- June 6, 2019

- Weapons and ammunition

- Michael Michaelis

Have you thought about how to strengthen the MP-512 air force with your own hands at home? This question is often asked by pneumatic enthusiasts, but few of them know that to carry out such an event it is not at all necessary to have any serious knowledge. It is enough to follow certain instructions, as well as follow the care recommendations, so that the spring mechanism serves faithfully for several years.

Required Tools

To strengthen your air rifle, it is recommended to prepare everything properly in advance. For example, you need to acquire high-quality tools for fine work, which will allow you to make some changes in the barrel channel of the air gun. We strongly do not recommend using various “alternative” options. Otherwise, you risk damaging the weapon. Here are just the basic tools you will need to strengthen:

- high-quality blade for a hacksaw for metal (preferably new);

- electric drill with small carbon steel drill bits;

- a set of needle files - files necessary for processing the barrel.

Before you begin the strengthening process, be sure to make sure that you have all the necessary tools on hand. Otherwise, you will have to constantly be distracted from your work, looking for missing elements. Also, take care in advance about the place where the modification will be carried out. It must be clean, dry and protected from strong winds. The ideal option would be a workbench on which you can fix the weapon.

Reactivate your weapon

Before strengthening the air with your own hands, it is necessary to re-preserve the weapon. This procedure involves removing the factory grease, which can be found in large quantities on a newly purchased rifle. To be fair, it is worth noting that re-preservation should also be carried out for used air vehicles. Before sawing the trunk, be sure to make sure that there is no oil left in it.

To remove grease, it is best to use a cleaning rod and a rag soaked in a solvent or a special compound, which can be purchased at a gun store (quite expensive, but the most preferable option). However, watch the intensity of your movements. Careless actions can scratch the barrel, causing the weapon to fire inaccurately. That is why it is highly not recommended to use folding cleaning rods.

Ways to improve

Now I would like to dwell on the main ways to increase power offered by the Internet.

Among one of the top methods on the Internet in an attempt to understand how to strengthen an air pistol, there is a secret method of an inventor who, with the help of ballpoint pens, television antennas, magnetic fields, antimatter and other magic, accelerates airsoft guns to the power of excellent air guns. A cascade of such devices, when applied to a conventional pneumatic ball blaster, is apparently capable of propelling a BB gun beyond the fourth cosmic speed (550 km/s), thereby leaving a fiery lead greeting to the alien intelligence (intergalactic hardball). This is where the search interestingness ends, what follows is the pure truth. Those interested can read the whole story in a small abbreviation:

There are a lot of ways to make an air gun more powerful, most of them lie within the range of increasing the final speed by 10-20 m/s. For some, these may seem like ridiculous numbers, but within the framework of the hardball movement with its regulated restrictions, this is sometimes more than enough. The main thing is not to overdo it and not to create conditions for reviewing safety precautions, because after all, we are for a safe pastime.

And although this article deals exclusively with air pistols, no one has canceled their division into classes - gas cylinder, spring-piston and multi-compression. The list of possible works will depend on their type.

Gas bottles

Gas cartridges for beginner shooting enthusiasts are the most affordable among weapons, and therefore the desire to increase their power is greatest. Let's allow ourselves a little theory. The energy transferred to the bullet in these pistols is taken from compressed carbon dioxide in a can. The main limitations here are the CO2 pressure, the volume of the expansion chamber, the flow of released gas, and the tightness of the gas flow.

Of course, the first limitation will not allow pneumatic compression to beat CO2, but for the needs of hardball and bottle rippers, working out these parameters can work wonders with a competent approach and direct hands.

So, what is generally done with poor gas cartridges to increase their power, and at the same time the speed of the shot:

- Expansion chamber boring

- Working with the valve

- Increasing barrel length

- Working with springs

- Increasing the mass of the trigger-barrel

- Reducing the caliber of the barrel and bullet - special maniacs

Each pistol requires a separate approach; we will not dwell on specific actions here. As detailed articles are written, useful links will appear. Already now, for almost any model of pistol, you can find discussions and even videos in a search engine (the veracity of which is still recommended to be considered).

We remember that any work requires straight hands and a clean head, otherwise you can damage the gun. We also do not forget about common sense, for example, work on a serious increase in the power of the blowback can, at a minimum, deprive the barrel of this function.

I would like to note that for a long time now, for the most famous models (usually domestically produced, they love to sort through them), you can purchase ready-made upgrade kits according to the list above, which allow you to strengthen your air pistol without much hassle. For example, I’ll give you the over-powered Anix 101.

Upgrade of pure Anix 101 (barrel, false silencer, camera and other little things) - produces up to 220 m/s

You can also always find craftsmen who are ready to produce high-quality work on your favorite toy.

Complete overhaul of the bunker Drozd - up to 220 m/s

Spring-piston system

And although this class is still more specific to rifles, we’ll say a few words about ways to raise hell here. Again the top works:

- Enlargement of the compression chamber

- Work on springs

- Increase in piston mass

- Barrel length (as long as it's not at rifle level)

Nothing astronomical will work here either, but you can push the barrel beyond the prohibited 7.5 J without special skill in using a file. Just replacing a spring can sometimes make fabulous transformations. The main thing again is a competent approach and subtle calculation.

Types of rifles for reinforcement

Have you decided to install a reinforced spring on the air intake? Then you should understand that not all types of pneumatics can be easily reinforced. Therefore, before making any modification, be sure to read this information:

- rifles with a gas mechanism - as a rule, cannot be strengthened;

- rifles with a spring mechanism - can be easily modified.

Although such statements are relevant only if the strengthening involves replacing the shock-spring mechanism. If you decide to use weighted ammo, then that's a completely different story.

Increasing the power of spring-piston pistols

New concept for upgrading spring-piston pneumatics

Spring-piston pneumatics (SPP) are represented by the most reliable and accurate samples intended for sports or amateur use. Unlike similar rifles, PP pistols usually have a significantly lower firing speed, which is structurally due to the smaller dimensions of the chamber.

There are the following ways to give more energy to a bullet from such a weapon:

- increasing the volume of the pneumatic chamber. The method consists of processing its inner surface on a machine, removing a thin metal layer.

This approach requires the involvement of an experienced turner, otherwise you may end up with a pistol that is disfigured and unsuitable for shooting. - replacing the barrel with a longer one. This operation also requires a qualified approach, otherwise there is a risk of radically deteriorating the accuracy of the sample (in case of improper installation);

- installation of a more powerful spring. When replacing, you should take a spring several turns larger than the previous one. The main requirement is its length in a compressed state - it must fit in the pistol when cocked;

- installing a metal washer one or two coil lengths thick under the spring. This will cause the spring to be slightly compressed, increasing resistance when charged. This method and the previous one are one of the easiest ways to upgrade a pistol;

- increase in the mass of the piston pushed by the spring. The principle of the method is to obtain more energy from the part that compresses the air, and due to this, pumping more pressure. A piston of increased size and weight can be ordered from a turner.

Any upgrade to the pistol’s spring-piston system involves exceeding the operating parameters specified by the manufacturer. The power should be increased gradually, avoiding the pursuit of too high speeds, which can negatively affect the performance and durability of the weapon.

Review of three Elite II Umarex, 92 KWC and M-92FS models of the popular Beretta air pistol in one article. Here we discuss their structure and diagram, basic equipment and repair methods. You can read how to modify the Makarov air pistol here. Find out the power and speed of bullets of different models.

Method number 1: trimming the trunk

Have you ever heard about sawn-off hunting rifles that our fathers and grandfathers made? A similar manipulation can be done with an air rifle. Many gun enthusiasts will say that such actions lead to a decrease in the effective range - this is true. But the power of the rifle increases several times. However, pruning must be done with extreme caution, using a hacksaw rather than a grinder with a disc.

This method cannot be called the most perfect, because few owners of an air conditioner would want to spoil the newly purchased device. However, if you have an old MP-512 or IZH lying around in your garage, then you can strengthen it in order to increase penetrating power at medium and short distances. After all, the shorter the distance the bullet travels in the barrel, the more energy it has when leaving the channel.

Defects of a gas cylinder gun (CO2)

The structure for diagnosing a non-working sample is standard - first you need to determine the problem, and only after that begin to eliminate it. The method of “disassembling the gun completely, and then you’ll see” is not suitable. The fault detection steps for various causes are as follows:

- poisons gas from the cylinder - check the place where the gas is released from the magazine by immersing it in a container of water (preferably with alcohol, so that it evaporates faster). After this, the leak will be easily visible visually. The repair will consist of replacing the rubber seals at the sealing point of the cylinder and the pneumatic chamber;

- low bullet speed - look to see if the barrel gasket is damaged. The problem is often solved by replacing it;

- balls sticking into each other when shooting or they fly out of the barrel in pairs - the problem may lie in a deformed barrel gasket or a magazine spring that is too powerful;

- The trigger mechanism does not work - shake the gun in a quiet room. If an extraneous sound is heard from inside, similar to the knocking of metal fragments, it means that the parts are broken and need to be replaced (including the spring);

- the cylinder is enough for a small number of shots - listen to see if the cylinder hisses (whether the gas is released). Place a drop of alcohol on the rubber seals in the gun - if gas escapes, the gaskets must be replaced;

- visual damage - finding chips, cracks and shifts of sighting devices.

Method number 2: replacing the spring

To strengthen an air rifle, it will be enough to partially disassemble it and replace the main element that affects the speed of the bullet - the spring. However, before you carry out a modification, be sure to make sure that you have a part that exceeds the characteristics of the original copy. Russian manufacturers often put weak springs in rifles, but foreign models have a very strong striker mechanism.

Before purchasing a spring in a store, it is best to remove the old sample from the rifle and take it to a gun shop, because the part may simply not be suitable in length, diameter and other parameters. For reinforcement, you should choose an option made of a higher quality alloy and with a smaller distance between the turns. However, if you overdo it, the piston may simply not withstand the load and break apart.

Features of work related to the repair of pneumatic weapons

The operation of air guns has its own characteristics. Lack of regular maintenance and care can lead to mechanical damage. Subsequent repair work will be associated with certain difficulties. It may be necessary to replace cuffs or bypasses, install a gas spring, and also straighten the barrel.

To determine the correctness of this type of action, you should first carry out diagnostics. Analysis of the technical condition of the weapon allows you to determine the cause of the breakdown and create a sequence of further actions.

In most cases, diagnostics are carried out free of charge, and the final cost of repair work will depend on the results obtained.

Defect

Defect detection is understood as a set of measures aimed at identifying obvious defects, as well as establishing the possibility of further use of the weapon. In this case, the level of wear of the working surfaces, the presence of chips and cracks are taken into account. In addition, defect detection allows you to determine the following points:

- the presence of rust on the metal coating of the rifle;

- traces of mechanical damage;

- presence of damage to the wooden part;

- trunk curvature.

Problems with the barrel can arise due to improper use of the weapon or be the cause of a manufacturing defect. In any case, they must be allowed.

Pneumatic cylinder repair

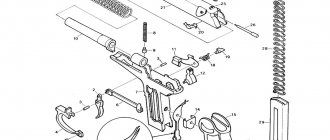

The importance of repairing the air cylinder is due to the fact that it acts as the main element of this type of weapon. The pneumatic cylinder consists of a sleeve, rod, piston and flanges.

Problems with each of these parts can disrupt the operation of the entire system. When performing repair work, the design features of these elements should be taken into account. It is very important to regularly ensure that the cylinder does not have mechanical defects on the outside, and that no dirt gets into its internal cavities.

Replacing cuffs

If you resolve the problem yourself, it is recommended to follow the following sequence of actions:

- Lubricate the piston fungus with special lubricant.

- Place the cuff in boiling water (for 30-40 s).

- Remove and dry the cuff.

- Place the cuff on the piston fungus using a screwing motion.

- Perform centering.

- Cool the cuffs.

If a positive result is achieved after the cuff has cooled, you can install it in the compressor.

Replacing the bypass

The optimal bypass in an airgun is equivalent to 3.2 mm. If this indicator is lower, then maximum pressure occurs earlier and lasts slightly longer.

As a result, the bullet accelerates very slowly and sluggishly. The wide bypass ensures maximum pressure later. This provides a short and sluggish bullet acceleration.

Replacing the bypass is due to the need to optimize the operation of the rifle. In this case, you can also resort to directly reducing the bypass volume or optimizing the cross-sectional diameter of the barrel gasket.

Replacing the mainspring

Replacing the mainspring is due to the fact that during operation this element can stretch. Using a weak spring leads to frequent misfires in shooting.

To carry out work to replace it, you must first remove the trigger mechanism. In some cases, the mainspring can be pressed with a nut to compensate for shrinkage. When removing the trigger, you must hold it firmly.

You can form a spring stop and a slot through which it is best to insert the latch, presented in the form of a pin, by using a vice. When installing a new spring, remember that it compresses very poorly. The pin can be pulled out after installing the guide. After this, it is necessary to assemble the trigger mechanism and check the correct operation of the system.

Gas spring installation

The gas spring is presented in the form of a cylinder with gas, which on one side has a movable rod. This element is pushed outward by compressed gas. This creates the force necessary to set the piston in motion.

Replacing a traditional coiled wire spring with a gas spring can significantly improve shooting accuracy. The gas spring is installed as follows:

- Removing the axle screw.

- Removing the safety button axle pin.

- Removing the stop and all its components.

- Installing a gas spring.

- Installing the centering washer.

- Installation of the stop.

- Screwing in the screw.

It is most advisable to install the gas spring into the piston with the rod inside out.

Barrel straightening

The barrel of a weapon determines the direction of flight of the bullet. The smoother it is, the projectile will fly much better and more accurately. During operation, certain problems may arise with this element of the rifle, but the most common malfunction is swelling of the barrel.

The danger of using a weapon with such a defect is that the barrel may burst when fired. Straightening may be necessary to correct this problem.

The straightening procedure begins from the defective location and subsequently moves to the center. Impacts on the bushing should not be too strong, but as effective as possible. You should be very careful when straightening the joints. Before removing the bushing, you must first lubricate it.

Setting up the trigger

High-quality adjustment of the trigger mechanism improves shooting accuracy and makes the flight of the bullet more predictable. The trigger mechanism is too tight due to the high spring stiffness.

The length of the free play of the trigger can be adjusted, as well as the maximum force of the sear and trigger. During adjustment work, certain problems may arise with the fit of the fuse. This element must first be removed.

Cleaning and lubrication of air guns

To clean air guns, use a cleaning rod with an attachment and a piece of woolen cloth. For this purpose, you can also resort to using special napkins.

Method #3: Weighted Bullets

To increase air, some gunsmiths recommend using weighted bullets. Such ammunition increases not only the flight range, but also the penetrating ability of the weapon. Bullets with a flat surface are suitable for the MP-512. Their weight is approximately 15% more than that of standard herringbones, so the penetration power will also be higher. But do not forget that the cost of such cartridges leaves much to be desired.

We also draw the attention of readers to the fact that such ammunition is not suitable for hunting, since it does not pierce the flesh of game, but only leaves bruises on it. Flat bullets are often used for zeroing optical sights, as they help determine the area of impact of a ballistic projectile with maximum accuracy. Although if the shooter’s goal is to shoot at cans or bottles, then there is not much difference in the tip of the ammunition.

Upgrade goals

First, let's try to find out why the average buyer of an air gun needs manipulations to increase power? The usual opinion is that it is better to crush bottles. Taking into account the fact that bottles from an increase in power from a certain moment begin to crumble equally, other thoughts arise.

Pneumatic lover in the eyes of the population

It’s good if these thoughts are simply related to the human desire to have something no worse than others, or to the edge of the constantly approaching zombie apocalypse. Otherwise, if we are talking about self-defense or intentional harm to a person’s health, we will not be able to help. In both cases, the costs will not be justified and will violate at least one of the laws of the Russian Federation. So, we consider pneumatics exclusively for the purposes of sports and recreational shooting, and the process of increasing power is nothing more than a hobby and sporting interest. In this fascinating process, it is worth remembering that any work that increases the power of a pistol beyond 7.5 J and a caliber over 4.5 mm falls under the article of the Code of Administrative Offenses.

Method number 4: high-quality lubricant

It's no secret that a ballistic projectile loses some of its energy while moving through the barrel channel. To minimize this type of loss, it is highly recommended to use a quality gun lubricant. The better the oil, the easier the bullet will overcome the frictional force inside the barrel. Therefore, the penetration capacity will also increase. To be fair, it is worth noting that pneumatics should be lubricated constantly.

So, for quality care, it is best to give preference to regular machine oil, which is poured into the engine. However, do not use the drill under any circumstances, because its composition can completely ruin the air barrel. As an alternative, a special silicone lubricant for pneumatics is suitable, which can be purchased in almost every gun store in a large assortment.

Method number 5: replacing fasteners

Have you ever felt the air escaping when firing an air rifle? Typically, a light breeze can be felt on the shooter's right cheek or neck. This is due to poor attachment of the breech to the body. Due to the bolt not being long enough, some of the air is not sent into the barrel channel in order to push the bullet out at a higher speed, but simply flies out through the holes in the body.

Therefore, to strengthen the air, it will be enough to unscrew the old breech bolts, and then use a drill to make a new hole (slightly deeper). Then you need to use a needle file to cut new grooves for the fasteners. The finished hole should be approximately 2 millimeters deeper than the old one. Carefully tighten the new bolt, using special rubber washers to seal it.

When you need expert help

It is better not to try to strengthen PCP pneumatics on your own: due to the design features, it is easy to deteriorate the performance. Parts may need to be replaced, and only experience will tell you which ones are suitable for a particular “air”. For example, changing a smooth barrel to a rifled one or shortening it can increase or decrease shooting performance.

It is not recommended to change the standard tank to an enlarged one yourself. The device may not be able to withstand increased loads.

Mainsprings for pneumatics

Mainsprings for air rifles can be divided into three types: twisted steel, high-pressure gas (HPG) and low-pressure gas (LPG).

Twisted steel spring

Numerous experiments by their manufacturers with various materials, notches, and “square” profiles ended in nothing. It is not surprising that all currently produced steel springs for pneumatics do without innovations and visually differ mainly in the cross-section of the wire, diameter and number of turns, depending on the characteristics of the compressor.

True, the material differs very greatly: which manufacturer uses which steel grades, quenching and tempering modes - this is a great mystery. It is difficult to determine the difference by eye, but already upon installation, pure Dian softness appears immediately. And vice versa, on the same Diana 350, in pursuit of power, they often installed cut springs from Gamo Hunter 1250. It’s not clear why spoil a truly accurate rifle with an even shot? Well, if you want “power”, buy a “Hunter” right away or even a cheap one in comparison with the German models “Hatsan 125”.

There are usually few standard sizes within one manufacturer. Gamo, for example, until recently, actually used, with the exception of its “children’s” models, only two. Another one was added with the advent of the so-called “black” series of powerful rifles, of which the “Black Bull” became a prominent representative.

Table of characteristics of steel mainsprings

| spring parameters | |||||||||

| manufacturer | model | type | F | length | thickness | turns | weight | an effort | rigidity |

| compression | |||||||||

| mm | mm | mm | G | kg | kg/cm | ||||

| IzhMekh | Izh-22 | 188 | 2.8 | 31 | |||||

| Izh-38 | 19.5 | 2.8 | 40 | ||||||

| MP-60 | 19.5 | 217 | 2.6 | 32.5 | |||||

| MP-512 | 19.5 | 220 | 2.8 | 34.5 | |||||

| MP-513 | 23 | 310 | 3.4 | ||||||

| Hatsan | 70 | 20.8 | 320 | 3.0 | 43 | ||||

| 125 | 21.5 | 350 | 3.2 | 44 | |||||

| 135 | 21.5 | 350 | 3.5 | 44 | |||||

| Gamo | Hunter 440 | 19.8 | 290 | 3.0 | 34 | 100 | 92* | ||

| Hunter 1250 | 22.5 | 400 | 3.5 | 40 | 180 | 150* | |||

| Norica | Krono/56 | 260 | 3.0 | ||||||

| Dragon/Quick | 18.4 | 325 | 3.0 | 43 | |||||

| Marvic Gold/Storm | 18.4 | 335 | 3.0 | ||||||

| Cometa | 300 | 18.2 | 290 | 2.9 | 37 | ||||

| BAM | B3-1 | 18.5 | 200 | 2.8 | 27 | ||||

| B4 | 19 | 245 | 2.9 | 33 | 95 | ||||

| Diana | 31/34 | FAC | 21 | 290 | 3.2 | 33 | |||

| 48/52/54 | F | ||||||||

| FAC | 21 | 300 | 3.2 | 35 | 110 | ||||

| Magnum | 21.3 | 300 | 3.3 | 32.5 | 122 | ||||

| 350 | F | 20.5 | 300 | 2.9 | 35 | ||||

| FAC | 20.7 | 350 | 3.2 | 40 | 102 | ||||

| Weihrauch | HW 30 | 18.5 | 205 | 2.8 | 29 | ||||

| HW 50 | |||||||||

| HW 80 | 3.8 | 32 | |||||||

| HW 95 | FAC | 18.8 | 270 | 3.0 | 34 | ||||

| HW 97 | 19.8 | 285 | 3.0 | 34 | 110 | ||||

| HW 98 | 20.5 | 285 | 3.2 | 34 | |||||

| Air Arms |

FAC

21

235

3.3

28

*For Gamo Hunter 440 and 1250 the maximum purely technical force characteristics are given - with full compression until the coils touch

The situation with the Chinese clones of Gamo and Diana is strange. Their owners often complain that the purchased springs turn out to be either shorter or longer than necessary, or do not fit into the piston. Counterfeit? Having original rifles, I have never encountered anything like this, although I purchased more scarce Dian spare parts not in a store, but via the Internet.

Among the advantages of steel springs, of course, are price, widespread availability (for major rifle models) and lack of maintenance. The average resource is about 3 thousand shots.

Disadvantages: a metallic ringing when fired, which is almost absent among the “Germans” with a central hook, and creaking when cocking (all can be cured by installing a plastic cup in the piston), plus the inability to walk for a long time with a cocked rifle - supposedly, the spring “sits down” quickly. I don’t know about the day, but nothing will happen to her in a couple of hours.

High pressure gas spring (HPG)

In essence, they are not particularly complex (see drawing). But they require very careful adjustment of everything. It is especially not recommended to skimp on seals - the rod can easily become skewed during installation.

Until recently, only models of domestic “handicraft” production were present on the market, which were based on pneumatic stops for “fifth” doors and car hoods. I put quotation marks not by chance: after the massive appearance of branded products on sale - “Vorteks”, “Nitropistons”, etc., it turned out that they were significantly inferior in quality and durability to the products of folk craftsmen.

In terms of the level of production culture, appearance of products and design, our people also rose to the occasion (photo above).

Recently, the “firms” have improved the quality, but the sediment remains... But on the Russian market there have appeared many domestic outright fakes of “foreign cars” and even some springs that IzhMekh never produced. In general, willy-nilly you should be vigilant and attentive.

Domestic scramjet engines are produced for all known air rifles with a lower piston hook. Alas, it is technically impossible to install gas springs on weapons with a central hook, the same “Diana” and “Wairauhi” (with the exception of a couple of models).

I can’t say anything definite about the use of nitrogen in a number of branded GPs (Nitropiston, IGT, etc.). After all, almost four-fifths of ordinary atmospheric air consists of nitrogen. It seems that all this is more a part not of technology, but of marketing and fashion, like the practice of inflating car tires with nitrogen, now almost forgotten due to absolute stupidity. But the use of dried air for “blowing” is quite justified, as it extends the service life of the product.

As a rule, the pressure in the gas springs is optimized by the manufacturer for each rifle model. Sometimes craftsmen, reluctantly, make GP at the insistent requests of lovers of “power”. The result is always the same - it’s good if the valve has the ability to bleed air. Never before has a fanatical race for additional meters per second yielded anything, since spring-piston pneumatics, especially high-end ones, are a fairly balanced mechanism, where changing only one parameter leads to very unexpected results (see “Types of spring-piston rifles”).

Why do they sell all these products with the loud names “Power”, “Magnum”, “Premium”, etc.? Let's take a specific example.

So, for each rifle model there is an optimal spring force and, accordingly, pressure in the GP. Responsible sellers warn buyers about the right choice. This distinguishes recognized masters - Gnome, Vado, Lex and others, who with great reluctance take on the production of GP for lovers of “power”, warning in correspondence against the wrong step.

In this regard, it is more difficult for online stores. For example, go to the Airgunstore website. There you will see a list of GPs in several sections. The first is entitled “We recommend! [100%]". It contains the correct springs for each model. Now look at the next two sections - “MegaPower VD [125%]” and “GigaPower VD [150%]”. These are the notorious “reinforced” GPs. As you can see, Airgunstore does not recommend them, but is forced to sell them, because otherwise it would lose thousands of buyers from the orderly ranks of beginning airgunners.

What is a gas spring and how does it work?

When a shot occurs, the gas pushes the rod in the opposite direction. GPs were the first to be installed in pneumatics in Britain. This happened in the early 80s at a plant owned by Theoben Engineering.

The spring itself was called the “Theoben Gas Ram”. A piston was used as a cylinder in the pneumatic mechanism. Today, such systems are used even in popular rifles.

The first great popularity came to these mechanisms after they began to be used to open car trunk doors. Even now, a number of large air rifle manufacturers make GP from parts produced for cars. This is due to the reliability of the technology and its versatility.

Speaking about the Hatsan company, they abandoned this technology. GPs are produced with pumping valves that fit the standard fittings of branded high pressure pumps. The gas spring itself consists of several parts:

- housing (sealed) with gas inside;

- centering and restraining rod rim;

- stuffing box reservoir (for sealing);

- plunger (rod).

As mentioned above, a number of GP models are produced based on a mechanism for opening the trunk of a car. But for this, manufacturers use only the main elements, that is, the rod, its sealing gland, plunger and reservoir shell. The centering support washer, rim and reservoir are produced separately.

Only typical high-pressure gas pumps fall under this description. Speaking about low-pressure gas pumps, it is not customary to use gas stops as blanks. Each part of the mechanism is produced according to individual drawings.

Main advantages of GP

Most owners of pneumatics with gas springs prefer this system due to the following advantages:

- a rifle with a GP has less recoil. There are also no various parasitic unpleasant vibrations that disturb the shooter. Thus, there is a much greater chance of hitting the target;

- when compared with a coil spring, the GP affects the reduction in trigger force;

- the platoon is uniform regardless of the entire segment of movement. At the end, the shooter puts in less effort. There are also no crunching or squeaking sounds characteristic of coiled springs;

- speaking of power, the characteristics declared by the manufacturer will in practice be as close to the truth as possible, which is not always possible to say about systems with coil springs.

The GP lasts 6-8 times longer. But for this, the shooter must regularly care for the pneumatic and clean it every time after use in an aggressive environment.

When the pneumatics are charged, the load on the remaining parts, which is created by the spring, is much less, which also has a positive effect on their service life.

Regarding mechanisms with coil springs, they try not to keep them in the cocked position. This rule does not apply to systems with GPU.

Disadvantages of GP

Studying information about gas springs, one can conclude that they have no disadvantages, but this is not the case. One of the disadvantages is temperature dependence. This is because the force on the rod depends on the weather. Like other pneumatics, it is not advisable to use rifles with GP in severe frost.

It is harmful because the metal loses its strength, the lubricant thickens, and polyurethane and rubber seals harden, which can lead to damage. Rifles with GP are not recommended for purchase by shooters who do not like to care for their weapons.

A GP is a mechanically complex product for an amateur, therefore, if a person does not clean it in a timely manner or installs any parts incorrectly, this will affect the service life and shooting characteristics. Gas springs are also more sensitive to mechanical abrasive contaminants, which will also reduce the service life of the spring.

Common spring failures

Almost all gas spring failures are associated with loss of pressure. This happens over time, regardless of the model of pneumatics. But some gun owners try to increase the system's power by changing the pressure to match the levels of more expensive rifles. Technically, the shooter can do this, but in reality, it will lead to negative consequences.

After some time, the rifle will definitely fail due to the breakage of the spring itself or other parts damaged due to excessive pressure for which they are not designed. The pressure must clearly correspond to the model, since the spring force is always selected based on the volume and diameter of the cylinder.

In addition, it has an optimal value, which is necessary for reliable operation of the mechanism without overload. If the pressure does not match the model, this will lead to breakdowns that are difficult to predict, and the pneumatic itself will not receive an increase in power.

To increase the speed of the bullet at takeoff, experienced shooters advise replacing the GP and a number of parts on which it puts stress during shooting. But without experience in such work, it is better not to start and seek help from professionals who will recommend a trusted manufacturer and suitable parts.

Replacing a spring in an air rifle - step-by-step instructions

Regardless of the model of air rifle, replacing a gas spring almost always follows the same principle. In this case, replacing the GP will be considered using the example of the Hatsan rifle.

Step 1

Disassembly. Before disassembling, the owner of the pneumatic gun must have a clamp. You will need it because the trigger mechanism of most air rifles is secured with pins. And the pins themselves are preloaded with a mainspring.

Therefore, you need to tighten the back, which cannot be done manually. First you need to unscrew the 4 side screws and another screw, which is located behind the trigger. Now the stock can be separated from the mechanism. Next, you should knock out the cotter pin of the safety lever and disconnect it. Now the screw securing the rear support of the GP is unscrewed.

The picture below shows how the spring was deformed after about 3000 shots.

Step 2

Installing the spring in the piston and measuring the precompression of the GP (the preload should be at least 3 millimeters).

Step 3

Disconnecting the spring guide from the stop (rear) and leveling the plane using sandpaper.

Step 4

Drill a hole.

The recess should be 2-3 millimeters and the diameter should be 10 mm. A centering washer is inserted into it. It usually comes complete with a spring. To make it more convenient during assembly, the washer is fixed using auto-sealant (any synthetic-based glue can be used).

Step 5

Installation of the stop. To make it more convenient to install the stop, during compression of the GP, it is allowed to cut off its rear part, as shown in the figure.

Step 6

Completion.

The rifle should be securely mounted in the clamp and the stop should be pressed into its original position. Next you need to insert the cotter pin and screw in the screw. It doesn’t matter what the design of the clamp will be.

The main thing here is to securely fix the rifle, since when the GP is compressed by the clamp screw, there is a risk that the stop will come off, and a sharp compression of the rod will cause damage to the spring. The rifle is assembled in the reverse order.

Precompression

Precompression is the distance by which it is necessary to compress the gas spring at the time of its installation, overcoming the resistance of the rod. For example, a master disassembled an air rifle and pulled out the spring. If it is not reinstalled, the rifle can be assembled by hand without any effort. The backdrop fits without resistance, and all screws and pins also fit without problems.