Standards for the Makarov pistol and Kalashnikov assault rifle

A standard is a temporary, quantitative and qualitative indicator of the completion of certain tasks, techniques and actions related to the use of weapons and military equipment during service and combat training.

Fire training standards are developed in accordance with the requirements of orders, manuals, manuals and instructions based on the experience of training units, taking into account the tactical and technical characteristics of weapons.

The development of standards should be preceded by a study of the design of weapons, rules for handling them, safety requirements and necessary provisions, manuals, instructions and manuals. Training on meeting standards related to disassembling and assembling weapons is carried out only with training weapons and training ammunition in a separate training place. Practicing and passing standards on military weapons is prohibited! When disassembling a weapon, pay attention to placing parts and mechanisms in the order of disassembly, handling them carefully, avoiding unnecessary force and sharp blows, preventing falls and excluding replacement with parts of another weapon. Pay special attention to the correct separation and attachment of the return spring to the 9 mm PM barrel. When assembling a Makarov pistol, it is prohibited to control the trigger!

The standards are considered fulfilled if the conditions and procedure for their implementation are met and there have been no violations of the requirements of manuals, instructions and guidelines.

If, when passing the standard, the trainee makes at least one mistake that could lead to injury, damage to the weapon or delay in shooting, fulfillment of the standard is stopped and the employee is given an “unsatisfactory” grade.

For violation of the sequence of fulfillment of the standard, which does not lead to the breakdown of the weapon, as well as for each error that leads to a violation of the conditions for fulfilling the standard, manual, manual, a grade of “unsatisfactory” is also given.

Repeating the control standard in order to increase the grade is prohibited! The time for fulfilling the standard is counted from the command “Proceed to fulfill the standard”

until the employee’s report

“Complied with the standard.”

The employee's assessment for meeting the standard is determined by:

“satisfactory” if the employee met the deadline (in terms of speed, fulfilled the requirements), and did not make a single mistake.

“unsatisfactory” if the employee did not fulfill the requirements (violated the sequence of fulfilling the standard, did not meet the deadline).

| No. | Standards for the Makarov pistol | Time estimate (s) | |

| satisfaction | bad | ||

| 1. | Preparation for shooting from various positions: standing, kneeling, lying from behind cover | no more than 4 no more than 6 no more than 9 | more than 4 more than 6 more than 9 |

| Conditions (order) for compliance with the standard: pistol in a holster; the magazine, equipped with a training cartridge, is located in the pistol grip; the leader indicates the target, firing position, shooting position and gives the command “Fire”; the employee assumes a firing position, inserts a training cartridge into the chamber and fires an aimed shot “blank” | |||

| 2. | Incomplete disassembly of the pistol | no more than 8 | more than 8 |

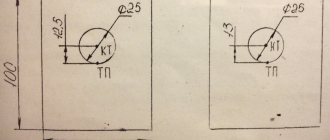

| Conditions (order) for fulfilling the standard: weapons on the table; the employee is at the weapon. The procedure for partial disassembly of the pistol: - remove the magazine from the base of the handle; — make sure that there is no cartridge in the chamber, to do this, turn off the safety (lower the flag down), move the bolt to the rear position, put it on the bolt stop and inspect the chamber, then press the thumb on the bolt stop to release the bolt; - separate the bolt from the frame, for which pull the trigger guard down, skewing it to the left (right), rest it against the frame, then move the bolt to the rearmost position, lifting its rear end, push it forward, removing it from the barrel, return the trigger guard to initial position; — remove the return spring from the barrel. In this case, the parts of the pistol must be placed on the table in the order of disassembly. Do not throw gun parts | |||

| 3. | Reassembling the pistol after partial disassembly | no more than 10 | more than 10 |

| Conditions (procedure) for compliance with the standard: the weapon is disassembled; parts and mechanisms are neatly laid out on the table; the employee is at the weapon. The procedure for assembling the pistol after partial disassembly: - put the return spring on the barrel; - attach the bolt to the frame, for which, while holding the frame, pull the trigger guard down, skewing it to the left (right), rest the trigger guard against the frame, insert the free end of the return spring into the bolt channel and move it to the rearmost position so that the muzzle the barrel passed through the bolt channel and protruded outward. Lower the rear end of the shutter onto the frame, pressing it against it, release the shutter, return the trigger guard to its place, turn on the safety (lift the flag up); — insert the magazine into the base of the handle; — place the weapon on the table with the safety facing up. It is possible to attach the bolt to the frame without pulling the trigger guard | |||

| 4. | Loading the magazine with cartridges | no more than 20 | more than 20 |

| Conditions (order) for fulfilling the standard: the employee is at the table on which there is a magazine and 8 training cartridges (in bulk); On the command “Equip the store”, the employee equips the store and places it on the table. It is forbidden to use the magazine feeder tooth and rest the magazine against yourself or the table. | |||

| 5. | Unloading a pistol | no more than 12 | more than 12 |

| Conditions (order) for compliance with the standard: the employee is at the table, holding the pistol in his hand at an angle of 45º in a safe direction; the pistol is equipped with one training cartridge (in the chamber); two more training cartridges are in the pistol's magazine. At the “Unload” command, the employee removes the magazine from the base of the pistol handle, turns off the safety, moves the bolt to the rear position, removes the cartridge from the chamber, returns the bolt to the front position, turns on the safety and puts the weapon in the holster. He removes the cartridges from the magazine and places them on the table. He takes the pistol out of the holster, inserts the magazine into the base of the grip, puts the weapon in the holster and fastens it. It is forbidden to equip (unload) the magazine by pulling back the feeder spring. | |||

| 6. | Changing the magazine from various positions: standing, kneeling, lying down | no more than 6 no more than 7 no more than 9 | more than 6 more than 7 more than 9 |

| Conditions (order) for compliance with the standard: unloaded magazine in the pistol grip; the pistol is in the employee’s hand at an angle of 45º in a safe direction, the bolt is on the slide stop; spare magazine, equipped with one training cartridge, in the holster pocket. The leader indicates the target, firing position, shooting position and gives the command “Fire”. The employee removes the magazine from the base of the pistol grip, holds it in his hand or stows (places) it in a holster (or pocket), removes a spare magazine and inserts it into the base of the pistol grip. Removes the pistol from the slide stop and fires an aimed shot “idle” | |||

| No. | Standards for the Kalashnikov assault rifle | Time estimate (s) | |

| satisfaction | bad | ||

| 1. | Preparation for shooting from various positions: standing, kneeling, prone | no more than 6 no more than 7 no more than 9 | more than 6 more than 7 more than 9 |

| Conditions (order) for meeting the standard: the machine gun is held in the “On the belt” position with an attached magazine equipped with a training cartridge. The leader indicates the target, firing position, shooting position and gives the command “Fire”. The employee takes the shooting position, places the training cartridge into the chamber and fires an aimed shot “blank” | |||

| 2. | Incomplete disassembly of the machine | no more than 18 | over 18 |

| Conditions (order) for fulfilling the standard: machine on the table; the employee is at a weapon; the magazine pouch is on his trouser belt (equipment). The procedure for partial disassembly of the machine gun: separate the magazine; check if there is a cartridge in the chamber, to do this, lower the translator down, move the bolt handle back, inspect the chamber, release the bolt handle, pull the trigger; remove the pencil case with accessories; separate the cleaning rod (for modifications of the AKS-74U type assault rifle this action is not performed); separate (open) the receiver cover; separate the return mechanism; separate the bolt frame with the bolt; separate the bolt from the bolt frame; separate the gas tube from the barrel lining. In this case, the parts of the machine must be placed on the table in the order of disassembly. It is prohibited to throw weapon parts | |||

| 3. | Assembling the machine after partial disassembly | no more than 28 | more than 28 |

| Conditions (procedure) for compliance with the standard: the weapon is disassembled; parts and mechanisms are neatly laid out on the table; the employee is at the weapon, the magazine bag is on his trouser belt (equipment). The procedure for assembling the machine gun after partial disassembly is as follows: attach a gas tube with a receiver lining; attach the bolt to the bolt frame; attach the bolt frame with the bolt to the receiver; attach the return mechanism; attach (close) the receiver cover; pull the trigger and put the safety on the machine gun; attach a cleaning rod (for modifications of the AKS-74U type machine gun, this action is not performed); insert the pencil case into the buttstock socket (magazine bag pocket); attach the magazine to the machine; place the weapon on the table with the bolt handle facing up | |||

| 4. | Loading the magazine with cartridges | no more than 40 | more than 40 |

| Conditions (procedure) for fulfilling the standard: the employee is at the table on which there is a magazine and 30 training cartridges (in bulk without using a clip). At the command “Equip the store,” the employee equips the store and places it on the table | |||

| 5. | Unloading the machine gun | no more than 12 | more than 12 |

| Conditions (order) for compliance with the standard: the employee is at the table, holding the machine gun in his hands at an angle of 45º in a safe direction, the fire selector is in the lower position; the machine gun is equipped with one training cartridge (in the chamber); two more training cartridges are in the machine's magazine. At the “Unload” command, the employee disconnects the magazine and places it on the table. Pulls the bolt handle back, removes the cartridge from the chamber, releases the bolt handle, releases the hammer and puts the weapon on safety. Removes cartridges from the magazine and attaches it to the machine gun. Places cartridges and weapons on the table with the bolt handle facing up |

Procedure for assessing the fire training of a police officer

The individual assessment of fire training of employees is made up of the marks they received for performing control exercises, the standard for fire training and the control test.

— “Satisfactory” – if “satisfactory” grades were received for completing the control exercise, the fire training standard and the control test.

— “Unsatisfactory” – in other cases.

To determine the results of shooting, the following criteria are established:

— The target is considered hit if the bullet penetrates it or touches the edge.

— A hole in a target with circles (or affected areas) that touches the line of the circle (affected area) is counted in favor of the shooter.

— The “criminal with a hostage” target is considered hit when only the part of the target indicating the criminal is hit.

— If an employee violated the conditions or procedure for performing an exercise or safety measures, an “unsatisfactory” rating is given, regardless of the result of the shooting.

Control exercises for pistol shooting are:

— For police officers, exercises 4 – 8 and 11 of the Shooting Course.

— For employees of special forces and aviation units, exercises 4 – 9, 11, 13, 14 and 16 of the shooting course.

— For non-police officers, exercises 2 and 3 of the Shooting Course.

Control exercises when shooting from a machine gun are:

— For police officers armed with AKS-74U, 9A-91, exercise 5 of the shooting course.

— For employees of special forces and aviation units, exercises 2 and 4 of the Firing Course.

— For employees who are not police officers, as well as for 3rd and 4th year cadets of educational institutions of the Ministry of Internal Affairs of Russia, exercises 1 and 2 of the Shooting Course.

Control exercises and standards to be passed and assessed during fire training classes, as well as final classes, are determined by the head (chief) of the body, organization, unit of the Ministry of Internal Affairs of Russia, taking into account the official categories of employees.

During inspections, control and targeted checks of an agency, organization, unit of the Ministry of Internal Affairs of Russia, control tests in the theoretical section of fire training, control shooting exercises and standards for fire training are determined by the official assignment. If a standard or exercise is not completed due to a malfunction of the weapon, ammunition, target equipment, or for other reasons beyond the control of the employee, then with the permission of the inspector or the shooting director, they are performed again. It is prohibited to repeatedly take control tests in the theoretical section of fire training, as well as perform fire training standards and exercises in order to improve the grade.

When conducting final classes, employees nominated for tests for assignment (confirmation) of qualification titles perform:

— Exercise 4 of the shooting course for pistol shooting (target No. 4c) with counting hits and scored points - for police officers.

— Exercise 3 of the Shooting Course for pistol shooting (target No. 4c) with counting of hits and points scored - for non-police personnel.

The level of fire preparedness of employees during tests for assignment (confirmation) of qualification titles is determined in accordance with the Criteria for assessing the level of fire readiness of employees submitted to tests for assignment (confirmation) of qualification titles.

SAMPLES OF TARGETS

| Half-length figure of a criminal (target No. 1) | Half-length figure of a criminal with a hostage (target No. 1a) | Special belt (target No. 2) | Special waist (target No. 2a) | Special waist (target No. 2b) |

| Special waist (target No. 2c) | Special belt (target No. 2d) | Full-length figure of a hostage (target No. 3) | Full-length figure of the criminal (target No. 3a) | Tall figure of an armed criminal (target No. 3b) |

| Chest figure with circles (target no. 4) | Chest figure with circles (target no. 4c) | Head figure (target no. 5) | Head figure (target no. 5a) | |

| Chest figure (target no. 6) | Criminal with a hostage in a hideout (target no. 6a) | Chest figure (target no. 6b) | Chest figure (target no. 6c) | |

| Chest figure in the window opening (target No. 6d) | Chest figure on the fence (target No. 6d) | Waist figure (target no. 7) | Criminal with a hostage (target no. 7a) | Waist figure (target no. 7b) |

Growth figure (target no.  | Building layout (target no. 9) | Mock-up of a truck (target No. 9a) | Wheel (target no. 10) |

Hand fragmentation grenades

Disassembly and assembly of PM: types, when used

Testing the ability to use a Makarov pistol, knowledge of its design and the purpose of all its component elements is carried out by carrying out complete and incomplete disassembly of the weapon. These procedures are also performed in some emergency cases when the gun needs to be cleaned.

Partial disassembly of the PM is performed when the gun needs to be cleaned, all parts need to be lubricated, and its combat effectiveness must be checked.

Complete disassembly is recommended only if the gun is heavily soiled, if it has been exposed to rain or snow, or if it has fallen into water. The mechanism of a weapon that has been subjected to such influences urgently needs complete cleaning and inspection.

Complete disassembly of the PM is a procedure that is used very rarely. This is due to the fact that it greatly reduces the resistance of the mechanism and its components to wear, which reduces the service life of the weapon.

Complete disassembly of the PM is also carried out when switching to a new weapon lubricant. It is also performed if necessary to repair the entire mechanism of the pistol or its individual parts.

Recommendations

Assembly/disassembly of the PM is carried out on a flat surface

This could be a table or bench, the surface of which must be covered with clean oilcloth. When disassembling the PM, it is very important to ensure that the mechanism being removed and its spare parts are placed on the table surface in a certain order. It is recommended to place them in the same order as they were removed, excluding their impacts against each other

The work should be carried out very carefully and carefully, without excessive effort. If not one firearm, but several PM pistols are assembled/disassembled, then in this case the spare parts and mechanisms must be numbered. This will make assembly work easier, since the parts being assembled cannot be mixed up.

Recommendations

Assembly/disassembly of the PM is carried out on a flat surface

This could be a table or bench, the surface of which must be covered with clean oilcloth. When disassembling the PM, it is very important to ensure that the mechanism being removed and its spare parts are placed on the table surface in a certain order. It is recommended to place them in the same order as they were removed, excluding their impacts against each other

The work should be carried out very carefully and carefully, without excessive effort. If not one firearm, but several PM pistols are assembled/disassembled, then in this case the spare parts and mechanisms must be numbered. This will make assembly work easier, since the parts being assembled cannot be mixed up.