The Soviet light amphibious tank T-38 took part in the fighting on the Khalkhin Gol River in nineteen thirty-eight, during the annexation of Western Ukraine in thirty-nine, during the conflict with Finland. The last time the T-38 was used was during the offensive on the Karelian Isthmus in 1944, on the Svir River. The experience of military testing of the T-37A turned out to be disappointing. As it soon became clear, the design of the machine had many shortcomings. Among them especially

Annoying were the shortcomings in the design of the transmission, which turned out to be insufficiently reliable. In addition, the caterpillars flew off; the buoyancy of the amphibian was insufficient. As a result, the design bureau of plant No. 37 received an order to design a vehicle that would eliminate the shortcomings of the serial tank. The design was supervised by N. Astrov, work on the project began at the end of thirty-four. During the design, the main attention was paid to both eliminating identified deficiencies and improving the reliability of the tank’s components and assemblies.

Development of the tank and the path to production.

In the early summer of 1935, testing began on a new amphibian, which received the military designation T-38. The overall layout of the vehicle was generally the same as that of its predecessor. Although the driver was not on the left, but on the right. Accordingly, the tower was shifted to the left. The components of the serial T-37A are widely used in the design of the tank. The T-38 turned out to be lower and wider, and had no additional floats at all. The armament was left the same, the same DT rifle-caliber machine gun. The design of the tower, with the exception of some details, remains the same. The engine also remained the same, the same GAZ-AA. The engine, together with the main clutch and gearbox, was located along the axis of the vehicle between the commander and driver seats. The chassis of the T-38 is largely borrowed from its predecessor. In particular, the design of the caterpillar and suspension bogies repeated that of the T-37A. The changes affected the drive and guide wheels, which became similar in size to the road wheels. Movement on the water was provided by a three-blade propeller; a flat rudder was used to change the direction of movement. Power was taken for movement from a gearbox mounted on the gearbox. However, the T-38 tank turned out to be insufficiently reliable in operation and during the testing period it often ended up being repaired rather than on the training ground. But, despite this, on February twenty-ninth, nineteen thirty-five, it was accepted into service instead of the T-37A. Both tanks were in production at the same time for some time. The production car differed in details from its prototype. The changes affected both the driver's hatch and the armored hull. An additional road wheel was added to the chassis. The T-38 armored hulls were produced exclusively by the Podolsk plant, which by that time was able to produce in sufficient quantities. In 1936, a number of T-38s with welded turrets were produced from the stock of T-37A, produced by the Izhora plant.

Tactical and technical characteristics of the T-38

Performance characteristics of the T-38 light amphibious tank

| Combat weight, kg. | 3160 |

| Crew, kg. | 2 |

| Overall length, mm. | 3730 |

| Width, mm. | 2220 |

| Height, mm. | 1660 |

| Ground clearance, mm. | 290 |

| Track width, mm. | 200 |

| Armament | |

| Machine guns, pcs x type. | 1 x DT |

| Cartridges, pcs. | 1515 |

| Armor thickness. | |

| Vert. body, mm. | 9 |

| Horizon. body, mm. | 6-4 |

| Tower, mm. | 9 |

| Engine | |

| Type. | 4t/4ts/k/w |

| Brand. | GAZ-AA |

| Power max., hp | 45 |

| At rpm | 2400 |

| Gearbox transmission. | 4/1 |

| Speed max. | 45 |

| Fuel type. | 1st grade gasoline. |

| Tank capacity, l. | 120 |

| Power reserve. | |

| -highway, km. | 240 |

| -country road, km. | 120 |

| Ud. pressure kgf./cm.2 | 0,43 |

| Obstacles to be overcome. | |

| Rise, deg. | 30 |

| Descent, deg. | 30 |

| Ditch, mm. | 1400 |

| Wall, mm. | 600 |

T-38 tank armor scheme

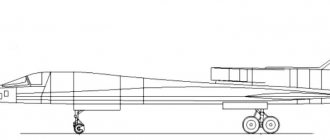

Light tank T-38, manufactured in 1936.

Bottom view. T-38

Design features

The design of the T-28 tractor is based on the concept of the base model DT-24 and advanced technical solutions for its time.

- An original for its time arrangement of the power unit on a semi-frame, integral with the gearbox housing, was used.

- The chassis with unsprung suspension and drive wheels of the rear axle received an additional margin of safety. The technical capabilities of the 28th model were expanded by a wide range of adjustment of the chassis track and front axle ground clearance.

- For more efficient operation of the tractor between rows, it is proposed to replace standard wheels with a set with narrow pneumatic tires. Widening the track due to the reverse installation of wheels increases the safety of the unit on steep terrain.

- There is no shortage of repair and consumable materials. Many spare parts and components of the T-28 are unified with previous models, so the maintainability of the tractor is quite high.

Based on the successful model in many respects, several modifications have been developed, characterized by increased ground clearance, the presence of front-wheel drive, increased to 40-50 hp. power of power plants, extended life of components and individual units.

Photo: T-28 tractor

Improving the design of the T-38

The development of the tank in the series did not mark the end of work to improve its design. In 1936, the tank was equipped with a new type of trolley. When completing the warranty mileage, the new design trolleys showed their advantage. The commission's report on the test results contained proposals to install the M-1 engine to improve the dynamics of the T-38. In addition, the report contained comments that the tracks still continue to fall off on rough terrain, the crew’s jobs leave much to be desired, and the suspension damping does not work well. It was necessary to improve both buoyancy and visibility on the left side for the driver. In 1937, the design of the tank underwent some changes, the most significant being the new type of bogies and the introduction into production of a radio version equipped with a 71-TK-1 radio station and a whip antenna. In the spring of the same year, production of the T-38 had to be stopped due to a large number of complaints received from the army. After the summer maneuvers, the design bureau of plant No. 37 strongly recommended modernizing the T-38 tank. The gist was this:

- increasing the speed of movement;

- improving buoyancy and speed on the water;

- strengthening the tank's armament;

- increasing the service life and reliability of components and assemblies;

- increasing ease of casing;

- unification of components and parts with the Komsomolets tractor.

The modernization process was very slow. The small design bureau was busy ensuring the production of the Komsomolets tractor and work on the T-29 amphibious tank project. Therefore, the first two modernized T-38s saw the light only in the spring of 1938. Only two prototypes of the tank were made - T-38M1 and T-38M2. The vehicles had bogies from the Komsomolets tractor and a 50 hp GAZ M-1 engine. The T-38M1 variant had an armored hull increased in height by 100 mm, which ultimately resulted in an increase in displacement by 600 kg. In addition to this, changes affected the sloth; to reduce longitudinal vibrations, it was moved down one hundred millimeters. The tank is equipped with a radio station. The armored hull of the T-38M2 was increased by 75 millimeters, so that the increase in displacement was 450 kg. The location of the sloth remains the same. The tank did not have a radio station. Otherwise the tanks were identical.

During tests in May-June 1938, both tanks showed their superiority over the serial T-38. ABTU decided to begin mass production of the T-38M, taking into account the identified changes that seemed justified during the testing process. The plan called for mastering the production of the T-38M armored hull by the beginning of 1939. However, they were able to receive the first buildings only in February. As a result, the first three T-38Ms left the workshop in April 1938. After passing the tests, interest in these tanks waned. The T-40 tank seemed more promising at that time. Therefore, the order was limited to a pilot batch of seven vehicles, which were later used as training vehicles. In 1939, Plant No. 37 received an order to produce 122 non-modernized T-38s, using the backlog of armored hulls preserved from the year thirty-seven. In total, over the years of production, 1,175 linear tanks and 165 radio-powered T-38s were produced, including 7 T-38Ms.

On pure enthusiasm

By the beginning of 1943, a twofold situation had developed. On the one hand, due to the gradual wear and tear of existing equipment both in agriculture and at the front, an urgent need for tractors arose. On the other hand, during the war a turning point came, and the state had the opportunity to allocate funds for the restoration and development of industry.

NATI was entrusted with the development of a medium-power caterpillar tractor that could be used both for arable and row cropping. At the same time, in Lipetsk, based on the surviving buildings of Stankostroy, the construction of a plant began to produce a new model.

Of course, establishing production in wartime conditions is not an easy task. There were not enough funds and equipment. The plant did not have steel casting shops, so many parts had to be imported from other enterprises. There were no machines for cold stamping. Instead, some parts were simply cut out by hand.

There weren't enough staff either. Designers, technologists, and workers at tractor factories were recalled from the ranks of the Red Army. Many of the employees of the new enterprise were private soldiers who returned from injury. In fact, both construction and production were based on the same enthusiasm. However, the plant was restored as soon as possible and by the end of 1944 it produced 5 cars.

Light tank shielding

Based on the results of the use of tanks during the Spanish Civil War, the T-38 with a shielded hull was tested in the second and third quarter of 1938. In accordance with the assignment, the side and frontal armor of the tank was strengthened. No other information or test results were found. In 1941, VAMM students developed a design for reinforced concrete armor for the T-38. In essence, it was a removable formwork, which made it possible to fill the armor with concrete immediately before the battle and dismantle it after, if the need arose. However, the war interrupted further work on this topic. They returned to the idea of shielding again at the beginning of the war. According to the project developed at the NIBT test site, a 12-mm armor sheet was attached to the top sheet of the T-38. The sheet was installed in such a way that it covered the turret box and had a cutout for observation by the driver. Screens also covered the upper part of the side and forehead of the tower. The shelling tests showed quite satisfactory results, but work on this topic was stopped in October 1941.

Specifications

The following data refers to the T-38M model, while the data in the information field refers to the first version of the T-38 from 1958.

- Engine: four-cylinder four-stroke diesel engine

- Engine type: D-48L

- Power: 50 hp (37 kW)

- Engine capacity: 4.50 l

- Cylinder diameter: 105 mm

- Piston stroke: 130 mm

- specific fuel consumption: 200 g/PSh (272 g/kWh)

- Tank capacity: 115 l

- Starter: single-cylinder petrol engine PD-10M.

- Engine weight: 660 kg

- Transmission type: manual transmission with five forward and one reverse gears

- Maximum speeds: forward: 4.32-10.30 km/h

- reverse: 4.03 km/h

Dimensions and weight

- Ground clearance: 640 mm

- Track width: 1340 mm

- Wheelbase between sprockets: 1740 mm

- Weight: 3950 kg

- Power-to-weight: 79 kg/hp or 12.66 hp / T

- specific ground pressure: 0.4 kg/cm²

20 mm cannon in a tank. A new attempt to strengthen weapons

A new attempt to strengthen the armament of the T-38 was made in the summer of 1941. Then the staff of the NIBT test site rearmed a couple of tanks with a 20-mm ShVAK cannon. According to documents, such vehicles were designated as T-38SH or T-38SHVAK. The tanks were handed over to OKB-16, where some changes were made to the design to ensure ease of loading, holding and the ability to fire single shots. At the beginning of August, the gun was installed in the tank and sent for testing. In the process, many shortcomings were revealed. The most significant was the lack of a machine gun, which did not allow rational use of the gun's ammunition. When firing from a cannon in bursts, there was such strong vibration that the turret temporarily jammed. The unsuccessful design of the sight did not make it possible to fire further than three hundred meters. In addition, the commander’s firing was not convenient enough. Despite all the shortcomings, the rearmament experience was considered successful and thus another T-38 was rearmed. No further testing of tanks of this modification is known. On October 1, 1941, by order of People's Commissar Malyshev, work on these tanks, as well as on shielding the T-38 and T-40, was stopped.

Attachments

- snow removal/utility blade;

- utility brush (suitable for models T30, T25, T45);

- double/four-furrow plow;

- potato digger of screening type;

- universal single-row/double-row potato planter;

- cutter-cultivator (2.1 m);

- shovel;

- hydraulic rakes;

- fertilizer diffuser;

- three-row cultivator-hiller;

- rakes;

- rotary rakes;

- rotary mower type Zarya;

- disc harrow.

All attachments from Belarus tractors and mini tractors are successfully suitable for T-30 devices and modifications.

Further modification

The developers took into account the main shortcomings of the brainchild, made a number of improvements, and in 1961 the next modification appeared - the T-38M tractor.

The main thing was to increase the power of the power unit to 50 hp. With. The maximum speed increased to 10.3 km/h.

The upgrades made did not improve the performance of the machine. Nevertheless, they were produced for a long time at the Lipetsk and Vladimir plants, producing a total of 26,300 units in the T-38 modification, 103,800 units in the T-38M modification.

Having been on the assembly line from 1958 to 1973, it gave way to modern and productive technology.

Price of the T-28 tractor and its modifications

Production of this model has been stopped for quite some time, so the chances of purchasing a car with zero mileage are minimal. For the most part, future owners realize their plans by purchasing a used car that has a given remaining service life.

There are offers on the tractor market, the cost of which varies over a fairly wide range. The price of a tractor in satisfactory technical condition is in the range of 35-40 thousand UAH ($1300 - 1500), overhauled or with a set of working equipment at the level of 80-100 thousand UAH ($3000 - 4000).

A large assortment of spare parts makes it possible to completely restore power characteristics, but the economic side of such a project is partially or completely at risk.

Video: review of the T-28 X4M-A tractor

Tractor LTZ-55: technical characteristics, features and reviews

The LTZ-55 tractor was produced for many years at the Lipetsk Tractor Plant. Over the entire period, more than one thousand units of equipment have entered the market. Tractors of this class were produced mostly as specialized equipment for agriculture and public utilities. Despite this, the machine has become widespread in other areas.

This model has managed to seriously compete with foreign-made analogues. An advantageous feature of domestic products was the price, which was significantly lower than for imported goods. And the quality of the equipment was not inferior, and in some indicators it even surpassed its analogues. Despite the withdrawal of the tractor from production, there remains a demand for it. These models of equipment are used in many CIS countries.