“The Fifty-First” is 65 years old

Dmitry Dashko, photo UKER OJSC "GAZ", TsMAMLS and from the author's archive

In January 1946, the first batch of GAZ-51 cars was assembled; Six months later, in June, the continuous assembly of the truck began, which became the main worker of the roads in the next thirty years.

Brief history of the model

If not for the war, the GAZ-51 would have been put into mass production already in 1941. Preparations for this had been carried out since 1937, and everything necessary for this was already ready. The design, development, testing of a new universal economic truck, approval of this model and its preparation for launch into the “series” were completed. GAZ-51 from an experimental batch was exhibited at the All-Union Agricultural Exhibition in Moscow in the summer of 1940.

This truck, which replaced the pre-war semi-trucks GAZ-AA and GAZ-MM, was practically incomparable with its predecessors in terms of its technical performance.

The design of the GAZ-51 in the last years of the war was subjected to a total revision and modernization. A group of designers, led by Alexander Prosvirnin, tried to take into account the best experience gained during the operation of cargo vehicles in wartime. Including trucks supplied from the USA under the Lend-Lease agreement.

In accordance with this experience, not only the engine and its supporting systems have been improved. The design included a hydraulic brake drive that was new at that time; The changes affected both the cabin and the cladding.

It was decided to increase the wheel size and increase the load capacity to the optimal 2.5 tons. Serious work was carried out to ensure significant (up to 80%) unification with the all-wheel drive, future basic army version of the truck - GAZ-63.

An experimental (“installation”) batch of 20 GAZ-51 trucks was produced in 1945, and the year 1946 had already given the national economy of the war-ravaged and resurgent country 3,136 serial trucks of this brand. The first years of operation showed that the GAZ-51 largely surpassed its predecessors (even the three-ton ZIS-5) in all respects.

It was fast (at that time, of course, the speed was 75 km/h), reliable, economical, durable and hardy, as well as convenient and easy to operate. Compared to its predecessors, the GAZ-51 had a softer suspension with new effective shock absorbers. It was significantly ahead of everyone in terms of performance, demonstrating lower fuel consumption.

GAZ-51 in the workshop of the Gorky Automobile Plant.

In the fall of 1947, a control rally of the GAZ-51 was held along a 5,500-kilometer route: from Gorky to Moscow, from there through Belarus and Ukraine to Moldova, and back to Gorky. The truck performed flawlessly.

The production of GAZ-51 was constantly increasing, reaching its maximum in 1958, when more than 173,000 trucks of this brand were produced in a year. Additionally, their production was established at the Odessa and Irkutsk car assembly plants. In addition, the Soviet Union helped establish the production of copies of the GAZ-51 in Poland (the truck was produced under the name "Lublin-51"), in North Korea ("Singri-58") and the People's Republic of China ("Yuejin-130"). The last truck of the brand GAZ-51 rolled off the assembly line of the Gorky Automobile Plant on April 2, 1975 and went to the enterprise museum.

Pre-war period

In the spring of 1941, technical documentation was transferred to the assembly shop of the plant to launch the machine into mass production. But the war began, and the production of the new car had to be suspended. The developments in the units were useful for other vehicles, including military ones. The GAZ-51 engine and gearbox, driveshaft with crosspieces on needle bearings, clutch with release bearing and other components were used in the production of military equipment.

Technical characteristics of GAZ-51

Our days. “Alive and healthy” GAZ-51 on the roads of the capital.

Design Features

GAZ-51 on virgin soil.

Some technical innovations used in the design of the car were subsequently used by Soviet and foreign automakers on cars of other brands. Among them:

- wear-resistant engine cylinder liners made of special cast iron;

- chrome alloy coated piston rings;

- radiator vertical blinds;

- pre-heater operating by means of a blowtorch (An ignorant person may think that we are talking about warming up the oil pan and oil, as drivers sometimes do today. In reality, the coolant was heated in the heater boiler, and, according to the principle of a thermosyphon, circulated in the cooling jacket, warming up cylinders and combustion chambers);

- oil cooler (their use significantly strengthened the durability of the engine),

- bimetallic thin-walled crankshaft liners (steel-babbitt, instead of bearings filled with babbitt without liners, and later - steel-aluminium).

The engine received lubrication of crankshaft and camshaft bearings under pressure and replaceable liners, high-quality oil filtration, adjustment of valve clearances, a carburetor with a “falling” flow of the combustible mixture, and a closed-type cooling system with forced circulation. Now the driver could control the oil pressure and water temperature in the engine from his seat using instruments - previously there were no such instruments at all.

The driver’s work was also significantly simplified: with the advent of devices for automatically adjusting ignition timing and generator output, there was no longer a need to constantly adjust them “on the fly”, using a lever on the steering wheel, and a switch under the hood. The gearbox was changed and a completely new cardan drive with crosspieces on needle bearings was used.

The rear axle received a fundamentally new design of the differential and axle shafts, which simplifies the repair of the entire unit. Easily removable and independent of the axle shafts of the rear wheel hubs on double roller bearings appeared. The lever-cable mechanical brake drive was replaced by a hydraulic drive system and differentiated distribution of braking forces between the front and rear wheels.

The single front transverse spring with reaction rods gave way to two longitudinal packages, and the rear console “cantilever” suspension with its reaction rods was replaced by a simpler, reliable suspension with “springs”, designed for higher loads.

Those first used on the GAZ-51 have become generally accepted in the practice of the global truck industry: aluminum cylinder head, insertable valve seats, adjustable mixture heating, double oil filtration, closed crankcase ventilation. Double oil cleaning worked for drainage, and oil was supplied to the rubbing parts after a single rough cleaning. The easily removable brake drums used on the GAZ-51 also became a new word in the automotive industry. For those years these were extremely advanced and progressive solutions.

Weight and dimensions characteristics

- Length – 5.715 m; Width – 2,280 m; Height – 2,130 m.

- Ground clearance – 245 mm.

- Wheelbase – 3.3 m.

- Rear track – 1,650 m; Front track – 1,589 m.

- Curb weight - 2,710 tons; Gross weight – 5,150 tons.

- Tire size – 7.50:20.

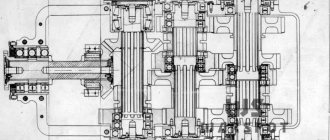

Engine GAZ-51

The engine of this truck is an improved modification of the GAZ-11 gasoline engine, created at the Gorky Automobile Plant in the 30s on the basis of the American Dodge D-5 lower-valve in-line engine purchased under license. Characteristics of the four-stroke 6-cylinder carburetor engine GAZ-51 in numbers:

- Cylinder displacement - 3,485 cm/cubic;

- Power – 70 horsepower at 2750 rpm;

- Torque - 200 Nm at 1500 rpm;

- Number of valves - 12;

- Cylinder diameter - 82 mm;

- Compression ratio - 6.2;

- Fuel consumption (low-octane gasoline A-56, A-66) – 20-25 liters per 100 km.

Engine GAZ-51.

A closed, sealed engine cooling system was used for the first time on a production truck from this plant. This minimized water loss from evaporation. And the latter, in turn, together with the less frequent need to add water in hot weather, resulted in a significant reduction in scale in the system.

For the first time, blinds and a thermostat were also used. During the entire production of the car, the cooling system received the only fundamental change. Until 1955, the fan and water pump were driven by dual narrow belts, and after that the engine received only one, but wider and more durable, accessory drive belt.

The lubrication system received two filters, and on the pre-war lorry there was no oil filtration at all, except for the mesh at the oil pump. A plate-slot all-metal coarse filter cleaned all the oil taken by the pump from the sump. It had a mechanism for manually turning the plates and cleaning them daily. After the first stage of cleaning, the oil was supplied to lubricate all working parts. After preliminary cleaning in the first filter, part of the oil entered the ASFO type fine filter (automotive super filter sump), with a filter element made of cardboard plates assembled into a single block. The purified oil after this filter was not supplied for lubrication, but was drained back into the sump through the drainage line. But due to this, the turnover of oil through both sequential filters was quite intensive, which ensured its normal cleaning during a relatively short (1,500 - 2,000 km), but service life prescribed by the factory.

The GAZ-51, like a number of other cars of that time, had “constant gas”, a forced fixed opening of the carburetor throttle valve by a special manual drive from the driver’s seat. Firstly, when warming up the engine, it was not necessary to abuse the “choke” with the help of the air damper, enriching the combustible mixture - the engine maintained speed well even on manual gas. And secondly, the low intensity of traffic in those years, on long-distance flights, made it possible to drive on “autopilot” - by turning on the fourth speed and setting the required engine speed, not being “tied” to the accelerator pedal, but sitting in any free position, just while driving.

The fuel pump with a glass sump cup was also designed in an original way by today's standards. Without disassembling it, you could always see its operation, control the cleanliness of the filter, and check the absence of air leaks through the diaphragm and gaskets. No tools were required to remove the cap, clean the sludge, or blow out the filter. True, there was also a drawback: in the heat, the large glass sump provoked the accumulation of steam plugs inside and a refusal of gas supply. In this case, a rag was hung on him, cold water was poured on him, and the car could continue on its way.

Despite the relatively low power, the GAZ-51 engine has excellent traction. It was possible to start the car even with a failed starter, and with a non-functioning battery, or without it at all - by using the handle of a manual “crooked starter”.

It should be noted that the GAZ-51 engine did not have a significant safety margin in case of prolonged operation at high speeds and heavy loads. The engine could fail due to melting of the babbitt from the bimetallic crankshaft main liners.

When operating for a long time at high speeds, the oil supply was insufficient, and the lack of an overdrive and the main pair of the rear axle with a large gear ratio contributed to the “over-torque” of the low-speed engine. Therefore, to maintain the high resource and durability of the engine, the carburetor had a speed limiter, and the maximum practical speed of the GAZ-51 did not exceed 75 km/h, regardless of road conditions.

On the first cars with a wood-metal cabin, a gas tank with a capacity of 105 liters was located under the body. After the introduction of all-metal cabins, a 90-liter fuel tank was located under the driver's seat. The drivers received a nice gift in the form of a high filler neck with a wide flare. Now the car could be refueled on the road without bending over, even from a bucket. Another pleasant surprise was the standard measuring ruler for the remaining fuel, in case of failure of the electric fuel gauge.

Transmission, suspension, chassis, cargo platform GAZ-51

The layout of the GAZ-51, with the engine and cab moved forward (which, with a fairly short base, made it possible to have a fairly long cargo platform at its disposal), was traditional for hooded trucks in general.

The GAZ-51 transmission includes a single-disc dry clutch, a 4-speed gearbox without synchronizers and a single-stage final drive.

On the engines of the first production cars, a semi-clutch was used, which had additional weights at the outer ends of the release levers, which diverged to the sides as the engine speed increased, and contributed to an increase in the compression force of the pressure and driven disks. And later more powerful peripheral pressure springs began to be used.

The simplest mechanical clutch drive consisted of a shaft with a crank and a threaded rod with a special “shaped” adjusting nut. The shaft was rotated by the clutch pedal attached to it, the release rod was pivotally connected to the crank, and its nut fit into a special socket of the release bearing fork.

Rear axle GAZ-51.

The car used a four-speed three-way gearbox. Basically, it repeated the gearbox of the pre-war lorry - the same gear ratios, 1 - 6, 4; 2 – 3.09; 3 – 1.69; 4 – 1.0; Z.H. – 7.82, the same lack of synchronizers. But these units were not interchangeable with each other due to the different shapes of the crankcases, and the different ends of the secondary shafts, designed for connection with cardan transmissions that were completely different in design.

Due to the lack of synchronizers, it was necessary to change gears with double clutch release. When accelerating the car, when you press the pedal for the first time, the previous gear is turned off, and when you press it again, the next required speed is turned on. And when the speed decreased, between squeezes a little more “gas lifting” was required to better equalize the revolutions of the intermediate and secondary shafts.

The suspension design of the GAZ-51 truck is dependent, but essentially modern even by today's standards: 4 longitudinal, semi-elliptical springs and two springs on the rear axle (which is comparable to the modern generation of the Gorky car). The introduction of hydraulic lever shock absorbers of 2-way action in the front suspension of the GAZ-51 can also be called a solution ahead of its time. A rigid front axle, with a heavy kingpin and steering knuckle, had a positive effect on the stability and controllability of the car.

The GAZ-51 gearbox had an interesting feature - forced locking of reverse gear. It was impossible to accidentally turn on “reverse” at high speed of the car, confusing it with direct transmission. To engage reverse, the driver had to press a special flag next to the “knob” of the gear shift lever. The rod from the flag, repeating the shape and length of the lever itself, moved to the side a ratchet with an automatic locking spring.

The cardan transmission with two shafts and an intermediate support had three crosspieces on needle bearings.

The rear axle of the car was assembled inside a beam with a split crankcase. It had a “direct” single main gear - the axis of the drive gear and the axle axles of the wheels were located in the same plane. The gearbox had a gear ratio of 6.67 units, and later found application in the drive axles of three-axle trucks ZIS-151 and ZIL-157. The rear axle axle shafts were of a completely unloaded type, and were removed and installed independently of the fastening of the rear wheel hubs.

The car frame has open channel-type side members and variable cross-section, has five riveted cross members connecting them and a removable cross member of the rear engine mount.

The rear suspension consisted of main springs, which had 13 leaves, and additional “suspension”, which had 7 leaves. The main springs had one main leaf each, and were hingedly attached to the frame, on lubricated steel pins, and the additional packages had only a sliding support fit on brackets. Shock absorbers were not installed in the rear suspensions of the trucks. They were used only for the chassis of bonneted buses of the “651” model, and PAZ-653 ambulances.

The front springs had 11 leaves each - two main leafs, one radical leaf, and one “reverse” leaf each, which was placed on top of the main ones. The “reverse” sheet, unlike all the other sheets in the package, was not curved in the opposite direction, but straight. And the root leaves were double, since their ears, with different twist diameters, fit into one another. The front springs, as well as the rear units, were hinged on lubricated pins.

Shock absorbers in the front suspension until the mid-60s were used of the lever type, and after that they were replaced by telescopic units.

The front axle of the car consisted of a simple cross beam and steering knuckles. The steering knuckles in the horizontal plane were supported by special thrust ball bearings, and in the vertical plane they were mounted on kingpins with plain bearings, the role of which was played by bronze bushings. This design of the front, non-driving axle is still used on GAZ trucks, including the 3309 model.

The wheels of the GAZ-51 car with a tire size of 7.50 x 20 inches during the entire production period had three varieties. In the 40s, disks with two windows, such as the ZIS-5, were used. In the 50s and the first half of the 60s, “six-window” wheels of the ZIS-151 type were used, with side and locking rings. And from the second half of the 60s, six-window wheels unified with the GAZ-52 began to be installed with a single side split ring, which also served as a locking ring.

It is necessary to dwell in more detail on the wheel mounting. It was standard, and in terms of fasteners it was unified with most Soviet trucks. And now, for the sake of “Western democratic values,” such wheel fastening is almost universally a thing of history.

The mounting threads for the front and rear wheels were not the same. There were nuts for the front wheels, as well as kits for the rear dual ramps, which were attached independently of one another. The inner wheels of the rear axle were fastened with special internal cap nuts - liners, with external and internal threads, and the external cylinders - with special nuts that worked on the outer threads of the liners. The internal threads of both the front wheel bearings and nuts were the same, which made it possible not only to unify the studs of the front and rear hubs, but also, if necessary, to use the fittings on the front hubs.

The independent fastening of the rear wheels eliminated the possibility of their simultaneous loss on the move, which is increasingly becoming fashionable among “Gazelles.” After all, until the outer ramp begins to “play” on its loose nuts, the inner cylinder fittings pressed by it will not even budge! For footers, and both types of nuts, there was a unified Soviet all-Union cargo “balloon” with opposed heads. A hex head set to “38” was used for the front wheel nuts and the outer nuts of the rear slopes, and the opposite head with a square set to “22” was used for the footers.

To prevent the fasteners from self-unscrewing when the wheels rotate, they had different thread directions. For the left side of the car, parts with a left-hand thread were used, and for the wheels on the right side - with a classic right-hand thread. Nuts and futorkis with left and right threads differed in appearance. The “left” products of all three varieties first had characteristic grooves in the middle of the edges, and then the nuts at the ends were marked “O”, and for the foots, the letter “L” appeared in the center of the turnkey squares.

The cargo platform of the vehicle was made of wood. If necessary, the folding tailgate could be used as an extension of the floor - for this purpose, chains were used that, when folded, held the tailgate in a horizontal position. The internal dimensions of the GAZ-51 body (length x width x height) are as follows: 2.940 x 1.990 x 0.540 m. The height was increased as much as necessary using extension sides. A new body with three folding sides (+ side) began to be installed on the GAZ-51 in 1955.

The GAZ-51 was the first to use an original and quite convenient under-body spare wheel mount. It was made in the form of a folding bracket, which had “working” and “transport” fixations, and its ratchet and threaded fastenings. If a spare wheel was needed, the driver, using a regular “spring wheel”, unscrewed the transport fixing nut of the folding bracket, which continued to be held by the working fixation lock. Next, the lever for the remote drive of this lock was pressed with the foot, and the bracket with the spare wheel was folded back all the way to the road. After that, the same spray gun was used to unscrew the two nuts securing the wheel to the holder. As the reader guesses, all three holder nuts are the same as on the right front wheel. After installing the broken ramp on the holder, the driver manually or using a standard jack pressed the installed wheel into a horizontal position. The lock automatically locking the holder in the working position was activated. Then the transport locking nut was tightened, and behind the steering wheel. This solution is still used on all large “lawns”.

Engine

The power plant of the vehicle fully corresponded to the tasks assigned to the truck. The optimal volume of the cylinders made it possible to develop sufficient power for movement in any mode. The GAZ-51 engine had the following characteristics:

- type - gasoline;

- number of cycles - 4;

- cylinder volume - 3,485 cc;

- power - 70 horsepower at 2750 rpm;

- torque - 200 Nm at 1500 rpm;

- cylinder arrangement - in-line;

- number of cylinders - 6;

- number of valves - 12;

- cylinder diameter - 82 mm;

- compression ratio - 6.2;

- cooling system - circulating liquid, closed circuit;

- The power supply system is carburetor.

GAZ-51 truck cab

By modern standards, the truck's cabin looks more than spartan. However, compared to the cab of a semi-truck, it is more than comfortable and ergonomic. On the dashboard, unlike the same semi-truck, there is already a full set of instruments that are familiar in modern cars.

There is even a clock in the interior of cars of later years, just like in passenger cars. The windshield can be raised forward/upward, allowing a flow of oncoming air into the cabin in summer. An extraordinary exotic feature is the manual drive of windshield wipers. But - as an additional and backup, of course. And the main operating mode was vacuum driven by vacuum in the intake manifold.

Since there was a shortage of metal in the post-war years, the cabin until 1950 was made of wood (blocks of wood, plywood and tarpaulin); then - combined, wood-metal; and since 1954 - all-metal, heated.

The rational design of the front of the car, with a hood tapering forward, was, to some extent, revived in the trucks of the Gorky plant of the late 90s / early 2000s (GAZ-3307 and similar models of this family).

Stalin Prize

The performance of the GAZ-51 was higher than that of the popular “three-ton” ZIS-5, while Gorky’s car consumed 30% less fuel. Taking into account all the advantages, both speed and economic, the machine was recognized as the most suitable for the needs of agriculture. Starting from the end of 1946, almost all cars were sent directly from the assembly line to collective and state farms. And in 1947, the group of car creators, together with the chief designer of the Gorky plant A. A. Lipgart, was awarded the Stalin Prize.

Modifications of the GAZ-51 car (in chronological order)

- GAZ-51 N is an army version, with a lattice body from the GAZ-63, equipped with benches along the sides, as well as an additional 105-liter gas tank. Produced from 1948 to 1975.

- GAZ-51 U - export version, for temperate climates. Produced from 1949 to 1955.

- GAZ-51 NU is an export modification of the army version of the truck for temperate countries. Produced from 1949 to 1975.

- GAZ-51 B is a gas-cylinder version running on compressed gas. Produced from 1949 to 1960.

- GAZ-41 is an experimental half-track modification, built in 1950.

- GAZ-51 Zh is another gas-cylinder version for running on liquefied gas. Produced from 1954 to 1959.

- GAZ-51 ZHU is an export gas-cylinder version running on liquefied gas for a temperate climate.

- GAZ-51 A is a modernization of the basic GAZ-51 model, which replaced it in 1955 and was produced until 1975. It differs from the GAZ-51 in having a larger cargo platform, folding side walls, and an improved braking system.

- GAZ-51 F - pilot batch, equipped with an 80 hp engine, with ignition of a prechamber-torch design with a power of 80 hp. It was released in 1955.

- GAZ-51 AU - export version for temperate climates, serial production lasted from 1956 to 1975.

- GAZ-51 Yu - export version for tropical climates, produced from 1956 to 1975.

- GAZ-51 S is a variant equipped with an additional 105-liter fuel tank. Serial production was carried out from 1956 to 1975.

- GAZ-51 SE is a variant with an additional 105-liter gas tank and shielded electrical equipment.

- GAZ-51 R is a cargo-passenger version, the sides of the body of which were equipped with folding benches, and a door and a ladder were provided in the rear side. Produced from 1956 to 1975.

- GAZ-51 RU - export version of the cargo-passenger modification, for temperate climates, production years - 1956-1975.

- GAZ-51 T - cargo taxi, 1956-1975.

Truck tractor GAZ-51P.

- GAZ-51 P – truck tractor. Produced from 1956 to 1975. For the first time in the USSR, a hydraulic vacuum brake booster was used on the GAZ-51P truck tractor.

- GAZ-51 PU - export version of a truck tractor, for temperate climates, years of production - 1956-1975.

- GAZ-51 PU is an export modification of the truck tractor, designed for tropical climates, produced from 1956 to 1975.

- GAZ-51 V is an export version, with a payload capacity expanded to 3.5 tons. Was equipped with a 78-horsepower engine

- GAZ-51V , with oversized tires up to 8.25-20″ and the rear axle of the all-wheel drive GAZ-63. Serial production was carried out in 1957-1975.

- GAZ-51D is a chassis with a shortened frame, designed specifically for GAZ-93A, GAZ-93B and SAZ-2500 dump trucks, which were made by the Saransk and Odessa dump truck plants. In serial production from 1958 to 1975.

- GAZ-51 DU is an export version of a dump truck chassis for temperate climates.

- GAZ-51 DU is an export version of a dump truck chassis for tropical climates.

In addition to trucks, a number of small class hooded buses were built on the GAZ-51 chassis. They were produced both in Gorky and at the Pavlovsk bus plant PAZ, and at the Kurgan bus plant KAvZ. And also at car repair plants throughout the Soviet Union: in Borisov, Tartu, Tosno, Kyiv, Kaunas, etc. About a hundred excursion buses with open “convertible” bodies were very colorful. GZA-653, PAZ-653, AS-" - ambulance buses-vans on the GAZ-51 chassis.

Excursion bus based on GAZ-51 in Gagra.

Countless large, medium and small enterprises throughout the Union republics produced a variety of specialized vehicles on the GAZ-51 chassis: furniture and insulated vans; grain trucks and tankers, firefighting and municipal special vehicles, aerial platforms, mobile repair shops, etc.

Improvements

The engine is the successor to the GAZ-11 power plant, which was once created on the basis of a Chrysler lower-valve engine under a 1937 license. The piston group was constantly improved, liners were installed from special wear-resistant cast iron, compression piston rings were chrome-plated, and new bimetallic (steel-babbit) liners were developed for the main and connecting rod journals of the crankshaft. As a result of the use of technical innovations, engine life has increased significantly.

Reviews from drivers and owners of GAZ-51

All people who have experience working on GAZ-51 trucks agree that this is an extremely reliable, unpretentious vehicle that is resistant to any tests. The design of all components and parts is simple, “like a children’s construction set,” which greatly facilitates maintenance and repair. “Everything is easy, accessible, everything is very simple, there are a minimum of keys. You can always “farm” something out of wire to “get there.”

Our days. GAZ-51 of the Dagomys tea factory.

The vehicle practically does not feel the load of two and a half tons set by the manufacturer, easily coping with larger loads. The off-road capability is amazing, despite the fact that this is not a four-wheel drive truck.

Driving and operating a car has its own characteristics that you need to get used to and adapt to. For example, in old films you can see how the driver of a GAZ-51 shakes the steering wheel from side to side, although in the story the truck drives straight. And this is not a “cinematic blunder.” Because the steering wheel play was between 15 and 20 degrees. To “catch” the car, it was necessary to periodically work with the steering wheel.

The brake pedal was quite stiff, especially by today's standards. In order to achieve the desired deceleration, it was necessary to make a very significant physical effort.

Considerable muscular tension (unthinkable and completely forgotten these days) was also required to “fold the steering wheel” and to move the gear lever. Since there were no synchronizers in the box, everyone who mastered the GAZ-51 learned to double-depress the clutch when switching to a higher gear and re-engage when shifting down.

GAZ-51 takes part in a rally in Scandinavia.

On the Internet you can find many memories of people who, during their school or student years, went to agricultural work right in the back of a cargo-passenger GAZ-51. In completely unthinkable conditions from the point of view of modern ideas about security. Namely: more than half of the children (or youth), unable to fit on the folding benches, simply sat in the back on upside-down buckets for the duration of the trip. And no one has ever heard of any accidents associated with such movements!

Modernization

During the modernization, an aluminum block head and insert valve seats were used. The car gradually absorbed all the advanced technologies, its design was systematically improved. In 1954, the car's cabin became all-metal, and a heater was installed at the same time. The new cabin became an incentive to change the shape of the front end; the lining acquired a more modern look; the wings and headlights organically fit into the overall style. Special vertical louvers were installed behind the radiator grille, which prevented excessive cooling of the engine in winter.

Cost of GAZ-51 truck

Despite the fact that the production of GAZ-51 trucks was curtailed more than forty years ago, on electronic bulletin boards you can find many offers for the sale of cars of this brand. Usually - the first half of the 70s. The range of prices is very wide: from 20 thousand rubles for a car in a condition “close to scrap metal”, to 250 thousand rubles, which is what they ask for restored copies of a GAZ-51 on the move in fully working condition.

Go to other RUBRICS of the site

Expansion of production

The USSR State Planning Committee submitted monthly applications for the production of GAZ-51 in quantities significantly exceeding production capabilities. Thus, the question arose about expanding assembly areas. In 1948, the production of popular cars was mastered at the Odessa Auto Assembly Plant, and in 1950 the assembly line was launched in Irkutsk, where production continued from 1950 to 1952, then the production of trucks was curtailed for a number of reasons. In Odessa, cars were produced for 27 years. The last car to roll off the assembly line on April 2, 1975 was sent to the factory museum.

Structural advantages of the car

Technical parameters of the GAZ-4301 truck

Vehicles are able to withstand quite severe operating conditions, since the vehicle is equipped with the highest quality frame. The car was characterized as the most reliable. The driver could start the car even with a faulty starter, as well as with a completely broken battery. This could be done using a special starting handle. The wheelbase of the car deserves special attention. Its size is only 3.3 meters, but the slightly shifted forward cabin of the GAZ line 51, as well as the most thoughtful engine location, made it possible to obtain a large amount of free space. It is there that the GAZ mark 51 gearbox is located.

Frame GAZ 51

The general design of the 51st GAZ is advantageous. Each car block contains one or two parts that are designed to take on a serious load. These include an easily removable drum built into the brake mechanism, a separate compartment for the oil pump, as well as plug-in valves. Replacing such parts was not difficult, therefore, with proper operation, the GAZ 51 and its technical characteristics do not change over time, and the total service life of the engine, GAZ 51 gearbox and the car itself can reach 50 years.

The advantage is not only the engine of the GAZ 51 car, but also its frame, which is additionally reinforced with a special cross-shaped cross member. The design features of this element are able to provide an ideal connection between numerous spars. At the same time, special towing hooks are attached to the frame. They are under the wings.

Tuning

Some cars of the past, which were discontinued many years ago, sometimes get a second life. Enthusiasts and collectors are engaged in restoring cars from the 50s and 60s. They find preserved rarities in landfills or abandoned garages, transport them to their workshops, and there the long and painstaking process of reviving the car begins.

Along with the restoration, the exterior is often updated. This creative process is called tuning. As a result of alterations, the car can radically change its appearance.

The GAZ-51, the tuning of which became possible thanks to the use of the latest technologies and the latest technical means, is one of the cars of the middle of the last century that has good potential for transformation.

At the first stage, it is necessary to make a list of all the changes that the tuning masters intend to make to the exterior of the car. The accuracy of the drawings is important. GAZ-51, the tuning of which can be complicated by the dimensions of the car, should be carefully measured and two sets of technical documentation made - the original dimensions and modification parameters. Then you can get to work. For full tuning, you will need equipment in the range of a repair shop: gas welding, grinder, drilling machine, set of plumbing tools, painting equipment.

GAZ-51, whose technical characteristics are considered ideal for tuning conditions, can become a good object for creativity. A tuned car can become a participant in an exhibition of rare automotive equipment, as well as a fair for the sale of vintage vehicles. If the rarity is in good technical condition, it will be able to take part in a car rally or even in competitions.

The founder of “63rd”...

In parallel with the GAZ-11-51, several types of all-wheel drive 2- and 3-axle versions were developed. The first of them was the GAZ-63. It would be more correct to call it GAZ-11-63, but in the documents of the People's Commissariat of Defense (the main customer), Gorky's products were listed under simplified indexes (GAZ-42, GAZ-60, etc.), which eventually took root in the factory indexing .

Work on the GAZ-63 began in April 1938, but it would not have been successful without the development of CV joints and the purchase of equipment for their production. The all-wheel drive truck was given such great importance that its development even slightly delayed work on the base model. Pyotr Ivanovich Muzyukin, the future chief designer of UAZ, was appointed lead designer for GAZ-63 with the participation of GAZ lead designer Vitaly Andreevich Grachev.

The first GAZ-63 was assembled 2 months earlier than the GAZ-11-51 and appeared in March 1939. By the way, it turned out to be the first GAZ car with both drive axles, ahead of the well-known passenger all-wheel drive GAZ-61. However, the high interest of the Red Army played a cruel joke on the machine: practically no information about the machine was leaked either to the press or to reference literature. Over time, the car was completely forgotten, and if it weren’t for the surviving army report on its testing at the Kubinka training ground, we would have no idea where the well-known GAZ-63 began.

Due to the urgency of the order, priority was given to the transmission and chassis, working on the exterior according to the residual principle.

The GAZ-63 model of 1939 was originally equipped with a 76-horsepower version of the GAZ-11 engine, a 4-speed gearbox and an original transfer case with a built-in range (gear ratio 1.82:1), the control lever of which had four positions: 1 - “ only the rear axle is engaged”, 2 – “both axles are engaged (rigidly)”, 3 – “neutral” (no power transmission to the wheels) and 4 – “both axles are engaged through the range-shifter”. Increased traction properties of the car were ensured by both main gears with a gear ratio of 6.67:1, and special tires measuring 34x7" with developed lugs of the "Ground Flu" type. A completely new, original front axle was developed, similar to the GAZ-AA drive axle only in the crankcase. Non-adjustable ball and roller bearings were used for the hubs. At first, the GAZ-63 had many imported components: constant-velocity joints, pivot joints, the same tires...

The car temporarily received a cabin and hood from GAZ-AA (later they were planned to be unified with similar streamlined units of the GAZ-11-51), but a different, more voluminous and efficient radiator; as well as fenders with headlights and sidelights from the GAZ-M1 and extended wheel arches. GAZ-63 model 1939 was designed for a load capacity of 2 tons on the highway and 1.5 tons off-road. The length of the vehicle was about 5200 mm, the weight with full load was 5450 kg. Then, during tests on the GAZ-63 model of 1939, an 85-horsepower version of the engine was installed, with which the truck, with a full load of 2 tons, developed speeds of up to 85 km/h on the highway, and on off-road terrain it could overcome fords of 0.8 m and climbs of up to 30 ° on hard ground, and about 20° on grassy or loose soil. The truck's fuel consumption reached 25–30 l/100 km in relatively good road conditions, and increased to 55–60 l off-road.

Repeated tests

The GAZ-56 truck was sent for testing again in 1960.

Instead of being accepted by officials, the truck made a test run, which took six months. During this time, twenty-five thousand kilometers were covered. Cars from different countries and manufacturers took part in this race. The trucks traveled along roads with different types of surfaces. Moreover, they ran through different regions with difficult conditions. And the 56th coped with the test perfectly. Reliable springs and a durable frame helped with this. There were also breakdowns. The most important thing was that the electric coupling installed on the cooling system fan often failed. Later it was decided to abandon its use. The engine also showed itself on the bad side. He lacked power. While driving, the driver had to fully concentrate on the car. It was necessary to operate it only in a gentle mode. In addition, other shortcomings were discovered. The hubs were not reliable enough, as were the spring mountings. The rear axle often leaked. Every day the driver had to inspect his vehicle, carry out its maintenance and repairs

Nevertheless, the car received permission for mass production. True, it never came off the production line. At the plant, the lines were busy with the production and production of several models of passenger cars. At first there was a desire to move the production of the truck to the Ulyanovsk plant. But nothing came of it either. The company was busy producing a model with a load capacity of eight hundred kilograms. It required lower costs than the GAZ-56. Therefore, they decided to abandon the idea of assembling the car at another plant.

It was difficult for ordinary people from the village to accept the GAZ-56 truck, the description of which we are considering. The quality of roads did not matter much at that time. Then, first of all, they thought about how to transfer cargo, and only after that they calculated the costs that would contribute to this. The GAZ-56 had ground clearance of only two hundred and twenty millimeters under the rear axle. This was very little for difficult rural roads, which at certain times were similar to off-road. In such conditions, only the ZIS-5, which was distinguished by cross-country ability and endurance, could operate. Even the GAZ-51, which was a very popular truck in those early post-war years, was not the best option for such difficult terrain.

But urban users would like the truck. It could be used by trade and motor transport enterprises to transport goods in small quantities. A carrying capacity of one and a half thousand kilograms would be enough for transportation and daily use. This would allow the organization to save money and make a profit. Small dimensions combined with good maneuverability would allow the car to cope with its function.

The development of the project remained a theory. True, some developments were used in subsequent years to produce other models.