PT-76 is the only example of a light amphibious tank created in the post-war period. It was put into service in 1951 and is considered the most widespread and successful in its class in the history of tank building. The impetus for the development of this vehicle was the acute shortage of transportation means and the lack of amphibious equipment in service in the Soviet Army. It was clear to the USSR government that in the event of an acute conflict with the West, military operations would take place in Central Europe, which is distinguished by a significant number of water barriers.

Light tank PT-76 Object 740

Soviet light amphibious tank. Adopted into service in 1951. During serial production, from 1951 to 1967, it was modernized several times; a total of 3039 PT-76s were produced, as well as a number of vehicles based on it. The tank was in service with the Soviet Army, but was later largely replaced by infantry fighting vehicles. However, as of 2004, up to 100 tanks of this type were in service with the Russian armed forces.

About 2000 PT-76 were exported to a number of countries, in some of which it served as the basis for the production of their own modernized versions. As of early 2008, it still remains in service in a number of countries.

By decree of August 15, 1949, the development of a new amphibious tank was entrusted to two VNII-100 design teams located in Leningrad and Chelyabinsk. In parallel, an amphibious tank, designated Object 740, and an amphibious armored personnel carrier, Object 750, which later became the BTR-50, were to be developed as unified as possible.

According to the updated technical specifications, the tank was supposed to have a mass of 13-14 tons, armament from a 76-mm cannon with 40 rounds of ammunition and armor up to 10 mm. The V-6 engine was supposed to provide the tank with a speed of 40 km/h on land and 10 km/h afloat. By the end of 1950, the design bureau was obliged to provide a prototype tank for testing.

This time, various options were considered for propulsion of the tank afloat, but in the end a water-jet propulsion system was chosen. The main designer of the tank was N.F. Shashmurin. However, the water-jet propulsion system had many opponents, and as a result, Moscow VRZ No. 2 began developing an alternative project that used propellers as propulsion, modeled on earlier developments.

Meanwhile, work on Object 740 was progressing well, and many of the shortcomings of its predecessors were taken into account when designing the tank. Prototypes of the tank and armored personnel carrier were completed in the spring of 1950 and entered state testing by June of the same year. By that time, samples of VRZ No. 2 were completed - the K-90 tank and the K-78 armored personnel carrier.

Comparative tests of object 740 and K-90 were carried out from July 5 to July 29, 1950. During testing, the 740 object showed significantly better maneuverability than the K-90. The selection committee also noted that in terms of a number of parameters, in particular, armor thickness, specific ground pressure, speed on land and power reserve, the new tank even significantly exceeds the requirements issued by the task.

Surveillance and communications equipment

In non-combat conditions, the commander of the PT-76 can monitor the terrain while standing in the open hatch. In combat, in addition to the sight, the commander has three periscope viewing devices located in the rotating commander's cupola. The devices are installed in a dense group and provide visibility only into a relatively narrow sector. The main one on early production tanks was the binocular commander TPKU

, on the PT-76 of later releases and the PT-76B, replaced by the slightly different

TPKU-2

.

Both devices have a 5× magnification and a field of view of 7.5° horizontally, allowing observation at a distance of up to 3000 meters and are equipped with a coordinate grid for target designation and fire adjustment, as well as a rangefinder scale for determining the range to a target of known height - 2.7 m ("tank"). On the sides of it there are two prismatic periscopic TNP

one-time increase.

The loader for viewing the terrain in battle has only one rotating periscope MK-4 single-magnification device, located in the turret roof in front of the hatch. The driver-mechanic on the march conducts observation through the open hatch, but in combat, to view the terrain, he is served by three TNP devices, located like a fan in front of the hatch and providing visibility of the frontal sector. For observation afloat with the wave-reflective flap raised, PER-17

or

PER-17A

, later replaced by

TNP-370

.

For driving the tank at night, the PT-76 of later releases and PT-76B are equipped with a TVN-2B

, installed in place of the central TNP.

TVN-2B is an electro-optical device that works by illuminating the FG-100

, or, on the PT-76B,

FG-125

with an infrared filter, providing the driver with a vision range of 50-60 m and a field of view of 30° at one-time magnification. The remaining crew members do not have any night vision devices.

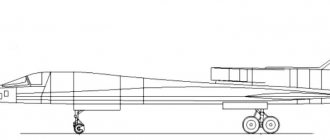

PT-76M Object 907

It was released in a single copy in 1959. It was a modernization of the PT-76 tank. Developed at the design bureau of the Stalingrad Tractor Plant. Created specifically for Marine Corps units. It had convex outer sides to improve seaworthiness. Among the improvements, it is worth noting the rear location of the engine compartment, an increase in engine power (from 240 to 300 hp), and an increase in tank capacity to 500 liters. The tank is equipped with navigation equipment and a night sight.

The tank did not survive the tests. Further development was stopped, since it did not receive any special advantages over the PT-76, and the production of two almost identical models did not make sense. For the Marine Corps, they slightly modernized it (they put a nozzle on the fan pipe so that it wouldn’t flood) and handed over the PT-76 tank. The only model is in the museum in Kubinka.

Other modifications of Soviet tanks

The designers of the Soviet Union loved to experiment with different types of weapons, which is why the world saw various developments and modifications of tanks. For example, in 1941, at a time when the Great Patriotic War had already begun, tanks with flamethrowers were developed at a plant in Leningrad, which received the unofficial name “chemical”.

During these years, the first self-propelled artillery systems in the Soviet Union began to be developed on the basis of the T-26. They also developed special mine-laying and sapper tanks, which were supposed to clear the area of mines. So-called “floating” combat vehicles were also created on the basis of the T-26 tank. In order for this weapon to float, special inflatable floats were invented. If necessary, air was removed from the floats and the tank could drive along the bottom of a river or lake. It contained a special pipe, that is, a kind of underwater passage.

It should be noted that Soviet designers sometimes came up with absolutely fantastic things. For example, designer Oleg Antonov invented a flying tank. It was a special device, a kind of hybrid of a glider and a tank. It was made on the basis of the T-60. Despite its massiveness, the combat vehicle was still able to take off, but the engines overheated and the tank was crash-landed. It was never put on the assembly line and was produced in only one test sample.

Light tank Object 934 Judge

Soviet experimental landing light amphibious tank. Developed at the Volgograd Tractor Plant. Not mass produced.

At the end of 1969 - beginning of 1970, at the direction of the USSR Minister of Defense A. A. Grechko, the R&D plan for 1970-1973 included the development of a light tank to replace the PT-76 tank.

The main requirements set by the thematic card, which was sent on December 4, 1969 to the Deputy Minister of Defense Industry of the USSR Zh. Ya. Kotin:

1.

Combat weight of the tank - no more than 15 tons;

2.

Armament: - rifled 100-mm D-33 cannon;

— anti-tank missile system 9K111 “Fagot”; — a 12.7 mm machine gun for firing at ground and anti-aircraft targets; 3.

Protection:

a)

armor: - from a 23-mm armor-piercing projectile at heading angles ± 35°;

- from a 12.7 mm armor-piercing bullet at heading angles ± 70°; - from a 7.62 mm armor-piercing bullet at all heading angles; b)

anti-nuclear: - collective automatic, with sealing of the habitable space, with the creation of back pressure and filtration of the forced air;

- radiation attenuation factor - no less than that of the BMP-1; 4.

Mobility: - maximum speeds: on land - 70 km/h; afloat - 12 km/h; — fuel range on land — 700 km.

The development was carried out on a competitive basis by ChTZ, VgTZ, MMZ with the participation of VNIITransmash. It was planned to provide a preliminary design by the second quarter of 1970. However, none of the competition participants met the deadline.

The Chelyabinsk Tractor Plant was the first to present its project on April 29, 1971. The project bore the index “Object 788”. BMP-1 was chosen as the base.

On May 21, 1971, the Volgograd Tractor Plant presented its version. The project had two options:

Object 934 - classic accommodation of the crew in the hull; tank weight - 14.8 tons; Object 934B - placement of the crew (including the driver) in a capsule tower; tank weight - 14.6 tons.

After reviewing the preliminary designs, Object 934 was selected. Then the following development phase dates were established:

preliminary design - 2nd quarter of 1972; technical project - 4th quarter of 1972; three samples for factory testing - 2nd quarter of 1973; three samples for field testing - 4th quarter of 1973; submission of proposals - 2nd quarter 1974.

Due to a number of fundamental disagreements between GABTU, GRAU, designers, due to the change of the general designer of the R&D "Judge" (whose views were radically different from the views of his predecessor), due to the change of the USSR Minister of Defense and many other factors, they were consistently thwarted all terms of development stages. The project was very controversial and each of the participants in the “Judge” R&D project saw the new amphibious tank in their own way.

As a result of successive postponements and shifts in the development and submission of prototypes for preliminary and state tests, Object 934 “Judge” has lost its relevance. By the time three prototypes were manufactured, development of the prototype Object 688 (later BMP-3) was already underway.

On February 21, 1980, at a meeting of the Military Technical Cooperation of the Moscow Region, General Yu. M. Potapov expressed the opinion that in connection with the advent of “Object 688”, which had such powerful weapons, the topic of “Judges” had lost its relevance. As a result, the OCD “Judge” was closed. However, in the document from the Office of the Chief of Tank Forces on the closure of work on Object 934, it was written that the results of the development were allowed to be used.

T-37A evaluation

Based on the above facts, I believe it would be correct to conclude that all the failures were due, first of all, to the non-core use of the tank, which had a very narrow specialization.

Indirectly, my point of view is confirmed by the successful operations carried out by him, related to the crossing of water barriers. In general, for its time and in its class, the “thirty-seventh” was a quite effective machine, and only increased technical requirements and the general negative course of the beginning of the Second World War did not allow it to fully reveal its potential.

Light tank Object 685

Soviet experimental landing light amphibious tank. Development of Kurgan "SKBM". Not mass produced.

An experimental light amphibious tank, developed in 1975 at the Kurgan Design Bureau under the leadership of A. A. Blagonravov. It was not accepted for service and was not mass-produced. All developments on this tank were subsequently used in the design of the “Object 688” (BMP-3).

In 1972, by order of the GABTU, the Kurgan Machine-Building Plant received an order to manufacture a new light tank on a competitive basis. The tank was intended to replace the PT-76, which was outdated by that time. The work was carried out on a competitive basis in parallel with the Object 788 and Object 934 tanks. Prototypes of the vehicle were demonstrated to A. Kh. Babajanyan and N.N. Pavlov, however, further work on the car was stopped.

Object 685 is designed according to a classic layout scheme. The tank had air conditioning, a collective protection system against damaging factors and equipment for self-entrenchment. The tank was also adapted for parachute landing.

Armored hull and turret

The hull and turret were made from sheets of light armored titanium alloy. The frontal armor of the tank could withstand 23 mm shells.

Armament

The main armament was a 100-mm 2A48-1 rifled gun, which was equipped with a hydraulic stabilizer and an automatic loader. The ammunition consisted of 40 rounds. As an additional weapon, a 7.62 mm PKT machine gun with 2000 rounds of ammunition was installed. In addition to it, 4 Strela-2 MANPADS were placed in the vehicle to counter air targets.

The vehicle was also equipped with 8 grenade launchers of the 902B “Tucha” smoke screen system for firing 81-mm smoke grenades.

Engine and transmission

The main engine was a 2V-06-2 multi-fuel engine with intermediate air cooling and gas turbine supercharging. The mechanical transmission and engine were a single unit. Most of the units were unified with the BMP-1.

Chassis

The chassis had an original design, the suspension was torsion bar with installed telescopic hydraulic shock absorbers on rollers 1, 2 and 6. To prevent the tracks from being thrown off when the tank was turning, a limit disc was installed on the drive wheel.

For movement on water, the chassis body had two water jet propulsors.

Combat vehicles for the Soviet Union from German designers

In the early 1930s, German soldiers and officers were trained on the territory of the Soviet Union, namely in various military educational institutions near Kazan. In turn, the military of the Soviet Union also went to the German General Headquarters to study.

In those days, the countries cooperated closely with each other in the military sphere. In March 1930, a special agreement was concluded, according to which German specialists were to arrive in the Soviet Union in order to develop new promising tanks and combat vehicles for the USSR. A delegation of engineers arrived from Germany, in which Edward Grote, a famous designer all over the world, was appointed chief.

Special commissions were created that were supposed to buy foreign combat vehicles for the Soviet Union. For example, in these years, the British Vickers Mk.II tanks, as well as many others, were put into service for the Red Army. At that time, the USSR design bureau, with the help of German specialists, was already producing a variety of domestic tanks of the medium and heavy categories. It was in 1931 that combat vehicles began to be produced en masse on the territory of the Soviet Union. T-27 wedges were produced.

If we recall the most interesting tanks in terms of their design, then this is the T-28 model, which had three turrets. A year later, the T-35 tank was created, which already had five turrets. In 1931, tanks were already being made in four factories on the territory of the Soviet Union. German specialists helped their Soviet colleagues develop different types of similar military equipment. In those years, the Red Army supplied amphibious, light, wheeled-tracked, heavy, medium and other types of combat vehicles.

Light tank Object 906 PT-85/PT-90

Soviet experimental light amphibious tank. Development of the Volgograd Tractor Plant. Not mass produced.

Object 906 was created in the design bureau of the Volgograd Tractor Plant, the work was led by I.V. Gavalov. The tank was developed in two versions: PT-85 (with an 85 mm cannon) and PT-90 (with a 90 mm cannon). In 1961-1962, six prototypes of the PT-85 were manufactured, two of which were tested at the NIIBT test site in Kubinka in 1963, but the vehicle was not accepted for service.

Object 906 had a classic layout, with a crew of 3 people.

Armored hull and turret

The body is completely sealed and welded from rolled aluminum armor sheets. The use of aluminum instead of steel made it possible to reduce the total weight of the hull by 1.5 tons compared to the light amphibious tank PT-76. The engine and transmission were located in the rear of the hull. The tower was made of steel armor plates. The frontal armor of the hull and turret could withstand shots from 14.5-mm caliber bullets from a distance of more than 100 m. An automatic loader was located in the turret.

Armament

The PT-85 tank used the 85-mm D-58 cannon as the main armament; the PT-90 version was supposed to use the 90-mm D-62 cannon. In both versions, the transportable ammunition amounted to 40 rounds, of which 15 were loaded into the mechanized stowage of the automatic loader. The gun had a two-plane weapon stabilizer.

Additionally, the vehicle had a 7.62-mm SGMT tank machine gun coaxial with the cannon. The carried ammunition was 2000 rounds.

Surveillance and communications equipment

To ensure communications, the Object 906 tank had a radio station R-123. A telescopic sight was installed to monitor the area.

Engine and transmission

The experimental tank “Object 906” used a liquid-cooled 4-stroke diesel engine. The engine power was 300 hp. The transmission is mechanical. The main friction clutch was borrowed from the PT-76 tank; in addition to it, the transmission included: a simple stepped gearbox and final drives.

Chassis

Object 906 had a tracked propulsion system. To overcome water obstacles, the chassis was equipped with water cannons. The chassis of the tank consisted of 14 aluminum support rollers, 8 support wheels, and two idler wheels. To maintain the required track tension there was a special compensating device. Type of suspension used: individual torsion bar with 6 telescopic hydraulic shock absorbers.

Combat use of the T-37A

The T-37A made its debut at Khalkhin Gol, where it was used as a simple infantry tank, but its poor armor caused heavy losses. He performed equally disgustingly in Poland, mainly for the same reasons.

In the Finnish theater of war, which was better suited for its operation, the “thirty-seventh”, although it did not make a splash, in the absence of serious anti-tank weapons, could be effectively used for its intended purpose.

T-37A captured by the Finns

At the beginning of the Second World War, over two thousand of these vehicles were still present in the Red Army units, most of them were lost in the very first weeks of the invasion. As a result, one can count on one hand the operations in which they took a significant part:

Fighting in the area of the famous “Neva patch” in 1942, where these tanks helped establish a bridgehead on the “German” shore. Unfortunately, in the end the operation was a failure, which caused the loss of twenty-three “boxes” involved in it.

Crossing the Svir in 1944 - thanks to better preparation, the operation was successful, effectively becoming the “swan song” of the “thirty-seventh”.

There are also known cases of successful use of T-37A in local battles, but most of them served in training units and immediately after the war went into scrap metal.

Light tank Object 911B

WITH

Soviet experimental amphibious light tank from the 1960s. It was created in 1963-1964 by the Volgograd Tractor Plant Design Bureau on the basis of the experimental Object 911 infantry fighting vehicle and was intended to serve as a light airborne reconnaissance vehicle. A number of unconventional solutions were used in the design of the tank: an “all-in-turret” layout with a capsule of increased armor and radiation protection for the crew; a weapon system borrowed from the infantry fighting vehicle with an automatic loader and a smoothbore cannon for firing active-missile projectiles; hydropneumatic suspension with adjustable ground clearance. In 1964, the only prototype of the tank was made, which passed factory tests, but was not accepted for service.

“Object 911B” had a layout with the engine-transmission compartment located in the rear part and the combined combat compartment and control compartment in a high-security capsule in the middle part; in the frontal part there was a cargo compartment, which served to provide buoyancy. The tank's crew consisted of two people: a driver and a commander, who also served as a turret gunner.

Armored hull and turret

“Object 911B” had highly differentiated bulletproof armor protection; The turret and hull of the tank were assembled from sheets of rolled armor steel with a thickness of 4, 6, 8, 10, 20, 35, 40 and 45 mm. The complex-shaped armor capsule of the hull was assembled from sheets of medium-hard steel grade 49C

35 mm thick in the front and rear parts;

45 mm at the top and 20 mm at the bottom of the sides. The engine, transmission and cargo compartments were assembled from sheets of high-hardness steel grade 2P

.

The forehead of the lightly armored hull consisted of a 10-mm sheet, located at an angle of 45° and smoothly turning into the bottom. The vertical sides of these compartments were 8 mm thick, and the roof and stern were 6 mm thick; the upper part of the stern of the hull was vertical, and the lower part had a slope of 48° and smoothly passed into the bottom in the lower part. The bottom of the engine, transmission and cargo compartments was made of stamped 4-mm carbon steel sheets.

To ensure the necessary rigidity, the bottom of the cargo compartment was equipped with two longitudinal belts of U-shaped beams, and the engine-transmission compartment was equipped with two transverse belts of H-shaped beams and longitudinal external zigs. To provide additional buoyancy, removable displacement fenders were installed on the sides of the hull.

The tank's turret had a conical shape and was made of a 40-mm frontal and two side sheets with variable angles of inclination from 48° at the front to 40° at the side. The roof and the developed niche of the tower were assembled from 10 mm armor plates.

In general, the level of armor protection of the tank provided protection for the habitable capsule: in the frontal projection - from 76.2 mm caliber armor-piercing shells with an initial speed of 655 m/s from a distance of 2000 meters; sides - from 14.5 mm caliber armor-piercing bullets B-32

KPV machine gun at all distances.

The crew boarded and disembarked through individual hatches in the turret roof. If necessary, cargo or two people could be transported in the front compartment, with boarding through hatches in the roof, while ventilation of the compartment was ensured.

Anti-radiation protection of the habitable capsule was provided by the installation of anti-radiation screens, which provided a 15-fold attenuation of gamma radiation, and an anti-nuclear protection system (EPS).

The latter included a sealing system for the habitable compartment based on the Electron-3

, which registered a burst of gamma radiation from a nuclear explosion, and a filter-ventilation unit that provided an excess pressure of at least 0.44 kPa in the compartment to prevent radioactive dust from getting inside.

The tank's fire-fighting equipment consisted of an automatic fire extinguishing system "Rosa"

, which included two 2-liter cylinders with the composition “3.5” and six

TD-1

: four in the engine-transmission compartment and two in the cargo compartment.

Armament

The main armament of the tank was a 73-mm smooth-bore semi-automatic gun TKB-04 "Thunder". The gun had a monoblock barrel, a vertical wedge breech, semi-automatic copy type and a concentric hydraulic recoil device.

The gun was fired with active rockets, which were modified shots for the SPG-9 easel grenade launcher. The range of a direct shot at a target 2 meters high was 800 meters, the maximum sighting range was 1300 meters.

The gun's ammunition consisted of 40 rounds of cumulative shells with armor penetration of 300 mm of homogeneous armor steel. The gun was equipped with an automatic loader with a belt-type magazine with a capacity of 27 rounds, located in the turret niche. The automatic loader conveyor had an electromechanical and redundant manual drive; if necessary, manual loading of the gun was possible.

The gun was placed in the front part in a twin installation, which provided it with vertical guidance angles from −5° to +30°; horizontal aiming was carried out by turning the turret. , the PKB-62 “Shield” periscope combined optical sight was used.

. The day branch of the sight had a magnification of 6× and a field of view of 15°, while the night branch was an electro-optical device with a magnification of 6.7× and a field of view of 6°, which worked by enhancing natural night illumination.

Vertical and horizontal aiming of the gun was carried out using an electromechanical or backup manual drive. The mount paired with the gun housed a 7.62-mm PKT machine gun, which had 2,000 rounds of ammunition in 8 belts. In addition, for self-defense of the crew, the tank was equipped with ten F-1 fragmentation grenades and a signal pistol with 10 rounds of ammunition.

Chassis and water propulsion

The chassis of the tank for each side consisted of six hollow support and three supporting single-pitch rollers made of MG-6

with external shock absorption, idler and rear drive wheel.

The suspension of the road wheels is individual pneumatic (hydropneumatic), with relaxation-type hydraulic shock absorbers on all rollers. The suspension made it possible to change the ground clearance, trim and roll of the vehicle and was controlled using a hydroelectric system from the driver's seat. The tracks of the “Object 911B” are steel, fine-linked, double-ridged, with an open metal hinge.

The sloth, drive wheel and tracks of the built prototype were borrowed from the PT-76B tank, but the production vehicles were supposed to use the tracks of the Object 906 tank. To move afloat, the Object 911B used a water jet propulsion system, similar in design to the PT-76 water jet, but differing in its lower location, at the level of the axis of the transmission load shaft, and a pneumatic drive for controlling the water jet flaps instead of a mechanical one.

Foreign operators

One car was delivered to Turkey for testing in the first half of the 30s, but Ankara showed no interest in purchasing a license.

About three dozen were captured by the Finns, one of these “boxes” was transported to Sweden, where it is still located, the rest were written off a year before Finland left the Second World War. In addition, captured vehicles were occasionally used by other Axis countries.

Shot down T-37A

Light tank/self-propelled gun 2S25 Sprut-SD

Sossian airborne self-propelled anti-tank gun. Developed in the design bureau of the Volgograd Tractor Plant and the Yekaterinburg OKB-9 under the scientific supervision of the Klimov Central Research Institute of Precision Engineering (TsNIITochMash).

The chief designer of the chassis is A. V. Shabalin, the 125 mm 2A75 gun is V. I. Nasedkin. The 2S25 Sprut-SD self-propelled gun is designed to combat tanks and other armored vehicles and enemy personnel as part of units of the airborne troops, marines and special forces.

Previously, in 1982, TsNIITochMash carried out research work on the creation of a self-propelled anti-tank gun, light in weight and in 125 mm caliber. During the work, a prototype self-propelled gun was manufactured based on the BMP-2 infantry fighting vehicle, which confirmed the fundamental possibility of creating a light anti-tank gun in 125 mm caliber.

The research results became the basis for the protocol of the Commission of the Presidium of the Council of Ministers of the USSR dated July 29, 1983, which prescribed preliminary work to assess the possibility of developing a self-propelled anti-tank gun based on the components and assemblies of a promising airborne combat vehicle.

During the search for the base chassis, TsNIITochMash came to the conclusion that the chassis of the Object 934 light tank was suitable for these uses. In 1983, one of the three prototypes of the Object 934 tank was transferred to TsNIITochMash, where a prototype of a 125-mm airborne self-propelled anti-tank gun was manufactured at its base in the period from 1983 to 1984.

The sample was manufactured according to the classic turret design, but a deckhouse version and a version with external weapons were also considered. In 1984, experimental firing was carried out at the Kubinka training ground, which showed that the accuracy of fire of the gun was no worse than that of tank guns, and the loads acting on the crew and body of the gun did not exceed permissible values.

The resulting developments formed the basis of the development work under the name “Sprut-SD” (GRAU index - 2S25).

Testing and adoption

In 1984, the tactical and technical specifications for the creation of a 125-mm airborne self-propelled anti-tank gun "Sprut-SD" were approved; on October 20, 1985, by the decision of the military-industrial commission of the Council of Ministers of the USSR, the development of a new 125-mm SPTP for the USSR Airborne Forces was officially launched.

In February 1986, the development of landing equipment for the 2S25 self-propelled guns began. The landing equipment received the designation P260 and was created on the basis of the P235 parachute-jet equipment, intended for landing the BMP-3.

In the period from 1990 to 1991, State tests of the 2S25 self-propelled guns were carried out. However, tests of the P260 system revealed its shortcomings, the main of which were: difficulty in operation, high manufacturing cost, complexity of the cassette unit of the parachute-jet braking engine.

On May 30, 1994, by the decision of the Russian Air Force, the Russian Airborne Forces and the developer of landing equipment - Moscow - the development of the P260 parachute-jet landing systems was canceled, and the same decision began the development of the P260M Sprut-PDS strapdown landing system.

In 2001, additional tests of the 2S25 self-propelled guns were carried out. On January 9, 2006, by order of the Minister of Defense of the Russian Federation, the 2S25 self-propelled anti-tank gun was adopted by the Russian Army.

Armored hull and turret

The fighting compartment of the 2S25 self-propelled gun on a slipway in the workshop of the Volgograd Tractor Plant.

The SPTP 2S25 chassis retained the geometry and layout solutions of the Object 934 light tank. The body is made of welded armored aluminum sheets. In the front part of the hull in the center there is a control compartment with a driver's workplace. To the right of the driver is the position of the commander, to the left is the position of the SPTP gunner on the march and during landing.

The fighting compartment is located in the middle part of the hull; a rotating shoulder strap with a rotating turret and a fighting compartment is installed on the roof of the hull. The fighting compartment contains workstations for the gunner and commander of the self-propelled gun, mechanized stowage and an automatic gun loader. At the rear of the body there is a motor-transmission compartment with a power plant.

The armor of the frontal projections of the turret and hull is reinforced with steel linings and provides the crew with protection from 12.7 mm caliber bullets in a ±40° sector, as well as all-round protection from 7.62 mm caliber bullets and artillery shell fragments.

Armament

The main armament of the SPTP 2S25 is the 125 mm 2A75 smoothbore gun, which is a modified version of the 2A46 tank gun and its modifications.

Initially, the gun was planned to be equipped with a muzzle brake to reduce the force of recoil resistance, but as a result, the problem of recoil of the gun when firing was solved by increasing the recoil length to 740 mm, as well as using hydropneumatic chassis suspension mechanisms to absorb the residual recoil impulse of the gun. The mass of the gun is 2350 kg.

The gun is stabilized in two planes and equipped with an automatic loader, providing a maximum rate of fire of up to 7 rounds per minute.

The automatic loader includes a conveyor mechanism that houses 22 cartridges with shots, a chain mechanism for lifting cartridges, a chain rammer and a mechanism for removing spent cartridges from the fighting compartment.

The gun can be fired from the ground at an angle range from −5 to +15° vertically when firing forward and from −3 to +17° when firing backwards. In addition, the Sprut-SD self-propelled gun is capable of firing from afloat in a range of ±35° horizontally.

The transportable ammunition load of the 2S25 self-propelled gun is 40 rounds. Additionally, a 7.62-mm PKT machine gun with 2,000 rounds of ammunition in one belt is paired with the gun.

The ammunition load of the Sprut-SD self-propelled gun is unified with tank guns of the 2A46 type. High-explosive fragmentation, cumulative, armor-piercing sub-caliber and guided projectiles can be used for firing. The standard ammunition includes 20 high-explosive fragmentation, 14 armor-piercing sub-caliber and 6 cumulative (or guided) rounds.

Armor-piercing sub-caliber rounds 3VBM17 provide penetration of up to 230 mm of homogeneous armor steel located at an angle of 60° at a distance of 2000 m, cumulative 3VBK25 - up to 300 mm, guided 3UBK20 - up to 375 mm.

Surveillance and communications equipment

To aim and fire from a gun and a coaxial machine gun, the gunner's workplace is equipped with a 1A40M-1 daytime monocular periscope sight.

The sight is equipped with a built-in range finder and ballistic computer and allows you to measure ranges to targets, develop a lateral lead angle when shooting at moving targets, and also guide a guided weapon system using a laser beam.

The longest effective range when firing using the 1A40M-1 sight is up to 5 km with high-explosive fragmentation shells, up to 4 km with armor-piercing sub-caliber, cumulative and guided shells, and up to 1.8 km when firing from a coaxial machine gun.

For operations in night conditions, the 2S25 self-propelled gun is equipped with a TO1-KO1R night optical-electronic complex with a TPN-4R gunner's night sight.

The recognition range for tank-type targets is up to 1.5 km. The commander's seat is equipped with a 1K13-3S commander's sight-guidance device. The 1K13-3S device allows for reconnaissance and gun guidance in both day and night conditions, and includes a laser guidance channel for guided weapons, a ballistic computer and a built-in range finder. In terms of functionality, the commander's and gunner's reconnaissance and guidance systems are almost identical.

External radio communication is supported by the R-173 radio station. The radio station operates in the VHF range and provides stable communication with similar stations at a distance of up to 20 km, depending on the height of the antenna of both radio stations. Negotiations between crew members are carried out through the R-174 intercom equipment.

Special equipment

The 2S25 self-propelled gun is capable of overcoming water obstacles by swimming without the use of additional equipment. For this purpose, the chassis of the self-propelled artillery mount is equipped with two water cannons, the dampers of which are located in the lower part of the rear hull plate. For operations in conditions of radiation, chemical or biological contamination of the area, the SPTP 2S25 is equipped with a system of protection against weapons of mass destruction.

To camouflage and set up smoke screens, two brackets with 6 grenade launchers of the 902V system for firing 81-mm 3D6 smoke grenades are placed on the rear plate of the self-propelled gun turret.

Engine and transmission

The 2S25 is equipped with an opposed 6-cylinder four-stroke diesel engine 2V-06-2S with a power of 510 hp. liquid cooling. The transmission is mechanical, with a torque converter, friction gear shifting and a hydrostatic turning mechanism.

Chassis

The 2S25 chassis is a modified chassis of the Object 934 light tank. The chassis consists of seven pairs of single rubber-coated road wheels and six pairs of support rollers. There are drive wheels at the rear of the machine, and guides at the front. The caterpillar belt consists of steel double-ridge links with rubber-metal hinges.

The 2S25 suspension is hydropneumatic, with variable ground clearance. Each support roller is equipped with an air spring, which acts as a power cylinder when changing ground clearance, as well as the function of a hydraulic shock absorber. The clearance can vary from 100 to 500 mm, the change time is no more than 7 seconds.

Sources:

M. V. Pavlov, I. V. Pavlov.

Domestic armored vehicles 1945—1965

A.V. Karpenko.

Review of domestic armored vehicles (1905-1995)

M. N. Svirin.

Stalin's steel fist. History of the Soviet tank 1943-1955

S. Suvorov.

The “floats” will still serve

History of the creation of amphibious tanks

History of the creation of amphibious tanks

Amphibious tank Vickers-Carden-Loyd mod. 1931 on display at the Military Historical Museum of Armored Weapons and Equipment in Kubinka

The world's first truly reliable amphibious tank was developed and built by the English company Vickers Armstrong. Its prototype was manufactured during April 1931 at the company's experimental station in Chertey and was tested on the Thames River. The buoyancy of the tank was ensured by its low weight, trough-shaped riveted hull and balsa floats mounted above the tracks. In addition, the prototype had a kapok float mounted across the rear of the hull. The turret along with the machine gun was borrowed from a 6-ton Vickers Mod.A tank. Frontal 9-mm armor protected the vehicle from armor-piercing bullets at distances over 150 m, and 7-mm side armor at distances over 250 m.

The tank had a locked suspension. On each side there were two double-roller balancing bogies, suspended on quarter-elliptical leaf springs. The last support rollers of the rear bogies served as guide wheels. The width of the small tracks is 257 mm.

Carbureted 6-cylinder Meadows EST engine producing 90 hp. allowed a vehicle weighing 2.75 tons to reach speeds on land of up to 64 km/h, and afloat - 9.7 km/h. The engine, transmission, which included a four-speed 9AU gearbox, and radiator were located on the right, and the turret and driver's cabin were shifted to the left. Movement afloat was carried out using a propeller. Maneuvering - using a ring steering wheel, controlled from the driver's seat.

Based on the test results, the kapok float was removed, and the roof of the aft hull was pulled back strongly. However, due to the shifted center of gravity, the stern of the tank sank deeply into the water while afloat.

In June 1931, the tests were completed, and all documentation was transferred to the Vickers plant in Elswick, where the combat vehicle, called Vickers Carden-Loyd and the War Ministry index A.4, was subsequently mass-produced. However, in August of the same year, the British Army ordered only two tanks, which underwent an extensive military testing program. Also, two cars each were made for Siam and the Netherlands. The largest batch of amphibious tanks - 29 units - was purchased by China; They became part of the 1st and 2nd tank battalions of the Chinese National Army, took part in street battles with the Japanese in Shanghai in 1937, and then almost all of them were lost.

On February 5, 1932, the Soviet foreign trade company ARCOS (Arcos Ltd. - All Russian Cooperative Society Limited) ordered eight amphibious tanks from Vickers. The first vehicle was delivered on June 21, and the last on October 22 of the same year.

After the arrival of the first purchased tanks, their testing and comprehensive study, intensive design of domestic models began. However, no license was purchased.

Vickers-Carden-Loyd mod. 1931

Vickers-Carden-Loyd during testing in Finland. 1933

By August, at OKMO in Leningrad, under the leadership of N.V. Barykov, the T-33 amphibious tank was created, and at plant No. 37, then in Cherkizovo near Moscow, under the leadership of N.N. Kozyrev, the T-41 tank was manufactured. In the fall, their comparative tests took place.

The T-33 amphibious tank was not much different from the English prototype. Its body was trough-shaped and riveted. In the rotating turret, shifted to the left side and to the stern, there was a DT machine gun with 2140 rounds of ammunition. A wave-reflecting shield with a viewing slot was installed in front of the tower. The tower was rotated manually, using handles welded from the inside. Ford AA engine with 40 hp power. located along the starboard side; the transmission, which included an automobile-type clutch, gearbox and final drive with a simple differential and shoe brakes, was located in the front of the car. The design of the chassis was almost completely borrowed from the Vickers Karden-Loyd tank.

Movement afloat was provided by a three-bladed propeller and a large-area rudder installed in its jet. The buoyancy of the tank was increased by two floats attached to the fenders. True, they were no longer made of expensive balsa, but were filled with cork or dried seaweed.

With a mass of 3 tons, the tank developed a speed of 45 km/h on land and 5 km/h afloat.

The T-41 amphibious tank was developed in two versions. The first sample had a large reserve of buoyancy, but was too high, had a non-reversible propeller and poor controllability afloat, since the rudders were not installed in the flow, but on the sides of the propeller. On the second sample (possibly converted from the first), these shortcomings were partially eliminated, however, due to an unsuccessfully chosen hull shape and an incorrect location of the center of gravity, when moving afloat, the bow of the tank was buried and the stern was raised.

With a mass of 3.2 tons, identical power plant and chassis to the T-33, the T-41 on land reached speeds of up to 40 km/h, and on water - 4.5 km/h.

Light amphibious tank T-33 at the storage base for prototypes at the NIBT Test Site in Kubinka. 1930s. Most of the chassis elements on the starboard side are missing

T-41 amphibious tank

Standing apart from the T-33 and T-41, which were a development and partly a direct copy of the Carden-Loyd tank, stood the PT-1 wheeled-tracked tank, created in the same 1932. Work on it began two years earlier, when the UMM of the Red Army developed a tactical and technical specification (TTZ) for a medium amphibious tank with a combat weight not exceeding 20 tons, armed with a 45-mm cannon and three machine guns, with a crew of 6 people, maximum speed on the highway 30 km/h and armor that protected against 37-mm shells at a distance of over 1000 m. In August 1930, the TTZ was sent to Izhora for a technical report.

Based on this technical specification, the Technical Department of the EKU OGPU developed a project for the wheeled-tracked amphibious tank PT-1 (lead designer - N.A. Astrov). By autumn, a prototype of the PT-1 tank was ready.

The body of the vehicle was given a shape that ensured good stability and low resistance when moving afloat. To create a reserve of buoyancy, additional displacement tanks were provided along the sides of the hull. Along the perimeter of the body there was a handrail antenna for the 71-TK-1 radio station. The turret was cylindrical in shape, with a small aft niche in which part of the gun's ammunition was located. The 45-mm 20K cannon of the 1932 model was paired with a DT machine gun. Two more of the same machine guns were placed in ball mounts on the sides of the turret; the fourth diesel engine is in a ball installation in the frontal plate of the hull on the right. The machine gun barrels were protected by casings, apparently to prevent water from getting inside the tank when moving afloat. The cannon's ammunition consisted of 88 rounds, and that of the machine guns - 3,402 rounds.

In the rear part of the hull there was an M-17F carburetor engine with a power of 500 hp. and power transmission units: the main dry friction clutch, a gearbox with a rotation mechanism, which used a double differential, two power take-offs for propellers and two final drives.

Photocopy of the working drawing of the PT-1 tank

Wheeled-tracked amphibious tank PT-1L. 1934

Amphibious tank 11T-1A during factory tests. 1934

The undercarriage, for one side, included four dual large-diameter rubber-coated road wheels, a rear drive wheel and a idler wheel. The engagement is ridge. When moving on wheels, all support rollers were driven, in which gearboxes were built-in. The power supply from the gearbox to the road wheels was carried out using two onboard cardan shafts. The front and rear pairs of road wheels are controlled.

With a mass of 14.2 tons, the combat vehicle developed a speed of 62 km/h on tracks, 90 km/h on wheels, and 6 km/h when afloat. The crew of the tank consisted of 4 people. The maximum armor thickness is 10 mm.

In the fall of 1932, the PT-1 was demonstrated to the leaders of the party and government led by Stalin. The display was supposed to take place in Moscow, on the Khamovnichesky parade ground, where the tank was driven from the Crimean Bridge, but not the modern one, of course, but the old one, built in 1872. This is how his direct participant N.A. Astrov recalled it: “Driving the tank across the bridge - and it was moving at a speed of about 60 km/h - became an impressive spectacle, although it did not last long. Hearing the roar, passers-by stopped and stared. The times were naive: an experienced combat vehicle walked through the city in the middle of the day, no additional security, except for two policemen who prohibited other movement when the tank approached the bridge on its short path from the plant to the Khamovnichesky parade ground and back.

The PT-1 at that time had no analogues abroad and, although it was far from being fully developed, with improvement it could become a useful combat vehicle for our army.

He manufactured the PT-1 “Red Proletarian” tank, although not all of its components. The plant received weapons elements, optical instruments and an aircraft engine. And the armored hull was made at the Izhora plant. “Red Proletary” was already a powerful enterprise back then and, although it had never produced tanks before the PT-1, it coped with this generally difficult task. During testing, virtually no manufacturing defects were identified.

On that gloomy autumn day, the parade ground was covered with icy crusts of still loose snow. And since it itself was not very level, there were quite large puddles in some places. The mud was, one might say, full - just right for testing the tank.

All kinds of authorities huddled together in a fairly close group next to a large puddle, apparently hoping that the cars of even higher authorities, primarily Stalin himself, would stop in front of it. Perhaps this would have happened if the parade ground had been dry or dusty like summer. However, Stalin's car stopped directly at the demonstration site.

Stalin is wearing a fur coat just below the knees, on his head is a deeply pulled fur hat with exorbitantly long ears, almost reaching to the waist, that were fashionable in those years. The color of his face and the skin of his hands without gloves was dark brown, one might say, with a greenish tint. The face bore many traces of smallpox. The eyes are completely black. I saw the details of the appearance later, when I was nearby.

In a slightly hoarse voice, quietly, as if fearing a cold, he asked where the speaker was (as if I didn’t hear the question, since I was standing far away). The authorities were afraid that Stalin would ask questions that no high-ranking military man could answer, and someone from the group, who undoubtedly knew my role in the creation of PT-1, loudly shouted: “Astrov is here for a report!”

My soul was almost down to my heels, and I was thoroughly frozen—not a pleasant state. Still, he ran at a vigorous trot to the “master” of the country. Following half a step behind, I, as clearly as possible, and, most importantly, loudly (we were all warned that his hearing was poor), began to report, or rather, simply talk about the features of the new tank. Despite the mud underfoot, Stalin walked around the car, listening carefully to me. Then he asked several questions that showed that he knew tanks quite well, and noticed that there were many unusual things about the PT-1. In particular, he inquired about the size and volume of the tower. Answering, I said that the 45-mm cannon was weak for such a vehicle and should be replaced with a more powerful one. Questions followed again: “What caliber, when will you make it?” He answered: “Comrade Stalin, we will install it as soon as we have the necessary gun; we ourselves do not know how to make guns.” He asked what kind of engine the tank had, and, hearing that it was an aviation engine, gasoline, he muttered with a hint of displeasure: “But they promised a diesel car.” The inspection took only five to eight minutes. Nodding slightly, either to the guard who constantly accompanied him, or to me, Stalin quietly, as if to himself, muttered: “Continue!” and, without making any sign, without even nodding to any of the superiors, he left. He also did not honor us, “engineering,” with either a farewell nod or a gesture.

However, taking into account the experience of previous shows, the authorities, who did not dare to approach the tank even half a step during its inspection, congratulated me on my success. Unfortunately, due to circumstances beyond our control, further work on the PT-1 was stopped, and it did not reach series production.”

However, work on the PT-1 continued until 1934. Thus, three resolutions of the STO in April, June and August 1933 indicated specific deadlines for the creation of prototypes of the PT-1 tank, both in floating and non-floating versions. The decree of the STO “On the Tank Armament System of the Red Army” dated August 13, 1933, in particular, stated: “From 1934, begin the gradual introduction into production of the PT-1 amphibious vehicle as an operational tank in such a way that from 1936 completely switch to full-scale production of this tank at the base and through the production of the VT tank.”

Apparently, we were talking about the PT-1A tank. It differed from the PT-1 in its elongated hull, reinforced armor protection to 13-15 mm (vehicle weight increased to 15 tons), the installation of one propeller, the introduction of a mechanism for disabling the rotation of the rear wheels into the steering wheel system, and simplified transmission by eliminating the front drive support rollers and replacing the ridge gear with a lantern gear. If one track was lost, it was possible to synchronize the operation of the wheeled and tracked propulsion systems due to the differential. The number of firing points in the tank was slightly reduced - the onboard turret machine guns, the practical use of which in battle was questionable, were abandoned. Apparently, due to this, it was possible to increase the ammunition load. Now it consisted of 96 shots and 4851 rounds.

T-43 amphibious tank, manufactured at the Moscow plant Xv 37

In 1934, at the Leningrad Experimental Mechanical Engineering Plant named after S.M. Kirov (plant No. 185), only one prototype of the PT-1 (or PT-1A) tank was produced and, according to the resolution of the STO dated June 19, 1935, it was decided to “leave it for armament tank BT. Refuse to replace it with PT-1.” Apparently, this decision was influenced by the much more complex design of the PT-1 tanks, compared to the BT. First of all, this applies to transmission and control drives. In addition, PT-1 and PT-1 A had a small reserve of buoyancy and insufficient maneuverability when driving on wheels. True, due to their high specific power, they had good mobility on water: the relative speed (the so-called Froude number) for the PT-1 was 0.34, and for the PT-1 A - 0.565. As is known, for displacement vehicles the maximum value of this number is 1.

As for the non-floating versions of the PT-1, work on them, also carried out in the Technical Department of the EKU OGPU under the leadership of N.A. Astrov, led to the creation of a project for the IT-3 wheeled-tracked fighter tank, and in 1934 - to the production of experimental copies of wheeled-tracked tanks T-29-4 and T-29-5.

To complete the story about the history of the creation of Soviet wheeled-tracked amphibious tanks, it is necessary to mention two more examples of such vehicles. In 1934, at two enterprises at once—Moscow plant No. 37 named after S. Ordzhonikidze and Leningrad plant No. 185 named after S.M. Kirov (former OKMO)—two prototypes of the T-43 tank were manufactured. The leading designer of the Moscow machine was N.N. Kozyrev, the Leningrad one - M.P. Ziegel. The tanks differed from each other in weight (4.4 and 3.6 tons), the shape of the hull and turret, the power transmission and propulsion circuits, as well as the design of the chassis. A GAZ-AA engine was installed in the rear of both tanks across the hull. The power transmission is mechanical, with power take-off to four driving road wheels. One machine had a propeller; on the other, to move afloat, the driving wheels, instead of spokes, were equipped with blades, the jets of water from which were directed back using special casings. The suspension of the front wheels of both cars was individual, and the leading support wheels were locked. Spiral springs were used as an elastic element.

Wheeled-tracked amphibious tank T-4.1 on wheels, manufactured at the Leningrad plant .M 185. 1934

The complexity of the design, poor cross-country ability on wheels due to irrational distribution of mass across the road wheels, and the low reliability of the tank as a whole were the reasons why work on it did not go beyond the prototype stage.

The T-43-2 tank, designed somewhat later, differed from the T-43 in the installation of an anti-aircraft machine gun and a smaller number of drive wheels.

The first mass amphibious combat vehicle of the Red Army was the T-37 tank. The development and production of its prototype was carried out at OKMO. By decree of the USSR Service Station of August 11, 1933, the T-37 was adopted for service, but was not mass-produced.

The documentation for it and the prototype itself were transferred to Moscow plant No. 37. As a result of the deep modernization of this project, taking into account the experience accumulated during the construction and testing of T-41 tanks, the T-37A light amphibious tank was created under the leadership of N.N. Kozyrev . The latter retained the layout of the T-37 hull: the front location of the transmission compartment, the middle location of the control compartment combined with the combat compartment (the driver was on the left, and the commander was on the right), and the aft one was the engine compartment.

The T-37A hull had a riveted-welded structure and was assembled on a frame made of corners. The thickness of the armor plates was 4.6 and 8 mm. On the roof of the turret box, a cylindrical turret was installed on a ball bearing, offset to the starboard side. Its rotation was carried out manually, using handles welded from the inside. It should be noted that production vehicles had two versions of hulls and turrets. The fact is that plant No. 37 only assembled tanks, and the hulls and turrets came from the Podolsk machine-building and Izhora plants.

The armament consisted of a 7.62-mm DT machine gun (2142 rounds of ammunition in 34 magazines), mounted in a ball mount in the front plate of the turret. Without turning the latter, it could be aimed horizontally up to 30° to one side, and vertically from -20° to +30°. To observe the terrain, viewing slits were used in the hull and turret.

Above: Early production T-37 A amphibious tank (without floats). Bottom: T-37TU radio tank. A late production vehicle (with floats) is on display at the Swedish Tank Museum in Axwell. The fastening elements of the handrail antenna, like the ca.ua antenna, have not been preserved

Automobile carburetor 4-cylinder engine GAZ-AA with a power of 40 hp. at 2200 rpm it was located longitudinally, closer to the left side of the car, with the flywheel forward. It allowed the tank to reach a speed of 38 km/h. The power reserve reached 185 km. The tank controls were duplicated.

The transmission consisted of a single-disc main dry friction clutch (simply put, an automobile clutch), a 4-speed gearbox, a driveshaft, a main gear, a bevel differential with shoe brakes (rotation mechanisms) and a water propulsion drive. The latter included a ratchet clutch that connected the toe of the engine crankshaft to the propeller shaft, and a reversing mechanism (rotating the blades).

Movement afloat was provided by a two-bladed propeller. Turning afloat was carried out using a rudder installed in the propeller flow. To pump out water, a special pump was provided at the bottom of the hull. Speed afloat - 6 km/h. To increase displacement, floats filled with cork were attached to the fenders on the left and right.

T-37A

A tank column on Uritsky Square in Leningrad before the parade. November 7, 1936. In the foreground are T-37A and T-37TU tanks with hulls and turrets produced by different factories.

The tank's suspension was blocked, spring-loaded, with two double-roller bogies on each side. The fine-linked track chain was made of malleable cast iron. The combat weight of the tank was 3.2 tons (for the T-37 it was 2.9 tons). Crew: two people.

The tank was in mass production from 1933 to 1936. During this time, Plant No. 37 produced 1,909 linear tanks, 643 T-37TU radio tanks with a 71-TK-1 radio station, equipped with a handrail antenna, and 75 BKhM-4 chemical vehicles. It should be noted that in documents and military literature of those years, T-37A tanks were usually designated simply T-37.

As part of the development of the design of this vehicle, prototypes of the T-37B and T-37V tanks, as well as a prototype of the SU-37 self-propelled gun with a 45-mm cannon, were manufactured.

The chassis units and the engine-transmission unit (with the exception of the propulsion drive) were borrowed from the base tank for the self-propelled guns. A 45-mm 20K tank gun with a standard telescopic sight was installed in the front part of the self-propelled gun's hull. To the left of it, in a ball mount, there was a DT machine gun, to the right was the driver’s seat. The cannon's ammunition consisted of 81 rounds, and the machine gun's ammunition consisted of 1,071 rounds. The crew included two people. The involvement of a driver to service the gun (he acted as a loader) forced him to fire only from a standing position.

The weight of the vehicle increased to 4.5 tons, and therefore one additional support roller was introduced into the chassis on each side. The SU-37 self-propelled gun was significantly superior in firepower to the base vehicle. Its low height—1610 mm—provided good camouflage when conducting ambushes. However, the reliability of the self-propelled guns turned out to be low, and the engine and transmission were overloaded.

T-37A amphibious tanks before crossing a water obstacle

T-37A afloat

However, the design of the base vehicle, the T-37A, also left much to be desired. In this regard, it is not without interest to cite

excerpt from the memoirs of N.A. Astrov, one of the creators of the T-37A. This is what he wrote: “Most of the shortcomings of the T-37A amphibious tankette, and the next one, the T-38, were predetermined by the categorical requirements of the customer. Firstly, be based only on engines of production cars, if possible, and on their other components. Which engines to choose from: ZIS-5 or GAZ-M? The first one was heavy for a small amphibian (452 kg) and did not fit well into its hull. The GAZ-M engine, although low-power (50 hp), was lighter (252 kg) and more compact. His data, together with another mandatory requirement - the car must float - in fact, determined the dimensions of the hull, the weight, the thickness of the armor, the level of armament, and other characteristics.

In addition, the T-37A design suffered from two serious flaws. The brakes of the turning mechanisms, located outside the hull and when afloat, immersed in water, became wet - as a result, the tank temporarily became uncontrollable. And even with dry brakes, due to their extremely poor design, controllability (degree of braking and turning radius) did not always depend on the driver’s intentions and driving conditions. Sometimes it was necessary to slightly correct the direction, but the brake would stick tightly - the tank would make an unexpectedly sharp turn.

The insidiousness of self-locking brakes almost cost me my life. On a hot summer day, we conducted another experiment, trying to increase the tank's swimming speed. We usually went to the Bishop's Pond, which is behind the Preobrazhenskaya Gate in Moscow, or, if a longer swim was required, outside the city, to Bear Lakes. On the way from there everything happened. The experiments that day ended almost without results, and in order to console myself a little, I replaced the regular driver in the T-37A wedge and took control myself.

We had to drive 25 kilometers along the Shchelkovskoe highway. Moving in the middle, I prevented the bus from overtaking the tank, but it was so noisy inside that I didn’t hear its signals for a long time. And having realized what was happening, he carefully turned the control lever to the right to bring the car to the side of the road. Then the right brake grabbed tightly - the tank ended up in a ditch and instantly capsized. The first thing I experienced while the wedge was standing on the tower, and I seemed to be on my head, was bewilderment. Then, as if thinking, the car swayed and lay on its right side - the driver’s seat was on top, on the side not pressed to the ground. But the hatch cover slammed shut in front of me, and the first attempt to open it was unsuccessful. Turning around, I saw a bright yellow flame of gasoline leaking from the tank onto the overheated engine and exhaust pipes.

Self-propelled artillery unit SU-37

It's crap: the tank is about to explode. I realized that the tank had a fire extinguishing device. But, fortunately for me, it didn’t work. The fact is that the fire extinguishing mixture decomposed at high temperatures, turning into phosgene, which, if I swallowed, I would hardly have written these lines. However, it was considered a last resort to fight the fire and the crew uses it as they abandon the vehicle.

He leaned on the hatch cover with all his strength, his head got through, but it turned out to be difficult to get out. Twitching violently, he tore his overalls and jumped out wearing scraps of smoldering pants. Then a group of our vehicles arrived, returning from testing, and people began to throw earth at the burning tankette, fortunately everyone had shovels. It was of little use, and the danger of an explosion remained. We decided to call a fire truck. We succeeded quite quickly, but when we saw a red car flying from Moscow, the tank exploded.

Once at home, I called my superiors and heard a calm response: “Are you safe?” Well, thank God, forget about it.” Indeed, no one ever asked me sensitive questions about the emergency, and the wedge, of course, was written off as scrap metal.

In addition to those already noted, the T-37A had another extremely serious drawback. When we started receiving truck rear axles from GAZ, their differentials started breaking down - strange, unpredictable. Some passed the warranty period flawlessly, others broke down after being unable to withstand the first test. These breakdowns taught me to participate in the inspection of emergency bridges, moreover, to demand that they be dismantled only in my presence. Washing parts yourself gives a lot for understanding the causes of breakdowns and wear, the operation of seals, etc. From my point of view, every designer should not be afraid to get their hands dirty for this purpose. Unfortunately, the job of the chief does not always allow this.

One day, one might say, I was caught at the scene of the crime - at a deep baking sheet with kerosene - by the factory and special machine trust authorities. It was extremely disapproving of this behavior of the chief designer.

Life, however, has given me many examples when such a scrupulous study of details literally helped me out. However, I admit, it did not help to find out the reasons for the mysterious breakdowns of GAZ differentials. Now, after many years, I believe that the friction coefficients of steel axle gears on cast iron differential housings could vary significantly due to the instability of the chemical composition of the metals. But we did not study this characteristic of the cast iron-steel pair, on which the distribution of torque along the axle shafts primarily depends. However, peace be upon the T-37A, “born” Vickers-Carden-Lloyd.

We had to urgently redesign this wedge to free it from other shortcomings. For what? At that time, they firmly believed that a small tank, called a reconnaissance tank, with weak armament (one 7.62 mm machine gun), with bulletproof armor (but floating!) was an absolutely necessary, important type of armored weaponry for the Red Army.”

In 1936, at plant No. 37, under the leadership of the new chief designer N.A. Astrov (appointed to this position in 1934), the T-38 amphibious tank was developed. Then its mass production began.

In terms of its main indicators, it was close to the T-37 tank, however, replacing the differential (which did not provide stable straight-line motion and caused large losses of power when turning) with multi-plate onboard clutches and power take-off to the propeller through a special gearbox significantly increased the maneuverability of the tank.

Small amphibious tank T-38

However, almost immediately after the T-38 entered service with the troops, complaints started coming from the military. During the summer maneuvers of 1937, it became clear that in combat terms the new vehicle was no different from the T-37A and essentially remained the same wedge with a rotating turret as its predecessor. Its small displacement did not allow the T-38 to transport even two infantrymen on its armor through water obstacles. An overload of 120-150 kg during maneuvering afloat resulted in the commander's hatch being overwhelmed by water, as a result of which the tank sank. To improve seaworthiness, on the T-38, on the recommendation of the ABTU, units tried to install floats removed from decommissioned T-37s, but this did not help much. When moving on land, the tank also did not behave in the best way. Its off-road performance also caused criticism - a consequence of insufficient specific power, and the low efficiency of the cooling system led to rapid overheating and engine failure.

The results of the summer maneuvers of 1937 led to the fact that the tank was declared unfit for combat, its production was suspended, and an NKVD commission arrived at plant No. 37. As a result of the investigation, the design bureau of plant No. 37 received the task of modifying the vehicle. Its improved version was given the index T-38M.

In the spring of 1938, two samples of the T-38M tank were manufactured - T-38M-1 and T-38M-2. They differed from the serial “thirty-eighth” by the GAZ M-1 engine with a power of 50 hp. and transmission from the Komsomolets tractor (except for final drives). The drive wheels and suspension bogies were also borrowed from Komsomolets. In addition, the sloth of the T-38M-1 was lowered to the ground. Engine cooling was improved, metal fenders were installed instead of wood, and a new track with higher ridges and reinforced pins was introduced. By analogy with the T-37, the vehicle received duplicate control. Externally, both samples were similar, but the T-38M-1 had a side increased by 100 mm compared to the T-38, and the T-38M-2 - only by 75 mm. As a result, the displacement of the first increased by 600 kg, and the second by 450 kg. The tanks were tested using a new technique specially developed by ABTU, and confirmed the fundamental correctness of the main design changes. However, numerous minor shortcomings reappeared. It got to the point that N.A. Astrov was suspended from work for two months, but then returned to the design bureau. In January 1939, the T-38M tank was put into service. However, it was a kind of synthesized version: a T-38M-1 hull with a radio station, a T-38M-2 chassis, and an improved turret. ABTU demanded that the weapons be strengthened, and by the summer of 1939, a prototype of a welded conical turret with a DK heavy machine gun was developed. True, it was not installed or tested on the tank. And only 15 units of the T-38M tanks themselves were produced in 1939. All of them were used as training ones, since they had dual controls. In 1939, work on modernizing the T-38 was stopped - from the end of 1938, Plant No. 37 was already creating a new amphibious tank, the T-40, which the military was focusing on.

On the basis of the T-38 units, in 1936, two prototypes of the SU-45 self-propelled artillery mount, armed with a 45-mm cannon, were built.

T-38

The first sample had an open top body. The gun and crew were protected in front by an armor shield, and on the sides by folding armor plates. A tarpaulin awning was provided for protection from precipitation. The gun was mounted on a carriage box and secured to the front of the hull. The gun's ammunition consisted of 100 rounds. At the front of the vehicle was a DT machine gun with a bipod for firing at ground and air targets.

In the rear part of the self-propelled gun, separated by an armored partition, there was a GAZ-A engine with an aluminum head. In order to increase the compactness of the power compartment, the engine was located across the body. The engine systems, gearbox and transmission units (drive wheels, final drives, clutches and brakes) were mainly borrowed from the T-38 tank. The chassis was also unified with the T-38 tank, with the exception of the guide wheels taken from the T-37.

The weight of the vehicle was 4.2 tons, the crew was 3 people, the armor was 9 mm. Maximum speed is 45 km/h.

The SU-45 turned out to be too heavy, as a result of which its traction and dynamic qualities turned out to be low and its reliability insufficient.

The second sample had a mass of 3.4 tons, a crew of 2 people. The driver, also known as the gunner, was located on the left, the loader on the right. Ammunition - 51 shots and 1100 rounds. The vehicle was protected by 8 mm armor.

In 1936, equipment for smoke emission and flame throwing was installed on the experimental T-38 in Moscow. At the end of the year, the vehicle successfully passed field tests. It was decided to rework the installation drawings of chemical equipment in relation to the serial T-38. However, the XT-38 tank was not mass-produced.

In 1939, Research Institute No. 20 developed a telemechanical group of tanks, which included the TT-38 teletank, armed with a DT machine gun and a KS-61T flamethrower (ammunition capacity of 1512 rounds and 45 liters of fire mixture), and a TU-38 control tank, armed in a similar way. The teletank could also carry a demolition charge, and the flamethrower could fire 15-16 one-second shots at a range of 28 m.

In 1936 and 1937, Plant No. 37 produced 1,228 T-38 tanks (165 of them with a radio station), then a year-long break followed, and in 1939 another 112 vehicles left the workshop. However, back in 1935, the T-38 began to be produced at the Gorky Automobile Plant, producing 36 tanks of this type. The latter circumstance, apparently, prompted the Gazovites to develop their own amphibian - “to spite” the Muscovites.

Small amphibious tank TM

Small amphibious tank TM during testing

As a result of this unspoken competition, the “Molotov Tank”, or TM, appeared, created on the basis of the T-37. The work on it was directly supervised by the chief engineer of GAZ, V. Danilov. The tank was longer than the T-37: instead of two bogies, road wheels were installed on each side. The weight of the vehicle was 4.5 tons. The conical turret with the DT machine gun was located on the right, the driver's position was on the left. Movement afloat was carried out using a propeller. The main features of the TM include the presence of two GAZ-M1 engines installed in parallel; using normal GAZ-AA disc clutches in combination with GAZ-AAA disc brakes as onboard clutches and blocking engines through the front ends of the crankshafts. Another important innovation was the use of a steering wheel as a control.

In 1937, they managed to produce two TM tanks - one was sent to Kubinka to the NIBT Test Site, the other was left for testing at the plant. In terms of its navigability, it was superior to the T-37A, but had no other significant advantages over the T-38 and was not mass-produced.

To replace the T-37A and T-38 amphibious tanks, the T-40 light amphibious tank, designed under the leadership of chief designer N.A. Astrov, was intended. It was put into service on December 19, 1939 and is considered the best domestic amphibious tank of the pre-war period (more about it in “Armor Collection” No. 4 for 1997, “Light Tanks T-40 and T-60”).