The car frame is of the spar type. It consists of two large spars, which are connected by a special buffer (1 piece) and cross members (6 pieces). The spars are made of stamped sheet steel. There are special hooks installed on the front of the frame that can be used for towing. A device with a double-sided spring is installed on the rear of the frame; when driving with a trailer, the spring acts as a shock absorber.

Also note that some subtypes of the Ural 4320 frame have some design differences from the standard layout:

- Frames on tractor-trailer models - the rear parts of the car are shortened; there are tow hooks on the rear (instead of a towing device); There are platforms on the frame that protect the machine from dirt and dust.

- Frames Ural-377C and Ural-375H/SN - the height of the platform is reduced by 4.5 cm by reducing the height of the balancing brackets.

- Ural-375A - chassis length increased by 33.5 cm.

Frame maintenance

The service looks like this:

- To assess the condition of the rivets, you need to tap them with a hammer. If the rivet is poorly secured, it must be replaced either with a new rivet or with bolts. Replacing holes is done like this: weld the old holes and drill new ones next to them.

- Deflections are assessed visually, as well as using special rulers and templates. The geometric conformity of the frame is checked using a series of measurements on some diagonal sections (normally, the difference between two diagonal measurements of the same section should not exceed 5 millimeters). Also, to assess deflections, measurements are taken of the rear and front ends of the frame (the difference should be no more than 4 millimeters).

- The towing device must be periodically cleaned of dirt and lubricated with protective materials. You also need to periodically check the bolts securing the tugboat to the frame (if necessary, the bolts need to be tightened or loosened). When checking, you need to pay special attention to the towing hook nut - it must be tightened in such a way that the hook cannot move along its axis.

TRUCKS GAZ, ZIL, KAMAZ, URAL, MAZ, KRAZ

_________________________________________________________________________________________

Frame, platform and cabin components of Ural-4320

The frame of the Ural-4320, Ural-5557 vehicle The chassis of the Ural-4320, 5557 vehicle is used to ensure direct interaction with the road or dirt surface. The chassis of the Ural-4320 consists of a frame, suspension and axles. The Ural-4320, 5557 frame is the skeleton of the car.

Fig. 35 Frame of Ural-4320, 5557 13 - frame spars; 12, 14, 16, 19, 21 - transverse beams; 11 — rear suspension bracket lining; 15—rear bracket of the front suspension, 18—front bracket of the front suspension; 20— rear buffer, 22— cross member of the coupling device; 24 — towing hook; 25 — front buffer; The Ural-4320, 5557 frame is designed for installation and fastening of the engine, transmission units, chassis, additional and special equipment, control mechanisms, as well as the cabin and body. On Ural-4320, 5557 vehicles, spar riveted frames are used. The frame of the Ural-4320, 5557 is riveted and consists of two stamped side members of variable cross-section, connected by cross members and a front buffer. Caring for the Ural-4320, 5557 frame involves monitoring the condition of the bolted and rivet joints. It is necessary to ensure that the geometric design of the frame and the strength of its elements are not violated. If the rivets are loose, cut them off and replace them with new ones. It is allowed to replace weakened or cut rivets with threaded connections with bolts of strength class 8.8 and nuts with locknuts. The towing device (hook) of Ural-4320, 5557 vehicles is mounted in a special cross member. Caring for the towbar involves lubricating and cleaning it from dirt.

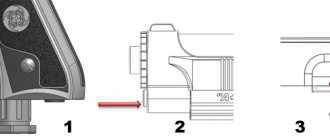

Rice. 36. Towing device (hook) for Ural-4320, 5557 vehicles 1-nut; 2-body; 3-ring pressure; 4-element elastic; 5-tow hook; 6-guide bushing; 7.9-oil nipples; 8-cotter pin; 10-plate locking; 11-bolt The guides of the towing hook rod Ural-4320, 5557 are lubricated through oil nipples during vehicle maintenance. The towing hook of the Ural-4320 vehicle in the body support 2 (Fig. 36) and bushing 6 should rotate freely by hand. Axial movement of the hook in the body is allowed no more than 0.5 mm. To ensure it, tighten nut 1 until a gap appears between body 2 and pressure ring 3 due to deformation of the elastic element (determined by the free movement of the towing hook). Then unscrew the nut until axial movement of the hook is eliminated and secure it with a locking plate with a bolt. The locking plate 10, together with the bolt 11 screwed into its hole, and the towing hook rod can move by the amount of gaps in the connection. When working with a trailer, install a locking pin 8. Cabin of the Ural-4320, 5557 vehicle The cabin of the Ural-4320, 5557 vehicle is closed, three-seater, all-metal, with a blind wind window and thermal insulation, attached to the frame at four points through rubber cushions. When the frame is deformed, the elastic fastening protects the Ural-4320 cabin panels from overstress. The Ural-4320, 5557 cabin is equipped with a pneumatic windshield wiper, windshield washer and heater. The windshield wiper of the Ural-4320, 5557 cabin is included in the pneumatic system of the vehicle. It consists of a pneumatic motor with a spool valve and a mechanism for laying brushes along the lower edge of the glass, two brushes, rods and brush drive levers. The windshield wiper is turned on by turning the tap head counterclockwise. The tap is located on the instrument panel of the Ural-4320, 5557 cabin. By rotating the head of the tap, you can adjust the speed of movement of the windshield wiper arms. When turning the tap head counterclockwise, the intensity of the brushes increases. When you turn the tap head clockwise until it stops, the wiper turns off. At the end of the work, the brushes should be placed along the lower edge of the glass. If the brush placement mechanism does not work, the tap is turned on and off again by the driver. The Ural-4320, 5557 cabin windshield washer consists of a pump, a 1.5-liter fluid reservoir, hoses, and two spray nozzles. The diaphragm type pump is installed on the left side of the cabin on the floor. The reservoir is located on the left side of the hood. Water from the tank is pumped through hoses to the sprayers and washes the windshields when you press the pedal. The cabin windows of the Ural-4320, 5557 are washed while the windshield wipers are turned on. The direction of the jet is controlled by the position of the spray nozzle. At sub-zero temperatures, non-freezing liquid is poured into the tank. The cabin doors of the Ural-4320, 5557 are equipped with locks and window lifts. When closing the cabin door, the upper guide pin of the lock fits into the groove of the latch and protects the door from sagging. The lock pawl comes into contact with the door latch and, turning, locks the door. In this position, the pawl is secured with a latch and lock. The door locks can be locked in the closed position. To do this, you need to turn the lock drive handles towards you. When the locks are closed, the lock driver 3 stops the latch, preventing it from disengaging with the latch. The driver's door lock can also be locked from the outside with a special key. The Ural-4320, 5557 cabin door lock is opened by turning the lock drive handle away from you or by pressing the button on the outside handle. In this case, the latch releases the latch and the pawl, under the action of the spring, returns to its original position. The door windows are equipped with sliding and turning glass. The windows of the cabin doors are lowered and raised by lever-type lifting mechanisms. Cabin heater Ural-4320, 5557 The Ural-4320 cabin is heated by air heated in the heater, which is included in the engine cooling system.

Rice. 37. Diagram of operation of the Ural-4320, 5557 cabin heater and windshield blower 1-warm air supply pipe for blowing windshields; 2-outer hatch drive handle; 3-air heating distributor; 4-lever for driving the air heating distributor dampers; 5-lever for driving the internal hatch; 6-electric motor with fan assembly; 7-internal hatch cover; 8-heater radiator; 9-drainage pipe from the heating radiator; 10-water supply pipe; 11-faucet; 12-external hatch cover; 13-deflector The supply of air from outside to the heater radiator Ural-4320, 5557 is regulated using the cover 12 (Fig. 37) of the external hatch and from the cabin with the cover 7 of the internal hatch. When the Ural-4320, 5557 cabin heater fan is turned on, the heated air enters the air heating distributor 3, from where it is distributed throughout the cabin through controlled dampers. The flaps are controlled by lever 4. When the lever is in the upper position, air flows through the deflectors 13 to blow the windows; in the lower position, air flows to warm the feet of the driver and passengers. When the position of the lever changes relative to the extreme positions, the amount of air supplied to blow the windows and heat the feet of the driver and passengers changes accordingly. The cover 7 of the internal hatch is controlled by lever 5. In the upper position of the lever, the hatch is open, in the lower position it is closed. The optimal position of the heating controls for the Ural-4320, 5557 cabin: simultaneous intake of air from the outside through the hatch, adjustable by lid 12, from the cabin through the internal hatch, closed by lid 7, and supply of heated air to the windshields, legs of the driver and passengers by setting lever 4 to the middle position. The fan switch is located on the instrument panel. Tap 11, located on the right water pipe of the engine, must be open during operation at subzero air temperatures. In summer, the Ural-4320, 5557 cabin heater must be disconnected from the cooling system by closing valve 11. If water is used as a coolant at subzero temperatures, the Ural-4320 cabin heater valve should be closed before filling the cooling system to prevent cold water from entering heater radiator and its freezing. For additional heating, the Ural-4320, 5557 cabin is equipped with an autonomous heating unit (AHU). The autonomous heating system is located inside the cabin on the floor under the passenger seat. The cabin of the Ural-4320, 5557 is ventilated through the hatches of the heating system, openings of the rotary and sliding glass doors. If natural ventilation of the Ural-4320 cabin is insufficient, open the outer hatch and turn on the fan. The driver and passenger seats are separate, the shock-absorbing element is rubber belts and sponge rubber. The driver's seat can be adjusted forward or backward. Adjustment limit 110 mm. Using a handle located on the left side of the stand or on the right side of the stand, the seat is fixed in the desired position. The driver's seat has a mechanism for changing the tilt of the cushion and the seat height position with an adjustment limit of 80 mm. To change the seat height, remove the two front screws on the left and right sides of the seat. Having established the required height of its front part, tighten the screws a few turns, but not tightly, loosen the fastening of the rear part of the seat by unscrewing the two screws four to five turns. Once the seat position is fully adjusted, securely fasten the screws. The conical part of the screw must be fixed in one of the five conical recesses. The driver's seat backrest has an adjustable tilt angle. To change the angle of the backrest, unscrew the nuts on the left and right sides of the seat two or three turns and, having selected the desired position of the backrest, screw them securely again, or use the handle located on the left side of the seat. The tail of the car Ural-4320, 5557 For ease of engine maintenance and repair, individual tail units are made detachable. The tail of the Ural-4320, 5557 is attached to the frame through a rubber support pad, and to the cabin through rubber buffers. Alligator-type hood with 90° opening angle. Car platform Ural-4320, 5557 Car platform Ural-4320-10, Ural-4320-31, Ural-4320-0911-30 with one folding tailgate. The general view and fastening elements of the Ural-4320, 5557 platform on the frame are shown in Fig. 38.

Rice. 38. Fastening the Ural-4320, 5557 platform to the frame of the 1-arc awning in the transport position; 2-stepladders; 3-bracket for fastening the platform to the car frame; 4-side extension side; 5-side board; 6-tailgate locking chain; 7-front extension side; 8-front middle seat mounting bracket; 9-side front; 10-seat side platforms; 11-mounting brackets for the rear middle seat; 12-sided rear; 13-driver signal button; 14-seat middle platform; The four front stepladders (two on each side) have spring shock absorbers. The spring size in working condition should be in the range of 80--81 mm. Wooden spacers are placed between the upper flanges of the frame side members and the longitudinal beams of the base of the Ural-4320 platform. The tailgate of the Ural-4320, 5557 platform is folding. There are add-on grilles on the front and side sides; awning arcs are installed in the extension grilles of the side sides, which are fastened with spacers. The removable awning in the front has a window and valves for ventilation. In the non-working position, the awning arches are installed in special sockets in the front part of the platform and secured with belts. To transport people, the Ural-4320, 5557 platform is equipped with three longitudinal rows of seats. The side seats are folding. The middle row of seats is removable and consists of two parts, which, when removed, are secured with straps in special brackets on the platform spikes. For the safety of passengers, a safety belt is fastened parallel to the rear side, which, when driving, must be passed through the bracket of the back of the middle seat. There are tool storage boxes on the side sides of the Ural-4320, 5557 platform. The Ural-4320, 5557 platform is equipped with seats for transporting people, add-on grilles for the front and side sides and awning arches with struts. The middle seat can be removed and fixed to the front side, the side seats can be folded to free up space when carrying cargo. The Ural-4320, 5557 vehicle is equipped with a platform awning. The platform of the Ural-43202-0351-31, Ural-4320-0611-10, Ural-4320-0611-31 cars is wooden, with three folding sides. The side boards in the middle part are connected by a tie of two chains. When operating a Ural-4320, 5557 vehicle, periodically check the bolted connections of the cabin parts, tail, platform and their fastening to the frame; If cracks are found in parts, weld them and paint them. If it is necessary to carry out welding work, remove the old paint layer from the surfaces of the parts. Before touching up damaged areas (mechanical damage, cracks, chips, rust, welding soot, splashes), the old paintwork must be cleaned with fine-grained or waterproof sandpaper. Wipe the cleaned surface with a rag soaked in gasoline or solvent, dry it and paint it with a spray bottle or soft brush with enamel of the same color in two layers, waiting for 5-10 minutes. Periodically remove and dry the cabin floor mat, as a damp mat loses its thermal insulation properties and contributes to corrosion of the cabin floor.

_________________________________________________________________________________________

- GAZ-3307 clutch maintenance

- Steering system GAZ-3307

- Gearbox parts for GAZ-3307

- Maintenance of the rear axle GAZ-3307

- Maintenance of the fuel system of the D-245 diesel engine

- Clutch GAZ-3309 with a diesel engine

- Operations for disassembling the GAZ-3309 gearbox

- GAZ-3309 front axle service

- Repair of cardan shafts of GAZ-3309 cars

_________________________________________________________________________________________

_________________________________________________________________________________________

- Operations for assembling basic components of the ZIL-130 engine

- Service and repair operations for the ZIL-130 gearbox

- Maintenance and repair of ZIL-130 clutch

- Repair and adjustment of the rear axle ZIL-130

_________________________________________________________________________________________

- KAMAZ-4310, 43118, 43114

- KAMAZ-5320, 55111, 53212, 5511, 55102

- KAMAZ-65115, 6520, 65117

- KAMAZ-4308

- Engine KAMAZ-740

_________________________________________________________________________________________

- Parts of the cylinder block and head of the YaMZ-236 engine

- Service maintenance of the YaMZ-236 piston group and crankshaft

- Diagnostics and technical adjustments of the YaMZ-236 engine

- Design and adjustment of fuel injection pump and injectors of the YaMZ-236 engine

- Cylinder block and piston YaMZ-238

- Components of the YaMZ-238 diesel fuel supply system

- Design and adjustment of the fuel injection pump of the YaMZ-238 diesel engine

- Technical design of the YaMZ-239 gearbox

_________________________________________________________________________________________

- Components of the front axle and steering rods of the Maz-5516, 5440

- Steering system of Maz-5516, 5440 cars

- Clutch and gearbox parts Maz-5516, 5440

- Maintenance of drive axles of MAZ-5516, 5440 vehicles

- Power steering for Maz-5551, 5335 cars

- Maintenance of cardan transmission of Maz-5551, 5335 cars

- Maintenance and adjustment of clutch MAZ-5551, 5335

- Repair and service of the rear axle of MAZ-5551, 5335 cars

_________________________________________________________________________________________

- Gearbox Ural-4320

- Construction and adjustment of Ural-4320 bridges

- Maintenance of transfer case Ural-4320

- Steering components Ural-4320

_________________________________________________________________________________________

- Servicing the KRAZ-255, 260 gearbox

- Steering mechanism and power steering Kraz-255, 260

- Adjustments and repairs of the power steering cylinder and steering rods of the Kraz car

- Drive axle components and drive shafts Kraz-255, 260

Frame repair Ural 4320

If cracks are detected, it is necessary to weld the damage to restore the integrity of the side members. Please note that welding is only a temporary measure - after welding, it is recommended to contact a repair organization that will replace the damaged frame from the old one to a new frame. Repair and weld cracks as follows:

- At the end of the crack, drill a small hole (4-5 millimeters in diameter). Along the crack on both sides, make small grooves for welding (the optimal depth is 3-4 millimeters). After this, use a welding machine to apply a seam from the hole along the crack. At the end, clean the seam and weld a reinforcing lining on the inside (the optimal material for the lining is low-carbon sheet steel, thickness - about 7 millimeters).

- Old cars (1972 and earlier) have a characteristic feature - the upper and lower parts of one of the cross members of such cars are connected using special rivets. If you find a crack on the bottom of the cross member next to the rivet, then next to the crack you need to drill a hole (3-5 millimeters in diameter) and install the cover with a bolt type fastening. Such linings need to be fastened into holes for rivets; the linings can also be installed in special holes with a diameter of about 10-11 millimeters (bolts must be selected with diameters of 9-10 millimeters, respectively). Low-carbon sheet steel, the thickness of which is 6-8 millimeters, is suitable as a lining.

- Cracks in the shoes of older models of cars must be welded according to a special algorithm. First you need to remove the outer rivets (usually there are 8 of them installed). Then, at a distance of 3-5 millimeters from the rivets, you need to make a series of holes with a diameter of about 1.5 cm. At the ends of the cracks you need to make holes with a diameter of 4-5 millimeters. Now you need to do the welding. Finally, you need to attach the cross member using bolts and nuts. The optimal material for crossbars is sheet steel 6-8 millimeters thick.

Please note that it is recommended to weld the frame and side members using special electrodes of class E42A, E46A or E50A (the optimal rod diameter is about 4 millimeters). Finally, after all necessary repairs have been completed, it is recommended to repaint the frame.

Not available:

| № | Part code | Name | Part Information |

| 5557Я6-2800012-10 | Frame assembly | Quantity 1 Model 5557Y6 Group Frame Subgroup Frame assembly Serial part number 012 Additionally Not interchangeable with a part previously released under the same number | Not available |

| 335930-P29 | Washer 14 | Quantity 1 Coating galvanizing and passivation (zinc with chromating) | Not available |

| 5323-3506154 | bracket | Quantity 1 Model 5323 Group Brakes Subgroup Air brake piping Part serial number 154 | Not available |

| 250514-P29 | Nut M12-6N | Quantity 2 Coating galvanizing and passivation (zinc with chromating) | Not available |

| 5557X-2905534 | Shock absorber bracket, right, assembly | Quantity 1 Model 5557X Group Car suspension Subgroup Front shock absorbers Part serial number 534 | Not available |

| 4320-2902442 | Rear right front spring bracket assembly | Quantity 1 Model 4320 Group Car suspension Subgroup Front springs (front suspension springs) Part number 442 | Not available |

| 250561-P29 | Nut M16x1.5-6N | Quantity 12 Coating galvanizing and passivation (zinc with chromating) | Not available |

| 336047-P29 | Washer 17 | Quantity 8 Coating galvanizing and passivation (zinc with chromating) | Not available |

| 332702-P29 | Bolt M16x1.5x55 | Quantity 8 Coating galvanizing and passivation (zinc with chromating) | Not available |

| 4320Я5-2801136 | Rear cab support | Quantity 1 Model 4320Я5 Group Frame Subgroup Frame Part serial number 136 | Not available |

| 251648-P29 | Nut M14x1.5-6N | Quantity 1 Coating galvanizing and passivation (zinc with chromating) | Not available |

| 332572-P29 | Bolt M14 | Quantity 1 Coating galvanizing and passivation (zinc with chromating) | Not available |

| 5557Я5-2801172 | Cross member No. 4 frame | Quantity 1 Model 5557Я5 Group Frame Subgroup Frame Part serial number 172 | Not available |

| 5323РХ-4712139 | bracket | Quantity 1 Model 5323РХ Group Additional equipment Subgroup 4712 Part number 139 | Not available |

| 5323-4245039 | bracket | Quantity 3 Model 5323 Group Special equipment Subgroup 4245 Part number 039 | Not available |

| 375-2918156 | Plate | Quantity 4 Model 375 Group Vehicle suspension Subgroup Rear balance suspension Part serial number 156 | Not available |

| 252138-P2 | Spring washer 14 | Quantity 12 Coating phosphating and oiling | Not available |

| 330020-P29 | Bolt M14x35 | Quantity 8 Coating galvanizing and passivation (zinc with chromating) | Not available |

| 4320YAT-3724389 | Connector mounting bracket | Quantity 1 Model 4320ЯТ Group Electrical equipment Subgroup Electrical wires Part number 389 | Not available |

| 4320U2-2801174 | Additional crossbar No. 1 | Quantity 1 Model 4320У2 Group Frame Subgroup Frame Part serial number 174 | Not available |

| 5557Я6-2801020 | Right frame spar | Quantity 1 Model 5557Я6 Group Frame Subgroup Frame Part serial number 020 | Not available |

| 5557Я6-2801021 | Left frame spar | Quantity 1 Model 5557Я6 Group Frame Subgroup Frame Part serial number 021 | Not available |

| 4320Я5-2801152 | Cross member No. 3 frame | Quantity 1 Model 4320Я5 Group Frame Subgroup Frame Part serial number 152 | Not available |

| 4320U5-2801100-10 | Cross member No. 2 frame | Quantity 1 Model 4320У5 Group Frame Subgroup Frame Sequential part number 100 Additionally Not interchangeable with a part previously released under the same number | Not available |

| 4320-2902443 | Rear left front spring bracket assembly | Quantity 1 Model 4320 Group Vehicle suspension Subgroup Front springs (front suspension springs) Part number 443 | Not available |

| 250558-P29 | Nut M14-6N | Quantity 10 Coating galvanizing and passivation (zinc with chromating) | Not available |

| 5557X-2905535 | Left shock absorber bracket assembly | Quantity 1 Model 5557X Group Car suspension Subgroup Front shock absorbers Part serial number 535 | Not available |

| 375-2902610-B | Front spring buffer bracket | Quantity 2 Model 375 Group Vehicle suspension Subgroup Front springs (front suspension springs) Serial part number 610 Additionally Interchangeable with a part previously released under the same number | Not available |

| 4320Ya3-2801082 | Additional cross member | Quantity 1 Model 4320Я3 Group Frame Subgroup Frame Part serial number 082 | Not available |