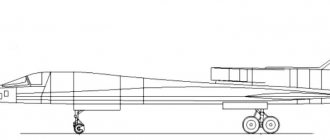

SU-100, Self-propelled artillery unit

Self-propelled gun SU-100

By mid-1944, it became completely clear that the existing means of combating the latest German tanks were clearly insufficient. It was necessary to qualitatively strengthen the power of the tank units of the Red Army.

The issue of increasing firepower was resolved by using on the self-propelled gun a gun with the ballistics of a 100-mm B-34 naval gun. The preliminary design of the vehicle was handed over to the People's Commissariat of Tank Industry and the Self-Propelled Artillery Directorate in December 1943. On December 27, 1943, the State Defense Committee adopted Resolution No. 4851 on arming a medium self-propelled gun with a 100 mm gun. To implement this resolution, the NKTP, by order No. 765 of December 28, 1943, ordered Uralmashzavod:

1. By 01/15/44, design a medium self-propelled gun based on the units of the T-34 tank and arm it with a 100-mm S-34 cannon designed by TsAKB; 2. By 02/20/44, manufacture and conduct factory tests of the self-propelled gun. The gun must be delivered from factory No. 92 by 01/25/44; 3. By 02/25/44, submit the self-propelled gun for state testing.

The deadlines were very strict. Having received the drawings of the S-34 gun at Uralmash, they were convinced that this gun was not suitable for self-propelled guns: it had impressive dimensions, when pointed to the left, it rested on the second suspension, and did not allow the driver’s hatch to be placed. Major changes were needed in the body of the self-propelled gun, including in its geometric design.

This entailed changing the welding and assembly stands. It was necessary to switch to a torsion bar suspension, shift the driver's workplace and all vehicle control units 100 mm to the left, expand the upper part of the hull to match the dimensions of the tracks, which would cause an increase in the weight of the self-propelled guns by 3.5 tons compared to the SU-85. At the same time, the TsAKB took an irreconcilable departmental position: while giving its S-34 tank gun for installation on the self-propelled gun, it demanded that it be used without changes and insisted on adapting the self-propelled gun to the gun. Uralmash turned to Plant No. 9, and by mid-1944, under the leadership of F.F. Petrov, a new 100-mm D-10S gun was designed. The D-10S was created on the basis of the D-10 naval anti-aircraft gun, which was lighter than the S-34 and was installed in a serial hull without significant changes to it and without excessively increasing the weight of the vehicle. Using this gun and the chassis of the T-34/85 tank, Uralmash designers quickly developed a new self-propelled gun, which later received the index SU-100.

The SU-100 had exceptionally high firepower and was capable of fighting enemy tanks at all aimed fire distances.

The armor-piercing shell of its 100-mm cannon from a distance of 2 thousand meters hit armor 139 mm thick, and at a distance of up to a kilometer pierced German tanks almost right through. Serial production of the new self-propelled artillery mount began in September 1944, and by the end of that year the factories had produced about 500 of these formidable combat vehicles.

The SU-100 had a classic layout for its time. The fighting compartment, combined with the control compartment, was located in the front part of the hull, in the conning tower. It housed controls, weapons with sighting devices, ammunition, a radio station with a tank intercom, front fuel tanks and some tools and spare parts.

The engine compartment was located directly behind the combat compartment and was separated from it by a special partition. The transmission compartment was located in the rear of the hull. It housed the main clutch, a five-speed gearbox, side clutches with brakes and final drives. In addition, there were two fuel tanks and two inertial oil air cleaners. The capacity of all internal fuel tanks was 400 liters, which provided the vehicle with a cruising range of 310 km.

The chassis of the self-propelled gun is similar to the chassis of the T-34 tank. In the right front part of the fighting compartment, a 100mm D-10S cannon was installed in the frontal plate of the hull. It had two sights: telescopic and panoramic. The practical rate of fire of the gun is 5-6 rounds per minute. Ammunition - 33 rounds of unitary loading.

The shortwave radio station provided reliable communications at a range of up to 25 km. In the front left corner of the cabin there is a place for the driver, opposite whom there was a rectangular hatch in the front plate. Two prismatic viewing devices were installed in the hatch cover. To the right of the gun is the vehicle commander’s workplace. Behind the driver's seat is the gunner's seat, and in the left rear corner of the fighting compartment is the loader's seat. In the roof of the fighting compartment there were two rectangular hatches for the crew, two fans under the hoods and a fixed commander's cupola. There are five viewing slots with armored glass in the turret walls, and periscope viewing devices were installed in the turret hatch cover and in the left wing of the gunner's hatch cover.

The gun's fixed armor was cast and had a complex configuration, and was bolted to the front plate of the hull. From the outside, the gun installation was protected by a movable armored spherical mask. The armored body of the SU-100 was a rigid armor box made of rolled armor plates and consisted of a bottom, front and rear parts, sides and a roof of the engine and transmission compartment. The bottom was assembled from four sheets, connected by welding and reinforced with special overlays. In the middle part of the bottom on the right there was an emergency exit hatch for the crew, the cover of which folded down to the right. The front part of the hull was formed by upper and lower inclined armor plates. The tilt of the upper frontal armor plate is 50°. In the lower frontal plate on the right there is a rectangular hatch for access to the track tensioning mechanism; in the top there is a cutout for installing a gun, as well as a driver's hatch. At the bottom of the sheet, two towing hooks were welded to the left and right.

The side of the SU-100 consisted of upper and lower parts. At the front, a tension wheel bracket was welded to the lower side sheet. The upper side sheet consisted of two parts - front and back, and the last sheet was installed with a greater slope than the front one. Landing handrails, brackets for external fuel tanks and attachment points for spare parts and accessories were attached to the upper side sheets. Along the sides there were fender shelves, on which boxes for various accessories were installed, one on the left front and one on the rear right.

The stern of the self-propelled gun consisted of two inclined sheets - the upper folding one, in the center of which there was a hatch with a cover, to the right and left of the hatch there were cutouts with armored caps for exhaust pipes, and the lower one, on which the final drive housings were mounted, two tow hooks and two mounting loops for the upper folding armor plate. In front of the roof of the fighting compartment, there was a commander's cupola on the right, and to the left of it was the cap of the gun mounting bracket. There was also a rectangular panorama hatch. The hatch for the entry and exit of the crew is at the rear of the roof.

The engine compartment was covered with three armor plates. The middle one had a rectangular engine hatch, the side ones had longitudinal shutter windows and three hatches for access to the oil tanks and suspension shafts of the fourth and fifth road wheels. On top, the side sheets were covered with convex armored caps with meshes for air passage to the blinds. The transmission compartment had a hinged convex sheet metal lid with five windows covered with mesh.

In February 1944, the first prototype passed factory tests, consisting of 30 shots and 150 km of run. From March 9 to March 27, state tests were held at ANIOP in Gorokhovets, where the self-propelled gun fired 1040 rounds and covered 864 km. In its conclusion, the commission noted that the prototype had passed the test and could be adopted by the Red Army after making some changes. On April 14, the plant was ordered to immediately prepare for mass production of the SU-100. However, the TsAKB again demanded the formal implementation of the GKO resolution, that is, the production of an experimental self-propelled gun with the S-34 cannon. Negotiations and correspondence on this issue began again. As a result, a decision was made to partially rework the S-34 cannon, which was originally designed to arm the IS-2 heavy tank.

The alteration, which consisted of reducing the width of the cradle by 160 mm, making new insert pins, a new frame, rotating mechanism, traveling mount, removing the boss for the coaxial machine gun and installing a sight, was carried out at factory No. 9.

The self-propelled gun with the S-34 gun received the index SU-100-2. At the same time, a second prototype of the SU-100 self-propelled gun was built, which became the flagship for serial production vehicles and included all the improvements recommended by the state commission. Its tests took place at ANIOP from June 24 to June 28, 1944. After firing 923 rounds and running 250 km, the state commission recognized that “the tactical and technical indicators of the SU-100 ensure the successful defeat of modern enemy armored vehicles at distances of 1500 meters for the Tiger and Panther tanks, regardless of the point of impact projectile, and for “Ferdinand” only when it hits the side armor, but from a distance of 2000 meters.”

The SU-100-2 self-propelled gun with the S-34 cannon was delivered by a special train to the training ground in Gorokhovets in early July 1944. It was tested to the same extent as the SU-100, was considered inferior and was not recommended for service. The SU-100, on the contrary, was adopted by the Red Army by decree of the State Defense Committee No. 6131 of July 3, 1944. The new combat vehicle was created on the basis of units of the T-34/85 tank and the SU-85 self-propelled guns.

All main components of the tank - engine, transmission, chassis - remained unchanged. Only due to some overload of the front rollers, their suspension was strengthened, increasing the diameter of the spring wire from 30 to 34 mm. The hull, borrowed from the SU-85, underwent a few but very important changes: the thickness of the frontal armor was increased from 45 to 75 mm, a commander's cupola and MK-IV type viewing devices were introduced, and two fans were installed to intensively clean the fighting compartment from powder gases. In general, 72% of parts were borrowed from the T-34, 4% from the SU-122, 7.5% from the SU-85, and only 16.5% were designed anew. The D-10S gun with a barrel length of 56 calibers had an initial armor-piercing projectile speed of 895 m/s. The ammunition consisted of 33 unitary rounds with BR-412B armor-piercing tracer shells, OF-412 high-explosive fragmentation grenades and naval fragmentation grenades. An armor-piercing blunt-headed projectile with a BR-412B ballistic tip penetrated 110 mm armor at a distance of 1500 m at an impact angle of 60°.

Production of the SU-100 began in September 1944, and for three months it was carried out in parallel with the production of the SU-85. From September 1944 to the 3rd quarter of 1945, 2495 SU-100 were manufactured at UTMZ. At the suggestion of L.I. Gorlitsky, both artillery systems - D-10S and D-5S - were mounted in the most unified housings, suitable for installing either of the two guns or any ammunition rack.

The travel mount, rotating mechanism, sights and armor protection of the guns were changed. The design of the SU-85 especially benefited from this unification. Suffice it to say that the ammunition load has increased to 60 rounds. The first unified self-propelled guns were released in July 1944. In August, the plant stopped production of the SU-85 and switched to producing “hybrids” designated SU-85M.

In the summer and autumn of 1944, the ESU-100 self-propelled guns with electric transmission and the SU-122P with a 122-mm D-25T cannon were experimentally manufactured. Production of the SU-100 continued until March 1946, during which time 3,037 self-propelled units were produced. According to some reports, production was resumed in 1947 and another 198 self-propelled guns were produced. In the 50s, under Soviet license, the SU-100 was produced in Czechoslovakia.

Since November 1944, the medium self-propelled artillery regiments of the Red Army began to be re-equipped with new self-propelled guns. Each regiment had 21 vehicles. At the end of the year, they began to form SU-100 self-propelled artillery brigades, each with 65 self-propelled guns. SU-100 regiments and brigades took part in the hostilities of the final period of the Great Patriotic War. SU-100s were used in large numbers to repel the German counter-offensive near Lake Balaton (Hungary) in March 1945. In other sectors of the front, the use of self-propelled guns of this type was limited.

In the post-war period, the SU-100 was in service with the SA (until the end of the 70s), the armies of the Warsaw Pact countries, as well as many countries in Asia, Africa and Latin America. They were used in combat operations in the Middle East, Angola, etc.

Crew, people – 4 Weight, kg – 31600 Length, m – 9.45 Width, m – 3.00 Height, m – 2.25 Armor, mm – 45-75 Armament – 1 x 100 mm D-10S Ammunition – 34 shots Engine – V-2-34M, 12-cylinder diesel, 520 hp. Power reserve, km – 310 Max. speed, km/h – 50

Acquaintance

SAU-100 (photo of armored vehicles - below) is a medium-weight Soviet anti-tank self-propelled artillery unit. This model belongs to the class of tank destroyers. The basis for its creation was the T-34-85 medium tank. According to experts, the Soviet self-propelled guns-100 are a further development of the self-propelled guns SU-85. The tactical and technical characteristics of these systems no longer satisfied the military. Due to the insufficient power of Soviet artillery installations, German tanks such as the Tiger and Panther could impose battle from long distances. Therefore, it was planned in the future to replace the SAU-85 with the SAU-100. Serial production was carried out at Uralmashplant. In total, Soviet industry produced 4976 units. In the technical documentation, this installation is listed as a tank destroyer SU-100.

Description

According to experts, the SAU-100 has the same layout as the base tank. The front part of the armored vehicle became the location of the management and combat compartments, and there was a place in the rear for the engine and transmission compartment. In German tank construction, a traditional layout was used, when the power unit was installed on the stern, and the drive wheels and transmission were installed on the front. The E-100 Jagdpanzer self-propelled gun had a similar device. Design work on this model was carried out in 1943 in the city of Friedberg. The Germans, as we see, also tried to optimize the production of armored vehicles as much as possible. For example, Wehrmacht experts considered that the production of the super-heavy Maus tank would cost the country too much. Therefore, the Jagdpanzer was developed as an alternative to the Maus. The combat crew of the SAU-100 tank consists of four people, namely: driver, commander, gunner and loader.

The driver was located in the frontal part on the left, and the commander was located on the right side of the gun. Behind him there was a workplace for the loader. The gunner sat behind the mechanic on the left side. To allow the crew to embark and disembark, the armored hull was equipped with two hinged hatches - in the roof of the commander's tower and at the stern. The combat crew could land through a hatch located in the bottom of the fighting compartment. The hatch in the wheelhouse was used for a panorama of the gun. If necessary, crew members could fire personal weapons. Especially for this purpose, the armored hull of the self-propelled gun was equipped with holes that were closed using armor plugs. The roof of the cabin was equipped with two fans. The cover in the engine-transmission compartment and the hinged upper aft plate contained several hatches through which the mechanic, as in the T-34, could get to the transmission and power unit. All-round visibility was provided by five viewing slots in the tank's turret. In addition, the turret was equipped with a Mk-4 periscope viewing device.

Vertical wing of the loader hatch

The vertical loader hatch on the SU-100 hull remained in place until March 1945. The flap was removed during the modernization of hull parts in order to reduce the formation of cracks in the armor during the manufacture of parts.

Vertical door of the loading hatch on the SU-100

The prefabricated model SU-100 from Zvezda does not have it, I will do it. In general, nothing complicated. Well, you'll have to tinker a little with the hinges. Plus, don’t forget to imitate the goujons on the hatch flap.

Model SU-100 "Zvezda". Place for a vertical hatch.

About weapons

The SAU-100's main weapon was a 100-mm D-10S rifled gun manufactured in 1944. An armor-piercing projectile fired from this gun moved towards the target at a speed of 897 m/s. The maximum muzzle energy was 6.36 MJ. This weapon had a semi-automatic horizontal wedge breech, electromagnetic and mechanical triggers. In order to ensure smooth vertical aiming, the D-10S was equipped with a spring compensating mechanism. For recoil devices, the developer has provided a hydraulic recoil brake and a hydropneumatic knurler. They were placed on both sides above the trunk. The total weight of the gun, bolt and opening mechanism was 1435 kg. The gun was mounted on the front plate of the wheelhouse on double axles, which made it possible to aim in the vertical plane within the range from -3 to +20 degrees and in the horizontal plane - +/-8 degrees. The gun was aimed by manual lifting sector and rotary screw mechanisms. During the shot, the D-10S rolled back 57 cm. If it was necessary to perform direct fire, the crew used a TSh-19 telescopic articulated sight with fourfold magnification. This system provided visibility in the field of view up to 16 degrees. From a closed position, a Hertzian panorama and a lateral level were used. Within one minute, up to six shots could be fired from the main gun. In addition, two 7.62-mm PPSh-41 submachine guns, four anti-tank grenades and 24 hand-held fragmentation anti-personnel defensive F-1s were supplied for the combat crew. Later the PPSh was replaced with a Kalashnikov assault rifle. According to experts, during the Great Patriotic War the crew of the SAU-100 in rare cases could use additional light machine guns.

Imitation of the junction of a beam and a frontal armor plate

As a result of increasing the thickness of the upper frontal armor of the vehicle to 75 mm, a step was formed when connecting the VLD with a cast beam. This situation on the SU-100 remained until the end of the war.

SU-100. Early type of VLD and NLD welding with front cast beam

Zvezda offers a post-war version of the joint between the front beam and the upper armor plate of the SU-100. This point will definitely need to be improved.

Model SU-100 from Zvezda. Changing the shape of the joint between the cast beam and the upper VLD on the model

TTX

SAU-100 has the following tactical and technical characteristics:

- armored vehicles weigh 31.6 tons;

- the crew has four people;

- the total length of the self-propelled gun with the gun is 945 cm, the hull is 610 cm;

- installation width - 300 cm, height - 224.5 cm;

- ground clearance - 40 cm;

- equipment with homogeneous, rolled steel and cast armor;

- thickness of the bottom and roof - 2 cm;

- on a highway, self-propelled guns travel up to 50 km per hour;

- armored vehicles overcome rough terrain at a speed of 20 km/h;

- The self-propelled gun can travel 310 km on the highway and 140 km on rough terrain;

- the specific ground pressure indicator is 0.8 kg/sq.m. cm;

- the artillery mount overcomes 35-degree slopes, 70-centimeter walls and 2.5-meter ditches.

About the transmission

This system is represented by the following components:

- multi-disc main dry friction clutch;

- five-speed manual transmission;

- two multi-disc dry friction side clutches and band-type brakes using cast iron linings;

- two simple single-row final drives.

All control drives are mechanical. So that the driver could turn and brake the self-propelled gun, two levers were placed on both sides of his workplace.

About ammunition

For the main armament of the self-propelled gun, 33 unitary shots were provided. The shells were stacked in the wheelhouse - the manufacturer made special racks for this purpose. Seventeen of them were on the left side, eight on the rear, eight on the right. During the Great Patriotic War, ammunition consisted of sharp-headed and blunt-headed caliber armor-piercing, fragmentation and high-explosive fragmentation shells.

After the end of the war, the ammunition was supplemented first with more effective armor-piercing UBR-41D shells, which had protective and ballistic tips, and then with sub-caliber and non-rotating cumulative ones. The self-propelled guns' standard ammunition included high-explosive fragmentation (sixteen), armor-piercing (ten) and cumulative (seven shells). Additional weapons, namely PPSh, were equipped with 1,420 rounds of ammunition. They were placed in disk magazines (twenty pieces).

About the chassis

According to experts, in this area the self-propelled gun is practically no different from the base T-34 tank. Each of the sides of the self-propelled guns had gable road wheels (five pieces each). Their diameter was 83 cm. Rubber tires were provided for the chassis with the drive wheel, Christie suspension and sloth. Installation without support rollers - to hook the upper branch of the belt, we used support rollers. The drive wheels with ridge gearing were located at the rear, and the idlers with tensioning mechanisms were located at the front. Unlike the T-34, the chassis of the self-propelled gun, namely its front rollers, was reinforced with three bearings. The diameter of the wire springs was also changed from three to 3.4 cm. The caterpillar track was represented by 72 stamped steel tracks, the width of which was 50 cm.

In an effort to improve the maneuverability of an artillery mount, the tracks were in some cases equipped with lugs. They were fastened with bolts to every fourth and sixth tracks. In the 1960s The self-propelled guns were produced with stamped road wheels, like in the T-44M.