All-wheel drive truck GAZ-63 with a conventional wooden body All-wheel drive trucks appeared in the Soviet Union only after the end of the Great Patriotic War. The very first of them was the GAZ 63, which for a long time remained the only example of such a car. This vehicle was used both in the army and in civilian life; it was used for transportation in various regions of the USSR, and was also used in other countries. Even today, such cars can still be seen on the roads of Russia, although now as “collector’s items.” The GAZ-63 fully fulfilled its purpose, but it will remain one of the symbols of the Soviet automotive industry for a long time.

History of creation

In the second half of the 30s of the last century, the designers of the Gorky Automobile Plant first thought about developing an all-wheel drive truck of their own design. More precisely, it was about creating several chassis options, on the basis of which a whole family of new cars could then be produced.

In 1939, one of the first prototypes of such cars was produced, called the GAZ-63, but in appearance it was indistinguishable from the familiar “lorry”.

The reason for this similarity is simple - the original cabin for the new truck has not yet been created, it was simply taken from the GAZ-AA, which had already been mastered in production. Further work did not progress very far since the war began. They remembered about the GAZ-63 only in 1943, when Andrei Lipgart, chief designer of the Gorky Automobile Plant, prepared a design document that provided for the creation of several new types of equipment at once - ordinary universal trucks, off-road vehicles and passenger cars.

An experimental GAZ-63 truck with a cab from the American Studebaker

Despite the fact that victory was still quite far away, and all this equipment was supposed to be built only after the war, the State Defense Committee approved Lipgart’s proposal.

One of the main ideas of the project was the maximum unification of the GAZ-63 and GAZ-51 cars. Work on these machines has been carried out since 1943. All-wheel drive was not provided for the GAZ 51. The first prototypes of both trucks were again equipped with a “foreign” cabin - this time from the American Studebaker, supplied to the USSR under the Lend-Lease program. Only in 1945 did the GAZ-51 and GAZ-63 appear with their own appearance, characteristic only of these cars.

These vehicles differed from other Soviet trucks primarily in the progressive layout of their internal components, thanks to which the body became more spacious while maintaining the same overall dimensions. This was achieved by installing the engine in the nose of the car, above the front axle, and not behind it.

Despite the structural similarity of the two new trucks (the level of unification was ultimately 80%), serial production of the GAZ-63 began only in 1948, two years after the assembly line of the GAZ-51 began. The explanation here is simple - the all-wheel drive car was more complex in its design.

The further fate of the vehicles also turned out to be different - the GAZ-51 mainly had “civilian” use, and most of the GAZ-63 trucks were sent to the army. Military use was facilitated by the vehicle's increased cross-country ability, which allowed it to move quite confidently along dirt roads, and sometimes just on the ground.

Truck GAZ-51, “sibling” GAZ-63

GAZ-63 was produced until 1968. A total of 474,464 of these cars were produced in various modifications. During their operation, many vehicles were equipped with various body options, which made it possible to significantly expand the scope of application of trucks.

Design Features

GAZ-63 is an all-wheel drive off-road truck with increased ground clearance and a standard two-axle base. The main load-bearing element of the structure is the frame. All its parts are made of steel and connected to each other with rivets, with the exception of the second transverse support, which is attached to the side members with bolts and is used to install the engine. The front of the frame forms a buffer on which two hooks are located. They are used when towing is necessary.

Cabin

A very characteristic feature of the GAZ-63 car was the initial lack of its own cabin. This was a kind of sign of the times - the main thing was the creation of the car itself with all-wheel drive, and almost no importance was attached to the “design” of the driver’s workplace. The prototype truck, manufactured in 1943, had a cabin “borrowed” from the American Studebaker. True, this option was not intended for mass production.

The cabin of the early GAZ-63 had a mixed design, which was due to the post-war shortage of rolled steel. Many elements, including the doors and back wall, had to be made of wood with painted plywood paneling. As a result, the cabin became angular and flat in places. It was possible to completely abandon the use of “lumber” only in 1957, when the metal became available in significant quantities.

GAZ-63 truck cab, view through the driver's side door

Starting this year, the cabins have acquired noticeably more rounded, smoothed outlines. In addition, windows began to be installed on the side windows.

In general, the double cabin of the GAZ-63 is quite modest: the level of comfort is almost zero, the driver’s seat can only be adjusted in the longitudinal plane, moving it forward or backward. However, the designers took care of ventilation - you can open not only the side windows, but also the windshield. The cost of this solution is dust penetration. In addition, some cabins had an upper hatch.

Among the “conveniences” we can also note a heating system and glass cleaners. Interestingly, the cabin was heated only while driving. When the car stopped, the flow of warm air hit only the inside of the windshield.

Body

The body of the GAZ-63, more precisely, the cargo platform, is located directly behind the cab. This part of the machine structure is made of wood and fixed to the frame. The tailgate can be folded down for loading or unloading. There are folding benches on the sides of the cargo platform. The capacity of the body is 12 people.

It is allowed to “build up” the side boards using wooden lattice boards made in accordance with the standards established for them. In addition, you can cover the body with an awning stretched over four removable arches. These elements themselves are mounted with support on the side boards, where the standard fastenings necessary for this are located.

GAZ-63 with arches installed in the body for stretching the tarpaulin awning

It should be noted that when the tailgate was folded down, it did not tip down, but was fixed with chains at the level of the floor of the cargo platform.

Suspension and wheels

The front and rear axles of the car are equipped with semi-elliptical longitudinal springs made of steel sheet. Fluctuations in the length of these parts under load are compensated by a swinging earring to which their rear end is attached. The rear springs are equipped with cushions, and the front part of the suspension has hydraulic lever shock absorbers that operate in both rebound and compression modes.

Most modifications of the GAZ-63 used single wheels with discs with a diameter of 18 inches or 457.2 mm. Tire pressure can be reduced, which improves maneuverability on loose soil, snow and wetlands. But this significantly accelerates tire wear. A compressor was not installed on the truck; however, the tires were inflated not manually, but using a special mechanism. At first, a pump driven by a gearbox was used, and then the car was equipped with a device that allowed the tires to be inflated with air coming from one of the engine cylinders.

Rear axle

The GAZ-63, unlike the GAZ-51, is an all-wheel drive vehicle, but the second axle remains the “main” one. Both halves of it are connected to the rear axle housing. This part of the car structure consists of two cast iron parts bolted to each other. The axle housings are fastened using rivets. Spring cushions and flanges are welded to the casings, on which elements of the braking system are installed.

Exterior view of the rear axle of the GAZ-63 car

In general, the design of the rear axle of the GAZ-51 and GAZ-63 is the same, only the final drive ratios differ, being 6.67 and 7.6, respectively.

Power point

The GAZ-63 all-wheel drive vehicle is equipped with a GAZ-51 carburetor internal combustion engine (the same as on the truck of the same name). With a displacement of 3.485 liters, this engine develops a power of 70 horsepower. The maximum torque is created at a rotation speed of 1500-1700 rpm and is 20.5 kgf (201 Nm).

Initially, this engine used a K-49A carburetor, but back in the early 50s it was replaced with a K-22GG with improved characteristics. The engine has six cylinders arranged in a row, cooling is liquid.

Starting the engine may seem rather unusual to modern drivers who are accustomed to the fact that the starter is turned on either with the ignition key or with a special button. The GAZ-63 was equipped with an ST-08 starting electric motor, which is turned on using a foot pedal. At first, GAZ-51 trucks were equipped in the same way, however, in the 60s they received more modern starters, while they decided not to touch the all-wheel drive vehicle.

The motor is equipped with an original preheating system. Under the hood of the truck, on the right side, there is a boiler. You can heat it up using a blowtorch inserted into the flame pipe through the hatch in the front right wheel fender. Of course, the boiler must contain a coolant, which is ordinary water.

GAZ-63 truck engine

On GAZ-63 cars restored by amateurs, sometimes it is not the standard engine that is installed, but a diesel engine with increased power.

Transmission

GAZ-63 cars were equipped with a four-speed manual gearbox. The list of gear ratios for each stage is as follows:

- 6,4;

- 3,09;

- 1,69;

- 1,00.

The gear ratio for reversing is 7.82.

In addition, there is a two-speed transfer case. The gear ratio for the first of them is 1.96, for the second – 1.0. The front axle of the car can be switched off, thereby reducing fuel consumption. In general, the “transfer case” contributes to an additional increase in cross-country ability.

Gear control is performed using levers installed in the cab. The manual transmission does not have synchronizers, which significantly complicates the driver’s work.

Fuel system

GAZ-63 uses A-66 or A-70 gasoline as fuel. The main fuel tank is located under the cabin and is attached between the longitudinal members. This container holds 90 liters. In addition, on the left side member, under the loading platform, there is another tank with a capacity of 105 liters - initially it was the main one. Fuel is supplied using a diaphragm pump. The total fuel supply is enough to travel approximately 740 kilometers with a full load.

Additional tank for GAZ-63 truck

Characteristics of the GAZ-63 transmission

GAZ-63 car gearbox

The transmission of the GAZ-63 truck consists of a manual gearbox with 4 shift stages, a transfer case with two stages and a range. In total, the driver had 8 shift stages at his disposal.

The multiplier is designed to increase torque. It provides smooth, even power shifting, reducing stress on gears and extending transmission life. Taking up little space, it significantly increases the traction range of the drive wheels.

The presence of direct transmission in the range-multiplier allows you to save fuel on good roads.

The main transmission of the drive axles is carried out by single bevel gearboxes.

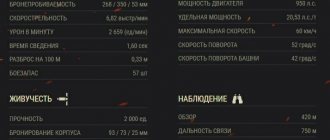

Specifications

| Curb weight | 3.28 tons |

| Full mass | 5.35 tons |

| Load capacity | 2 tons |

| Maximum speed | 65 km/h |

| Truck length | 5.525 m |

| Height | 2.25 m |

| Width | 2.2 m |

| Clearance | 0.27 m |

| Wheelbase | 3.3 m |

Fuel consumption depends on the weight of the car. When a regular GAZ-63 is fully loaded, the truck consumes 25 liters of gasoline for every 100 kilometers, moving at a speed of 40 km/h. At the same time, GAZ-63D or GAZ-63P truck tractors will require 35 liters of fuel to cover the same distance.

The technical characteristics given for the GAZ 63 do not directly affect cross-country ability. This most important quality was usually assessed by comparison with other machines.

Cabin structure of the GAZ-63 car

When developing an all-terrain truck, the main focus was on the chassis. A new cabin design was not developed.

Initially, it was given a shape similar to the Studebaker cabin, and in 1948 mass production of cars with a GAZ-51 cabin began.

The cabin interior is designed for two seats, the interior dimensions are quite modest. The driver's seat is simple, but not hard, and it is not adjustable.

Salon GAZ-63

The most necessary instruments and sensors were located on the dashboard:

- speedometer with a maximum mark of 100 km/h;

- to the left of it are fuel and oil level sensors;

- on the right – water temperature sensor, ammeter.

In the cabin, on the right side of the panel, there was a small glove compartment for necessary things.

Tuning

GAZ-63 trucks have long since become obsolete, and in their original form may only be of interest to collectors or employees of automobile museums. Nevertheless, there are enthusiasts who find such cars, restore them and even perform tuning for the GAZ 63. This does not mean so much a change in appearance as an independent modernization of the machine.

The easiest way to give a truck new qualities is to install a modern engine on it. Typically, various diesel engines are used for this purpose. The converted GAZ-63 turns out to be quite an economical and at the same time powerful car, while maintaining good cross-country ability.

Another type of tuning involves installing a new body on the GAZ-63 chassis. As a result, the truck can be turned into a pickup truck or minibus, like a Gazelle. Of course, such a technical alteration will require a lot of money, and registering it with the traffic police is a very difficult task.

GAZ-63, converted into a pickup truck. The “body” is made from two regular truck cabs, welded back to back.

Special vehicles based on an SUV

Fuel tankers, oil tankers, milk tanks, vans, mobile repair shops, staff and medical buses, disinfection units, auger-rotor vehicles were assembled on the basis of the GAZ-63. A firefighting vehicle for communication and lighting, and tank trucks of several modifications were produced by the Vargashinsky Fire-Fighting Equipment Plant. Staff and hose fire trucks were produced at the Moscow Fire Truck Plant.

For the military, in addition to basic models, staff and medical buses, shielded warm and sealed communication vehicles, disinfection and shower units DDA-53A were produced for sanitary treatment of personnel in the field, disinfection and disinsection of uniforms and equipment. The installation was equipped with a steam boiler running on liquid fuel or wood, the operating pressure of which was four atmospheres, an accumulator boiler, a hand pump, a steam elevator, control equipment, two open disinfection chambers and shower cabins with twelve shower nets.

Modifications

The all-wheel drive GAZ-63, in addition to the original base model, was produced in the following main versions:

- GAZ-63A. The main difference is the winch, which could be used, in particular, for “self-pulling” the car. This mechanism was driven by a special drive with a three-stage power take-off. Curb weight increased to 3,520 kg;

- GAZ-63E and GAZ-63AE - differ in that all electrical equipment is shielded and does not create interference in the radio range. This allowed four-wheel drive military trucks to be used as communications vehicles;

- GAZ-63D - used for transporting semi-trailers with a tipper body, is a truck tractor;

- GAZ-63U and GAZ-63AU are export versions of the original model and the version with a winch, respectively;

- GAZ-63Yu - “southern”, tropical modification of the car;

- GAZ-63P - another tractor, distinguished by a reduced wheel diameter. On the rear axle they were also usually double-sloped.

GAZ-63U and GAZ-63Yu were also produced with shielded electrical equipment. Such submodifications were designated, respectively, GAZ-63EU and GAZ-63EYU.

Of significant interest is the GAZ-63E chassis, which was produced separately. It was intended for the manufacture of small buses. These were the PAZ-663 geophysical laboratory and the PAZ-659 mobile shop. To improve stability, dual-pitch wheels were installed on the rear axle of the GAZ-63E. In addition, softer springs were used, and hydraulic shock absorbers were installed on both axles, and not just on the front.

Automobile shop PAZ-659, made on the basis of the GAZ-63E chassis

The GAZ-63 could be equipped with many different types of bodies, which ensured wide versatility of use of the vehicle. Here are just a few of the “specialties” of this car:

- MLRS BM-14;

- Snow removal machine with a screw-rotor mechanism;

- Carrier of the drilling and crane hydraulic machine;

- Refueler;

- Van;

- Medical car;

- Fire engine.

At the same time, dump trucks based on the GAZ-63 for some reason never appeared.

GAZ-63A

The GAZ-63A car was equipped with a winch. It was located in the front of the frame (behind the front buffer). The winch gearbox was driven through a cardan shaft from a power take-off mounted on the gearbox. The winch developed a force of 35 kN (3.5 tf) and had a working cable length of 65 m. A towing device with a shock-absorbing spring was installed on the rear cross member of the frame. The car had a metal 2-seater cabin and a wooden platform with a carrying capacity of 2 tons (for all types of roads) with high lattice sides, an opening tailgate and two folding benches.

This all-wheel drive vehicle could ford hard ground up to 0.8 m deep, climb up to 30 degrees, and move along a slope with a roll of up to 15 degrees. In the Armed Forces, the GAZ-63 was successfully used as a tractor for artillery systems weighing up to 2 tons. The dimensions of its cargo platform made it possible to accommodate the crew of the artillery system and stow transportable ammunition.

Reserve Lieutenant Colonel A. PROTASOV, Candidate of Technical Sciences.

Export to foreign countries

Despite the fact that the GAZ-63 was created primarily for the Soviet Armed Forces, a considerable part of these vehicles were sent abroad. Foreign recipients of this machine were primarily European countries that were part of the “socialist commonwealth”: Yugoslavia, the German Democratic Republic, Czechoslovakia and Poland. In addition, supplies were made to developing countries friendly to the USSR. In particular, the GAZ-63 ended up in Mongolia, Vietnam, North Korea, Laos, as well as in many African states and Cuba.

A number of trucks were sold to Finland. The GAZ-63 also sometimes ended up in other “capital countries”, but these were no longer direct deliveries, but the result of a chain of resales or some kind of accident.

Advantages and disadvantages

MLRS based on GAZ-63

The GAZ-63 car was very good for its time and had the following positive qualities:

- Simplicity and reliability of design, high level of maintainability;

- Compatibility of most components with the GAZ-51 car;

- High cross-country ability, which made it possible to confidently navigate rural areas and dirt roads;

- Significant load capacity, ability to tow implements and trailers;

- Ability to operate at low temperatures;

- Versatility.

Among the shortcomings, it is necessary to point out the lateral instability of the machine. When making a sharp turn, she could literally lie on her side. This was a kind of “payment” for the increased ground clearance of the car compared to the GAZ-51. The center of gravity moved upward, which led to a capsize. Attempts were made to correct this defect, but were not completely successful.

In addition, the GAZ-63 has all the typical disadvantages of trucks of the post-war period - a minimum of comfort for the driver and passengers, the lack of synchronizers for the manual transmission and a significant “gluttony” of the engine.

Loading platform of the GAZ-63 car

Cargo platform GAZ-63

The cargo-passenger platform had folding sides on the sides and rear. Folding benches were located along the high wooden lattice side boards.

There are slots for installing arcs on the side sides. An awning can be pulled over the arches.

GAZ-63 was appreciated by the Soviet army. It transported army personnel and was used to tow various guns and combat installations.

In agriculture, in off-road conditions, these cars were extremely necessary. The huge amount of cargo transported forced them to be used with considerable overload. The design of the vehicle could withstand such loads, although this significantly reduced its maneuverability and led to premature wear of parts.

The production of these truck models ended in 1968, but some of them are still in use, which confirms their high quality. These cars are sometimes offered on the secondary market.