GAZ-3309 is a popular flatbed truck that has been produced by the Gorky Automobile Plant group since 1994. Over all the years of production, the car has undergone some improvements, which also concern the production of modern, economical power units that meet Euro-4 environmental standards.

Of course, the truck does not have excellent cross-country ability and is designed for use within urban areas, or for freight transportation on paved roads in rural areas. The entire GAZ model range.

Car history

As we have already said, “Lawn” 3309 was released starting in 1994, which means it belongs to the fourth family of medium-duty trucks of the Gorky Automobile Plant.

The debut cars of this index had a 4-cylinder power unit that ran on diesel fuel. On top of that, the engine was equipped with a turbocharging system and produced 116 horsepower. The engine volume was 4.15 liters.

After some time, 3309 began to be produced with another engine operating on diesel fuel, which was also equipped with a turbocharging system, but already had six cylinders and produced as many as 150 horses.

However? three years later (in 1997), the production of such trucks was stopped. This was due to the fact that the GAZ-3309 was considered unprofitable for economic reasons.

After the Gorky enterprise began to be rebuilt, management decided to improve the cabin. As a result, the Lawn's cabin was significantly changed and they began to develop a diesel power unit for the car.

Thanks to the diesel engine, it was possible to obtain more power while reducing fuel consumption. But in order to make a diesel power unit, the technological staff worked hard.

During development, the company purchased a considerable number of new machines and stands. They served as a springboard for engine tests comparing them with gasoline variations. When there was a technological breakthrough, a diesel unit was developed, which received a turbocharging system.

Thanks to such a powerful engine, the car could easily transport a heavy-duty truck. Following the changes in the appearance of the cabin, the designers decided to pay attention to the internal components of the 3309. Even at the start of the 1980s, numerous assemblies were altered that were installed in the car.

And with the help of many modifications that affected the suspension, body, engine and transmission, the car became cheaper, but was able to increase its efficiency.

In addition, repairs, along with machine maintenance, have also become much easier due to the use of fewer parts. On top of that, thanks to their reduction, the number of possible breakdowns of various components has been reduced.

After 2001, the Gorky Automobile Plant began purchasing power units from the Minsk enterprise, which produces engines. From this moment on, a new revival of the model began, on which MMZ D-245.7 diesel engines began to be mounted.

Another 5 years later (2006), diesel power units that meet European environmental standards Euro-2 began to be installed on the Lawn. Two years later, the engines were already able to fit within the Euro-3 framework.

The plant also provides for the installation, if desired, of a pre-heater, which is very necessary on the territory of the Russian Federation. If we talk about the operation of the car, the GAZ-3309 is considered to be one of the most economical cargo models.

In addition, the efficiency indicators along with the endurance of the truck will please the buyer. The medium-duty truck has excellent technical parameters, as well as the presence of a powerful and reliable unit that is perfect for our roads.

The most difficult times for the GAZ-3309 were the months of 1998. That's when demand for domestic trucks dropped to an all-time low. This happened due to the collapse of collective farms, for which this machine was designed.

The Gorky Automobile Plant began to consider the production of trucks using diesel fuel unprofitable. But, fortunately, this lasted no more than a year, and in 1999 the release of “Lawn” was restored.

1999 served as a turning point for the truck. Its technical component was greatly improved with the introduction of the Minsk MMZ D-245.7 power unit. The latest engine had low fuel consumption and stood out for its good performance.

A similar engine was installed on the ZIL Bychok vehicles and the GAZ-3309 dump truck. The power unit of the Minsk Motor Plant was the most famous in the Russian Federation. They were able to fall in love with it in a short time, thanks to its good maintainability, power and amazingly low fuel consumption.

Spare parts were also inexpensive. It was possible to repair the vehicle even in “field” conditions. The last improvement was made in the 2000s, when Gorky engineers managed to adapt the Minsk engine to Euro-2 environmental standards. But by the end of the 2000s, vehicle production fell sharply. Why?

There are several reasons. One of them is the presence of an outdated design. The model has been produced for 20 years, and the shape of the cabin, along with the body, has not changed at all. It is also important that the type of truck is generally not suitable for the current transportation market.

In a similar vein, the Valdai turned out to be a successful model at the Gorky Automobile Plant. On top of that, the car has a fairly low level of comfort for the driver and passenger. It is clear that in the 1980s few people thought about this, but today it is not the 80s, and the level of comfort plays one of the most important roles when choosing a truck.

Today there are many modifications of this vehicle, among which there is a GAZ 3309 fuel tanker, a GAZ 3309 van, which is used for transporting various materials.

History[ | ]

Work on the creation of a new generation of medium-duty trucks of the GAZ brand to prospectively replace the previous GAZ-53A family began in the first half of the 1960s. At first, it was planned only to modernize the model produced by the plant. So, in 1963, a prototype of the GAZ-54 truck was released, testing of which continued for several years. Then, in 1972, a similar truck was built, designated GAZ-53-11. At this time, heavy trucks of the Magirus-Deutz brand of the West German concern Klöckner-Humboldt-Deutz began to arrive in the USSR. And although by Western standards these cars were not so outstanding, they made an impression on Soviet specialists; air-cooled diesel engines proved themselves to be excellent in the harsh conditions of Siberia. And the XXV Congress of the CPSU, held in February-March 1976, decided to begin the mass dieselization of the USSR truck fleet. It was decided to make the promising family of GAZ trucks diesel, and not just, but with air-cooled diesel engines.

The technical design of the new truck, designated GAZ-4301, was reviewed by the scientific and technical council of the Ministry of Automotive Industry on February 9, 1978. The work on the new machine was led by engineer Alexander Mikhailovich Butusov. Leading designer Valery Dmitrievich Zapoynov, designer Stanislav Vitalievich Volkov. The first prototypes were built in 1979. The second series of prototypes was completed in 1981.

In the spring of 1981, the XXVI Congress of the CPSU approved the decision to dieselize the fleet of trucks and develop new models of trucks with diesel engines, in accordance with which the development of a new model of GAZ truck with a diesel engine and an improved driver’s cab began [1].

As a result, the car received a more spacious, modern two-seater cabin, equipped with an effective ventilation and heating system, first used in 1984 on the experimental GAZ-4301 truck. The steering design, unlike its predecessors, includes power steering for the first time.

At the Avtoprom-1984 exhibition, a demonstration sample of the GAZ-4509 tractor was presented [2]. The production of GAZ-4301 was not established due to lack of finance and therefore the GAZ-3307 was developed, which was actually a modernized GAZ-53 with a new 4301 cab and a gasoline engine. On December 26, 1986, the GAZ plant completed testing of the GAZ-3307[3]. Serial production of a 4.5-ton GAZ-3307 (4x2) truck with a ZMZ-511 carburetor engine with a power of 125 hp. With. began in 1989 and continued until January 2022 (with a break in 1996-1997).

In 1992, GAZ launched serial production of the 5-ton GAZ-4301 truck with a 6-cylinder air-cooled diesel engine GAZ-542 with a power of 125 hp. pp., produced under license from the German company Deutz, as well as the GAZ-SAZ-4509 agricultural dump truck on its chassis for operation as part of the 8.6-ton GAZ-6008 dump truck (GAZ-4509 dump truck + GKB-8536 trailer). Production of the GAZ-4301 continued until 1995. A total of 28,158 trucks of the GAZ-4301 family were produced.

In 1993, production of a replacement for the GAZ-52 model was launched - a 3-ton truck GAZ-3306 with a 4-cylinder air-cooled diesel engine GAZ-544 with a power of 85 hp. With. According to some reports, in 1992, a 2.5-ton modification 33061 with a carburetor engine from the GAZ-52 was produced in a limited edition. Production of the three-ton GAZ-3306 (mainly in the “Cargo Taxi” version) continued until 1995.

At the end of 1994, with the development at GAZ of the production of a four-cylinder air-cooled turbodiesel GAZ-5441 with a capacity of 116 hp. With. The GAZ-3309 model with a lifting capacity of 4.5 tons appeared, completely unified in the chassis and cabin with the GAZ-3307 (externally it differs only in the engine air intake pipe on the left side of the cabin). The production of model 3309 was suspended until the end of 2001, and the carburetor 4.5-ton GAZ-3307 was restored to production. Subsequently, GAZ reoriented itself to the purchase of Belarusian diesel engines MMZ D-245.7 (a similar water-cooled turbodiesel was installed on the ZIL-5301 “Bychok”) from the Minsk Motor Plant (MMZ), which also began to be installed on the GAZ-3309 model, which was resumed in production.

Since 1999, as part of the 4th family of GAZ trucks, the all-wheel drive (4x4) vehicle GAZ-3308 “Sadko” has been mass-produced in military (carrying capacity 2 tons) and civilian (2.3 tons) versions. In the early 2000s, on its basis, the GAZ-3325 “Eger” family of utility vehicles with a double 5-seater cabin was created, as well as the full-size GAZ-3309 (GAZ-330811) “Vepr” SUV, produced to order.

In 2006-2008, the GAZ-3307, GAZ-3309 and GAZ-3308 were equipped with gasoline and diesel engines certified to Euro-2 environmental standards, and in 2008-2012 - Euro-3. Large-scale production of models 3307 and 3308 with ZMZ gasoline engines was discontinued in 2009, but their small-scale production on order continued, for example, for special versions certified for government agencies (for example, 406 units of GAZ-3307 were produced in 2010). In 2010-2012 medium-tonnage GAZ trucks (4x2) were equipped primarily with the MMZ D-245.7 E-3 diesel engine (model 3309), and all-wheel drive (4x4) models 33081 “Sadko” and 33086 “Zemlyak” were equipped with the MMZ D-245.7 E-2 diesel engine. In 2013-2016, all 4th generation GAZ trucks for civilian use used the MMZ D-245.7 E-4 turbodiesel with a power of 119 hp as the base engine. With.

In 2012-2016, a custom modification of the GAZ-33096 was made with a Cummins ISF 3.8L diesel engine, similar to that used on the GAZ-3310 Valdai truck. In 2013, the engine was certified to Euro 4.

In February 2013, a modification of the GAZ-33098 with a new Russian-made diesel engine, the YaMZ-5342.10 Euro-4 class, went into production, as well as a new version of the all-terrain truck GAZ-33088 “Sadko” with a similar YaMZ-5344 engine of the EEC-96 class. This gasoline version differs from diesel versions not only in the engine (the vehicle's curb weight is 310 kg lower), but also in the 12-volt on-board electrical system and the main gear with an increased number of 6.17. Unlike gasoline trucks of previous releases, the GAZ-3307 model of 2016 is equipped with a pneumohydraulic brake drive and ABS, as well as a plate-type (vane-type) power steering.

Since 2014, cars have been equipped with a new radiator grille with the factory emblem instead of the grille with the inscription “GAZ”.

A van on a GAZ-33091 chassis with a long wheelbase. Long-wheelbase "Dobrynya" with tuning cabin trim and sleeping compartment.

In January 2022, the GAZ-3309 and its modifications were discontinued.

Purpose

With consumer characteristics changing for the better, replacing outdated models on the assembly line became the main purpose of the GAZ 3309. At the same time, the operational functions remained the same. Installation of various equipment on the chassis allows the vehicle to be used on urban, intercity and interregional routes for transporting goods and as special vehicles. The GAZ 3309 line of vehicles is widely represented by utility vehicles such as garbage trucks, special vehicles for cleaning roads in winter and summer, and watering tankers. When equipped with isothermal vans, the GAZ 3309 is often used for transporting food products, furniture, building materials, water delivery services, etc. Dump trucks based on the GAZ 3309 are used to deliver bulk cargo when laying highways, constructing bridges and buildings, and delivering crops to processing plants. Vehicles with an extended wheelbase are equipped with special devices for the transportation of non-standard and special cargo (glass, plastic and wooden windows, sheets and blanks for furniture production, etc.). Tow trucks for passenger cars, mini cranes, and hydraulic manipulators are also equipped.

Specifications

Power unit

"Lawn" 3309 came with several variations of power plants. The most common was MMZ D-245.7E4. It featured a four-cylinder, four-stroke in-line engine running on diesel fuel, which had liquid cooling, direct fuel injection, a charge air cooler and turbocharging.

Such a power unit could meet European environmental standards Euro-4. Its volume was 4.75 liters, which allowed it to produce 125.4 horsepower. This engine weighed about 430 kilograms. Per 100 kilometers the engine consumes about 14.5 liters at a speed of 60 km/h.

A little later, YaMZ-5344, which was produced at a motor plant in the city of Yaroslavl, began to be installed on trucks. In terms of design, it was almost similar to the 4.75-liter engine mentioned above, but differed in its own technical parameters.

YaMZ-5344 was a 4.43-liter 134.5-horsepower engine, the compression ratio of which was a respectable 17.5. A pre-heater could be installed as a separate option. The Yaroslavl power unit consumes about 15.5 liters per 100 kilometers at a speed limit of 60 km/h.

The Lawn was also equipped with an Austrian-made diesel engine, which had an in-line arrangement of cylinders and an air cooling system. It was a 3.2-liter engine that produced about 150 horses.

The main disadvantage of such a power unit was poor maintainability. After working 200,000 km, the engines were not subject to major overhaul.

Fuel consumption

At a speed of 60 km/h, the benchmark fuel consumption is 14-16 l/100 km. With increasing speed, consumption can increase by 4-6 liters.

The GAZ-3309 fuel tank holds up to 105 liters of fuel.

Transmission

All two engines were synchronized together with a single 5-speed manual synchronized gearbox, which had constant gear mesh and a single-plate friction dry clutch, which has a hydraulic control.

The driving rear axle was equipped with a bevel gear differential. It is interesting that the diagram of how a manual transmission works is drawn not on the shift lever, but on the front panel (in the center, in the form of a small sticker).

Suspension

All modifications, along with the trim levels, received a rear-wheel drive layout, and the car itself was built on a solid frame base with dependent leaf spring suspensions at the front and rear.

The latter are based on longitudinal semi-elliptical springs, which are complemented in front by the presence of hydraulic telescopic shock absorbers of double-sided operation.

Brake system

The truck received a dual-circuit braking system, which had a hydraulic drive, a hydraulic vacuum booster, drum mechanisms and a vacuum receiver in each circuit.

Today, even the basic version of the GAZ-3309 has an ABS anti-lock braking system.

Steering

It is of the “screw-ball nut” type and is complemented by a hydraulic power steering wheel, which greatly facilitates driving the machine. The full catalog of technical characteristics of the GAZ 3309 diesel can be found on the official website.

Specifications

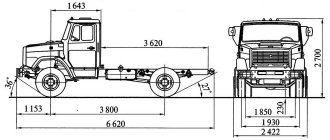

| Model | GAZ-3309 |

| Overall dimensions, mm | |

| Length | 6435/6330 |

| Width | 2180 |

| Height | 2350 (2905) |

| Wheelbase (mm) | 3770 |

| Permissible gross weight (kg) | 8180 |

| Curb weight (kg) | 3530/3200 |

| Engine | |

| Model | MMZ D-245.7 |

| Description | In-line 4-cylinder, 4-stroke, liquid-cooled diesel engine with turbocharging and charge air cooler, with direct fuel injection. |

| Working volume, l | 4,75 |

| Power, l. With. (kW)/rpm | 117,2 (86,2)/2400 |

| Max. torque, kgf*m (N*m)/rpm | 42,1 (413)/1500 |

| Chassis | |

| Wheels (width) | 6,OB-20 (2.25 R20) |

| Transmission | Five-speed manual synchronized |

| Fuel tank volume, l | 105 |

Modifications[ | ]

- GAZ-3306 - onboard with diesel engine GAZ-544.10 (R4 air-cooled, atmospheric, volume 4.15 l, 85 hp, Deutz license). Load capacity 3.0 tons. Produced in 1992-1995. GAZ-33061 is a transitional model based on GAZ-52 units with a GAZ-52 carburetor engine. Load capacity 2.5 tons. Produced in 1992-1993 mainly as a cargo-passenger taxi.

- GAZ-330701 - modification for the northern climate.

- GAZ-33081 “Sadko” - modification with MMZ D-245.7 diesel engine. Load capacity 2.3 tons. The prototype was designated as GAZ-33097 (GAZ-3309P).

- GAZ-33090 - onboard and chassis with MMZ D-245.7 diesel engine in modifications E2/E3/E4. Load capacity 4.5 tons. Production since 2001 (from 2022 only for export).

Device

GAZ-3309 was equipped with a 5-speed manual transmission with synchronizers in each gear. The steering mechanism of the car belonged to the “screw-ball nut” type. The model was equipped with a hydraulic power steering, which made driving easier.

The service brake system included a pneumohydraulic drive. GAZ-3309 was equipped with a mechanical parking brake located on the transmission. The model's dual-circuit braking system included drum brakes, a hydraulic drive, a vacuum receiver and a hydraulic vacuum booster. An ABS anti-lock braking system has appeared as a standard option.

The truck's wiring is single-wire with a voltage of 24 V. This element was one of the most problematic, since poor contact in the battery terminals regularly caused electrical equipment malfunctions.

The GAZ-3309 cabin could accommodate two people. The cabin was equipped with comfortable seats with soft fabric upholstery, imitation lateral support and a high backrest. The driver's seat also received vertical and horizontal mechanical adjustment. The seats were equipped with 3-point seat belts. The interior design was done in a very simple style. The front panel featured massive controls and round instruments. The cabin also received a sun visor, a heater and coat hooks.

There have been minor changes to the cabin design. The model retained the recognizable steel bumper, round headlights, traditional metal running board and elongated hood. The shortcomings present in previous versions remained in the GAZ-3309. The main problem was the rapid corrosion of the wings, which had to be replaced or treated with putty. A lot of plastic parts have appeared inside the truck. The glove compartment, tachometer and speedometer were not affected by changes. Another feature was the fabric door upholstery. Vibration and noise insulation were improved, which added comfort when driving. The massive bumper was highly durable and could withstand forces of several tons.

The most widely used modifications are the GAZ-3309 with a universal platform with 3 folding metal sides and a wood-metal floor.

All versions of the car had rear-wheel drive. The truck itself was built on a frame platform with dependent rear and front leaf spring suspension, which was based on longitudinal semi-elliptical springs, supplemented at the front with double-acting hydraulic telescopic shock absorbers.

In general, the GAZ-3309 has proven itself well and has been popular in the domestic market for a long time.

Appearance

If we talk about the exterior of the GAZ-3309, then the diesel variation is almost impossible to distinguish from the gasoline one. They differ only in the presence of an air intake pipe that runs along the hood and the window pillar of the cab.

With the help of such an element, a diesel car could drive through the deepest water obstacles, because the air to the power unit came from just such a pipe, which was located at a height of 2 meters. In addition, do not forget about the large wheels and rather high ground clearance.

From the photo you can see that by today's standards the truck has a fairly ascetic appearance. But, according to many drivers, the most important thing for a truck is its technological performance, because when a truck makes a good profit, its appearance takes a back seat.

The successor to the 53rd model received an almost unchanged cabin design. The truck has the same round headlights, a recognizable steel bumper, an oblong hood and a classic metal step, which makes it easier for the driver to enter the cabin. Based on feedback, the truck's cab design had many flaws.

For example, they often sinned on the wings, which almost always rusted. As a result, they required treatment with putty or the laying of new steel sheets over the metal damaged by corrosion.

However, the bumper itself, as before, is quite massive and durable. Due to the considerable thickness of the metal, it can withstand forces of up to several tons.

The driver can, without worry, attach the cable to one of the two holes in the bumper and get the car out of almost any swamp in tow. Although, it is worth admitting that the diesel variation of the “Lawn” almost did not allow it to get stuck even in the deepest and most embossed terrain, so often towing was simply not required.

Like all other current trucks, which are produced by Gorky Automobile, it has an all-metal cabin with a simple exterior design.

Moreover, it has straight contours with sharp edges, which are diluted by round optics, an impact-resistant bumper along with a massive radiator grille. The cabin received a pair of doors with a fairly wide opening. There is also the presence of large glazing, which provides easy access to the engine compartment in three directions.

Cabin interior

When comparing the interior of the 53rd model and the 3309, the latter has noticeably gained in convenience and design. The most important difference is that plastic parts were used. In addition, the interior of the 53rd model had preferably metal elements, which includes the dashboard itself.

Everything regarding the speedometer, tachometer and other information details was left in the same style. The glove box was made with a plastic lid. The thin steering wheel on the GAZ-3309 is presented with a two-spoke design, and, as before, has a very massive diameter.

It would not be superfluous to note that models with a diesel power unit were equipped with a hydraulic power steering wheel. At that time, hydraulic booster was considered a luxury option and was installed only on the 66th “Lawn” and large-tonnage KamAZ trucks. Among the “conveniences” the design staff equipped the cabin with only hooks for clothes, sun visors and a heater.

Thanks to the fact that the designers removed the second passenger seat, there was much more free space inside the GAZ-3309, which was sorely lacking in its predecessor.

The interior floor turned out to be smooth, just like its predecessor, the GAZ-53. Other changes include the presence of a new seating arrangement, which replaced one continuous wide “sofa”. Already in the cabin there is a separate driver and one passenger seat.

It wouldn’t be superfluous to add that the driver’s seat is now sprung and has been equipped with a separate mechanical backrest adjustment. Both seats have a high backrest, soft fabric upholstery and simulated lateral support, and are also supported by three-point seat belts.

The spaciousness of the interior was reduced, because in the previous model two passengers could sit next to the driver. However, this also has its advantages: due to the absence of one seat, you can see more free space inside.

Other changes include new fabric upholstery on the door panels, where there is a large pocket for things. Judging by the photos that can be seen in this article, the interior of the truck was designed in the style of the 1980s.

Many of the design parts are more angular, which is why the car's interior seems a bit old by today's standards. The last and most important improvement to the cabin allowed the designers to install thermal and noise insulation, which was not even expected in the 53rd model.

Now in the cabin there was much less audible extraneous sounds and noise from the operation of the power unit. In cool weather, the cabin did not freeze as quickly. But still, the stove’s power was not enough to heat the interior on cold days. Reviews from the owners only confirm this.

Modifications

Serial production of the GAZ 3309 was suspended several times. In 1997, this was due to a drop in demand; subsequently, delays were associated with conversion to new engines. However, the model has stood the test of time. About two dozen different modifications and configurations were produced, and production continues to this day. The main modifications include:

- GAZ-33090 – basic version with an onboard platform and chassis;

- GAZ-33092 - version with an enlarged cabin, designed to accommodate a fire crew of seven people;

- GAZ-33094 – extended base for installation of bonneted KAVZ-397650 buses;

- GAZ-33096 is an on-board vehicle with improved consumer properties, produced to order. Equipped with Cummins power units;

- SAZ-35071 – dump truck with three-way unloading;

- GAZ-3309 “Dobrynya” is a vehicle for long-distance transportation with a cabin equipped with a berth, a spoiler, and a hood that opens forward. Currently, it is the most modern and popular model.

Price of GAZ-3309 dump truck

The Gas-3309 dump truck combines the qualities of a small but roomy truck with good load capacity. Already in the basic version there is power steering, ABS, noise and heat insulation of the cabin, modern seats, an ERA Glonass button and a place for a tachograph.

The price of the Gas-3309 dump truck starts at 2.5 million rubles and largely depends on the version, configuration and other features. At the same time, there are no difficulties with servicing and repairing the car, thanks to the maintainability of its elements and the large number of service stations.

If you want to save money, you can buy a used Gas-3309 dump truck, which will cost significantly less. So, a 2013 truck can be bought for 600-900 thousand rubles. But here you need to pay attention to the type of superstructure, technical condition and other points.

Advantages and disadvantages

Pros of the car

- Good maneuverability;

- Good ride height;

- There are no problems with purchasing spare parts and components;

- Good maintainability;

- Low cost of the truck;

- There are various modifications of the car;

- Small dimensions;

- Created for rural areas;

- Unpretentious vehicle;

- Intuitive controls;

- Comfortable seats;

- Informative dashboard;

- Quite a powerful power unit;

- Not afraid of overloads;

- A pre-heater is available as a separate option;

- ABS;

- Hydraulic power steering;

- There is more free space inside the cabin compared to its predecessor;

- Low fuel consumption;

- Used in various industries;

- The driver's seat has mechanical adjustments;

- Good visibility;

- Seat belts.

Cons of the car

- Outdated cab and body design;

- The level of comfort is still much inferior to foreign options;

- Metal elements begin to rust quickly;

- Only one passenger seat;

- The quality of the interior materials used;

- It is often necessary to change the clutch and chassis parts.

Truck cab GAZ-3309

The cabin and body of the Gas-3309 dump truck differ little from the design of other representatives of this family. Thus, the cabin part is made of solid metal. Inside there are two seats for the driver and passenger. The design is simple and concise without any frills. When designing, the designers focused on classic straight contours.

For driver/passenger entry there are wide doors with large glazing and excellent visibility. There are large rear-view mirrors on the sides without automatic adjustment (the position can only be changed manually). Access to the engine compartment is provided by lifting the large lid. In this case, all nodes are open to the driver.

The driver and passenger seats are separated, have good comfort and a high backrest. Vertical and horizontal adjustments and 3-point seat belts are provided. There are no complaints about the cabin in terms of comfort either. Thus, a liquid heater with a radiator provides high-quality heating during the cold period, and a fan saves the day in the summer. There is also an independent air heater powered by diesel fuel.

In the manufacture of the body part, longitudinal channels and transverse beams were used, and a square pipe was used for the frame of the wall/ceiling part. The floor has square boards covered with moisture-resistant plywood, and galvanized material is fixed in the lower part to prevent the ingress of dirt and water.

Features and operation

Compared to previous models, GAZ 3309 is much more comfortable to operate and maintain. The passenger and driver seats have comfortable high backs with simulated lateral support. The driver's seat is adjustable in horizontal and vertical directions. To ensure safety, three-point seat belts are installed. The presence of glow plugs in the engine starting system makes it easier to start the engine in cold weather. Finally, the GAZ medium-tonnage truck received power steering, which significantly reduces driver fatigue, especially in conditions of intense urban traffic flow. It is no coincidence that it was on the basis of the GAZ 3309 that a modern model, characterized by free forms and the presence of plastic contours, was created, called “Dobrynya”. In some ways, the car is reminiscent of the American type of hooded long-range trucks, only much more compact in size. If previously produced medium-tonnage GAZ vehicles were far from ideal in terms of exterior, “Dobrynya” looks excellent against their background. If the GAZ 53 can be called a nondescript “workhorse,” then the GAZ 3309 “Dobrynya” is a “thoroughbred trotter.” High wheel arches, an original radiator grille, fog lights in the bumper niches and an unusual frame for headlights and turn signals give the car a new and recognizable look. The designers did not forget about practicality. Non-metallic parts of the cabin are mainly made of fiberglass. Thanks to its use, the overall weight of the machine is reduced, and the corrosion-resistant elements last for many years without losing their appearance. The engine hood lid opens forward, which facilitates access to engine systems and prevents it from opening when hitting a bump or from an oncoming air flow. For ease of entry into the car, wide footrests are installed, and the driver's seat is equipped with a lever suspension. A completely new solution for GAZ cars of this class was the installation of a berth. “Dobrynya” was first presented at the “Commercial Vehicles” exhibition back in 2006 and over the entire period of production and operation it has earned flattering reviews from both specialists in the use of the vehicle and its sales. To a large extent, this happened thanks to reliable diesel power units that meet the most modern technical parameters and environmental standards.