Currently, the cleaver knife is a heavy, long knife, similar to a very massive machete. Long gone are the days when cutlasses were used as infantry weapons in European armies. Nowadays, if a cleaver is used in the army, it is only as a sapper cleaver, representing an entrenching tool with the functions of a knife. The infantry cleaver these days is a real relic, preserved only in the collections of edged weapons or in the possession of a few knife lovers.

Most modern cleavers are marketed as tools designed for survival, although one look at a large cleaver is enough to feel an overwhelming respect for its owner. Soldiers' cleavers were often used as weapons; even its name is derived from the word “to cut,” which speaks quite eloquently about its purpose in everyday life.

Cleaver: general description

A cleaver is a large knife that belongs to a bladed cutting and piercing type of weapon. The length of the blade itself can vary from 20 to 72 cm, its width from 4 to 5 cm. The knife can be either straight or curved. It is not uncommon to find knives with double-sided sharpening, although this knife is characterized by one-sided sharpening.

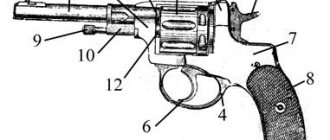

A distinctive feature of the cleaver is not only its size and weight, but also the handle, which is equipped with a hilt. The hilt consists of a guard and a pommel on the handle.

This element can be of two types:

- open, which protects the hand with a cross or no protection at all;

- the closed type implies the presence of several arches that connect the pommel to the guard.

Important! To make a good cleaver, it is necessary to correctly select and process the material from which the blade is made. The best option is laminated, stainless or carbon (carbon) steel.

Laminated cleavers have a very sharp blade that lasts for a long time. The strength of the blade is ensured by the carbon steel base. Alloy steel is laid on top of it in layers. Therefore, this option is called “laminated”.

The carbon steel knife has a durable blade and good sharpness. This type of steel is cheaper than the first option, but it requires more attention, as it is susceptible to corrosion.

Stainless steel blades have excellent corrosion resistance, but are not as sharp as the previous two options. To partially remove these disadvantages, carbon is added to the alloy, which increases hardness and chromium, which is not sensitive to corrosion.

Previously, the handle was made of metal, but modern knives have begun to be equipped with a plastic handle, which is resistant to aggressive environments and is not afraid of moisture.

In order to carry a cleaver, you must have a sheath.

How to make it yourself

You can make cleavers yourself at home. They are more preferred than factory ones. Tisak LLC produces such products.

The homemade device can be decorated as desired. In production, the center of gravity shifts backward. The thickness of the blade is the same or slightly increased towards the contour of the handle. In everyday life, the presence of a guard is considered unnecessary.

Cleaver knife.

Necessary materials

Carbon steel is the basis for most of it. The product must be hard and the blade must be sharp. Brand 95X18 is the best solution. Proper hardening promotes high fracture pressure.

Blank

Procurement algorithm:

- Choose high-quality steel. The shape, thickness and size are determined individually. The thickness is usually from 6 mm to 8 mm.

- Draw a layout on paper, cut it out, add 4 mm along all edges without changing the shape. Glued onto a steel strip.

- The metal is cut along the contour with sandpaper. The blade release is made without an edge.

- Drill holes for the handle fastenings.

Hardening

Hardening requires special equipment. The artisanal method will not work. Using improvised means can dull or break the blade. The help of a professional technician is necessary. Otherwise the metal will become brittle. Some tips:

- each grade of steel involves the use of suitable temperature conditions for cooling and heating;

- the blade must be hard;

- the surface surrounding the handle should be soft.

Hardening is one of the most important stages in manufacturing.

Finishing

Working method:

- Apply sandpaper to remove scale and deposits.

- Sharpen the workpiece so that the dimensions match the knife.

- Sharpen after finishing production of the handle.

- Grinding is used depending on the purpose of the product.

Making a pen

Making the handle and decorating it depends on the wishes of the craftsman. The easiest way is to make it wooden. Principle of operation:

- Choose hardwood. Pre-dry.

- The overlays are turned from the timber. The inner surface must be smooth and consistent in size. There are no clear criteria for the external side.

- Prepare holes for rivets. The pads are glued to the handle.

- The handle is drilled in the area of each hole on the blade. The diameter of the hole is identical to the diameter of the drill.

- Grind with sandpaper to the required size.

- The copper wire is heated. Afterwards it is cooled to give it softness and malleability. The diameter of the hole is equal to the diameter of the wire.

- The wire is inserted into the handle and the excess is cut off.

- The ends of the wire are struck with a hammer so that it fits well into the hole.

- Sanded and polished.

The history of the appearance of the cleaver and its varieties

According to some sources, cutlasses appeared in the 18th century. Then they began to equip the European and Asian armies of different countries. But according to other sources, cutlasses appeared much earlier.

- Approximately 1000 BC The first mentions of a weapon similar to a cleaver appeared. Moreover, the weapon was so universal that it was used in everyday life much more often than in battles.

- In the Middle Ages, knives had many varieties, the most famous of which were cord, dusak and malkha. The cleaver of that time was called a large knife or a small sword. Until about the end of the 15th century, the knife handle had a symmetrical shape, but then it became asymmetrical. Knives of that time could be one-handed or two-handed.

- In the 13th century, knives similar to cutlasses were used by sailors during boarding, since the knives were modest in size and in turmoil they were much more convenient to fight with. In the old days they were called boarding sabers. The weapon was quite heavy and every blow struck could be fatal. At this time, the cleaver acquired a guard, which not only protected the hand, but was also used as brass knuckles.

- In the 17th century, cutlasses began to be found in China. Officially they were called Batchamdou. They were not officially put into service, but they were actively used for defense at sea. Cleavers were also used to guard some targets.

- In the same 17th century, the knife became more widespread in Europe, as hunters became interested in it. With the help of this knife it was possible to cut branches, make a hut, and butcher the carcass of an animal. The cleaver completely replaced weapons, a knife and an ax.

- In the middle of the 18th century it began to be used in the Russian army. They were equipped with artillerymen, infantrymen, sappers and even engineers. Cleavers of that time had a bronze or wooden handle with a copper tip.

The functionality of the weapon is so wide that teeth were added to the back of the blade and the cleaver began to be used as a saw. Disadvantages included heavy weight and poor protection from cavalry. Gradually, the army began to get rid of it, and eventually only the drummers had weapons.

It was used in the Russian army until the end of the 19th century, until it was completely removed.

Ancient cleaver

Hardening

Typically, large cleaver knives are hardened in a special way, forming different hardness zones. This process requires a certain skill and the availability of appropriate equipment. Some people try to complete this process on their own, using improvised means, but the results are mediocre. Therefore, it is best to entrust this process to a specialist.

A true craftsman will harden the edge of the blade while leaving the area near the handle softer. A professionally hardened knife will sharpen well, cut well and not break when exposed to bending. Since ancient times, it was believed that this process is the main one, since it gives the blade certain properties and qualities. It is important to remember that each grade of steel has its own temperature regimes for both heating and cooling.

Typically, thermal therapists charge relatively little for their services. However, the skill level of these specialists is very different. That is why it is very important to describe the desired result in detail or rely on the recommendations of professionals. When processed correctly, the finished product should have a certain strength in specific places. It is checked with a special device, which is usually available in all thermal workshops.

Device and material of manufacture

The first cutlasses were called shortened sabers. They had a wide and curved blade at the end. The handle of the cleaver was cast from a copper alloy. This was all done together with a cup and a limiter.

The shape of the blade could be different - straight, curved and sharpened on both sides. The maximum length of the knife reached 72, and the minimum 64. The width was approximately the same everywhere - 4-5 cm. Most of the products had a hilt. The handle was also equipped with a cross or bow. The similarity between a cleaver and a saber lies in the presence of a fuchtel - the flat side of the blade.

Design selection

You can often find a cleaver knife, the photo of which shows that on the back of the blade it has a saw-shaped notch. This model was most often used in sapper or engineering troops. She was supposed to carry out certain work with wood or other available materials. Currently, such an add-on is not required. The saw is much easier to replace with modern string systems.

In fact, each user determines the appearance and shape of the knife for himself, focusing on personal needs. The main thing is that the product is comfortable, practical and durable. This applies to both the thickness of the blade and its width.

Modern uses of cleavers

The cleaver is a widely used modern weapon. In terms of parameters and functionality, it is superior to battle axes. A high-quality and functional cleaver can cope with many tasks.

- This weapon can help build a temporary shelter or equip a combat position. Of course, you won’t be able to cut down thick trees with a cleaver, but this knife is ideal for clearing the path.

- In an emergency, a cleaver can be used to break car windows. Thick ropes can be cut if necessary.

- Airborne forces with the help of a cleaver can solve important tactical problems, since they often have to land in forests.

- Most often, a cleaver can replace a knife. This tool can help you survive in extreme conditions due to its versatility.

- The cleaver is capable of removing small obstacles. He will not be able to fully replace an ax or sledgehammer, but he is still able to partially complete the task.

- Thanks to the strong steel, the cleaver can cut through handcuff chains or barbed wire.

Widespread use suggests that this weapon is indispensable for hunting or tourist needs.

Modern cleaver

Interesting! One type of cleaver can be found in a chef's kitchen in China. A special cleaver is used for cutting meat, root vegetables and other dense foods.

Finishing

How is the blade polished?

- After the workpiece has come from hardening, it should be turned into a full-fledged product. To do this, the metal is first treated with sandpaper to remove scale or plaque.

- It is worth noting that a standard Magadan hunter’s cleaver knife is usually not polished. Shiny products reflect sunlight well and can reveal a person’s location. Also, professional hunters consider such designs to be impractical. Therefore, the product is left in rough external processing.

- Next, all dimensions are adjusted to the required parameters and the descent is reduced to the very cutting edge. In fact, you should get a full-fledged knife, but only without appropriate sharpening. It is not done so that the craftsman does not get injured when creating the handle.

Tactics for using cutlasses

The cleaver has established itself as a multifunctional knife for all occasions. But it can also be used quite often in combat missions. Military or police officers can carry out various types of tasks without taking the life of a suspect. Using a cleaver you can do the following:

- set up a combat position;

- free yourself in an extreme situation, where there is a need to cut ropes, seat belts, break out glass, etc.

- for airborne soldiers, such knives are needed to cut the parachute lines after landing;

- during a combat mission, a cleaver can be used to cut down small obstacles that were not previously noticed by reconnaissance;

- The sea cleaver is especially important for divers, as they can get entangled in fishing nets and it is almost impossible to get out without a good blade, so the sea cleaver is vital.

Spread around the world

Nowadays, a cleaver is considered a melee weapon with universal potential. It is used:

- in battles;

- in the kitchen for cutting fish and meat.

The technical characteristics surpassed the combat dagger. The cleaver is used by police officers in many countries and military professionals. It is used when it is impossible to use a firearm. These situations are related to:

- arranging firing points by cutting branches or constructing canopies;

- release from a rope or car seat belt in an accident;

- the absence of line cutter knives - it is possible to cut off the straps of various loads hanging on branches after being thrown out of an airplane, as well as cutting off parachute lines in case of an unsuccessful landing on a tree;

- the possibility of building a shelter, preparations for traps, butchering caught animals, and preparing firewood;

- clearing paths in difficult forests, entering closed spaces;

- cutting fishing nets during underwater tasks, cutting wires and ropes.

The attitude of the Criminal Code of the Russian Federation to the knife data

By law, a cleaver is considered a hunting knife for sporting and commercial use. Its position is regulated by GOST R 52737. Any cleaver with a blade thickness of 3 mm, a width of 4.5 cm and a length from 21 to 50 cm falls under the classification of edged weapons. It will not be possible to purchase it without accompanying documents.

Important! A cleaver, which is a bladed weapon, must have a registration number.

Based on GOST, it is worth noting that a cleaver can be similar to a military weapon. In this case, the blade can be sharpened not only on one side, but also on the other. A hunting cleaver must be made of steel with a hardness of at least 40 Rockwell units.

There are souvenir models that are not highly durable. We are talking about knives whose hardness is less than 25 Rockwell units. In this case, no special permission is required to purchase such a knife.

Where is it used?

A cleaver is a universal weapon; it can be used to cut, chop, and stab. Therefore, it is suitable for tourist and military campaigns, hunting, fishing, and agriculture. It is often used instead of an ax; it can be used to chop branches and clear thickets on a path (for example, in the jungle). Ideal for cutting up animal carcasses. Thanks to the wide blade, it can be used instead of a shovel.

The cleaver is widely used in cooking and is one of the ten must-have knives for the kitchen. They are convenient for chopping meat, bones, and roots. Universal to use, multifunctional. No other kitchen knife is designed for chopping bones.

To purchase a combat, (hunting, sapper) cleaver, you need a license. An indication number is stamped on the blade, which is recorded in the certificate. To obtain permission to own this weapon, you must undergo a medical commission, including specialists such as a narcologist and a psychiatrist.

You do not need a license to purchase a kitchen cleaver. Such a knife is not subject to registration, but is certified. The document contains a note indicating that it is used for domestic purposes.