Hi all. On the eve of the holiday, I wanted to write about something thematic, interesting, useful, and most importantly, not too taxing on the brain. Remembering the Great Patriotic War, the first military association will probably be the legendary T-34 tank. The format of the site does not allow us to go deeper into such moments, so the search was turned to small arms of the Second World War.

We have already gone through most of the German models of pneumatics, and somehow it would not be human to place something like that on the eve of Victory Day. Among our weapons there are not so many pneumatic copies of “WWII participants” - Nagan and TT pistols come to mind. In 4.5 mm caliber, this would be enough if the manufacturers had not released a replica of the famous Shpagin submachine gun. In addition, the PPSh-41 was produced by two companies at once, and these are far from copies of each other.

On the paths of war

The PPSh was put into service on December 21, 1940, just six months before the start of the war. Nowadays, it is rare for a film to be complete without this submachine gun. The PPSh became one of the main small arms of the Second World War and deservedly received the status of a legend.

But his story does not end with the war. And although in 1950 the submachine gun officially replaced the Kalashnikov assault rifle, the “daddy” continued to march around the world. The weapon became a participant in the Vietnam and Afghan wars. Some countries only removed it from their arsenal in the 80s, although it probably still lives “on hand.”

“VPO 512” – SIZE MODEL OF THE FAMOUS PPSh-41

The PPSh became a definite symbol of the Soviet soldier during the Great Patriotic War. The full name PPSh-41 indicates the beginning of production of this submachine gun in 1941. For those who are interested in historical weapons, this legendary submachine gun designed by Shpagin is produced by the Molot-Oruzhie plant in the form of a weight and size model with the name “VPO-512”.

First, a few words about the PPSh itself and its famous designer. Georgy Semenovich Shpagin was born in 1897 in the village of Klyushnikovo, Vladimir region. He joined the army in 1916, where he ended up in a weapons workshop. After demobilization in 1920, he went to the Kovrov arms and machine gun factory, where gunsmiths V.A. were already working. Degtyarev and V.G. Fedorov. Shpagin's submachine gun received mostly positive reviews from weapons experts. The oblique cut of the casing at the muzzle performed two tasks simultaneously. It played the role of a compensator, which prevents the weapon from being thrown up when firing, as well as the role of a muzzle brake, which reduces recoil. All this increased the accuracy and accuracy of shooting. Also, PPSh turned out to be very technologically advanced in production, with relatively low labor costs, so its production could be established at any machine-building enterprise.

The PPSh was put into service at the end of 1940, and it began production in 1941, so it received its full name - “G.S. Shpagin’s 7.62-mm submachine gun, model 1941.” It was produced throughout the entire period of the Great Patriotic War, and mock-ups of the PPSh-41 are found mainly in 1942-45. For example, this model model is stamped 1945. This review is being prepared in the year of the 70th anniversary of the Victory, so this iconic layout can be an excellent gift.

The weight and size mock-up is made from the PPSh-41 combat model by deactivation. To be more precise, at first the Molot-Weapon plant produced air rifles called VPO-512, which were made by converting real PPSh. Then the production of pneumatic versions ceased, and the manufacturer began to produce a submachine gun in the form of a model. In fact, the PPSh model is a blank for an air rifle, only without the valve mechanism, which was located at the bottom of the receiver and was hidden by a disk magazine.

The name remains the same - VPO-512, and even on the box of the model it says “air rifle”, and in the passport there is a note “without a valve mechanism”. The trigger mechanism has been converted to use pneumatics, and there is a 4.5 mm piece in the barrel as a deactivator. The bolt is also deactivated, it moves, and there is a safety slide on the handle that allows you to lock it in the forward or rear position. The first releases of the PPSh had sector sights for a firing range of up to 500 meters, then they began to use reversible sights for two positions, 100 and 200 meters. The mockup also has a flip-over L-shaped rear sight.

On the top of the receiver, the PPSh model has a serial number and the mark of the manufacturer of the plant where this submachine gun was manufactured in 1945. This number is also recorded in the product passport. This sample also has similar numbers on the rear, on the trigger guard, as well as on the butt of the submachine gun. This option on one number is preferred by weapon collectors.

The PPSh-41 model can be disassembled in the same way as a combat model of a submachine gun. It has a detachable disk magazine, which is sometimes called a “tambourine”. If you move the buttplate of the receiver forward, you can tilt it up, and then remove the bolt and return spring. Using some tools, you can also completely disassemble the PPSh.

Despite all the advantages of the PPSh, one of the disadvantages of the combat model was considered to be its heavy weight, especially with a loaded magazine. However, in the case of the model, this is rather an advantage, since it is pleasant to feel the weight of the weapon in your hands, and to feel that this is a former combat submachine gun with its own history.

Replicas

The warehouses were emptied, but where did they go? We will not conduct an in-depth investigation here, but it is safe to say that a small part of the PPSh was spent on the production of replicas. Since relatively recently, the laws of our country have prohibited the redistribution of military weapons, so the models have been discontinued until the necessary certificates of conformity have been received. But the memory of them, as well as the existing samples on hand, acquired even before that very law, will remind us of such a phenomenon.

There are two versions of PPSh in 4.5 mm caliber on the market:

- VPO-512 PPSh-M “Daddy” - reworking of Vyatsko-Polyansky

- MR-562k PPSh-41 – work of the Izhevsk plant

Characteristics of the model of the PPSh VPO-512 Papasha rifle (PPSh-M, without valve mechanism)

| Housing material | metal |

| Base material | metal, wood |

| Equipment | Rifle VPO-512 “PAPASHA” (PPSh-M), magazine layout, passport |

| Number of charges | 1 PC |

| Manufacturer | IZHMASH (RF) |

| Combat prototype | Rifle VPO-512 "PAPASH" (PPSh-M) |

| Length (mm) | 840 |

| Type of ammunition | 4.5mm cartridge mockups |

Video review on MMG

Model of the PPSh VPO-512 Papasha rifle (PPSh-M, without valve mechanism) buy in the Popadiv10 online store. Model of the PPSh VPO-512 Papasha rifle (PPSh-M, without valve mechanism) at a low price of 23,990 rubles. You can pay for your order by mail upon receipt in any part of the Russian Federation. Before placing an order, be sure to check the price and contents of the product by phone (during business hours) or by e-mail and feedback system (at any time convenient for you).

Information on the product “Model of the PPSh VPO-512 Papasha rifle (PPSh-M, without valve mechanism)” is for informational purposes only, and is not a public offer, determined by the provisions of Article 437 of the Civil Code of the Russian Federation, characteristics, appearance, color and equipment may be changed by the manufacturer without notice.

Functional

The topic of functionality today will be devoted to the activities of combat PPSh. It would take up too much space to describe everything, so I offer a manual for handling the PPSh-41 using the MMG as an example:

I hope you looked at it, figured it out, and no one will think that the next frame shows a “murky fracture.”

In addition, I would like to say about the classification of the pneumatic sample. According to all papers, the models are classified as “Pneumatic rifle”. But due to the fact that outwardly it is still an automatic submachine gun, and one of the models has the makings of automatic shooting, the review is posted in the “Automatic Machines” section. I apologize to those whose ideals I deeply damaged.

VPO-512 PPSh-M “Dad”

“Molot” didn’t bother much with the legend: a rough rework and sending it to the market. Let's look at the performance characteristics of this model:

| Model | VPO-512 PPSh-M |

| Weight, kg no more | 4,25 |

| Overall length, mm | 840 |

| Store capacity, pcs. | 17 BB balls |

| Caliber, mm | 4,5 |

| Energy source | CO2 canister, 12 g. |

| Speed(m/s) | up to 130 |

| Production | JSC VPMZ "Molot" |

| Price (as found) | 14,000 rub. |

We immediately pay attention to the reduced ammunition capacity of the magazine - the large disk is made for beauty. The power is also not so great - 130 capes is not such a good indicator. Of course, the model fires only in single mode. Everything else, as in the combat PPSh, is still a redistribution. The exception, perhaps, is the bolt; its movement was prohibited by a welded bolt in order to prevent any bad actions)

I am attaching a photo of a store with a valve to clarify the whole mystery of the world:

False disk with a magazine like MP-654k

Otherwise, everything is already clear, either the functionality of the part is original to the combat model, or corresponds to other well-known domestic gas-cylinder pistols.

When converting it into a gas tank, the factory polishes the PPSh stock, that is, it gives it a marketable (from its point of view) appearance - it removes nicks, scratches and chips of the protective coating. The fact that PPSh fans would rather prefer an untouched surface does not bother him, of course. When grinding from the stock, the dowel nuts are disfigured, swivels and screw heads are peeled off. The combs become washed out, the neck becomes thinner, and the butt is noticeably flatter. There is no comparison with an untouched stock, either a regular dowel or a “front” one (there are comparative photos below on the topic pages).Apart from the incompetently “glamorized” stock, the appearance of the PPSh-M has been left unchanged. In this sense, it differs from the combat source only in a small hole in the left plane of the bolt box, which serves to fix the valve mechanism. However, the disk does not have a button and a nut; instead of them, machined blank dies are welded, which are not at all similar to them.

The solution to fixing the valve, by the way, is very successful: the hole for the button is small (diameter 5 mm), it is oxidized, and therefore the result of the alteration is almost invisible. Yes, and it’s convenient to remove the valve. To do this, you need to open the bolt box cover, press the button with a drift of a suitable diameter or the like, and remove the valve body by pulling it in the direction of the casing cover. It is better to use a brass or copper drift, or a strong wooden rod can also be used: the spring force under the button is small.

Note.

The valve is removed only in the direction of the casing cover. It is impossible to pull it out in the direction of the disk, since its supporting part is wider than the frame of the cylinder holder. Accordingly, when installing it into a box, it will not be possible to insert it from below.

The PPSh butt has a cavity for accessories, closed by a hatch, but of course the tools themselves are not included in the kit.

Note.

There is a persistent myth among amateurs that there is a certain standard case for accessories, which should be in the butt of the PPSh, but it is supposedly not sold along with the subject, since it was stolen at the stage of alteration. Don't believe it. PPSh-41 was never equipped with a pencil case, the kit included the so-called. Accessories included only a cleaning rod and an oiler. (And a pair of screwdrivers, if I’m not confused. One for unscrewing the shank connecting screw, the second for adjusting the height of the front sight.)

Regarding the protective coating of iron (early versions of PPSh-M). This is not paint or bluing, this is phosphating. There is an opinion that it was not “Hammer” who tried to phosphate the casing, but this is how the PPSh was preserved before being stored for long-term storage. Blued examples can be found, but they are just as rare as examples with sector sights made from early examples of the PPSh-41. But the “tambourine” and the butt plate, as a rule, are not subjected to phosphating; in most cases they are blued.

Later note.

Since about 2009, phosphated copies have also become rare; now PPSh-Ms are going on sale, in which almost all metal parts, except for the “stump” of the shutter, are coated with a fairly abrasion-resistant black composition, reminiscent of matte paint. According to competent people, this is nigrozin, printing carbon black based on BF glue. The origin of the “feature” is not really known. Either some of the PPSh were preserved this way when they were put into storage, or during the war their production was reduced in price in this way. Only the butt plate of the stock, the split axis of the casing and the fittings remained oxidized, but sometimes phosphated parts are also found among them.

The shutter of the original PPSh-41 belongs to the so-called parts. white group, i.e. during manufacturing, like the barrel of a TT pistol, for example, it was never oxidized or phosphated: do not forget to take this into account when making modifications in order to return the “entourage” appearance.

Later note.

These photos show a remake of early issues. In those years, the bolt of the original PPSh-41, when converting the machine gun into CO2, was cut more “humanely”, leaving the side planes along the entire length. Since about 2009, valves have been cut crosswise, turning them into short stubs. Of course, both are faster and more technologically advanced than carefully milling about 20-odd mm from the bottom. steel, preserving the ejector spring. It is necessary to cut through the shutter in one way or another so that in the deflated position it does not interfere with the operation of the valve mechanism. Well, and, again, deactivation, since the shutter is t.z. legislation is the main part of the weapon.

Later note.

An intact ejector spring is enough for the bolt to visually appear to be working, since even with the lid folded back, only its upper plane is visible. And it will not interfere with the operation of the valve if you put it in the cocked position before firing; fortunately, in the “past life” it could be fixed in it not only with a sear, but also with a sliding button-slider of the safety. Therefore, on my second copy I adapted the so-called. MMG of the PPSh-41 bolt, which was milled from the bottom to make it compatible with the trigger. The operation is not difficult if you have access to milling, but you will have to remove a lot of metal, and the steel of the shutter has rather nasty properties. The trigger itself will need to be sharpened from above approx. by 3-3.5 mm. (photos are on the pages of this topic). On my first PPSh-M with an early “cut” bolt, I made an imitation of this spring.

We fold back the latch, pull it forward and remove the “false magazine”. Before us is a valve block.

The entire valve group is very compact, making it easy to install the cylinder. It is tightened with a long screw, which, for ease of screwing, has a movable transverse axis, similar to a cotter pin on a vice screw. I replaced it on my copy with a steel ring that is more pleasant for the fingers, which is also good because it does not cling to the tambourine from the inside.

(Later note. Later I began to leave the standard knob. As it turned out, unlike the ring or, say, the swivel from the MP-654 screw, in no way does it come into conflict with either the cartridge or the back wall of the disk, especially if in the disk additional "custom" parts are placed, such as the base of the weighting agent or the spring plate that holds the standard nut with a slot. Before inserting the magazine into the groove of the valve valve, the axle-knob must be moved in the screw hole in the direction from the magazine, after the magazine is installed - back, so that did not cling to the disk wall.)

The valve body is cast from silumin (not from TsAM, that’s right). The trigger that hits the valve is hardened steel, and the expansion chamber is brass. This part, by the way, is no different from a similar part MP-651, or “Cornet”. Well, and accordingly, the seals are also Kornetov’s: under the valve there is a polyurethane washer with a funnel-shaped seat under a conical plate, a thin rubber ring seals the threads of the seal, and as an over-cylinder gasket there is a well-known polyurethane washer, the same as in the MP-654K seal.

The PPSh-M magazine is linear; there is no feeder lock, like the MP-654K magazine, and this is not very convenient. Therefore, if you often shoot from the PPSh-M, it is better to trim the nail of your index finger less frequently. The feeder itself is plastic (glass-filled polyamide). In principle, it is not difficult to replace it with steel, including from MP-654K, but this is pure perfectionism; plastic also copes with its task perfectly, and at the same time does not experience any problems from contact with the balls. The passport says that the store is designed for 17 balls, but in fact it holds 18. The store is made in a very interesting way. It is combined: the upper part is steel, the lower part is polyamide.

They are connected thanks to a kind of lock: the upper, steel part is equipped with something like a spherical end, which is inserted into a socket in the plastic half in a responsive geometry. Made carefully, reliably, there are no gaps or shatters. There’s just one thing that surprises me: is it really easier to produce than milling an all-steel magazine? But apparently it’s easier. Or cheaper, who knows. However, another strange thing is that it would have been even simpler and cheaper to make it entirely out of plastic.

The magazine is removed from the valve frame by pressing this button.

It is made in the form of a cylindrical nut and is spring-loaded, and therefore the axis with the magazine lock itself returns to its original position.

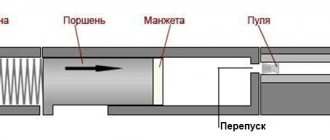

The operation scheme of the PPSh-M mechanics is extremely simple. The trigger, when pressed, acts on the longitudinal rod located in the groove of the bolt box, and that, in turn, on the spring-loaded trigger, which swings on an axis in the form of a pin. The trigger rises, and at the end of the rod stroke, having reached a critical point, it breaks off from its tip and hits the valve from above, due to which a portion of gas is thrown out of the chamber into the bypass. After this, the gas pressure in the chamber and the spring close the valve - the chamber is locked, and the valve and rod return to their original position under the action of the spring. The device is ready to fire again.

The stroke of the SK is quite long, however, by pressing it several times in a row, you can shoot something like a burst. However, due to the relatively small volume of the expansion chamber, the cylinder will cool quickly, and each subsequent shot will be weaker than the previous one.

What is surprising is the complete absence of any elastic seal in the valve between the gas supply hole in the rear plane of the magazine and the bypass channel, behind which there is the chamber outlet: a leak, and a very noticeable one, is inevitable here. If you want to increase the power of the “rifle” without increasing consumption, modification of this unit is absolutely necessary.

The chamber and trigger are fixed at the base of the valve with hardened pins; When dismantling these parts for the first time, the pins must be carefully knocked out with a drift and a hammer; later, when the mounting holes are slightly developed, they can simply be pressed out with a drift.

Note.

If there is no cylinder in the valve valve, you will encounter a phenomenon that can easily be mistaken for a malfunction: when clicking at idle after returning the valve to its original position, the tip of the rod may not come out from under the trigger shank. The rod will seem to jam, and it will stop interacting with the trigger. Don't be alarmed, this is not a defect or a breakdown. The fact is that the chamber is somewhat movable vertically at the base of the valve - the groove in it is slightly wider than the diameter of the pin securing it. Therefore, when there is no cylinder in the valve valve, the chamber, thanks to the spring that presses the trigger down, also moves down a little. Due to the lack of pressure in the chamber, the valve is also pressed into the chamber by at least 2 mm. Naturally, because of this, the trigger shank moves back a little further than when the valve is equipped, which is why the tip of the rod cannot come out from under it. And it’s good: clicking idle is not only useless, but also not very useful for the mechanism. Install a gas-filled cylinder and everything will fall into place.

The fire switch from burst firing to single shots, installed in front of the SK, on the PPSh-M serves as a safety device: when snapped into the rearmost position, it limits the thrust stroke. Therefore, it is impossible to fire a shot in this position.

The PPSh-M barrel is smooth, fits a 4.5-caliber explosive ball, new-made, cylindrical (and not cone-shaped, like the standard PPSh-41 “mortar”), hardened, and has a muzzle chamfer. In its breech there is a gasket with a large hole, trapezoidal in cross-section, made of soft polyurethane of a dark color: exactly the same as that of the MP-654K. The barrel is attached to the casing “incorrectly”. That is, not the same as the standard barrel of the original PPSh-41. In this latter, the conical-shaped barrel with its front end is inserted into the diaphragm of the folding radiator casing, and its rear end has 2 semicircular grooves, in 1 of which the barrel is held by a split axis, which also serves as a casing hinge:

upload a picture

Changing it on the PPSh-41 is very simple - just fold back the casing and knock out the split axis with a drift, and then pull the barrel in the direction of the bolt.

Here, the split axle performs only the function of a hinge for the folding casing, and the barrel is permanently attached, fixed in the base of the casing with a separate pin, the hole for which is drilled next to the large hole for the axle. Moreover, this hole is blind, and the pin is inserted approximately half the width of the base of the casing.

Later note.

From about the same time that the plant switched to painted iron and cut-off bolts, only so-called “castrati” went on sale. It is not known for what purpose this was invented, but a full-size new-made barrel is no longer installed on them. Instead, the plant deploys the standard “mortar” to a diameter of approx. 9 mm, and presses into it from the breech side a short, no longer than 60-70 mm, liner with a smooth channel of 4.5 mm caliber, also fixing it in the “mortar” with a transverse pin. Because of this, the power of the “castrati” in comparison with the PPSh-M of the first releases is of course none, lower than that of the “stock” MP-654. And there is nothing to say about accuracy, even relative ball-throw accuracy - after all, the ball, before leaving the barrel, flies (or rather crawls) along a wide “corridor” more than 200 mm long. in the vortex flow of gas flowing around it.

There is one more unpleasant moment here. A standard “mortar” with a liner-stub inside it is attached to the casing according to the previous scheme - permanently, with a blind pin, located as before next to the hole for the split axis of the hinge, and at the same time, as before, it is shifted back relative to the standard position: about 15 mm . But since it has a conical cross-section, its front end does not fit tightly into the hole in the front diaphragm of the casing. To put it simply, it dangles like horseradish in a bucket. It is not difficult to verify this; just tap your finger on the front of the barrel through the hole in the casing and hear a characteristic ringing sound. Accordingly, if we want to achieve something more intelligible and interesting from the PPSh-M than farting through a pipeline into an A4 sheet at 5 meters, we will inevitably have to re-barrel it: either change the “mortar” with the entire stub inside, or press out the stub and put it has a full-fledged liner. Simultaneously with this operation, it is not difficult to return the “mortar” to both its normal position and its normal fixation. The game is quite challenging, since you will have to drill out the blind pin and press out the “stub”, but it is worth the candle, especially considering that when we move the “mortar” forward to its original position, we get the opportunity to lengthen the barrel bore by pushing a new liner out of the “mortar” » back exactly the same length as it was shifted towards the cut of the casing.

It’s also bad that when shooting from a “stub,” the balls do not always fly out through the hole in the muzzle compensator, but hit it and leave on its inner plane “traces of mechanical action” that are not at all entourage.

Link to the topic on finalizing the PPSh-M

:

https://forum.guns.ru/forummessage/24/1075108.html

The PPSh-M kit includes spare parts, 4 sealing gaskets - for the valve, obturator, barrel and over-cylinder. It is very easy to miss them and throw them away with the box, since they are wrapped in discreet paper wrapping, lost among the packaging film and cardboard sealing inserts, so be careful.

Shooting my first PPSh-M through the chrono.

1 - 136 m/s 2 - 129 m/s 3 - 117 m/s 4 - 115 m/s.

Postponed, five minutes later another episode:

1 - 156 m/s (!) 2 - 149 m/s 3 - 146 m/s...

In short, if you want to hit more than just a bottle at 10 meters, serious work is necessary.

Later note.

In this topic I am writing about my first PPSh-M, which has been living with another owner for a long time. On my second one, which I’m not going to part with, after a little modification of the valve, shutter and conversion to a full-size liner, I was able to get 167 m/s with an explosive ball from a fresh cylinder, and on the next two up to 170.

Sighting PPSh-41 couldn’t be simpler. The front sight is adjusted horizontally by moving it in a transverse milled groove: to do this you need to use a hammer and a drift, preferably a soft one, of course - brass or copper. Vertical adjustment can be made by turning the threaded pin of the front sight through the upper hole in its protective ring, but for this you will have to make or buy a special key.

The rear sight with narrow rectangular slots is reversible and can occupy 2 positions: for shooting at 100 and 200 m (sighting range PPSh-41). However, the bar is marked with the numbers 10 and 20.

The balance and ergonomics of the PPSh are quite acceptable, although with a full disk of live ammunition it would probably be pulled downwards by the muzzle. But if we remember that powder gases tend to throw the barrel up during shooting, then everything here is logical and compensated. And the beveled end of the casing - the know-how of designer Shpagin - also worked to partially counteract this phenomenon.

To remove the disk, you need to fold back and lightly press in its direction the latch located on the box between it and the SK bracket. The “tambourine” sits in its place very tightly, and if you apply too much force, it can come off too sharply, hitting the bottom of the valve with the edge of the neck “at the end.” Therefore, you don’t need to pull too hard; after retracting the latch, just rock it a little from side to side, then it will come off gently.

Note.

The PPSh-41 was standardly equipped with two disk magazines, individually fitted to each specimen. If both were lost, a disk from another copy or a new one often had to be adjusted anew. The adjustment is not difficult, but when converting a PP into a gas tank, of course no one bothers with it. In addition, the “tambourines” on PPSh-M are often prefabricated - the cover is late, the box is early, or vice versa. Therefore, some tambourines fit tightly in the box without gaps and can be easily unfastened, while others dangle in all directions, or even do not hold at all. When checking the purchased copy, you should take this into account.

Actually about the “cut”: what was cut in the original PPSh.

1. A cut was made in the upper part of the massive steel bolt (note - the gates of the latest PPSh-M releases are “cut” across, see note above), thanks to which the ejector and its spring disappeared as a fact.

2. Of course, the trigger mechanism has been thoroughly redesigned.

3. All the guts from the “tambourine” were removed, otherwise the valve valve simply would not have fit there, and also shaped slots were made in the reinforcing steel plates of the neck - without this, the base of the valve valve and the linear magazine would have prevented the tambourine from being attached; the disk cover is welded to the box at two points, and the latch to the cover at one; the button and nut have been replaced with mock-ups; For some reason, the upper side reinforcing ribs of the neck are welded to the box, each at 2 points.

These photos show a tambourine of late releases, coated with nigrosine.

Weight of the “rifle” according to the passport:

Without bullets and cylinder - 4.25 Without magazine - 3.70 Without magazine and valve mechanism - 3.45.

MP-562 PPSh-41

The Izhevsk model is more interesting for us. Although from afar it looks like the same converted combat PPSh-41, upon closer examination you can see a glowing red light, warming the hopes of hardball players... To immerse yourself in the atmosphere, I suggest you take a look at the thematic video:

Yes, gentlemen. This is a real automatic PPSh. Here are some more technical characteristics:

| Model | MP-562 PPSh-41 |

| Weight, kg no more | 4,5 |

| Overall length, mm | 850 |

| Store capacity, pcs. | 70 BB balls |

| Caliber, mm | 4,5 |

| Energy source | CO2 canister, 12 g. |

| Speed(m/s) | up to 120 |

| Production | Izhevsk Mechanical Plant |

| Price (as found) | Up to 24,000 rub. (there are much cheaper ones) |

On average, this is the same as VPO-512, but better. The main differences are automatic fire (modified Drozd system) and full use of the magazine disk. Considering that this is, after all, Izhevsk, there are probably many modifications that transform this toy into the category of an ideal pneumatic machine...

So, the implementation of the machine is almost the same as in the MP-661k. The electronics are located in the receiver, the power is in the butt. The original fuse retains its function here; in addition, a classic LED is hung on it. The fire mode switch (single-six) is also in the original place - in the area of the trigger.

Let's also look at the store. The cylinder is still screwed into place, but now the balls are charged in the normal way - along the circumference of the disk.

An example of loading and shooting can be seen in the following video:

Pneumatic PPSh-41 "MP-562K". Review and photos.

Good afternoon, lovers of pneumatics and history!

I congratulate everyone on the upcoming Defender of the Fatherland Day and present a review dedicated to the unique product of Izhevsk Mechanical Plant OJSC - the pneumatic PPSh-41 "MP-562K".

Unfortunately, this pneumatic submachine gun was produced for only a couple of years and currently all samples have found their owners.

But, nevertheless, I consider it my duty to write this review for future, so to speak, generations! ))) Moreover, on our favorite website www.air-gun.ru there is very little information about the MP-562K.

Echo of war...

As children, we all watched films “about war” and there was always a PPSh with a round disk in the frame...

Many monuments to the Soviet wars of liberation depicted soldiers with these weapons.

The PPSh was created by Georgy Semyonovich Shpagin chambered for the 7.62×25 mm TT cartridge and was adopted by the Red Army in 1940, where it served with minor modifications until the 50s.

It would seem that in our time, having huge warehouses with outdated weapons in stock, we can please our fellow citizens with interesting “alterations”, but after a slight thaw, a law was passed prohibiting such actions.

To date (beginning of 2015), only a few pneumatic variants have been made from military weapons in Russia, these are “MP-562K” (PPSh-41), “MR-656” (TT) - both IzhMekh and “VPO-512 PPSh- M" (Daddy) produced by the Vyatsko-Polyansky Molot plant, which is famous for its smooth-bore weapons.

In addition, there are also “firing” signal pistols: “TT-S” from the Tula Tokarev combat pistol and the Nagan system revolver - “MR-313”, NAGAN-S VPO-503 (Bluff) and R-2. There are also alterations into traumatic versions (but this is subject to a license).

How I wanted to hold this legend in my hands (not a Chinese-Taiwanese toy, but our dear one)!!! And now the dream has come true!!!

View and authenticity 5 points! Complete with the original shoulder strap it looks absolutely wonderful!

The receiver still bears the factory marks, number and year of manufacture – 1943.

A brief look at the technical features of

the MP-562K.

The uniqueness of the “MP-562K” lies in the fact that the PP (submachine gun) is based on a real Shpagin combat submachine gun (years of manufacture may differ from copy to copy).

The insides of the PPSh have undergone alterations, but the charismatic profile, recognizable throughout the world, has remained unchanged!

Weight 4.5 kg, material made of steel - there’s nothing to complain about, everything is “original”!

The only conditional disadvantage is that the new-made shutter lever on the right side is fixedly fixed and only performs the function of turning the drive on and off (aka the fuse).

Yes, yes, it’s the drive, since shooting in this model is realized through an electronic system powered by 6 AA 1.5V batteries (R6, LR6), hidden in the butt.

Shooting is carried out both in single shots and in short bursts with a cut-off of 6 balls.

The fire switch retained its functionality from its combat ancestor and is located in front of the trigger, which is very convenient. Under the rear panel on the left you can see a red LED that signals that the power is turned on.

The drum magazine has been completely redesigned for installation inside a 12 gram canister of CO2 and 70 explosive balls, which are located around the perimeter of the drum.

The sighting devices have undergone almost no modernization, the front sight is in a protective ring and the L-shaped rear sight with a range of 10 and 20 meters (in the original 100-200 m).

Of course, connoisseurs of rare weapons will discover a dozen differences between the “MP-562K” and its combat counterpart, but, nevertheless, what is important to us is the fact that this is a working PNEUMATIC submachine gun, and not just an MMG.

But still, it is necessary to bring the specimen that came to me to a more or less “combat” appearance.

The first thing that had to be done was to get rid of the “wonderful” rough coating that was obtained at the factory after processing the metal components.

We managed to quickly disassemble the PPSh, after which all the necessary parts were sanded (I don’t post a photo of the “naked” PPSh for ethical reasons).

Then degreasing and bluing with the proven Clover. Lubrication of parts and assembly, which went almost without problems (small springs and parts tend to jump under the table).

I took hold of the “drum”, but decided not to change anything, I just unscrewed the magazine head... from which 6 steel balls fell out... I was surprised, poured them into a box with baby bags and screwed the head back on.

But my doubts did not deceive me and after reading the Internet I found out that these balls are larger in diameter than the hole in the magazine head and always remain inside, performing the function of a flexible feeder, I had to return them to their place!!!

A very interesting detail in the drum is a metal radiator with a magnet to prevent the cylinder from overcooling during tempo shooting!

The rifle, as the manufacturer positions it, is equipped with a rifled barrel and it’s not a fact that this is good...

The MP-562K comes with a standard oil can and screwdriver, as well as a loading accelerator, which is very important with such a magazine capacity.

First tests in action.

Finally, it got a little warmer outside (up to 0 degrees) and it was decided to conduct test shooting.

After all the necessary procedures: equipping the magazine, installing batteries and a cylinder, the first shots were fired... and it became clear that adjustment of the firing pin was necessary, because the balls flying out of the barrel left only a shallow dent on the reference board (and this from a distance of 50 centimeters)!

I decided to change the extension length of the solenoid striker by mechanically moving it. As a result, the speed of the ball's departure increased significantly and was clearly about 200 m/s.

As you can see in the photo, two balls went several millimeters into the tree. For comparison, sticking out on the right is a ball that was once fired from an S-TT...

But the happiness ended on the fifth shot with a sharp drop in power almost to zero... the cylinder “died”!

Having tinkered with the removal of the striker, I managed to shoot about 40 balls from one cylinder (5 super powerful ~ 200 m/s, 10 powerful ~ 130 m/s, 15 normal ~ 100 m/s and 10 clearly below 80 m/s ).

I shot from 10 meters, it was 0 degrees outside, there was wind... and 90% of the balls hit the target.

The result is visible in the photo.

Now I will start fine-tuning the striker when it gets completely warmer, because... you will have to use the power regulator, which is located on the board.

The puncture of the cylinder is very clear.

Something else needs to be done with the buttplate mounting system, because... It is attached with ordinary self-tapping screws and over time the wood will wear off, and you will have to constantly unscrew and tighten it!

As the play progressed, I modified the battery compartment - I glued a soft ribbon to make it easier to remove the batteries from the butt.

And finally, some photos of the interior...

Everyone, have a fruitful working week before the holidays!

Especially for www.air-gun.ru

Agent1969©

Z.Y. I'll add a diagram here...

Let me summarize

In the underground battle of PPSh models, in my opinion, the Izhevsk model is winning today. We are not talking about the ideal quality of work and thoughtfulness here, but still, among the proposed ones, this is the best option. The purchase of PPSh for hardball, as well as Juncker, can be debated for a long time. Proponents of replicas will support, proponents of practice will criticize. But regardless of this, the PPSh periodically pops up in our environment, and even more so among those who like to shoot cans in the garden - the model stands out from others in its appearance.

In general, the choice is up to everyone, but in terms of price and quality, you can find more interesting options in the “just shoot” class. Fans of historical replicas can be sent to choose airsoft pneumatics - there is a lot of this goodness. Sophisticated gourmets who need a combination of replica and traditional caliber are left to choose between the proposed options.