If you are planning a short-haul flight, there is a chance that a Sukhoi Superjet 100 will be served on the ramp: the cabin layout and the best seats are presented below. The airliner with the certification name RRJ was developed by Russian aviators with the participation of foreign companies. It became the first product of the domestic aviation industry whose noise characteristics received good marks when tested for compliance with European standards.

Model features

The Superjet is designed according to a classic aerodynamic design: the airliner has a horizontal tail (stabilizer) located after the wing. The design is common in military and civil aviation, as it ensures flight safety and optimizes takeoff performance.

The model is equipped with SaM146-1S18 engines: they are produced at a Franco-Russian plant. The option made it possible to increase the range of flights, passenger capacity and take-off weight (the indicator at which a ship can take off while complying with safety rules).

Another feature of the Sukhoi Superjet is the use of composite materials to reduce the weight of the aircraft. In the future, designers plan to increase their share, but the process is slowing down due to additional research. Representatives of JSC Sukhoi Civil Developments emphasize that they are going to study the impact of sudden temperature changes on materials.

As for the cockpit, it is equipped not with standard steering wheels, but with sidestick joysticks. This made it possible to free up space for a convenient and ergonomic arrangement of other devices, as well as improve visibility of the panel. To ensure effective operation of the sidesticks, the Fly-by-wire system has been introduced: the movements of the joysticks are transmitted by electrical signals.

Advantages and disadvantages

The undeniable advantage of Superjets is their unique layout, as well as their use in the development of innovative design solutions and technologies. This made it possible to make the passenger liner reliable and safe. During the design, the requirements and standards of the international companies FAA and EASA were taken into account as much as possible, which was noted during certification.

An important advantage is that the developers took into account the wishes and requirements of Russian and foreign potential customers. Thanks to this, the SSJ 100 is maximally adapted to various operating conditions and has acquired bases at different airports around the world.

The SSJ100 is quite suitable for all runway classes and has attracted the interest of many airlines. This was achieved thanks to the structural assembly features and the latest avionics system, which successfully lands the aircraft even in the most unsuitable weather conditions.

As for the shortcomings, experts discovered them during tests and first flights in 2011-2013. They were successfully eliminated, and passengers only noted certain everyday inconveniences associated with accommodation in the most inconvenient places. There is also a not very wide passage , which interferes with the transport of carts by flight attendants. Otherwise, there are no complaints about the operation of the airliner. Moreover, customers who regularly use airline services are completely satisfied with the affordable cost of tickets.

Today, the Superjet family is represented by the following models, each of which has its own features and advantages:

- Sukhoi SuperJet 100 is the first short-haul airliner equipped with 2 turbofan engines and a supercritical wing (flights up to 3040 km);

- Sukhoi SuperJet-100−95LR (the interior layout has been changed by lengthening the nose) - characterized by an increased take-off weight and flight range (4500 km);

- Sukhoi SuperJet-100−95SV - has maximum passenger capacity.

The development of a modification of the LR series made it possible to significantly increase the flight distance. It is characterized by low operating costs and improved aerodynamic characteristics.

Aircraft modifications

In addition to the basic modification, the following options have been developed:

- Sukhoi Superjet 100B-VIP is an administrative and business version of the aircraft. It combines the comfort and versatility of airliners designed to transport officials with the reliability of designs for scheduled airlines.

- Sukhoi Superjet 100LR (SSJ100 LR) is designed for short- and medium-haul flights. The modifications, which at one time became revolutionary for the Russian Federation, made it possible to increase the range by 1,400 km. Based on this version, the Sukhoi Superjet 100LR-VIP model was also released.

- Sukhoi Business Jet is produced according to individual orders. The model is operated by the Border Service of Kazakhstan.

All models have received international certificates, so they can also be used by foreign carriers.

Modifications of the Sukhoi Superjet cabin using the example of several airlines

Airbus A319 Aeroflot cabin layout

According to materials from the Wikidot Superjet website and the official VKontakte group, today about one hundred SSJ aircraft are in operation in the world.

Interesting fact! Aeroflot - Russian Airlines is the main buyer of the Sukhoi Superjet. The first flight of the aircraft under the Aeroflot flag took place on June 16, 2011 on the route Moscow - St. Petersburg.

Initially, the airline ordered aircraft with a simplified version of the Aeroflot Lite cabin. Currently, the air carrier operates the Aeroflot Full model, which differs from the previous one in the increased number of toilets, kitchens and the presence of individual airflow for each seat. As of July 2022, the airline’s fleet already includes 45 Superjet aircraft, all aircraft in operation are new.

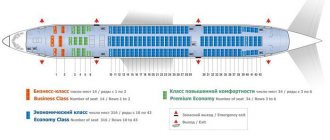

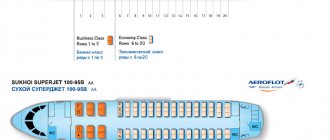

The Aeroflot Full cabin has a two-class layout of 12 business class seats (3 rows of 4 seats) and 75 economy class seats (15 rows of 5 seats) and is available in two versions: AF and AA. Their only difference is the presence of an additional toilet in the rear of the cabin for the AA model.

Aeroflot Full interior

In addition to Aeroflot, the aircraft's buyers include Russian and foreign airlines, Azimut, as well as Interjet (Mexico), CityJet (Ireland), Lao Central Airlines (Laos), Comlux (Switzerland).

Aircraft use aircraft with a 93-seat cabin (8 in business class and 85 in economy class) and a 100-seat economy class cabin. It is not known how many toilets, kitchens and other units are provided by the air carrier, since Yamal does not provide a layout of the cabins even during online check-in for the flight on its website. As of July 2022, the airline’s fleet includes 15 Superjet 100 aircraft.

Another buyer of the Sukhoi Superjet 100 airliner is aviation. Currently (July 2022), this carrier operates 8 Sukhoi Superjet aircraft. All aircraft of the carrier have a single-class layout with 100 seats (20 rows of 5 seats) or 103 seats (with an additional first row of 3 seats). The diagram below clearly shows their differences.

Salon Azimuth

What projects are in development

The designers expect to implement the following projects:

- The Sukhoi Superjet 100SV is planned for production in 2022, and it will be able to make its first flight in 2022. The capacity is going to be increased to 125 passengers.

- Sportjet by Sukhoi will be designed to transport athletes.

- Suhkoi Superjet 75, designed for 75 passengers, will be operated on routes up to 2 thousand km long. The developers hope that it will allow companies to reach a new business segment.

- Sukhoi Superjet 100R will include an increased share of Russian components.

As for the results of the already created models, in 2022 it turned out that their flight hours on Russian airlines decreased. But for foreign companies the indicator increased, and there were no complaints about profits. This is due to the fact that Russian carriers are having problems with the supply of components. To correct the situation, a set of measures was introduced to increase flying hours: it is too early to assess its effectiveness.

History of creation

]Aeroflot[/anchor] is the largest customer of these aircraft. Currently Aeroflot has 30 Superjet 100 models. Another 20 should enter service in the near future. The planes are used by domestic ones, Azimuth, and some foreign carriers. The development of the model involved: the Italian aircraft manufacturing company Alenia Aeronautica, the American corporation Boeing and other foreign manufacturers.

Production of the Superjet 100 began in 2003 . The first copy was presented 3 years later. Two years later it was presented to the world community at the Le Bourget aviation show. In 2012, the aircraft received the necessary aviation safety certificates. From this moment on, the aircraft received the right to fly to international European airports. Receiving a new certificate in 2014 significantly expanded the aircraft’s capabilities.

In 2016, it received EASA (European Aviation Safety Agency) certificate for the Long Range model (SSJ100LR) - an airliner with an increased flight range (up to 4500 km).

In 2022, the corporation introduced a model with a short takeoff and landing runway—this aircraft is equipped with engines with more powerful takeoff thrust. New wing mechanics and changes in avionics algorithms made it possible to reduce the takeoff and landing distance by 1,425 m.

Announced for release in 2022, the new SSJ75 model with 75 seats should become a new word in the domestic aircraft industry. The use of the latest Russian technologies and components (for example, the PD-14 engine or a heavy-duty wing made of composite materials) should not only solve the problem of import substitution, but also improve the aircraft’s reliability rating, which was shaken after the plane crash at Sheremetyevo on May 5, 2022 and other accidents.

The Sukhoi Superjet 100 is a short-haul airliner. By its design, it is a narrow-body, twin-engine, low-wing aircraft with a swept wing and a single fin . The aircraft is equipped with two PowerJet turbofan engines.

Superjet 100.

Which companies operate it: present and prospects

As for the operation of the Sukhoi Superjet 100 aircraft, reviews from companies are positive. The liners are used by the following carriers:

- Aeroflot (26 units);

- Gazpromavia (10);

- "Azimuth" (10);

- "Muscovy" (3);

- "Yakutia" (2).

There are also models in the air fleets of Armenia, Laos, Mexico, Indonesia and Switzerland. The manufacturer plans to expand cooperation with companies operating in Ireland and Italy. There is also the possibility of concluding contracts with Asian carriers.

Indeed, an increase in the maximum take-off weight of the aircraft by 3.57 tons, while (as knowledgeable people assured us) maintaining the weight of the airframe, makes it possible, while maintaining the same payload, to fill the tanks with more kerosene. And, thus, achieve a decent flight range - over four thousand kilometers with all seats occupied. It is appropriate to remember here that, according to a number of authors, the “load-range” characteristic was not the strong point of the Basic version of the aircraft. At the end of February, I had the opportunity to talk with a highly qualified specialist directly involved in the work on LR . We tried to put aside the topics of quality of project management and problems in the initial operation of Aeroflot aircraft and devoted most of the conversation to the advantages of the new aircraft. To begin with, the interlocutor spoke about the status of the work :

— The first copy of the Sukhoi Superjet 100-95LR (95032) made its first flight on February 12, 2013. And on February 15 he was transferred to Zhukovsky. The car arrived at the LII named after. MM. Gromov according to the preparation schedule for flight tests. It is being prepared for additional certification tests that precede the transfer of the aircraft to the customer. Today, this aircraft can easily pass tests with a weight of 45.88 tons, for which our base aircraft is certified. And additional certification tests are required to confirm the possibility of operation with a take-off weight of 49.45 tons, which, in fact, distinguishes the LR version from the B (Basic).

Externally, the plane will be no different from previous aircraft. Structurally, its wing has been strengthened to accommodate the increased take-off weight, but the aerodynamics remain the same. In the future, all machines will have exactly the same design. This also applies to the chassis - it is the same as on the basic version. We also kept the volume of the fuel tanks unchanged - they hold 12690 kg of kerosene with a density of 0.803.

— There are reports about the possibility of installing Whitcomb winglets ( winglets ). Will they become a distinctive feature of LR?

- No. The issue of introducing winglets is a separate issue; it is not directly related to LR. They can be on both LR and B as an option. Of course, on the LR and, especially, the business aviation version of the aircraft, winglets are more advantageous due to their longer flight range.

— Is the engine still the same SaM .146?

— The LR will have an increased thrust engine. Actually, the engine is the same, only its take-off thrust increases by 5%.

— At the Engines 2012 exhibition, a representative of NPO Saturn, answering the question of what guarantee the manufacturer of the SaM.146 engine gives to airlines, answered: “2500 cycles.” Has this number increased since then?

— Engine manufacturers themselves directly enter into contracts with airlines for warranty service of aircraft engines.

— Please compare the updated Superjet with the Bombardier CSeries.

— Even if we take the youngest member of the CS100 family with its take-off weight of 58 tons and the number of seats 110, it is clear that the Canadian car is larger. It is not a competitor to the Superjet. We have a passenger capacity of 98 people, if we take the basic cabin in one class layout with a seat pitch of 32 inches. The interiors of the base aircraft and the LR variant are completely identical. In short, the CSeries is a vehicle of greater mass and size, designed for a longer range and increased passenger capacity.

— Is the hourly fuel consumption of 1.8 tons declared by the Canadians much different from the Superjet’s figures?

- No, not by much. We are now at the level of 1.75 tons per hour, if the block fuel is divided by time.

— In the materials of the Transport Clearing House, the average consumption of Aeroflot SSJ100B aircraft in the fleet for 2011 is given at the level of 2296 kg per hour. True, this figure, along with many others from this source, differs significantly from the statements of aircraft manufacturers (in particular, for the Tu-204 - 3688 kg per hour, and the developer gives 3180). Please comment.

— According to our calculations, if you divide the fuel spent on the route by the flight time, you will get somewhere between 1.75 and 1.8 tons. And 2.2 tons - I don’t even know where these numbers came from!

— I can provide data received from Bombardier managers on the costs of Canadian regional aircraft in operation: CRJ700 - 1.45, CRJ900 - 1.6, CRJ1000 - 1.74 tons per hour. Please comment.

— If we are talking purely about cruising flight mode at the design altitude, then we have approximately a similar figure to yours for the CRJ1000. It would be more correct to compare with our main competitor Embraer E-190. We differ from him by 2% for the better. And that one has around 1.8 tons per hour, or more precisely, 1.782. Compared to the E-190, at the moment our unit costs are 2% better, and the cruiser costs are even slightly better. Block fuel includes taxiing, takeoff, and landing.

— The annual production rate at the Komsomol aircraft plant is planned to increase to 60 aircraft, how many of them will be in the LR ? How much more will it cost?

— It’s better to ask marketers who are directly involved in commercial offers about prices and their differences for options B and LR. The pace of release will depend on customers. And we have them. This year we are supposed to deliver the aircraft to our first customer, Gazpromavia.

— Is this the same plane that flew to Zhukovsky?

- No, the next car will go to the airline, the one after this one. And this one will remain with us; in the future we will conduct tests on it, including those related to the installation of wing tips. There are special views on it, since it is the first machine with a reinforced wing for increased take-off weight. Therefore, we will conduct all other tests on it.”

— Will the LR have any increase in airframe weight?

- Yes, now he will grow up a little. But we have a weight loss program that should compensate for this growth. The program is currently being executed. Moreover, it concerns not only the airframe - we also look at the weight of various on-board systems that come to us from foreign and Russian suppliers.

— Does the wing area remain equal to 84 square meters?

— The geometry is completely preserved, including the wing. The fact is that the design is certified, and we do not have the right to change it... If any change is made, this is already a “major change”. Now we are raising the take-off weight, strengthening the wing without changing the materials - this is also a “major change”. As a result, an addition to the type certificate is required.

— You are talking about certification in ARMAK, but what about the European aviation safety agency EASA?

Completely similar. We receive an addition to the type certificate in ARMAK, then the validation of the addition to the certificate occurs in EASA.

— The Europeans may demand additional flights and tests?

- Yes they can. First, we prove by what we close here - we provide the same documents for validation. We will show the results of flights based on take-off and landing characteristics and strength tests. We do not expect anything more than natural in relations with EASA.

“But EASA has the right to demand additional flights if the inspector has doubts about something or the materials presented seem insufficient to him.

- Yes, this can happen. In principle, they may ask for additional tests to be carried out on their basis.

— Most likely, it will turn out that you first fly everything required to Russia, get a piece of paper and only then contact EASA?

- Yes. We have LR's first domestic orders, so we must first obtain approval from local aviation authorities. And then you can distribute it.

— It was written that the first delivery of LR will take place in 2014...

— No, our first order is for 2013, with delivery before the end of the year.

— Can you handle it?

- We can handle it! The first aircraft is being assembled for the customer (95033) and the prototype is being prepared for testing, which is scheduled to begin in March. March-April we work on performance characteristics, then April-May on noise in the area. At the end of May we must prepare a report on the test results. So, in order to receive an addition to the type certificate by MAKS-2013.

— When will flights with increased mass begin?

— We assume that in April-May and beyond there will be tests to increase the take-off weight.

— According to available data, aircraft airframe parts made of composite materials weigh about a ton. Is their share expected to increase?

— We made the wing mechanization, the direction and elevator rudders, the fairing of the wing joint with the fuselage, and the landing gear doors from composite materials. Here are the main elements of the airframe, made of CM. In addition, there are also transparent radio fairings. As for the relative share... In the mass of an equipped aircraft, the share of the aircraft itself without equipment is about 80%. Of these, almost half is equipment - the power plant, on-board systems. And only from this half can some share be KM. True, the main propulsion system also has a CM. The fact is that the MSU includes engine nacelles, which are made from CM. Increasing the share of CM will require a large amount of certification work.

— As far as I remember, in 2011 there was talk about a program to reduce the fuel consumption of the SaM.146 by 4% and, at the same time, reduce the weight of the MSU. To achieve this, along with funds to expand production, Saturn was additionally allocated several billion rubles from the state budget. Have engine builders succeeded?

— First, let's clarify: the SaM.146 engine is produced by the Russian-French joint venture PowerJet. The engine weight reduction program is going according to plan. At the next meeting, engine builders confirmed the weight reduction figures that were set for 2012 - the targets were met. They have now presented a work program for 2013-2015. In terms of specific costs, serial engines currently correspond to the technical specifications that were submitted for this engine. Everything is under control here. Firstly, each engine undergoes its own acceptance bench tests at the facilities of the motor manufacturer; it is calibrated by thrust, its consumption characteristics are measured. After acceptance of the engine, when it arrives at the Komsomol plant, our acceptance testing program includes checking the fuel consumption of the entire aircraft. Using an agreed methodology, we evaluate the traction and consumption characteristics of engines. We confirm that the assembled power plant, when installed on the aircraft, complies with the technical specifications. We currently have no complaints against the manufacturer regarding fuel consumption; all engines fit very well within the technical specifications.

There are experimental engines that are installed on experimental aircraft, but they have higher consumption. And the overexpenditure that so many people talk about was recorded on experimental aircraft. This is primarily due to the fact that the engines that were used to determine the consumption characteristics are experimental. That is, they had a preparation installed in the flow part, in the tract. In addition, these are the engines that were used in testing at high angles of attack and determining takeoff and landing characteristics. During such tests, we only had more than a hundred shutdowns from the maximum mode, followed by a transition to the maximum takeoff thrust mode. Accordingly, these engines, at the time when we moved on to determining the consumption characteristics, had an equivalent flight time, in cycles and in loads during takeoffs and landings, equal to five, and maybe even ten years of operation. All production engines, which from the very beginning are used for aircraft delivery models, have the same consumption characteristics, and are better, noticeably better, than those of experimental aircraft.

— Which aircraft are also expecting delivery of LR in the near future?

— The Mexican airline Interjet, which will soon begin receiving aircraft through Superjet International, is definitely not expecting LR, because in their conditions it does not make sense. They have high altitudes and elevated ambient temperatures. On takeoff from the main airfields of Mexico City and Toluca, according to the parameters of the power plant, even 46 tons is not possible. In other words, Interjet's basic aircraft is enough for the eyes. Switzerland's Comlux is the launch customer for the LR-based Sukhoi Business Jet (SBJ). Perhaps car number 95032, which is now being tested, will later be equipped with a VIP class interior. The next number is 95033, it is intended for Gazpromavia. The fact is that before delivery to the customer, the interior must be installed, seats installed, systems tested, and painted. And only after completing all the above work, present the aircraft to the customer in the appropriate form. All this takes about two to three months. The prototype aircraft, which was transported to Zhukovsky in February, corresponds to the so-called “green” delivery version, that is, without an installed interior. This seems to shorten the time frame. But the plane with number 95033 will initially have an interior.

— In addition to the gain in the airframe, will there be any changes in the systems on the LR?

— The answer is negative: the basic systems remain the same, without changes. In theory, improvements could be associated with replacing [finishing] materials in order to reduce weight. The corresponding work is being carried out. They are associated with replacing seat suppliers so that in the future the new seats would be lighter in weight than those currently installed on Aeroflot aircraft. We adhere to the concept of increased comfort. Our seats not only have such a mass - at one time certain requirements were presented to the supplier company regarding the level of passenger comfort. The seats from B/E Aerospace are old in design, but they were modified for the SSJ100. The width of the chair, the size of the pillows and other specific requirements were discussed. Generally speaking, it is possible to lighten existing seats; such options exist and they fly. In particular, one of the Russian airlines ordered other seats.

— When, flying on Aeroflot flights, you approach a “superjet”, you can’t immediately distinguish it from an “Airbus” in appearance - they are painted in the same livery and look equally magnificent from the outside. But when you walk into the salon, you immediately feel the difference. Why do superjets have such a dull, gray interior? Passengers do not have individually adjustable airflow valves. And the chairs look like they took them out of a twenty-year-old Boeing and put them here: the upholstery is fabric, dirty blue, the pillows are “weathered.” On other types of aircraft of this airline there are modern leather seats from Recaro (they used to install Aeroseat), and only in the “superjet” there are fabric B/ E Aerospace...

— I don’t agree with your opinion. In my work, I fly a lot with Russian airlines and I can say that many have worse seats than those in Aeroflot “superjets”. Indeed, Aeroflot ordered fabric upholstery from us, while its Airbuses have leather seats. Color scheme and materials - what they ordered is what we supply. You also noticed that on Aeroflot planes there is no air supply individually for each passenger. Airplanes have individual airflow adjustments. Aeroflot aircraft will also have it, on the Aeroflot Full variant. And the fact that it is not available on the Aeroflot Lite version is the airline’s decision. Individual airflow is an option that is implemented in the ceiling panel above the passenger's head. This does not change the routing of the main pipes; air still flows through these panels. In all production aircraft, the air lines are laid the same way, the valves are routed, and their installation is included in the list of options. One airline ordered this option, another did not.

— LR’s flight range is close to that of the Airbus A320 and Boeing 737NG. In the future, will LR be able to find a market in the United States and, in particular, operate on flights “from coast to coast” (US East – West coast)?

- Let's first clarify the distances. On our LR, the range is 4.1-4.5 thousand kilometers (2213-2429 nautical miles), depending on the cabin configuration and options. In the version with 98 seats, it is now 4.1 thousand kilometers. If we take a closer look at the topic of the US East-West coast, then the range there is more than three thousand nautical miles, when converted to the metric system - over 5560 km. The Airbus A319 and Boeing 737-700HGW/900ER have a maximum flight range with a full cabin of 3,200 nautical miles or more, which gives them the ability to fly US East - West coast. For an aircraft of our size, it makes no sense to have such a range; it is redundancy. Our machine is designed to “pump up” main routes. In the USSR, this work was performed by the Yak-42 and Tu-134. We are pleased to note that this year Aeroflot began to properly operate its superjets. And the result is visible to the naked eye. Aeroflot recently reported an increase in passenger traffic. If you look at the statistics, his passenger traffic grew, in particular, due to the fact that he began to “pump” short lines with our aircraft - previously ineffective routes. And along many routes there is a very good trend and dynamics. First they install the Superjet, it flies for 2-3 months, people see the regular flight of Aeroflot, they are satisfied with it in terms of price and quality. The airline's traffic is beginning to increase. And if at first a Superjet flew and carried 35-40 passengers, after a couple of months 50-60 tickets are sold for the flight, and then you look - they put an A319 or A320 on the route because the flow has grown, and it has become possible to load a “narrow-body” airliner. Aeroflot often puts our car on night flights and evening flights in order to maintain frequency. So: a machine that is designed to maintain frequency does not need a “coast to coast” range.

— The transition from SSJ100-95B to LR, where will it have the most noticeable impact, on which airlines?

— A good topic for marketers! In my opinion, these are the companies that have long shoulders, more than three thousand kilometers. And also those that have larger capacity aircraft, and flight loads are influenced by seasonal factors. Sometimes in conversations between representatives of such airlines or “off-season aircraft”. In the high season, our car is best used as a “pumping plane”, and in the off-season – as a “cost optimization plane”. Gazpromavia’s network includes more than 400 routes; for this airline, LR makes sense.

— If we talk about Moscow airlines, what long-distance flights can they supply the SSJ 100-95 LR ?

— If you fly from Moscow, then with our load-range characteristics the whole of Europe and almost half of Asia are covered. In practice, many attractive routes can easily be served by the basic version of the aircraft. As for flights across Europe, Armavia operated flights from Yerevan to Barcelona with 50-60 passengers on board, and the range there was 3550 km. The maximum flight duration of this airline on our plane was 5 hours 50 minutes. In addition to Barcelona, Armavia also operated long-distance flights to Marseille and Madrid with an incomplete load, and this was incomplete due to demand. Of course, LR will look better on flights in the eastern direction: Novosibirsk is about 3000 km, Krasnoyarsk is 3350 km. Here we are talking about flights with a full passenger cabin. And with incomplete LR it can fly to Irkutsk (4200 km), with some loading restrictions. One of the requirements when developing an aircraft for a government customer is a flight to Irkutsk with 20 people on board. We must implement the corresponding contract in the next two years and deliver the aircraft next year. It turned out that the stated requirement is met with a take-off weight of 45.88 tons, that is, the basic version is also suitable. The fact is that in this case the maximum take-off weight does not play a role: we “sit down” to the limitation on the volume of fuel tanks. In the SBJ business aircraft, which is being created on the basis of the SSJ100-95LR, we will install additional tanks in the cargo compartments (under deck), the range will increase to over 7000 km. This is the requirement of Comlux's launch customer: they want to fly from Paris to the USA.

— Has there been information about the modified Flight Management System ( FMS ), when will its installation on production aircraft begin?

— The first aircraft in the Aeroflot Full configuration with improved FMS will arrive to the customer in April. Generally speaking, every new version of our avionics includes a number of updates. And our avionics (but for some reason they don’t believe it, but this is true) are made using the most modern Integrated Module Avionics (IMA) technology. It is open, easily upgraded, including FMS. Each new version includes some additional FMS features. Changes are divided into packages. On machines transferred for operation in aviation, this is done according to the service bulletin. Implementing service bulletins is common practice. This is the operator's responsibility. It involves carrying out some work, replacing components, in this case software, as well as attracting specialists who carry out this work, and so on. This is at the discretion of the airline: the service bulletin is not mandatory from a flight safety point of view. Here it is necessary to make a reservation that there are mandatory bulletins for implementation. They come, for example, within the framework of Airworthiness Directives issued by authorities or resource support bulletins. And there are also optional ones, improving the design.

— The Airbus A380 is equipped with lightweight composite seats from a Japanese company from Kanagawa, resulting in a significant weight reduction. Is this relevant for you? Is there a choice of composite chair manufacturers in the world?

— There are several manufacturers of lightweight chairs on the market, but all of their products are expensive. In relation to the SSJ100, a set of one hundred seats with a “wound” frame can save up to 400 kg. The weight of the chair is affected not only by the frame, but also by the size of the pillows and the material with which the chair is covered. Leather chairs are heavier than those covered with fabric material, but more durable. For example, Armavia had leather seats, they were heavier than Aeroflot's. Also, the final weight is influenced by additional options that are offered for the chairs: pockets, tables. They also have mass. By optimizing this alone, each chair can be lightened by 1-1.5 kg. And if the back does not recline, another kilogram is removed. In short, there are various solutions for weight loss.

The main problem of companies offering seats is adaptation for installation on a specific type of aircraft. This is due to the location of the seats on the plane and the distance between the rails for installing the seats. The distance between rails and the location of rails in an aircraft differ depending on the type of aircraft. Even the standard triple block is installed differently on different aircraft. To do this, tests must be carried out, including qualification tests. The seat developer and manufacturer is responsible for this, and tests are carried out directly on the customer’s rails. We, as an aircraft manufacturer, supply our rails to B/E Aerospace - seats from this company are now installed on production aircraft. If there is any other equipment, we will supply it to him, including for testing 16g of overload. There is a requirement from the aviation authorities that the seat does not collapse under an overload of 16g, and at the same time be held in place. Tests must be carried out to demonstrate compliance with this requirement. If you are a customer and want new seats for your aircraft, then you pay for their adaptation to a specific type of aircraft. You pay twice: for seat qualification tests and when you purchase a set of seats for the plane. All these are additional costs and not all customers are ready to bear them.

— It is known that Interjet airlines ordered planes with Italian interiors and seats from Pininfarina. Why did they abandon B / E Aerospace ?

— I would not like to discuss the choice of an airline and criticize the products of one or another supplier. I will only note that Pininfarina is designing the passenger cabin and developing seats, and the manufacturer is Alenia Aermacchi. She works directly with different factories that make components for her.

— According to a publication in the Vedomosti newspaper, citing sources in Aeroflot, the Superjet’s fuel consumption turned out to be higher than the previously promised figure. Did this affect the competitiveness of your products?

— The issue of determining competitiveness must be considered only integrally. There are aircraft that have better costs, but sell (sold) on the market worse than their competitors. For example, Boeing 737 Classic. Its costs are better than the next generation - the 737 Next Generation, noticeably better, by a few percent, and better than the A320 family of Airbuses. But they don’t take the “classics” anymore; production has stopped. I can give one more example linking competitiveness with fuel consumption. The CRJ has much lower fuel consumption than the E-jet, but for some reason Canadian planes sell worse than Brazilian ones. Now we read in the press that the Superjet consumes a lot of kerosene... But compared to our main competitor E-190, we have better fuel consumption.

— How else is the SSJ100 better than the E-190?

- Oh, it’s just a matter of bending your fingers! First of all, the comfort of the cabin. And, in our opinion, this is how Embraer won over Bombardier, and we are now winning over Embraer. Since I have to go on business trips quite often, I can compare. It happens that on a separate flight they put either a CRJ, then a BAe-146, or an E-jet. My personal observation: the CRJ 700/900, and even more so the Embraer E-190/195, are perceived by passengers as an “overgrown regional jet.” In the fuselage section there is a central passage separating two blocks of seats, a pair in each, a fairly low ceiling and a fairly low line of shelves. All this together leaves the impression of a “regional size” aircraft, although the capacity, especially of the E-195, is close to narrow-body mainliners. The feeling of being in the cabin cannot be compared with either the Airbus A320 or the Boeing 737. But our plane can. Moreover, all the way everyone compares it to the Airbus 320. And this comparison, no matter how strange it may seem, comes naturally from the passenger side! The same cannot be said about either the CRJ or the E-jet.

But let's continue about the advantages of the SSJ over the E-jet. Our noise level is one of the lowest, it is lower than that of Embraer. True, from the point of view of the declared values for the noise level on the ground, we have parity, based on the fact that we tested the base model, putting timing at the forefront. We declared and demonstrated in tests a reasonable, conservative figure for the noise level, which gave us a comfortable passage of certification tests. We expect that our characteristics will “improve” as part of the LR tests. Despite the increase in take-off weight, the noise situation will not worsen: the higher thrust motor allows you to slightly raise the climb trajectory after lifting off from the runway.

Our luggage rack size is larger. We do not hear any complaints from passengers about problems with stowing hand luggage. For its part, Embraer says that a standard suitcase, which is allowed into the cabin as hand luggage, fits on the shelf. Indeed, some leather and fabric models fit right in, but metal suitcases of a “standard look” do not always. No matter what you do, the shelf won’t close!

From an airline convenience point of view, our luggage compartment is better than Embraer's. The specific volume of luggage compartments per passenger seat is very high. And a large luggage compartment is also an additional opportunity for the airline to make money by transporting associated cargo (like belly cargo). The height of the luggage compartment under the floor (deck) of the passenger compartment meets the requirements of the airfield workers' union. The loader fits into our luggage compartment without any difficulty.

The level of aircraft automation is very high. Our board functionality is similar to that of modern long-haul aircraft. And in terms of the level of functions that are aimed at ensuring the level of flight safety, we match, and in some ways exceed, the latest models of mainline aircraft from the giants of the aircraft industry - the Airbus A380 and Boeing 787. As part of the motorization program, Embraer also announced the replacement of the avionics complex and control system . We consider this proof that they really understand how far behind us they are. Embraer's press release uses the term "Open loop fly-by-wire system". After reading it, my colleagues and I laughed for a long time. When applied to a system without mechanical backup, this term seems to mean an open control loop! It turned out very funny with this “openness”.

Let me remind you that the first certified CDS without mechanical redundancy on a regional aircraft is the CDS on the SSJ100. Naturally, we have a side control stick, which Embraer will not have even on the improved version of the E-jet. They want to preserve the type-rating for the pilots, so they leave the steering wheel in the cockpit. Wanting to maintain the type-rating, Embraer specialists, however, judging by their own statements, plan to seriously rework the flight control system. They want, like us, to switch to a completely digital SDS without mechanical backup. What will happen to the functionality is not yet known. I think they will take a serious look and, apparently, will try to catch up with us. The level of SDS on the SSJ100 is comparable and even superior to the A380. Accordingly, we will keep this high level and raise it further as our aircraft develops.

— And in terms of the power plant, don’t you see any advantages?

— Now SaM.146 is actually the best engine in its class. Even with its moderate bypass ratio, it shows good flow characteristics. Our aircraft and engine are optimized for cruising flight at a speed corresponding to Mach number 0.78. At the same time, the SaM.146 has a smaller effect of the Mach number on thrust than some engines with a higher bypass ratio. Thrust is the sum of input and output impulse. Due to the fact that the “forehead” of the SaM.146 engine is smaller than it would be with a bypass ratio of 5-6 (like the CFM-56) or 6-7 (like the large engines from CFM International), it has less influence of the input pulse for traction. And in fact - less influence of Mach on thrust. This gives a gain in climb characteristics. "Superzhdet" shows very good climb rates at speeds and altitudes close to cruising - they are better than those of an aircraft with engines with a higher bypass ratio, although at the static point they differ little.

— With full weight, can the LR immediately reach a maximum flight altitude of 12 km?

— We have a straight climbing trajectory without “shelves”; we reach the optimal height immediately. In general, our aircraft always reaches its recommended ceiling up to an ambient temperature of ISA +15 degrees. And 12 km is not an optimal altitude, too high for an LR with full weight! There is a concept of flight based on reduced weight. The reduction is based on pressure. The reduced weight is the weight reduced to flight at altitude 0 at the lift coefficient Su, corresponding to the optimal kilometer flow rate. The first case: when the engine thrust is enough to immediately reach a height corresponding to the optimal reduced flow rate. The second is that there is not enough traction (not our case), then we have to do a “horizontal shelf” and after that resume climbing.

— Sometimes in prospectuses the Mach number of the SSJ 100 cruising flight is given as 0.78, in other cases 0.81-0.82. Which number is correct?

— There is a maximum cruising speed M=0.81, and there is an optimal cruising speed M=0.78. The “Superjet” is optimized for flight at M = 0.78, altitude 11 km. This is a design point, a design mode for us and for engine builders. Here we are talking about such a thing as Long range cruise. And there is also Max speed cruise (maximum cruising speed mode) and we have the corresponding flight Mach number M = 0.81. Since the aircraft has a high-aspect high-speed wing, we can easily move from M=0.78 to M=0.81 with a slight increase in kilometer fuel consumption. In fact, this is another advantage we have over E-jet. Due to the fact that our aerodynamic configuration is well optimized, the Superjet has a significantly lower sensitivity to changes in flight conditions relative to the design point. A change in cruising level by 5-6 thousand feet (1524-1829 meters) in our country leads to an increase in costs by no more than 3%. And for Embraer, the same change in echelon results in a one and a half times greater deterioration in costs. Because the Brazilian aircraft is equipped with CF34-10 engines with a higher bypass ratio, and a very large wing for an aircraft of their size. An important nuance: TsAGI optimized the wing for us, but they did it themselves (although they hired TsAGI specialists at certain stages and ordered purges from Russia). As a result, we got faster profiles. And this can be traced using documents like the Airport Planning Manual. For the E-190 there is a line M = 0.78, a separate line “Optimum Mach” and under it M = 0.81. But in our case, the “Optimum Mach” and M=0.78 lines practically coincide, and the M=0.81 line gives a slight change in range (taking into account the compensation margin, in fact the aircraft’s flight range practically does not change).

One day I came across an open publication with data on block fuel for different aircraft. I was very surprised by the published values for the E-190: with a flight range of 500 nautical miles (926.5 km), the consumption was 3100 kg (a 15% loss to us), and for the significantly larger A319 - 3300 kg. I began to look into it and it turned out that these data are average indicators on real routes from the airlines’ practice. They reflect Embraer's problem - in real operation, regional-class aircraft are quite often directed by air traffic controllers to "landed" flight levels. They are sent to FL330, FL320 (flight altitude 10058 m and 9753 m, respectively). It happens that for various reasons the pilot does not have time to reach cruising altitude in time or there is a transition in altitude between ATC zones. This greatly impacts the E-190’s costs. From a fuel economy point of view, the optimal altitudes for this aircraft, as well as for us, are FL390 and FL370 (11847 m and 11227 m). Due to a non-optimized wing and airfoils not as fast as the Superjet, going 3,000 to 5,000 feet down in altitude deals a dramatic blow to the E-190's fuel efficiency. A similar story was observed on the Yak-42. His wing is oversized even more. Aeroflot crews, flying short routes within Russia, often receive low flight levels from ATC. In the case when a Superjet flies, this is not so scary, because the change in altitude does not have a particularly bad effect on increasing costs due to the successful aerodynamic configuration of our aircraft.

Business class features

The seats in this class of service on the Superjet 100 are comfortable. They are arranged in 3 rows according to a 2-2 pattern. True, passengers seated in the first row will have less legroom due to the partition; You won't be able to put things on the floor either. There is also a toilet nearby, which can be a nuisance. But in any case, you will be more comfortable than in economy class.

Having extra space will allow you to stretch your legs.

The best options in the business compartment are the 2nd and 3rd rows. The legroom here is 1.5 times more than in the budget part of the cabin. In the 3rd row, noise can be heard from the "economy" mode, since the partition is quite thin.

Video Superjet 100 a/k Azimuth

First flight of airline Azimuth

Flight Pskov - Moscow Flight St. Petersburg - Krasnodar

Direct tickets from Rostov

| Where | departure date | Return date | Airline | Find a ticket |

| Volgograd | 04.02.2022 | 05.02.2022 | Tickets from 1,776 | |

| Simferopol | 01.02.2022 | 02.02.2022 | Tickets from 1,776 | |

| Samara | 22.02.2022 | 25.02.2022 | Tickets from 1,776 | |

| Kaluga | 02.02.2022 | 04.02.2022 | Tickets from 1,776 | |

| Saratov | 27.02.2022 | 27.02.2022 | Tickets from 1,776 | |

| Pskov | 04.02.2022 | 06.02.2022 | Tickets from 1,776 | |

| Belgorod | 09.02.2022 | 16.02.2022 | Tickets from 1,776 | |

| Voronezh | 01.02.2022 | 05.02.2022 | Tickets from 1,776 | |

| Mineral water | 08.02.2022 | 15.02.2022 | Tickets from 1,776 | |

| Bryansk | 05.02.2022 | 12.02.2022 | Tickets from 1,970 | |

| Astrakhan | 20.02.2022 | 27.02.2022 | Tickets from 2,360 | |

| Naberezhnye Chelny | 16.05.2022 | 24.05.2022 | Tickets from 2,460 | |

| Makhachkala | 22.02.2022 | 01.03.2022 | Tickets from 2,560 | |

| Permian | 16.02.2022 | 20.02.2022 | Tickets from 2,570 | |

| Moscow | 11.03.2022 | 04.04.2022 | Tickets from 2,692 | |

| Kaliningrad | 04.02.2022 | 16.02.2022 | Tickets from 2,948 | |

| Nizhny Novgorod | 21.03.2022 | 23.03.2022 | Tickets from 2,960 | |

| Ufa | 29.03.2022 | 10.04.2022 | Tickets from 3,348 |

Direct tickets from St. Petersburg

| Where | departure date | Return date | Airline | Find a ticket |

| Kaluga | 02.02.2022 | 06.02.2022 | Tickets from 1,776 | |

| Elista | 12.03.2022 | 26.03.2022 | Tickets from 1,824 |

Direct tickets from Moscow

| Where | departure date | Return date | Airline | Find a ticket |

| Pskov | 01.02.2022 | 02.02.2022 | Tickets from 1,776 | |

| Rostov-on-Don | 17.03.2022 | 27.03.2022 | Tickets from 1,856 |

Direct tickets from Krasnodar

| Where | departure date | Return date | Airline | Find a ticket |

| Makhachkala | 11.03.2022 | 14.03.2022 | Tickets from 1,776 | |

| Voronezh | 10.02.2022 | 17.02.2022 | Tickets from 1,776 | |

| Bryansk | 09.02.2022 | 16.02.2022 | Tickets from 1,776 | |

| Belgorod | 07.03.2022 | 14.03.2022 | Tickets from 1,776 | |

| Saransk | 29.01.2022 | 01.02.2022 | Tickets from 1,776 | |

| Mineral water | 08.02.2022 | 11.02.2022 | Tickets from 1,776 | |

| Penza | 15.02.2022 | 18.02.2022 | Tickets from 1,776 | |

| Kaluga | 27.01.2022 | 03.02.2022 | Tickets from 1,776 | |

| Simferopol | 24.01.2022 | 31.01.2022 | Tickets from 2,560 |

Direct tickets from Sochi

| Where | departure date | Return date | Airline | Find a ticket |

| Petrozavodsk | 07.02.2022 | 14.02.2022 | Tickets from 1,776 | |

| Makhachkala | 12.02.2022 | 19.02.2022 | Tickets from 2,760 | |

| Pskov | 22.01.2022 | 25.01.2022 | Tickets from 3,160 | |

| Kaluga | 02.02.2022 | 11.02.2022 | Tickets from 3,960 |

Economy class cabin

As for the location of economy seats on the Superjet 100, they occupy rows 6 to 20. The seats are placed according to a 2-3 pattern, with seats E considered the worst option: they are located far from the porthole, which does not allow you to enjoy the views, and from the aisle. But, if you often get up to go to the toilet, then the option will be more convenient than choosing a seat by the window. After all, you only have to bother one neighbor!

The design of the cabin does not imply the presence of seats near emergency exits, therefore the Space + category is represented only by the 6th row.

When choosing, consider the following:

- The best seats are in row 6 as you will get more legroom. There are no seats in front, and you won’t encounter a situation where your neighbor reclines his back, preventing you from sitting comfortably with your laptop. But the width of the seat will be slightly smaller, since the pull-out tables are mounted on the armrests. The latter do not fold completely, which can cause inconvenience. The disadvantages include the fact that this row is occupied by passengers with small children. Also, companies charge an additional fee for reserving seats in the 6th row, since they are classified as Space +.

- Seat 6D has the added disadvantage of bumping into the seat for business class passengers who decide to use the toilet in the rear.

- In rows 7-19 there are standard options: there is not much legroom, but you will not feel much discomfort.

- Traveling in row 20 will not be a pleasant experience. The backs of the seats do not recline, so sleeping will be difficult. The proximity of the toilet, where other passengers constantly look, also plays a role. It's a little more comfortable in seats 20A and 20F, located near the windows: you won't be disturbed by people scurrying along the aisle. The worst options are 20C, 20D and 20E.

Choose places by checking the map and make your trip comfortable. And finally, photos of the Sukhoi Superjet 100 interior will help you get your bearings (click to enlarge):

Plane crashes involving Sukhoi Superjet 100

The most recent crash involving an SSJ-100 occurred on May 5, 2022 . The plane crashed during a hard landing at Sheremetyevo. At the time of writing, 41 deaths are known.

SU1492 (Aeroflot) Moscow - Murmansk

The facts of the incident are as follows : a fire broke out on the airliner that made an emergency landing at Sheremetyevo, which could not be extinguished immediately. The plane was flying SU1492 Moscow - Murmansk. A few minutes after takeoff, it began to descend, and during landing, according to eyewitnesses, it hit the surface of the earth twice and then caught fire. The flames quickly engulfed the rear of the plane. There were 73 people and 5 crew members on board. Passengers had to leave the plane via two inflatable slides.

The final cause of the incident has not been identified at the time of writing. There are several versions: a malfunction of the vessel, errors by the pilot or dispatcher, unfavorable weather conditions.

Experts of the Interstate Aviation Committee pointed out several mistakes of the pilots: they decided to fly through a thunderstorm front, refused to run out of fuel before an emergency landing, and were unable to land manually, which indicates their poor pilot training.

The pilots tried to push the nose of the plane toward the ground instead of stabilizing it in a landing position. This caused the plane to bounce off the runway, making the situation worse. The passengers sitting in the rear section received serious injuries during the “jumps” of the liner, so they were unable to get out of the cabin on their own and died.

The crew made an emergency landing exceeding ground speed by 30 kilometers per hour. When approaching the runway, “the crew began to increase speed for an unknown reason,” which is why the plane landed closer to the middle of the runway. In addition, as the plane passed through a thunderstorm front, allegedly, “a power surge occurred in the generator, followed by a series of failures of the aircraft systems.”

Important! Once the official investigation is completed, the information in this section will be updated.

Indonesia 2012

Another disaster occurred in 2012 in Indonesia . The Superjet airliner crashed into a mountain during a technical flight. 45 people died; the cause of the disaster was recognized as an error by the pilots and dispatchers.

Minor situations

Other recent incidents involving Superjet:

- in March 2022, the Sukhoi Superjet 100 plane made an emergency landing at Sheremetyevo (the reason was a cracked windshield);

- in February 2022, when landing at Domodedovo, the plane hit a lamppost with its wing;

- the plane flying Moscow-Khanty-Mansiysk returned to Sheremetyevo for technical reasons;

- in October 2022, in Yakutia, the plane skidded off the runway;

- in June 2022, a liner flying from Irkutsk to St. Petersburg made an emergency landing in Barnaul (the reason was a false fire alarm).

Experts believe that the main reason for frequent accidents is the low quality of components that fail before the time stated by the manufacturer. There are especially many complaints about premature engine failure.

Passenger reviews: what to pay attention to

The cabin of the Sukhoi Superjet 100 is quite comfortable, and most passengers only complain about the design of the seats. They are comfortable, but the appearance is not up to world standards. In general, travel reviews are positive, although for optimal convenience you need to pay attention to the nuances.

01/21/2018, review of place 6A

There is a lot of extra legroom, so I had no problem placing my luggage on the floor.

04/05/2017, review of place 19A

During the flight, the noise of the engines bothered me, but on this plane it was heard everywhere. It was more comfortable for me than in the bow or central part: there is more privacy, because they try not to sit here.

04/05/2017, review of place 7A

Horrible flight: the seat was close to the engines and the noise was unbearable. Vibration was also added to it, so it was not possible to sleep. If you buy a ticket on the Superjet 100, take earplugs!

07/14/2017, review of place 20B

I flew a Superjet from Costa Rica to Mexico in July 2022. The legroom was good: the best I've found in my years of economy travel, even compared to larger jets. Carry-on luggage fits in the overhead bin, although there are problems with this on many planes. Even on the Boeing 727, my large suitcase couldn’t fit there!

In addition to the abundance of legroom, I appreciated the restrooms, low noise levels, modern design and lighting. I liked that there was a video camera at the bottom of the plane, and during takeoff we saw the process on the monitors. The company also offered free alcoholic drinks during the flight!

05/25/2016 review of place 15A

Flew from Kyiv to Moscow in 1 hour 20 minutes, because the airliner is used only on short and medium routes. The maximum duration of a flight on it is 3 hours. Please note that the size of hand luggage may be limited: I had no problems, but in winter, when you want to take warm clothes with you, you need to check the carrier’s rules in advance.

The seat itself was comfortable, with plenty of legroom (considering the length of the flight). If we had to fly longer, I would complain about the width of the passage: when I have to spend several hours in the air, I prefer to get up and walk around. But after an hour, my legs didn’t become numb, and there was no need to stretch them.

The food was not very good, so I recommend taking food with you. But the flight attendants were friendly and smiling, and the pilot did a good job. I didn't even feel a jolt when I landed! And we arrived on time, which is the most important thing. One thing I didn’t like was that the window was low and I had to tilt my head to admire the views. Otherwise, a good plane and a good crew!

Cabin disadvantages

Among the factors associated with pilot errors, the Federal Air Transport Agency pointed to ergonomic features and shortcomings in aircraft cockpit equipment. In particular, the agency noted the close proximity and identical shape of controls for various aircraft systems, their inconvenient location and the lack of protection against erroneous or unintentional switching on and off: protective caps, safety brackets, latches and locks. This follows from “Flight Safety Information No. 18” signed by the head of the Federal Air Transport Agency, Alexander Neradko. The document (available from Izvestia) was sent to the heads of airlines and civil aviation organizations.

Other factors include deviation from standard operating procedures in normal or abnormal situations and poor communication between pilots. Among the latter, the Federal Air Transport Agency listed the lack of mutual control and confirmation of operations with cabin equipment, overload of operations by one of the crew members in the absence of assistance from the other, sloppiness, inattention, distraction, as well as hasty decisions and actions of the pilots.

Parse button_1

Photo: RIA Novosti/Kirill Kallinikov

The department recommended that airline heads, among other things, draw the attention of pilots to the effective distribution of attention and “maintaining a good level of interaction among crew members” in situations involving an increase in the level of workload when aircraft systems fail, follows from the document.

Forced drawdown: the Federal Air Transport Agency announced a lack of money for pilot training

Who will finance the purchase of simulators for pilots?

The flight safety information of the Federal Air Transport Agency is designed for industry specialists and is issued to inform them about safety issues that it is advisable to pay attention to, taking into account Russian and international experience, an agency representative told Izvestia. She also pointed to a note that appears on the front page of every piece of information issued by the department. It also states that the document “may contain information about the preliminary results of the investigation of aviation events, which are clarified and supplemented during further investigation.”