Leopard 2 - the most successful Western tank in export markets

Let's move from Central Asia to Southeast Asia, where Singapore and Indonesia acquired Leopard 2 tanks.

Singapore independently carried out a deep modernization of 66 of its previously purchased Leopard 2A4 tanks, which by 2010 were brought to the new Leopard 2SG standard. The most significant innovation was the installation of a new armor kit from IBD (as on the Leopard 2A4 Evolution tank), which significantly increased security. Singapore became the first country to purchase this additional protection. Other improvements included the installation of Singapore standard communications equipment and a combat control system kit. However, some tanks do not have a permanent set of additional armor installed.

Leopard 2 Revolution

The details of the Leopard 2SG modernization have not been disclosed, but it is certain that the Singapore Army will continue to modernize these vehicles and they will remain in service for many years to come.

Singapore - modernized Leopard 2SG (left) and Leopard 2A4 (right)

Indonesia received the last of the 61 Leopard 2RI ordered in 2022 (Republic of Indonesia). This modernization option implemented by Rheinmetall for Indonesia is based on the modernization project it presented several years ago - Leopard 2 Revolution.

Qatari Leopard 2A7+ are being transported to exercises on Mercedes-Benz Actros tank transporters

In Leopard 2 Revolution, along with a set of measures to improve security (similar to the Leopard 2 Evolution project), weapons, fire control systems, sights and improved mobility were also improved. It is proposed to replace all tank electronics with new, modern digital systems, including improved displays, more powerful computers, etc.

A new SEOSS fire control system is being provided, integrated into the combat information management system. SAS improves situational awareness through 360-degree cameras and a variety of sensors. A weapons module with a machine gun or grenade launcher is installed on the turret. The protection of the ammunition rack and a number of other components has been increased. A panoramic sight and a C4I surveillance, command and reconnaissance system are installed. The tank is also equipped with an auxiliary power unit.

Leopard-2RI, Indonesia

A key feature of the modernization of the Leopard 2RI tank is its adaptation to tropical service conditions, increased armor protection and weapons. The tank received improved additional armor modules and a fire control system, fully electric gun and turret drives, all-round cameras, an auxiliary power unit and air conditioning. A new Rheinmetall DM11 multi-purpose round with a programmable fuse has been added to the ammunition load.

The final batch of modernized Leopard 2RI tanks delivered to Indonesia from Germany under the 2012 agreement. Tajung Priok, March 2022

The most advanced serial modification of the Leopard 2 tank today is owned by the small but very “monetary” Middle Eastern emirate of Qatar. In accordance with a contract worth 1.89 billion euros, concluded in April 2013, Qatar received 62 Leopard 2A7+ tanks, newly built by the German company KMW. This contract also includes the supply to Qatar of six FFG Wisent 2 armored recovery vehicles based on the Leopard 2, 24 PzH 2000 self-propelled howitzers of 155 mm/52 caliber, 32 Fennek combat reconnaissance vehicles, up to 60 Dingo Heavy Duty 4 x 4 armored vehicles and about 100 tank transporters MercedesBenz Actros 4058 6 x 6.

Qatari Leopard 2A7+, the most advanced serial modification of the Leopard 2 tank to date

Qatari tanks of the Leopard 2A7+ modification in some characteristics even surpass the Leopard 2A7 received by the Bundeswehr at the end of 2015. They have new thermal imaging sights for the commander and gunner, an improved control system, all-round television cameras, a high-performance air conditioning system (supplies air at the required temperature to the crew seats and cools part of the equipment), as well as the FLW 200 remotely controlled combat module. The Swedish-made Barracuda camouflage system shields the vehicle from heat, thereby reducing its visibility to thermal imagers and preventing the crew from overheating in desert conditions.

Leopard 2 became the most successful Western main tank in export markets - 18 countries chose vehicles of this family. This is a lot, considering that other Western third-generation tanks, with the exception of the American M1 Abrams, which was exported to six countries, were not exported at all (Israeli Merkava tank series, Italian C-1 Ariete, Japanese Type 10, Korean K2 Black Panther ) or are in service with the developing country and one foreign buyer (British Challenger 2 and French Leclerc).

Former Dutch Leopard 2A6NL tanks delivered to Finland, May 2015

The experience of combat use of tanks of the Leopard 2 family in military conflicts in Afghanistan and Syria by the armed forces of Denmark, Canada, Norway and Turkey allows military experts to assert that, despite all the identified shortcomings, this military equipment as a whole will meet the requirements for several decades .

Of course, for this, Leopards must be developed and modernized, primarily in the direction of increasing security (including in urban operations), as well as operational and situational awareness (automated command and control systems, the use of video cameras to provide crews working with closed hatches, all-round surveillance).

An additional impetus for improving Leopard 2 is given by the worsening situation in Europe and the corresponding increase in military spending by NATO countries. Therefore, the KMW company is full of optimism, according to its representative Christoph Müller: “It has definitely become clear that there will continue to be a need for MBT in the future. While there is always a question as to the total number of tanks you need, when protection, mobility and firepower are combined with surveillance capabilities, there are no other ground systems that can replace a tank."

Found a typo? Select a fragment and press Ctrl+Enter.

Tags: Land equipment Leopard 2A7V Afghanistan Bundeswehr

Previous article Bundeswehr paratroopers will switch to the original tracked “centipede”

Next article Military use of Leopards by Turkey in Syria

Provided by SendPulse

Like 1

Description of the design of the Leopard 2 tank

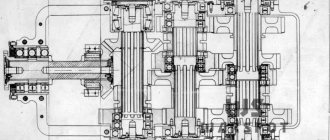

The main battle tank Leopard 2 has a classic layout with the control compartment located in the bow of the hull, the fighting compartment in the middle of the hull, and the engine-transmission compartment in the rear of the hull. The reserved volume of the tank is 19.4 m³. The tank's crew consists of four people: a driver - whose place is in the bow of the hull; tank commander, gunner and loader - whose places are in the turret.

The tank body is welded. Upper frontal plate General view of the Leopard 2K tank with a 105 mm cannon has a large angle of inclination. The sides of the hull are located vertically. The design of the armored hull uses combined armor and side screens made of reinforced rubber.

The driver's seat is located on the starboard side in the bow of the tank. For its landing and disembarkation, there is a hatch in the roof of the tower. Two monitoring devices are mounted in the hatch cover, the third one is to the left of the driver's hatch in the hull roof. There is an emergency hatch under the driver's seat. To control the tank, the driver uses a steering wheel, two pedals (the right one for fuel supply, the left one for brakes) and a gear switch block. A control and instrument panel is installed to the left in front of the driver. The volume of the control compartment is 2.3 m³.

To the left of the control compartment in the bow of the tank hull there is a stack of 120 mm rounds. In the bow of the hull, fuel tanks are located inside along the sides.

The tank's turret is of welded construction and is located in the center of the hull. The turret design uses combined armor. The internal surfaces of the tank's fighting compartment are covered with fabric mats (lining) made of high-strength aramid fiber. The turret houses a weapon system with a 120 mm smoothbore cannon. The main sight is installed on the right side of the turret. The roof of the turret is equipped with hatches for the tank commander, on the right, and the loader, on the left. Six viewing devices are installed along the perimeter of the tank commander's hatch. On the chase of the tank commander's hatch there is a bracket for attaching a turret for an anti-aircraft machine gun. An optical head of a PERI-R-17 panoramic sight is installed in front of the tank commander's hatch. A movable viewing device is installed in front of the loader's hatch. A turret for an anti-aircraft machine gun is installed on the loader's hatch chase. A fixed viewing device is installed in the roof of the turret, above the gunner's position.

The tank commander's workplace is located to the right of the gun behind the gunner's position. To the right, in front of the tank commander's seat, a PERI-R-17 sight is suspended from the turret roof. In front of the tank commander's seat there are controls for sights, smoke exhaust devices and built-in control of some systems. Behind the tank commander's seat, in the rear niche of the turret, there is a central control unit for the fire control system and two VHF radio stations.

The gunner's workplace is located to the right of the gun in the front of the turret. The gunner controls the weapon's aiming using his control panel. Behind the control panel there are flywheels for manual drives for weapon guidance. The main sight EMES-15 is installed above the control panel. To the left of the main one there is an auxiliary telescopic sight FERO-Z-18 (on the Leopard 2 tank there is a PZB-200 night sight monitor between the eyepieces of the main and auxiliary sights). To the right of the EMES-15 sight is the gunner's control panel. To the right of the gunner's control panel is the fire control system control panel.

The loader's workplace is located to the left of the gun. On the right side of the loader’s workplace is the gun breech, with a coaxial machine gun mounted on it and a box of cartridges for it. On the left side of the turret there is a mount for a submachine gun, a hatch for loading ammunition and a button for the mechanism for opening the armored door for storing shots on the left side of the rear niche of the turret. The loader's folding seat is attached under this button. The volume of the fighting compartment is 10.1 m³.

The main armament on the tank is a 120-mm Rh120 L/44 main gun from Rhtinmetall. The gun is installed in the center of the turret and has a manual lifting mechanism and a hydraulic lifting drive, providing declination and elevation angles from -9° to +20°. The gun barrel has a heat-insulating casing made of plastic and an ejector. The gun bolt is wedge, vertical. Loading is manual.

The tank's additional armament includes one 7.62 mm MG3A1 machine gun coaxial with a cannon and one 7.62 mm MG3 anti-aircraft machine gun.

The gun's ammunition load includes 42 120-mm rounds (15 are stored in the turret ammo rack, 27 in the stylized ammo rack in the tank hull) DM-12 MZ (with a cumulative multi-purpose projectile) DM13 KE (with an armor-piercing sub-caliber projectile). The ammunition load for the machine guns is 4,750 rounds.

The tank is equipped with an automated fire control system. It is based on the EMES 15 sighting system with a head mirror stabilized in two planes, developed by the American company Hughes (manufactured in Germany under license). The sight combines daylight optical and laser rangefinder channels. For shooting at night, a PZB 200 sight based on a low-level television camera is used.

The FERO-Z18 monocular optical sight is used as an auxiliary sight for the gunner. For the tank commander, a PERI-R17 panoramic sight with a head mirror stabilized in two planes is installed. The sight has only an optical daytime channel.

The tank is equipped with a two-plane electro-hydraulic stabilizer of tank weapons (the gun drive is hydromechanical, the turret drive is electromechanical) and a ballistic computer (located in the electronics compartment in the aft niche of the turret). The tank is equipped with a power unit in which a V-shaped 12-cylinder multi-fuel diesel engine with turbocharging MV873 Ka-501 is connected. 1500 hp and Renk HSWL354 automatic transmission. The power block is quick-detachable.

The chassis of the tank has, on one side, seven road wheels, a front idler wheel, a rear drive wheel and three support rollers. Individual torsion bar suspension with double-acting friction shock absorbers (on the first, second, third, sixth and seventh suspension units). Diehl 570F lantern tracks.

The tank is equipped with a quadruple automatic fire-fighting system, a collective protection system against weapons of mass destruction, and 16 smoke grenade launchers.

For external communications, the tank is equipped with two SEM 25/30 VHF radio stations. Underwater driving equipment is used to overcome water obstacles along the bottom.