is responsible for braking the truck, like other vehicles of the Kama Automobile Plant. It uses drum-type brake mechanisms with a diameter of 400 millimeters. Each drum is equipped with two brake linings 140 millimeters wide. Taking this into account, the total area of the brake linings is 6300 centimeters.

During operation, four brakes are used depending on the conditions. They all use the same mechanisms, but work independently of each other:

- Main. It is the main brake that is used when driving to reduce speed. This brake is controlled using a foot pedal. When turned on, all brake mechanisms of the vehicle are activated. It's worth noting that the front axle and rear bogie use separate pneumatic circuits;

- Spare. This type of brake allows you to stop the truck in the event that the main brake system has any malfunctions;

- Parking. Used during long-term parking. The parking brake uses all the same mechanisms as the reserve one, but unlike it, it completely locks the wheels of the rear trolley. For this purpose, spring energy accumulators were placed on the rear axles. It is turned on using a special lever installed in the cabin;

- Auxiliary. If previous systems interact with brake mechanisms, then this type uses the truck engine. When it is turned on, the fuel supply to the cylinders is partially stopped, and a special damper is activated in the exhaust system circuit, slowing down the exit of exhaust gases. Thus, additional resistance is created, which allows the car to slow down when the gear is engaged. Used mainly on long descents. The use of the main brake in such cases can negatively affect the condition of the brake mechanisms, namely cause their overheating, and as a result, rapid wear.

From the KamAZ-5350, this model also inherited a special electronic system that informs the driver about the condition of the brake linings and various malfunctions. If any elements do not function as they should, then this system emits a signal.

Total information

Section 1. GENERAL DATA

INTRODUCTION

The KAMAZ-4308 truck tractor or automobile chassis is designed for operation at ambient temperatures from minus 45 °C to plus 40 °C, relative air humidity up to 75% at a temperature of plus 15 °C.

KAMAZ-4308 vehicles, manufactured in the “T” version for delivery to countries with a tropical climate, are designed for operation at ambient temperatures from minus 10 ° C to plus 45 ° C and relative humidity up to 80% at a temperature of plus 27 ° C.

KAMAZ-4308 vehicles can be operated in dust conditions of up to 1.0 g/m3, wind speeds of up to 20 m/s and in areas located at an altitude of up to 3000 m above sea level, with a corresponding change in traction and dynamic characteristics, properties and fuel efficiency.

KAMAZ-4308 vehicles are designed for use on roads designed for an axle load of up to 100 kN (10 tf).

KAMA3-4308 is a towing vehicle (Fig. 1-2), designed for towing a trailer with various loads.

It is possible to install specialized equipment on the KAMA3-4308 vehicle chassis (Fig. 1-1, 1-3).

The KAMAZ-4308 vehicle provides performance properties during garage-free storage.

The established service life of the KAMAZ-4308 vehicle before overhaul of the main units, subject to compliance with all operating and maintenance rules specified in this manual or operating manual, is shown in the table.

| Category of operating conditions | Established vehicle resource, km, not less |

| I | 500000 |

| II | 450000 |

| III | 400000 |

| IV | 350000 |

| V | 300000 |

During the specified period, it is allowed to replace components and purchased products whose service life, established by technical documentation and standards, is less than the service life of the vehicle.

The classification of operating conditions and the list of the main units of the KAMAZ-4308 vehicle subject to major repairs are specified in the “Regulations on the maintenance and repair of rolling stock of road transport”.

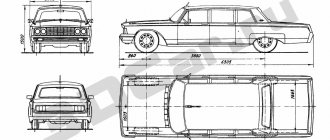

Rice. 1-1. General view of the KAMA3-4308 car chassis.

Rice. 1-2. Overall dimensions of the car 4308

Rice. 1-3. Overall dimensions of chassis 4308.

GENERAL INSTRUCTIONS AND WARNINGS

1. Before operating the vehicle, you must study this manual.

2. The new car must be registered. This provides technical advice on the operation and maintenance of the vehicle, the supply of spare parts and warranty service. A service book is included with each vehicle.

3. To ensure perfect operation of the vehicle, only factory-made spare parts should be used. The installation of various equipment and mechanisms on the vehicle and its chassis should be agreed upon with the developer and holder of the design documentation - with the Department for Development and Introduction of New Developments of KAMAZ OJSC. Otherwise, the car is not subject to warranty service.

When operating a vehicle, it is necessary to use grades of fuel, lubricants and operating materials in accordance with this manual.

4. It should be remembered that for the initial period of operation of a new car, a mileage of 1000 km is established, during which the requirements specified in the section “Operation of a new car” must be observed.

5. When starting the engine using an electric torch device (EFD), if the voltmeter needle goes beyond the scale, you should immediately release the EFU button, find and eliminate the malfunction. Do not press the ECU button while the engine is running to avoid damage to the voltage regulator.

6. The vehicle must be driven after the engine has warmed up to a coolant temperature of plus 40°C.

7. Do not start moving the car until the warning signals for the drop in air pressure in the pneumatic drive of the brake system go out and the buzzer stops buzzing.

8. It is necessary to monitor the indicator for clogging of the filter elements of oil filters: the indicator should not light up when the engine is warm. If the indicator lights up continuously, the filter elements need to be replaced.

9. When the emergency pressure drop indicator lights up in the engine lubrication system, stop the engine, find and eliminate the malfunction.

10. It is necessary to monitor the readings of the air cleaner indicator (signaling device); When the indicator (alarm) is triggered, the air purifier must be serviced.

11. To prevent the occurrence of cracks in the bosses for the cylinder head bolts, it is necessary to protect the threaded holes for the bolts from liquid or contamination when disassembling the engine and, especially, before installing the cylinder heads.

12. When parking the vehicle, it is necessary to disconnect the batteries from the electrical system by pressing the remote battery switch button. The button must be pressed briefly (no more than 2 s).

13. Do not disconnect batteries using the battery switch while the engine is running.

14. When carrying out electric welding work on a car, the batteries must be disconnected with a remote switch and the wires must be removed from the “+” and Ш terminals of the generator. The ground wire of the welding machine must be connected in close proximity to the weld.

15. It is necessary to monitor the temperature of the liquid in the engine cooling system; When the liquid overheating warning light comes on, you must stop the engine, find and fix the problem.

16. When driving on long descents, the crankshaft rotation speed should not exceed the maximum permissible value.

17. The vehicle is not allowed to move with the cross-axle differential locked on on a dry, hard road or when turning due to possible overloading of the axle shafts and their twisting. The lock must be turned on after stopping.

18. If there is a dent on the reaction rod pipe with a depth of more than 2 mm, a crack or a bend of more than 3 mm along the entire length, the reaction rod must be replaced.

19. If malfunctions associated with a coolant leak occur on the road, you can briefly use water in the cooling system, but only while driving to the place where the malfunctions can be eliminated.

20. When driving for a long time on dirty roads (with liquid mud), you need to periodically flush the radiator surface with water with sufficient pressure from a hose. To do this, raise the cabin and direct a stream of water to the radiator from the engine side. Direct contact of water with the generator must be avoided.

21. To ensure the operability of the thermodynamic air drying system, it is necessary to prevent contamination of the surface of the water separator radiator tubes and not to cover it with insulation.

22. When driving, monitor the crankshaft rotation speed using the tachometer. Remember that the engine develops its maximum torque (maximum traction force) at a crankshaft speed below the nominal speed. Do not exceed the maximum crankshaft speed. Select the speed on the route taking into account the most economical operating mode of the engine.

23. To protect tires from excessive wear, maintain the air pressure in the tires in accordance with the requirements of this Manual.

24. Due to the constant work to improve the vehicle, increasing its reliability and improving operating conditions, minor changes may be made to its design that are not reflected in this manual.

SECURITY MEASURES

1. Before driving, you should inspect the car and make sure it is in good condition.

2. It is not allowed to warm up the engine in enclosed spaces with poor ventilation.

3. It should be remembered that the TOCOL coolant used in the engine cooling system and the Neva fluid used in the clutch drive mechanism are poisonous; They must be handled carefully to avoid poisoning if ingested.

4. It is necessary to keep the engine clean and in good working order, since oiling of the engine crankcase and fuel leakage can cause a fire.

5. Open the expansion tank cap of an overheated engine carefully to avoid burning your hands with steam.

6. Do not lubricate or clean a running engine.

7. Do not disassemble the spring energy accumulators of the brake chambers on the car to avoid accidents. Disassembly must be done in a workshop using special tools.

8. You need to pay attention to the fastening of the rear suspension reaction rods. Operating a vehicle with loose reaction rods is not permitted.

9. You cannot work under a car if it is jacked up without a stand.

10. Before lifting the cab, the vehicle must be braked with the parking brake system, the gear shift lever must be in the neutral position, and the cab doors must be closed. When working under a raised cab, the position of the limiter must be secured with a safety pin. When lowering the cab, make sure that the locking mechanism is securely closed and that the safety hook is correctly installed in the groove of the support beam.

11. Before driving, make sure that the left and right cab locking devices are closed.

12. When lowering the spare wheel, you must not be in the wheel lowering area.

13. When braking with the auxiliary brake system, do not change gears in the gearbox.

14. Do not turn off the engine when coasting, as this turns off the compressor of the pneumatic drive of the brake system and the power steering.

15. You cannot operate a trailer with unconnected or faulty brake and electrical systems.

16. When braking with the auxiliary brake system, do not change gears in the gearbox.

TECHNICAL CHARACTERISTICS OF VEHICLE 4308

| Automobile model | Automobile | Chassis |

| Wheel formula | 4×2 | |

| Engine | CUMMINS B 5.9 180 CIV-0 | |

| Curb weight*, kg: | 5350 | 4350 |

| Weight of transported cargo, kg | 5500 | — |

| Maximum permissible weight of the superstructure with cargo, kgf | — | 6500 |

| Gross vehicle weight**, kg: | 11000 | |

| Total weight of the towed trailer, kg: | 8000 | |

| Gross weight of the road train, kg: | 19000 | |

| Distribution of curb weight on the road, kg: | ||

| through the tires of the front axle wheels | 3250 | 3050 |

| through the tires of the rear axle wheels | 2100 | 1300 |

| The same for the gross vehicle weight: | ||

| through the front tires | 4000 | — |

| through the rear tires | 7000 | — |

| dimensions | Rice. 1-1 | Rice. 1-2 |

| Maximum speed of the road train at full weight in top gear, km/h, not less: | 105 | |

| Control fuel consumption*** per 100 km of track when the road train is moving at the speed: — 60 km/h, l: — 80 km/h, l: | 14,0 19,0 | |

| Fuel tank capacity, l | 170 | |

* The curb weight of the vehicle includes the following weights:

— an unloaded vehicle with liquids and lubricants in components and assemblies; tools, accessories and an individual set of spare parts according to Appendix 2; fuel; engine oil and coolant.

** The total vehicle weight includes the following weights:

— equipped car; crew of two people (75 kg x 2); transported cargo (superstructure).

The total mass of a road train includes the following masses:

— equipped car; crew of two people (75 kg x 2); gross weight of the towed trailer.

*** Control fuel consumption is used to determine the technical condition of the vehicle and is not an operational standard.

— the width of the corridor occupied by a car when turning is no more than 3.5 m;

- during acceleration to a speed of 60 km/h - no more than 65 s;

— the greatest angle of the climb being overcome is at least 10° (18%);

- cruising range based on control fuel consumption at a speed of 60 km/h - no less than 850 km with a maximum filling volume of the fuel tank with a total capacity of 170 liters.

MARKING

Marking of the vehicle (chassis) is carried out in accordance with OST 37.001.269 and design documentation.

A manufacturer's plate is installed on the right panel of the cab, containing:

— trademark of the manufacturer;

— vehicle identification number (VIN), including:

— international manufacturer identification code (WMI) (3 characters) - “XTS”;

— descriptive part (VDS) (6 characters), consisting of the conditional code of the car model according to Table 1-1;

— index part (VIS) (8 characters), consisting of the year of manufacture code (1 character) and the vehicle serial number (7 characters);

- engine model;

— engine serial number.

Table 1-1

| Car model (chassis) | Engine model | Conditional code of the car model (chassis) |

| KAMA3-4308 | CUMMINS B 5.9 180 CIV-0 | 430800 |

When delivering cars for export, the plate is in English and contains additional information on:

— gross vehicle weight;

- loads on each axle.

A VIN is stamped on the right side member at the rear of the frame and on the interior panel of the cab front, including:

— WMI (3 characters) — “XTS”;

— VDS (6 characters), consisting of the conditional code of the car model according to table. 1-1;

— VIS (8 characters), consisting of the year of manufacture code (1 character) and the vehicle serial number (7 characters);

VDS and VIS of the vehicle components: frame and cabin are punched respectively on the right side member in the front part of the frame and on the inner panel of the cabin front on the right and consists of:

— frame (cabin) model designations (6 characters);

— year of manufacture code (1 character);

— serial production number of the frame (cabin) (7 characters).

Certified vehicles are marked with the Mark of Conformity on the right side panel of the door and the Mark of Conformity is placed in the “Operation Manual”.

When the car is shipped to the consumer, a label is attached to the inside of the windshield. The label contains instructions on filling the cooling system with antifreeze, on the disconnection and condition of the batteries (with electrolyte, without electrolyte), on the brand of fuel and the brand of lubricant in the engine crankcase and power train (summer, winter), as well as the dates when this should be done. Preservation of the vehicle in accordance with the requirements of the Operating Manual.

If the vehicle (chassis) has an anti-lock braking system, an anti-lock braking system sign plate must be installed on the outside of the front panel.

CONTROL MECHANISMS, EQUIPMENT AND INSTRUMENTS

The location of the vehicle controls is shown in Fig. 1-4.

Rice. 1-4. Controls:

1 — valve button for controlling the auxiliary brake system; 2 — clutch pedal; 3 — brake pedal of the service brake system; 4 — fuel pedal; 5 - combination switch; 6 — steering wheel; 7 — lever of the gearbox remote control mechanism; 8 — air filter clogged indicator.

Button 1 of the auxiliary brake system control valve is located on the cabin floor.

Clutch pedal 2 (mounted type) is mounted on a bracket under the instrument panel, to the left of the steering column.

Brake pedal 3 (mounted type) is located under the instrument panel, to the right of the steering column.

The fuel pedal 4 is installed in a bracket on the cabin floor, to the right of the steering column.

The combination switch 5 is attached to the steering column under the steering wheel 6 and consists of two levers for light switches, turn indicators, windshield wiper and washer, and sound signal switches. On the handle of the switches there are symbols of the switched-on consumers of electricity.

Lever 7 of the gearbox remote control mechanism is located to the right of the driver's seat.

Lever 1 (Fig. 1-5) of the light switch and direction indicators is located on the left side of the combination switch. When the lever is moved to position I, the right turn indicators are turned on, and when the lever is moved to position II, the left turn indicators are turned on. The switch has an automatic device to return the lever to the neutral position when the turn is completed and the steering wheel returns to the position corresponding to the vehicle moving in a straight line.

When lever 1 of the switch is in position O and at the same time position II of the central switch 26 (Fig. 1-5) the low beam headlights are switched on, in position IV of the lever the high beam headlights are turned on.

Rice. 1-5. Combination switch:

1 — lever for light switch and direction indicators; 2 — windshield wiper and washer switch lever.

Switch lever positions:

I - Right turn indicator is on; II - Right turn indicator on (non-fixed); III - Left turn indicator on (non-fixed); IV - Left turn indicator on; V - High beam flashing (not fixed); VI - High beam on; O - Everything is off; A - First windshield wiper speed; B - Second windshield wiper speed; C - Intermittent operation of the windshield wiper; D — Windshield washer switched on (non-fixed).

In addition, there is a non-fixed position III of the switch lever for headlight signaling, which is activated regardless of the position of the central switch.

Lever 2 (Fig. 1-5) of the windshield wiper and washer switch is located on the right side of the combination switch. When the lever is moved to fixed positions A and B, the low and high speed windshield wipers are activated, respectively. When the lever is moved to a fixed position C, the intermittent wiper operation mode is activated. The windshield washer switch has a non-fixed position D.

The electric sound signal is activated when the handles of levers 1 and 2 are moved towards the steering column.

The location of instrumentation, equipment and controls for special equipment is shown in Fig. 1-6.

All control and measuring instruments are located on panel 1 on the left side of the instrument panel.

The switch panel contains key switches/switches for electrical equipment. On the right side there is a glove box 14, illuminated by a soffit lamp. When panel 13 is pulled out, access to the electrical equipment fuses is provided.

Levers 21 for controlling the heater and cabin ventilation. The upper lever turns on and regulates the heating of the air coming from the heater, and the lower levers control the distribution of this air in the cabin. In the extreme right position of the lower arms, air is supplied only to the windows; in the CABIN position, air is supplied to the windows and the feet of the driver and passenger. Intermediate positions allow you to change the heating efficiency. Turning on the air supply is a key switch on the switch panel when the key is in position I and II in the instrument and starter switch lock.

The corrector control knob allows you to adjust the light beams of the headlights depending on the load (with the low beam on).

The parking brake control valve handle has two fixed positions: “braked” and “released”. In the braking area of the vehicle (from the “released” position to the “braked” position), after releasing the handle automatically returns back to the “released” position.

Rice. 1-6. Location of instrumentation, equipment and controls for special equipment:

1 — switch for additional headlights; 2 — rear fog lamp switch; 3 — instrument cluster; 4 — block of warning lamps of the brake system; 5, 6, 7, 18 — control lamp; 8 — block of warning lamps; 9 — speedometer; 10 — air pressure gauge; 11 — heater motor switch; 12 — PZD-12B heater control panel; 13 — fuse compartment cover; 14 — glove box door; 15 — heating deflector; 17 — valve for turning on the inter-wheel lock; 19 — instrument panel lighting regulator; 20 — switch for road train lights; 21 — control handles for the heater valve and air distributor flaps; 22 — external lighting switch; 23 — button for remote battery mass switch; 24 - plug; 25 — lamp switch; 26 — fog light switch; 27 — alarm switch; 28 — ECU switch button.

To set a constant engine crankshaft speed, you need to press the fuel pedal, pull out the rod and turn the rod to fix the required speed.

To stop the engine, you need to pull out rod 16. If the rod is recessed, the engine is ready to start.

Remote switch 23 for battery ground. When the button is pressed, the batteries are turned on, and when pressed again, they are turned off.

Central light switch 22, when switched to position I, the instrument panel lighting and side lights are turned on; in position II, the side lights and low beam headlights are turned on.

Switch 28 of the EFU has a non-fixed position - turning on the EFU. When you press the switch button, after 60-90 s the indicator in the right block 16 should light up, indicating that the system is ready to start the engine.

Switch 17 alarm. When you pull out the switch handle, all the direction indicators, as well as the indicator built into the handle, light up intermittently.

Speedometer 9 indicates the speed of the car (km/h), and the total counter installed in it indicates the total mileage of the car (km).

The scale has a built-in blue light filter for the indicator, which lights up when the high beam headlights are turned on.

The tachometer shows the engine speed (rpm). When the car is moving, the tachometer needle should be on the right side of the green field of the scale.

When the arrow is within the black field, engine power decreases, jerking appears, and fuel consumption increases.

The arrow should not enter the red fields of the scale - these are dangerous modes for the engine. For cars equipped with low-speed engines with a nominal crankshaft speed of 2200 min-1, the red field starts at 2200.

The instrument cluster is shown in Fig. 1-7.

Indicator 1 of oil pressure in the engine lubrication system. The oil pressure at the nominal engine crankshaft speed should be 400-550 kPa (4-5.5 kgf/cm2), and at the minimum speed - at least 98.1 kPa (1.0 kgf/cm2). Indicator lamp 2 for emergency oil pressure with a red filter lights up when the pressure in the lubrication system drops to 40-80 kPa (0.4-0.8 kgf/cm2);

Rice. 1-7. Instrument cluster:

1 — oil pressure indicator; 2 — warning lamp for emergency oil pressure; 3 — coolant temperature indicator; 4 - warning lamp for emergency coolant temperature; 5 - voltmeter; 6 - indicator lamp for battery discharge; 7 — fuel level indicator in the tank; 8 — fuel reserve warning lamp.

Indicator 3 of the coolant temperature in the cooling system. Indicator lamp 4 with a red light filter lights up when the temperature rises to (98-104)°C. Normal coolant temperature is 80 - 95°C.

Voltmeter 5 shows the voltage in the vehicle's on-board network. Indicator lamp 6 with a red light filter lights up when the battery is discharged.

Fuel level indicator 7 in the tank. Indicator lamp 8 with an orange filter lights up when the amount of fuel in the tank decreases to 1/8 of its full capacity.

Tabpipa 1-2.

Instrument scales are presented in the form of color zones. Each color zone has a certain range of values of the controlled parameter.

Interpretation of instrument cluster indicator zones:

The ranges of color zone values for each device included in the instrument cluster are shown in Table 1-2.

Signaling units are shown in Fig. 1-8. Switches 1 are used to check the serviceability of indicator lamps. Warning light 2 comes on when the oil filter is clogged. Indicators 3, 4, 5 and 6 light up when the air pressure drops in circuits I, II, III and IV of the pneumatic drive of the brake systems; they have red filters with symbols; when these indicators come on, an audible signal (buzzer) sounds. Indicator 7 lights up intermittently when the parking brake system is turned on and has a red filter with a symbol. Indicator 8 of the middle axle differential lock is not activated. Indicator 9 lights up when the rear axle cross-axle differential lock is engaged. The indicator 10 of the center differential lock is not activated. Signal indicators 11 and 12 light up when the right or left turn indicators of the tractor and semi-trailer are turned on and monitor the serviceability of the indicator lamps and have green filters with symbols. The indicator 13 of readiness for operation of the EFU has an orange filter.

Signal indicators 11 and 12 light up when the right or left turn indicators of the tractor and semi-trailer are turned on and monitor the serviceability of the indicator lamps and have green filters with symbols. The indicator 13 of readiness for operation of the EFU has an orange filter.

Rice. 1-8. Alarm blocks.

Chassis

KamAZ-53501 uses a frame structure with two channel spars and cross members.

The front part of the car is equipped with a dependent suspension. Its design includes two packages of longitudinally located semi-elliptic springs, two bi-directional hydraulic telescopic shock absorbers, rubber compression buffers, and a stabilizer bar.

The rear bogie of the truck is equipped with a classic balancer suspension. It uses longitudinal leaf springs and reaction rods. Unlike the front suspension, they decided not to use shock absorbers for the rear.

The model has disc wheels with rim sizes 10.00-20, but there are also modifications with sizes 12.2-20.9. The wheels are equipped with pneumatic tube tires measuring 390/95 R20 or 425/85 R21. There is a pressure regulation system on all wheels, which makes it possible to increase the truck's maneuverability on difficult road sections.

Dimensions:

- Total length – 8490 mm;

- Full width – 2550 mm;

- Total height – 3290 mm;

- Wheelbase length – 3340 mm;

- Rear bogie wheelbase length – 1320 mm;

- Front track width – 2050 mm;

- Rear track width – 2050 mm;

- Front overhang length – 1620 mm;

- Rear overhang length – 1590 mm;

- Ground clearance – 390 mm;

- The smallest turning radius is 11300 mm.

Loading platform dimensions

- Internal length – 5430 mm;

- Internal width – 2470 mm;

- Internal height of standard sides – 750 mm;

- The height of the platform with awning is 3290 mm.

Weight and load capacity

The curb weight of this truck is 10,540 kilograms. Its design is capable of carrying cargo weighing up to 10,000 kilograms. In this case, the total weight of the truck reaches 20,560 kilograms.

In addition, the truck is often used in conjunction with a trailer. The total weight of the trailer must not exceed 8000 kilograms. This provides a total weight of the entire road train of 29,000 kilograms.

Power supply

The electrical wiring of the KamAZ-53501 model is not much different from the civilian versions and predecessors. The constant voltage in the on-board network is 24 Volts. To operate all electrical appliances when the engine is off, two series-connected lead-type batteries are used. The capacity of each is 190 Ampere-hours, and the rated voltage is 12 Volts.

After starting the power unit, the required voltage is supplied to the on-board network by a three-phase generator with a power of 2000 watts. It is capable of delivering a nominal voltage of 28 Volts. In addition, it recharges the batteries during operation. It is also worth noting that the on-board network contains a rectifier unit, thanks to which the voltage from the generator is stabilized.

Manual

The instructions supplied with the truck contain the following recommendations:

- It is possible to start the motor from an external source of electricity. The switching socket is installed on the left wing of the cab. There is also a connection diagram there.

- It is allowed to operate the engine at full power only after warming up to 70°C. It is allowed to start driving with the engine partially warmed up to 40°C using low gears and speeds. Applying an increased load to a cold unit can cause damage to the crank mechanism components.

- The transfer case only shifts when the vehicle is stationary. Operating a truck with the locking housing removed is prohibited, as this leads to the simultaneous activation of 2 speeds and destruction of the unit.

- Turning on the oil pressure indicator should cause the movement to stop and the engine to turn off. You can continue your trip only after eliminating the cause of the breakdown. Similar recommendations apply to coolant temperature.

- During operation, it is necessary to monitor the air filter status indicator. A unit clogged with dust needs to be cleaned.

- When repairing units, clean blind holes from water and oil, since cracks may occur when screwing in the bolt.

- It is prohibited to disconnect batteries from the on-board network while the power unit is running. The shutdown is performed only while parked. If you plan to carry out welding work on a car, then you need to disconnect the batteries and generator from the on-board network.

- The differential lock cannot be engaged when the wheels are slipping. It is prohibited to drive on paved roads with activated blocking.

Peculiarities

KamAZ-53501 has become very popular not only in army units, but also in many civilian areas. Consumers purchase this truck both in civilian version and in military version from conservation. Moreover, the latter can be equipped with special add-ons, including multifunctional modules.

Many reviews often mention high reliability and impressive endurance. Indeed, the design of the model is distinguished by a large margin of safety, which allows it to withstand quite severe loads. The power units used are also famous for their reliability and also have excellent power performance.

Most of the components and assemblies are unified with other models of the Kama Automobile Plant, so finding the necessary part will not be difficult. As for the design itself, it turned out to be simple and understandable.

An all-wheel drive chassis, large single wheels, lockable cross-axle differentials and a tire pressure regulation system made it possible to achieve excellent cross-country ability. KamAZ-53501 is capable of negotiating swampy and snowy areas without any problems. Even in severe off-road conditions, the truck practically does not get stuck. It should be noted that optionally it can be equipped with a winch.

For a three-axle vehicle, this model has quite high maneuverability, especially on hard surfaces.

Thanks to all these qualities, the civilian version of KamAZ-53501 is actively used in the oil and gas industries and expeditions. For expeditions, models equipped with a modular superstructure are often chosen. An additional heater, additional seats, a small table and much more are installed inside.

Another feature is, of course, accessibility. If you can find similar foreign models, the cost for them, as a rule, will be much higher. Therefore, most consumers prefer the domestic KamAZ, despite the low level of comfort by modern standards.

Price

KamAZ-53501, decommissioned from military storage, can currently be purchased at an average cost of 2 million to 3.5 million rubles, depending on the year of manufacture and the installed superstructure. In most cases, such equipment has a mileage of up to 5 thousand kilometers. Not only onboard versions are available, but also KUNGs.

The cost of a civilian version with zero mileage starts from 1.8 million rubles for a standard on-board modification. Here the price tag is also affected by the type of installed add-on. For example, a truck crane based on KamAZ-53501 will cost 2.5 million rubles.

If we consider used equipment, most of the models available on the secondary market are presented in civilian versions, but there are also military versions. The cost of such cars varies from 1.6 million to 3 million rubles, depending on factors such as the year of manufacture, technical condition, and mileage.

In addition, the KamAZ-53501 truck can be rented. The cost of one hour of work averages from 1200 to 2000 rubles.

EOV-3523 on KamAZ-53501 truck

| Name of technical indicators | Unit measurements | EOV-3523 |

| Operating weight | T | 18,8 |

| Basic chassis | KamAZ-53501 | |

| Car engine power | kW (hp) | 191 (260) |

| Excavator engine | Deutz BF04M2012 | |

| Engine power | kW (hp) | 67 (91) |

| Engine speed | rpm | 2000 |

| Type of working equipment | Monoblock | |

| Pumping unit flow | l/min | 260 |

| Operating pressure | MPa | 32 |

| Pumping unit flow | l/min | 260 |

| Turntable rotation speed | rpm | 8 |

| Hydraulics | Bosch-Rexroth | |

| Hydraulic control circuit | LUDV diagram from Bosch-Rexroth | |

| Number of combinations of operations in a cycle | All | |

| SAE Bucket Capacity | m3 | 0,8 |

| Maximum digging depth | m | 5,0 |

| Largest digging radius | m | 8,44 |

| Kinematic unloading height | m | 6,1 |

| Cutting force: bucket | T | 8,0 |

| handle | T | 8,2 |

| Cycle | With | 12 |

| Fuel consumption in excavation mode | l/h | 12 |

| Technical productivity when developing soils of categories I…III | m3/h | 193 |

| Maximum movement speed | km/hour | 90 |

| Additional working equipment (hydraulic hand tools) simultaneous operation of 2 types of tools | manual jackhammer; manual hydraulic hammer drill; hydraulic cutting machine | |

| dimensions | ||

| - length | mm | 8830 |

| - width | mm | 2500 |

| - height | mm | 3900 |

www.tdsmi.ru

Reviews from owners and drivers

- Kamaz 53501 is a large and versatile truck capable of conquering any off-road terrain. In terms of off-road capabilities, the car is similar to the Ural, and without any exaggeration. Cross-country ability is excellent. High ground clearance and minimal body overhangs, the presence of blockers and toothy tires with a large profile, as well as the absence of a long hood (unlike the Ural) make Kamaz 53501 the most advantageous offer in this segment. I have had onboard 53501 in operation for two years. During this time, the machine was tested on different surfaces. It must be admitted that there are no significant changes compared to the older KamAZ vehicles. The car remained faithful to the good old design, familiar from its predecessors. Well, except that the seats have improved, but the ergonomics in the cabin have not changed. You can overcome deep snowdrifts, sand, mud, etc. My configuration includes a rigid hitch and standard anti-rollbacks. The six-meter body is roomy and has a well-organized interior space (there are loops and clamps for cargo so that it does not dangle around the body). Almost all such cars are now equipped with Chinese starters, which quickly fail. Perhaps this is the only unscheduled malfunction.

- Kamaz 53501 is a high-quality all-terrain vehicle, also endowed with a high carrying capacity. Yes, such wheels and a powerful frame chassis can withstand any load along with a trailer. I have a Kamaz 53501 Mustang series with a native 740 engine with 300 horsepower, as well as a turbocharger. There is also a pre-heater. The load capacity has been increased to 10 tons (10 tons in the standard version) - because of this, the frame has been increased by one meter. It must be admitted that the increase in the wheelbase had a negative impact on cross-country ability - for example, in swampy and mountainous areas. Accordingly, the approach and departure angles have decreased. But if the standard 53501 had plenty of cross-country ability, in my case there are quite enough off-road capabilities. The developers have provided for an unsuccessful fastening of the full-size spare tire located in front under the frame. Because of this, the spare tire is constantly splashed, so when dismantling it you can get pretty dirty, to put it mildly. Another serious drawback of this Kamaz, as well as other on-board trucks, is the high tailgate, which creates a whole dilemma when boarding/disembarking passengers.

- I have been working on KamAZ 53501 since 2016. I received the car in maintained condition, but at full speed. The operation of a flatbed truck is carried out in quarry conditions, as well as in mountainous and forested areas, and sometimes I also “moonlight” as a towing driver - I pull passenger SUVs out of the swamp. This Kamaz is ideally prepared for off-road use, especially in my basic version - with a regular wheelbase (there is also an extended one, which has problems with cross-country ability). I will note the high ground clearance and virtually absent body overhangs, as well as the cabover cab and excellent visibility on all sides. Large mirrors rattle when driving over bumps, but this is not a problem. A much more serious problem is with the suspension, which, on the one hand, can withstand high terrain, and on the other, has a short resource due to the poor quality of the chassis elements. Many components should be found at car dismantling yards, but a new part is still better than an old one. The 260-horsepower turbodiesel has decent performance and a large reserve of traction on mountain climbs, and thanks to this, it is not at all necessary to overcome swampy terrain from acceleration. Fuel consumption is from 28 to 35 liters per 100 km. The long-wheelbase version already has around 40 liters, so I made the right choice.

- I have a Kamaz 53501 with a mileage of 130 thousand km. The car has seen a lot in its lifetime, but is still capable of coping with tasks in difficult off-road conditions. Transporting goods in such terrain is not a pleasant pleasure, but not in the case of KamAZ 53501, which is capable of overcoming any obstacle, regardless of the depth of the obstacle. Thanks to large tires and no overhangs, you can be confident in overcoming ruts and inclines. It does not matter what type of surface is under the wheels - snow, soil, sand, crushed stone, gravel, etc. I agree that the comfort of the updated KamAZ 53501 is similar to previous vehicles of this level. The ergonomics are also a mess. The seat is hard and shapeless, lacking lateral support and normal adjustments, which can also be said about the steering column. But you can get used to the spartan landing, and in general you can forgive many of the shortcomings, which are more than compensated for by the advantages off-road. A rusting cabin, noise and vibrations in the cabin, an inconvenient gear shift lever, jerks when shifting to higher gears, etc. - all this is nonsense for a workhorse, although the only drawback can be considered the high consumption of 40 liters per 100 km - for 260 horsepower this is very a lot of.

Chassis... Engine Kamaz-63501

| What is the fuel consumption of this KamAZ per hour? Thank you. Auto, Moto. Malinovaya. Sakhcom Forum: Sakhalin and the Kuril Islands KamAZ-63501 vehicles underwent significant modernization several years ago, as a result of which it was possible to extend the service life of the vehicle, increase its maintainability, and reduce fuel consumption. The KamAZ-5350 is equipped with a model 142 clutch, a single-disc, diaphragm, pull-out type, most often used for vehicles of this class. |

- Length - 8.6 meters;

- Width - 2.55 meters;

- Height - 3.29 meters;

- The fuel tank holds 125/175 liters of gasoline;

- The power of the power unit is 260 horsepower.