Home / Military equipment / Soviet light tank T-26

T-26RT with a conical turret

The history of the T-26 tank is more than just the history of an armored fighting vehicle. This is the history of the emergence of a tank design school in the USSR and the history of the creation of mass production of tanks in the Soviet Union.

Combat use of T-26 tanks

Tank T-26RT model 1933

Quite a lot has been written today about the combat use of T-26 tanks and I simply don’t want to repeat myself, for the reason that I did not participate in these battles and cannot add anything to what has already been written. But I don’t want to invent it.

I have a desire to do an analysis of this combat use.

During the battles in Spain, the tanks performed generally well. On that battlefield they simply had no rivals - German and Italian vehicles were inferior to the Soviet T-26 in all respects. But already in Spain it became clear that this tank had extremely weak armor and with the appearance of anti-tank artillery (even small-caliber) on the battlefield, all the advantages of the Soviet tank ended.

The battles on Lake Khasan, on the Khalkhin Gol River and in Finland only proved the need to have tanks with ballistic armor in service. Light tanks cannot be used to break through prepared enemy defenses. The training and heroism of tank crews does not save these crews from armor-piercing shells and even from large-caliber armor-piercing bullets.

By the beginning of the Great Patriotic War, the Red Army had more than 8,500 T-26 tanks. We can say that as of June 22, 1941, these vehicles were outdated and did not correspond to the realities of the war that had begun. However, the T-26 fought quite successfully with Wehrmacht light tanks. But the time of the T-26 has already passed. It passed quite quickly for the simple reason that tank building at that time was moving forward by leaps and bounds and light tanks had to leave the battlefield in the history of tank building.

In the mid-thirties, the Tank-26 was, without any exaggeration, one of the best light tanks in the world. And, what is very important, this tank made it possible to create a tank industry and a design school in the USSR.

Of course, if this tank had not existed, there would have been another one. But there was a light tank T-26.

Tank T-26 model 1933

Tank T-26 model 1933

Tank T-26 model 1933

Tank T-26 model 1933

Tank T-26 model 1933

Tank T-26 model 1933

Aug 23, 2022 admin Tags: military equipment 8553

Share this post

- Related Posts

- T-90 versus Abrams. What will we measure with?

- Soviet light fast tank BT-5

- How the Russians will destroy all American aircraft carriers: American experts named five ways

- PAK FA T-50 vs F-22 Raptor. Virtual fight

Light infantry escort tank T-26 Part 2

Home » Alternative tank building » Light infantry escort tank T-26 Part 2

Editor's Choice Alternative Tank Building

Bull 11/18/2018 2290

17

in Favoritesin Favoritesfrom Favorites 8

On October 26, 1932, by order of the People's Commissar of Heavy Engineering G. Ordzhonikidze, the Special Engineering Trust (SPETSMASHTREST) was created as part of the Leningrad Plant named after. Voroshilov (former), , 2nd VATO plant in Moscow, Kharkov Locomotive Plant (KhPZ) named after. Comintern and workshop No. 112. The leadership of the newly formed trust was tasked not only with ensuring the mass production of tanks in production, but also with carrying out development work to create new, more advanced combat vehicles.

Most of the factories included in the trust produced tanks from 1927-1929. Moreover, if at the plant named after. Voroshilov, and at the 2nd VATO plant this production was already serial in nature by the fall of 1932, then KhPZ was preparing for large-scale production of rather complex wheeled-tracked tanks. , which previously specialized mainly in the production of machine tools and spare parts for tractors, from 1932 was also transferred to the production of tank parts for the plant named after. Voroshilov, as well as repair of MT-6 engines for KhPZ and Krasny Sormovo. In 1932, a pilot plant of Spetsmashtrest was also established, which in 1936 received its own number “No. 185”. In 1933-1934. The trust also included repair plants No. 104 and No. 105, the Kiev plant named after. V.Ya. Chubar and the Kharkov Automobile Assembly Plant (since 1936, plant No. 48), a special workshop of the AMO-ZIS plant and a motor production plant in Yaroslavl (construction began in 1933).

Actually, it was thanks to the creation of the trust that the development of tanks created on the basis of equipment purchased abroad was carried out in a relatively short time using domestic equipment from domestic materials. In the USSR, a very extensive annual tank construction program was planned, which provided for the production of up to 10,000 combat vehicles of all classes: 3,000 pcs. – light tanks, 5000 pcs. – wedges, 1500 pcs. – maneuverable and 500 pcs. - heavy, which was, however, reduced by the beginning of 1932 to 8100 units. (due to limiting the order for wedges from 5000 to 3100 pcs.). The implementation of this program directly depended on the provision of factories with domestic and imported equipment, the necessary range of raw materials, semi-finished products and units.

The projected widespread cooperation of production among the trust's factories, due to difficulties in their mastering the parts planned according to the plan and failure to meet delivery deadlines, could disrupt the implementation of the tank construction program. At the beginning of the second half of the year, it became clear that it was impossible to obtain the necessary equipment and difficulties in supplying production with tools and devices. This situation was aggravated by the already unsatisfactory production planning at the factories and the lack of a precisely established technical process for the production of tanks. Taking into account the capacities of the factories and their experience in creating complex vehicles, the Council of People's Commissars decided on widespread cooperation between tank builders and other related enterprises. It should be noted that the production of a number of complex parts and assemblies was first installed at cooperative factories and required a certain period of development. Along with the need to retrofit factories, the growth of the program required the attraction of a large number of new workers, mostly highly qualified, and specially trained engineering and technical personnel. Thus, given the 17 thousand workers employed in the production of tanks in 1931, by the end of 1932 it was planned to increase their number to 28,500 people. However, this was extremely difficult to achieve, especially considering the catastrophic lack of special educational institutions. Poor qualifications of the workforce coupled with undeveloped production, the novelty of the program and frequent changes made to the designs of basic products often led to defects. At the same time, the size of the defects was obtained not only due to the factories of the trust, but also to a large extent due to the fault of cooperative enterprises in other industries. All this determined by the end of 1932 the impossibility of the factories fulfilling the planned production program, as a result of which the plan was revised by the government towards its reduction, and the question of expanding the special machinery for the production of modern armored vehicles was also raised. As a result, the special workshops of car factories were included in the trust.

In 1932, the tank production and experimental design engineering department (OKMO) of Leningradsky were transformed into the Leningrad State Plant No. 174 named after K. E. Voroshilov. In 1933, OKMO was separated from plant No. 174 and the Leningrad Experimental Mechanical Engineering Plant No. 185 named after S. M. Kirov was formed. At this point, OKMO prepared a new model of the T-26 tank. Actually, the hull of the tank has remained virtually unchanged, but the armament and turret have changed. At the same time, the tank became three-seater. The armor of the T-26 tank also changed - the frontal, rear, side armor and turret armor began to be made of homogeneous armor 15 mm thick. The armor could not be penetrated by an armor-piercing rifle bullet, and there were no other requirements for the tank’s armor. This T-26 model was equipped with a commander's cupola of a simplified design - without a dome. This excluded natural ventilation of the fighting compartment. When the engine was running, ventilation of the fuel tank was carried out using an engine cooling fan. The suction of gases and air was carried out through a hatch that opened in the fire partition from the fighting compartment to the engine compartment. The tank commander combined the duties of loader and radio operator. In emergency situations, the gunner had the opportunity to load the gun himself. Why was there a first-stage ammunition rack located on the wall of the tower. Otherwise the tank remained the same.

In March 1932, the Red Army adopted the 45-mm 19K anti-tank gun, developed at Plant No. 8. Following this, they designed the 19K installation in a tank, which was called the “45-mm tank gun model 1932.” and factory index 20K. Compared to the 5K, the 20K tank gun had a number of advantages. The armor penetration of armor-piercing projectiles increased slightly, the mass of the fragmentation projectile increased sharply (from 0.645 kg to 2.15 kg), and the mass of the explosive in the projectile increased from 22 g to 118 g. Finally, the rate of fire was increased due to the introduction of a vertical wedge semi-automatic bolt. True, the debugging of semi-automatics took about four years, and the first series of 20K guns were produced with 1/4 automatic, then with semi-automatic for armor-piercing and 1/4 automatic for high-explosive fragmentation shells, and only in 1935 guns with well-functioning semi-automatic for all began to arrive types of ammunition.

In December 1932, the Defense Committee ordered the NKTP to produce T-26 tanks (starting with the vehicle with serial number 1601) with a 45-mm cannon. A new turret was designed for this cannon, coaxial with a DT machine gun, for the T-26 and T-23 tanks. Firing tests showed its complete reliability. Production of turrets for the 45-mm cannon began at the end of 1932 at two factories - Izhora and Mariupol. The first produced towers of an improved type (welded with a large niche), and Mariupol produced the first 230 towers according to the first option (riveted with a small niche). Turrets from the Mariupol plant were installed on T-23B1 tanks. And the T-26B tank was initially produced with a turret from the Izhora plant.

On March 17, 1932, by order of M. Tukhachevsky, one T-26 was transferred to the disposal of the Scientific Testing Institute of Communications. Here work was underway to create special tank communications equipment. The institute developed a special technique for maintaining communications in tank forces and proposed devices for its implementation, which were soon put into service. According to the methodology for communicating tanks in parking lots, in defense, in ambush and in a town, each tank was equipped with a special telephone with a push-button call. The platoon commander's car had a mini-switchboard for 6 subscribers instead of a telephone. For the convenience of laying cables, a special terminal box was installed in the rear of the tanks with a plug connector, to which communications delegates had to connect a two-wire line from the line vehicle to the commander’s vehicle or to connect to the telephone network of rifle units. When the tank started moving, the plug connector was torn and the connection stopped. In 1934, this system was modified - an armored box with a lid containing a telephone was mounted on the rear plate of the tank. The telephone was intended to communicate with the infantrymen directly following the tank. This telephone had a mutual call - that is, both the tank commander could call the infantry squad commander for communication, and the infantry squad commander could call the tank commander. Naturally, the phone could only be used when the tank was stationary.

The tanks of the platoon commander and above were supposed to be equipped with a simplex radio station with a communication range of up to 10 km. In September 1932, the first ten tanks with the experimental radio station TK-71-1 entered testing. All tanks received handrail antennas, the mounting posts of which were installed on the walls of the turret. The antenna input was located on the roof of the tower. The tests were successful, and the tank was officially put into service on January 1, 1933 under the designation T-26A2. But its mass production was not launched, as the plant was preparing to release a new model of the tank.

Already in 1933, 71-TK-1 radio stations, which had handrail antennas similar to the T-26A2 tank, began to be installed on some T-26B tanks. This modification received the index T-26B1. And if in the first year of production of the T-26B, the percentage of T-26B1 radio tanks was small (apparently due to the lack of the required number of radio stations). Then later it amounted to half, and then exceeded the number of tanks without radio stations. However, the 1934 exercises showed an unsightly picture: on the “battlefield,” tanks quickly turned into a herd of armored monsters. Joyfully jumping behind their leader - the radio tank of the unit commander. There was no question of any control over the battle. During the debriefing of the exercises, this issue was discussed with the high command of the Red Army and members of the government. The conclusion suggested itself - every tank should be radio-equipped, but the cost of the issue was not trivial. In the end they came to the conclusion: “... the loss of control, as well as the loss of the entire unit, due to the loss of control, is much more expensive than the cost of the radios on these tanks...”. Money was found and from November 1934 all tanks were produced in the T-26B1 modification.

Since 1934, the modernized version 71-TK-2 was adopted, and from 1935 - 71-TK-3. 71-TK-3 was a special tank shortwave simplex telephone and telegraph radio station and had an operating range of 4-5.625 MHz, consisting of 65 fixed frequencies spaced 25 kHz apart. The maximum communication range in telephone mode was 15-18 km in motion and 25-30 km from a standstill, in telegraph mode - up to 40 km; in the presence of interference from the simultaneous operation of many radio stations, the communication range could be reduced by half. The radio station had a mass of 60 kg and an occupied volume of about 60 dm³ (dimensions of the transmitter with a shock-absorbing frame: 362 × 260 × 237 mm. Dimensions of the receiver with a shock-absorbing frame: 432 × 246 × 236 mm). For internal communication between the tank commander and the driver, early tanks used a speaking tube, which was later replaced by a flashing device. Since 1935, tanks equipped with a radio station have been equipped with a tank intercom - TPU-3, for all crew members.

The development of the tank in other areas also continued. Since the 45-mm cannon, when firing with the engine turned off, created an unacceptable concentration of powder gases in the tank, in 1934 a fan was introduced on the right side of the roof of the fighting compartment. In 1935-1936, the transition to welded hulls was finally completed, and the labor-intensive welded gun mantlet was replaced in 1935 by a stamped one. Among the planned measures to increase mobility, the gearbox and final drives were improved. A number of other changes were introduced aimed at reducing production costs and increasing operational reliability. From the end of 1935, the T-26 began to be equipped with an additional ball mount with a DT-29 machine gun in the rear turret, and some machine guns began to be equipped with optical sights instead of diopter ones. At the end of 1935, a pin anti-aircraft machine gun mount was developed for the tank, still with the same DT-29, but based on the results of tests among the troops, it was considered inconvenient and, after modification, it went into mass production only in 1936. In addition, since 1935, for every fifth tank, the T-26 for combat operations at night began to be equipped with two spotlights mounted on the gun mantlet - the so-called “combat light headlights”.

The T-26 tank was exported abroad: to Afghanistan - two tanks of the first T-26 production, Turkey - two tanks of the first T-26 production and 64 tanks of the T-26B modification, to China 82 T-26B tanks and Spain - 297 T- tanks 26B. All export tanks are old tanks that have undergone major repairs; they did not have radios.

Light infantry escort tank T-26B1

Tank T-26B1: combat weight 10.4 tons, length - 4.63 m, width - 2.34 m, height - 2.375 m, ground clearance 0.38 m. Reservation: front, side, rear, turret - 15 mm, roof 8 mm, bottom – 6 mm. Armament: 45 mm 20K cannon (96 rounds), 7.62 mm TD-29 machine gun (2142 rounds). Engine: 4MT-21 with a power of 122 hp, maximum speed - 40 km/h, highway range - 240 km, crew - 3 people.

By 1935, in terms of combat qualities and reliability, the T-26B1 tank finally began to meet the requirements for a light infantry tank laid down during its design in 1931. But time and the World do not stand still. In 1935, intelligence reported the development, adoption and start of production of anti-tank rifles in Poland. In addition, it was reported that Poland had purchased a small number of Hotchkiss heavy machine guns. There was information that the Polish government was negotiating with the Hotchkiss company about establishing licensed production of these machine guns in Poland. There was no data on the armor penetration of Polish anti-tank rifles. But each 13.2 mm Hotchkiss machine gun mod. 1930, there was enough information. And this machine gun penetrated up to 30 mm of armor with a special armor-piercing bullet from a distance of up to 200 m. Similar information was received from Japan. There, at the production sites of the Yokosuka (for the navy) and Tachikawa (for the army) arsenals, the production of the Type 93 heavy machine gun, a licensed version of the same Hotchkiss Mle 1930, was underway. The threat was considered real, and an impartial analysis of the armor of serial vehicles showed that satisfactory protection They only have the AT-3 assault self-propelled gun, the T-28 heavy tank and the super-heavy T-29. At a meeting of the leadership of the Red Army and the GAU, it was decided to bring the armor of mass-produced tanks to the optimal minimum: frontal armor - 37 mm, side armor - 25. However, for the KhPZ tanks the task turned out to be very difficult. For the T-23 and T-24 tanks, the suspension had to be re-developed. But the T-26 and T-22 infantry tanks successfully underwent another modernization - to compensate for the increased weight, the designers of these vehicles simply added additional road wheels. This is how the new T-26V model appeared. And although it was a completely new vehicle - albeit made on the basis and therefore very similar to its predecessor T-26B1, the index was assigned to it as a tank that had undergone another modernization.

The combat weight approached 14 tons. Added rollers in the suspension compensated for the weight gain; now eight road wheels were installed on each side. The increased weight required an increase in the area of the supporting surface and the tracks had to be made new (increased from 260 to 360 mm, the pitch of the links did not change). The track and the combat weight pulled along the road wheels themselves, the idler, and the drive sprocket. The final drives, clutches, cardan and gearbox were strengthened. The engine was replaced with an 8MT-21 with a power of 240 hp. – V-shaped, air-cooled. The engine cooling system has been changed.

T-26V tank engine

Tank engine 8MT-21: designed on the basis of the crankcase of the M-6 aviation engine and the cylinder-piston group of the M-12 aviation engine. Developed by NAMI (A. A. Mikulin). Displacement – 16.32 l, cylinder diameter – 125.2 mm, piston stroke – 163.4 mm, compression ratio – 5.1, motor length – 1.32 m, motor width (without fan) – 0.97 m , motor height (without fan) - 0.79 m, power - 240 hp, engine weight - 241 kg.

The engine cooling fan was mounted on the drive disk of the main clutch. To compactly accommodate the 8MT-21 engine with a fan, the tank body was lengthened by 320 mm. The fan sucked air from the engine compartment through the louvres in the roof of the engine compartment near the turret box - an oil cooler was installed on the first stage louvers (on the starboard side). The fan then forced air into the cylinder chambers, cooling the engine. The heated air came out through holes in the roof of the MO, closed with a fine mesh. To maintain a large volume of fuel tanks and to ensure the dimensions of the blower fan, the engine was raised with a minimum gap between the MO roof and the cylinder heads. In order for the cardan to remain at the same level in the BO, it was coupled to the main clutch through a gearbox. To the right and left of the engine, behind the inclined fire barriers, there were fuel tanks. The supply of gasoline, on a good road, was enough for 220 km of travel.

Scheme of engine placement in the T-26V tank (cross section)

Thanks to the new onboard clutches and gearbox, it was possible to move the driver's workplace 30 mm forward. This made it possible to leave the hatch in the roof of the turret box at the same level, despite the increase in the dimensions of the turret due to thicker frontal armor. Otherwise, the body has not changed, although it has become completely welded, without a frame. The thickness of the vertical frontal armor plates of the tank was increased to 37 mm, and the side and rear plates to 25 mm. The roof and bottom were made from 10 mm sheets.

The tower became three-seater. The designers complied with the military's requirements to equip a workplace for a tank commander freed from other duties. True, he still performed the duties of a radio operator. The design of the turret was based on the turret of the T-26B1 tank. But it had a more developed rear niche, in which the tank commander was placed. The tank commander sat on a rotating seat, his legs dangling to the right and left of the cartridge case catcher. However, among the troops, tank commanders quickly began to use a different method of landing - they simply knelt on a rotating seat. Fortunately, the high commander's turret made it possible to do this. The aft niche was asymmetrical - on the starboard side it had a larger protrusion - the 73TK-3 radio station was located there. The new radio station allowed the use of a whip antenna and the bulky handrail antenna was abandoned. The tower was assembled from two curved vertical sheets - the frontal one, 37 mm thick. And stern, 25 mm thick. The ability to bend armor plates of such thickness was provided by a hundred-ton press purchased in Germany for the production of T-28 and T-29 tanks. Which was installed at the Izhora plant.

The production of a new tank required the development of a new engine. And although the 8MT21 and 4MT-21 motors were structurally identical, since the 4MT-21 was just half of another, the new motor was more complex. But the main thing is that the new tank required modernization of production. It was necessary to install an assembly line for a tank weighing up to 15 tons. Therefore, in May 1936, tank production at plant No. 174 was suspended and reconstruction began. Eight months later, on December 23, the plant assembled the first T-26B tank.

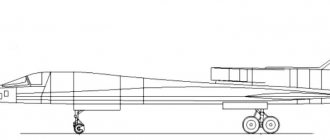

T-26V infantry escort tank

T-26V tank: combat weight 13.6 tons, length - 4.95 m, width - 2.46 m, height - 2.46 m, ground clearance 0.4 m. Reservation: front - 37 mm, side and rear - 25 mm, turret front – 37 mm, side and rear – 25 mm, roof and bottom – 10 mm. Armament: 45 mm 20K cannon (98 rounds), 7.62 mm TD-29 machine gun (2034 rounds). Engine: 8MT-21 with a power of 240 hp, maximum speed - 46 km/h, highway range - 220 km, crew - 4 people.

It should be mentioned that the T-26V tank also played a role in the political arena in the USSR. The modernized version of the light infantry tank (however, by that time they had stopped calling it “light”) was much more expensive than its predecessor and required a restructuring of production - also an expensive pleasure, by the way. People's Commissar of Defense M.N. Tukhachevsky, based on calculations, spoke out in favor of abandoning the production of this vehicle (as well as all modernized vehicles under the program to increase armor protection). Tukhachevsky was supported by the chief of armaments of the Red Army, I.A. Khalepsky. and the head of the Main Directorate of Mechanization and Motorization of the Red Army G. G. Bokis. Despite the fact that it was Tukhachevsky who initiated the modernization program to enhance the armor protection of all production tanks in 1935, the marshal called the program erroneous due to the high cost and a sharp decrease in the rate of production of tanks. The change in views of the People's Commissar of Defense M.N. Tukhachevsky became the reason for the proceedings along party lines. In addition, bad news came from Spain, where the civil war was going on - our tanks with bulletproof armor were defenseless against the increased capabilities of anti-tank guns. As a result, Tukhachevsky was removed from the post of People's Commissar of Defense and sent to the Turkestan Military District, and the T-26V tank was accepted for service and put into production.

Based on materials: https://www.redov.ru/transport_i_aviacija/tankovaja_mosh_sssr_chast_i_uvertyura/p9.php