The bow is rightfully considered the most popular simple homemade weapon. Its improved modification with mechanical tension retention, that is, the crossbow, is also very popular. You can make a crossbow with your own hands without much difficulty according to the drawings, and it is the most convenient, powerful and accurate throwing weapon.

Required elements and tools

To make a crossbow at home you will need:

- A board with the dimensions of the desired dimensions of the crossbow;

- plywood for adjusting the stock;

- car spring;

- a thin steel cable, such as from a motorcycle brake lever.

The main structural elements are a frame with a stock, arms with a bowstring and a trigger mechanism. The frame is any wood turned into the desired shape. You should take a long board, which is enough to cut out the shape from the butt to the shoulders of the crossbow. The stock is cut to fit the owner's shoulder. A guide for projectiles should be provided on top. It can be cut into the wood itself, but it is more convenient to glue plywood on top.

IMPORTANT! The tools you will need are a jigsaw or any other sharp object for turning wood, glue, rope, a hacksaw and several large bolts to connect the structure.

After making the base, you can move on to the throwing mechanism. Most often, an old car spring is used for a crossbow bow. A section of the spring of the required length is sawed off. A string of cable 1.5-2.5 mm thick is stretched between the ends of the arc. The arms are fixed to the frame and fastened with bolts. After this, the main part of the crossbow is ready, all that remains is to make the trigger mechanism and prepare the shells.

Design Features

The crossbow fires short arrows or special bolts. The main advantages of the weapon are noiselessness, compactness and ease of manufacture.

Since the device can be created independently, many home craftsmen want to try making a crossbow with their own hands. There is no need to purchase a wide range of professional tools for assembly. It is enough to have metal cutting and woodworking equipment at hand. Device design:

- Bed. All mechanisms and main components of the weapon will be installed in this place. The bed must be made of hard wood. It is advisable to use a multi-layer base so that the structure can withstand the loads placed on it. It is better to make a weapon in shape that resembles the butt of a gun. Thanks to this, you can easily hold the crossbow in your hands and reload.

- Shoulders. A bowstring is pulled on them. This is an important design that ensures the speed of departure from the arrow bed. Car springs are often used for manufacturing, but due to the fact that they have to be tightly tensioned, the design becomes inconvenient. An additional problem is that the power may be too high, and then you can be fined for such a homemade weapon. To create shoulders, spring steel is sometimes used or ready-made samples are ordered that have the required power ratings. An alternative is a spring crossbow, where shoulders are not used.

- Cross. This part is used to attach the shoulders. The material used for manufacturing is wood or steel. Professional crossbows have a mechanism that can be quickly removed to tension the plate.

- The trigger mechanism is necessary to fix the bowstring and subsequently release the arrow. This detail must be done very carefully, having previously studied more preferable options that are more reliable.

- Tensioner. To bring the crossbow into working condition, the bowstring must be pulled and locked in the firing position. This is precisely what a tensioner is required for, as it makes installation easier. If the crossbow is made in a small size, then this design element is not necessary, since the weapon will have a weak drawing power.

It is important to know that the tension power of the bowstring should not be more than 43 kg. This is the limit that can be used in Russia. Using a more powerful crossbow is a violation of the law, for which a person can be prosecuted.

Step-by-step instructions for making a crossbow

A crossbow at home is made in stages from the following elements:

- Crossbow stock;

- guide;

- bow and shoulders;

- bowstring;

- trigger mechanism;

- shells (bolts).

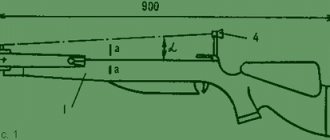

How to make a bed

The stock is cut from a solid wooden beam. It is advisable to choose viscous, moisture-resistant, smooth and aesthetic wood species. These include beech, oak, ash, birch and oak. In principle, any type of wood or board can be used, since the choice of material for this part is purely aesthetic. The optimal dimensions are approximately 3 cm thick and 90 cm long.

A recess for the bow is cut out in the front part of the stock. At a distance of 8-10 cm from the edge, a hole is drilled for attaching the bow. A bolt is then inserted into it, to which the throwing mechanism is tied with ropes. At the back of the crossbow, the butt is cut to the shape of the owner’s shoulder, for ease of aiming and accurate shooting. You can carry out optional additional decorative work to make the shape of the crossbow look more attractive.

REFERENCE: For ease of aiming, an aluminum or wooden cross is screwed onto the front of the stock. It should be screwed on top of the bow fixed to the stock. Additionally, the scope can hold the crossbow's arms, which will slightly increase the power.

Guide chute

A guide for throwing bolts should be placed on the top edge of the stock. It should be at least smooth, and ideally slippery. Modern crossbows use fiberglass and metal linings. At home, you can use plywood with a recess to fit the diameter of the bolts. The standard shape is a semicircle, but when working with plywood, you can make a triangular notch, which is somewhat simpler and will increase accuracy. Cutting corners are carefully ground.

Spring shoulders

The choice of shoulder material depends on the desired power of the crossbow. If the product is made for a decorative function, old skis are suitable for the shoulders. For a historically accurate product, a branch of a strong and elastic tree, ideally hazel, has been pre-dried for at least 4 months.

If you want to assemble a crossbow at home that you can not only show off, but also use for sport shooting and even hunting, you should use a metal bow. A popular and affordable material is car spring. It has optimal flexibility and elasticity, providing excellent tension and high shot power.

Review of drawings

At the first stage, a manufacturing scheme is developed. It is not recommended to take factory models as a basis, since they are characterized by a complex design, which increases the labor intensity of the process. Crossbow designs can vary significantly from each other, so it is recommended that you familiarize yourself with the most popular designs.

Classic model

To manufacture it you will need a minimum of parts and components. You can develop crossbow drawings yourself, but it is better to take an existing diagram. The components are a stock, an arrow guide, a shoulder module, a bowstring clamp with a trigger mechanism.

You can make a crossbow from wood according to the following scheme.

- Making a bed. It is recommended to make a full-fledged butt. For amateur models, you can limit yourself to a simple rectangular base. The wood needs to be taken as hard as possible, but with the possibility of processing it.

- Choice of material for the shoulder block. You need spring steel or its equivalent. It is important that at maximum tension it does not experience critical loads. The maximum length of one arm is up to 50 cm. To regulate the degree of tension, you can make a block crossbow.

- Trigger mechanism. The most complex module in the design. For manufacturing, you will need to follow the drawing exactly; the finished block is tested for fixing the bowstring.

- Tensioning method: manual or mechanical. If you need a crossbow for hunting, it is recommended to make a lever mechanism for quick loading.

For beginners, it is recommended to choose simple crossbow drawings. In the future, you can modernize the finished design or make a new model.

Spring

This is the best option if you need to hunt in water (again, we remember that hunting with a crossbow is also prohibited in the Russian Federation). Instead of the classic shoulder block, springs are used. They are located on the side parts of the bed, thereby reducing the dimensions of the structure. An underwater spring crossbow has a number of advantages - ease of manufacture, reliability, and the ability to adjust the tension force. The disadvantage is the short range of the arrow.

How to obtain a permit for smooth-bore weapons - procedure and list of documents

Features of making a crossbow for spearfishing:

- It is recommended to place the springs in steel tubes. This will reduce the risk of clogging and reduce the likelihood of injury.

- The minimum number of wooden components if the model will be used for spearfishing.

- To cock the mechanism you will need a lever block. If the spring is tight enough, it will be problematic to do this with a pin.

The advantage of this design is that you can make it yourself from scrap materials. A detailed description is not needed for this, since it is often necessary to adapt the drawing to the available components.

Types of homemade crossbows

A crossbow is a weapon with a long history, and throughout its existence, mechanical weapons have had many modifications. The most effective and interesting ones are still used today.

Block

In modern crossbows, to increase their power, an improved type of bowstring fastening on rollers is often used. In the standard version of the reversible bow, the projectile was fired with acceleration corresponding to the elasticity of the shoulders. When using a block trigger mechanism, acceleration increases many times over and, accordingly, such crossbows, even homemade ones made at home, are suitable for hunting and sport shooting.

Repeating crossbow made of wood

Repeating crossbows first appeared in China. Their specificity is in the original guide and in the simplified charging mechanism. The power of such a crossbow is much lower than that of a standard one and it is not suitable for accurate shooting, much less hunting. It can be assembled as an original wooden craft. The projectiles used are lightweight, without feathers or tips.

The bolts are placed in a cell above the stock and fall onto the guide as they are used. The trigger mechanism is an ancient goat's foot system, where cocking is accomplished by simply pulling a lever.

How to make a simple crossbow with your own hands

For this all you needed was a suitable stick and an elastic band.

Then they tied an elastic band in a forked stick, took a small pebble and went to hunt sparrows. To successfully shoot from a slingshot, you had to take a small pebble, place it in the center of the rubber band, pull it with all your strength and quickly release it, in a similar way to shoot from a bow. photo. Homemade crossbow

Today we only cheerfully remember our childhood pastimes, homemade weapons that brought so much joy, although in adulthood we replaced toy bows and slingshots with more modern and serious weapons - crossbows, hunting or sports bows. Let's just say that the design is practically the same, only more advanced, with many important elements, sighting and block mechanisms.

You can buy such small arms at any specialized store, but our desires do not always coincide with our financial capabilities. Therefore, we are not at all surprised that many fans of shooting with crossbows and bows want to make homemade small arms with their own hands. Despite the fact that this is not so simple, since you need to have the correct crossbow drawings, it is much more economical. Well, if you feel that you can make a crossbow yourself, then why not try it!

Is a crossbow suitable for hunting?

Most self-assembled crossbows have a tension of 30-40 kg, which allows them not to be considered a weapon and still be used for hunting small game. The crossbow can be used for shooting birds. When hunting small game such as hares and foxes, a shooting license will be required. Once you receive it, you can register your crossbow without any problems. A crossbow is not effective for hunting large game.

In this video you can see with your own eyes how accurate and powerful a crossbow is:

Conclusion

The main purpose of a crossbow is sports shooting. It can also be collected for the purpose of reconstructing historical scenes. Assembling and using for legal purposes a crossbow with a tension force of up to 42 kg is permitted in Russia without restrictions. It should be noted that the law prohibits the sale of uncertified crossbows with a tension force of more than 42 kg, but there is no liability for their manufacture, storage and transportation.

Pistol crossbow

A separate category includes the so-called pistol crossbow. Products of this type are distinguished by the following qualities:

- due to their reduced dimensions, they are extremely convenient for transportation;

- have high power and allow you to hit targets at both medium and long distances;

- have lower destructive power compared to block systems, but throw arrows at a higher speed;

- in addition to arrows, they can fire darts, harpoons, and metal balls.

Lodge

To make the part, you can use an easily processed wooden blank in the form of a board about 30 mm thick. It is worth noting that, despite the high strength indicators, oak is not very suitable for these purposes due to its significant weight. As for spruce and pine, the latter are not sufficiently resistant to mechanical damage and warp when in contact with moisture. Therefore, the type of wood should be selected depending on the goals and conditions of future use of the crossbow.

How to make a hunting crossbow truly practical? During manufacturing, special attention should be paid to the guide in the form of a groove for the arrow, which you should try to make as even, smooth and polished as possible. The condition of the groove largely affects the accuracy of shooting. It is advisable that the width of the stock be equal to the diameter of the arrows used. You can cut it using a circular saw.

It is rational to use a spring as a means of holding the arrow, which will press the projectile to the stock and will not allow the latter to slip out of the groove before firing.

Drawings for making at home

The photo above schematically shows a crossbow with all the necessary dimensions. Its main value is to understand what size its parts should be in relation to each other. Its entire length is 732 mm, with a height at the sight mounting point of 223 mm. The drawing shows a “pistol” handle (shaped like a pistol), for a reliable and comfortable grip.

The second hole is made to facilitate the construction, since the total thickness of the plywood handle (can be made of wood) is 30 mm. The arms are 302 mm long and are a universal option; their total length is 532 mm. For the first time, it is enough to make exactly according to the dimensions indicated in the diagram, and after testing, make adjustments.

Trigger

The material used to manufacture the part will be sheet iron. It is desirable that its thickness be at least 6-7 mm. The mechanism drawing is presented in the following diagram:

All parts are placed directly into the stock of a homemade crossbow. Here a special socket is cut out, through holes are made under the axes of the mechanism, onto which the escapement elements are subsequently installed. An example of setting the trigger is shown in the figure below.

LiveInternetLiveInternet

—Tags

—Categories

-Music

—A blogger's humorous horoscope

Horoscope for “Denis_Bulynin” for April 16, 2010

A smooth, clear pattern of megabytes on your hard drive is favorable for finding something useful in the

Lonely_Violet

.

Google suggests that it would be wise to finally decide for yourself whether to continue reading Pale_Man

.

There are several users with whom I would like to exchange a few words today. For example, with katrine_TEQUILA

.

Amazing desires sometimes visit a person. For example, suddenly get acquainted with Radio_Ultra

.