SU-57 (T48). Self-propelled gun from Lend-Lease

Already in November 1941, the Soviet Union joined the Lend-Lease program, under which the United States supplied its allies with military equipment, ammunition, strategic materials for the military industry, medicines, food and other list of military goods. As part of the implementation of this program, the USSR also received armored vehicles, initially from Great Britain, then from the United States, for example, until 1945, Soviet troops received 3,664 Sherman tanks of various modifications. But among the armored vehicles supplied to the Red Army there were much rarer vehicles; such specific examples rightly include the T48 anti-tank self-propelled gun based on the M3 half-track armored personnel carrier.

Initially, this self-propelled gun was created in the USA by order of the British military, and was immediately intended for delivery under the Lend-Lease program. From December 1942 to May 1943, 962 T48 anti-tank self-propelled guns left the Diamond T Motor Car Company workshops. By this point, the British military had lost interest in the installation, and the USSR agreed to supply this vehicle, becoming the largest operator of the T48 tank destroyer, which received the new index SU-57. In total, the Soviet Union received 650 self-propelled guns of this type; the vehicles were actively used by Soviet troops both as part of individual self-propelled artillery brigades, as well as motorcycle battalions and armored reconnaissance companies.

T48 from idea to implementation

Already at the very beginning of World War II, a mixed British-American commission on armaments began work in the United States. The task of the commission was to draw up a program for the development, design and production of various samples and types of military equipment. One of these models was the 57-mm self-propelled gun based on the chassis of the M3 half-track armored personnel carrier, common in the American army. Based on the M2 and M3 armored personnel carriers, American designers designed a large number of self-propelled anti-aircraft guns, self-propelled guns with various artillery weapons, as well as self-propelled mortars. Some of them were produced by American industry in fairly large quantities; the vehicle, based on half-track armored personnel carriers, was adopted by the US Army and the armies of the allied countries in the anti-Hitler coalition.

57 mm QF 6-pounder anti-tank gun

The British military liked the possibility of using an armored personnel carrier chassis as a base for different types of weapons. They expressed interest in creating a tank destroyer based on the M3, which would be armed with the British QF 6-pounder anti-tank gun. This British 57-mm anti-tank gun was actively used during the Second World War, both on a wheeled carriage and as the main armament of armored vehicles and tanks of the British Army. The gun's debut took place in North Africa during the fighting in April 1942. The gun was also appreciated by the Americans, who adopted the British gun for service, slightly modernizing the 57-mm gun; in the US Army, the artillery system was designated M1.

From a distance of 900 meters, the armor-piercing projectile of this gun penetrated up to 73 mm of armored steel located at an angle of 60 degrees. For 1942, these were acceptable figures, but with the advent of new German tanks and increased frontal armor of existing combat vehicles, the effectiveness of the 57-mm British anti-tank gun only decreased. The choice of this particular weapon for installation on the M3 armored personnel carrier was due to the fact that the British wanted to get equipment that would be comparable in armament to their own, for example, the Valentine and Churchill tanks. It was the gun that was the main and only armament of an anti-tank self-propelled gun on the chassis of a half-track armored personnel carrier, but already in combat units the vehicles could also be equipped with machine guns for self-defense.

The first copy of the new anti-tank self-propelled gun arrived for a test program at the Aberdeen Proving Ground in April 1942. Armed with an adapted version of the British 6-pounder (57 mm) gun, the armored vehicle was designated T48 - 57 mm Gun Motor Carriage. Already in October 1942, the American order for a new self-propelled gun was canceled, and the United States turned its attention to new 75 mm artillery systems and tracked self-propelled guns. At the same time, the production of the new self-propelled guns according to the British order continued, mass production began in December 1942. The cars were assembled by Diamond T Motor Company. However, by 1943, the British also lost interest in the new self-propelled gun, who realized that it was ineffective against the latest German medium and heavy tanks, and in addition, the UK developed a new 17-pounder gun (76.2 mm) QF 17 pounder, which became the best anti-tank weapon of the Allies, having received an armor-piercing sabot projectile with a detachable pallet.

M3 half-track armored personnel carrier

As a result, the newly developed self-propelled gun turned out to be unnecessary for the main customers, the British received only 30 T48 vehicles, and the Americans limited themselves to purchasing one anti-tank self-propelled gun; they simply converted another 282 ready-made self-propelled guns back into M3A1 armored personnel carriers. But the remaining 650 units found refuge in the USSR, the Soviet military showed interest in this vehicle and ordered it as part of Lend-Lease deliveries, 241 vehicles arrived in the Soviet Union in 1943, another 409 in 1944. Moreover, only in the USSR this anti-tank self-propelled gun was used for its intended purpose until the end of hostilities.

Design features of the T48 self-propelled gun

The layout and appearance of the American T48 self-propelled gun were traditional for vehicles based on such a base.

Similar combat vehicles were also in the arsenal of the German army. The Germans also equipped their Sd Kfz 251 half-track armored personnel carriers, known as the "Hanomag", with artillery systems of various calibers: 37 mm anti-tank guns, short-barreled 75 mm guns, and by the end of the war, 75 mm long-barreled guns. Perhaps, having become acquainted with similar combat vehicles at the front, the Soviet military decided to get their own analogue, which led to the supply of 650 anti-tank self-propelled guns from the United States. In the Soviet Union, the vehicle received a new designation SU-57. It is worth noting that the USSR did not produce its own armored personnel carriers at all, so such equipment in general was of great interest to the Red Army. The layout of the anti-tank self-propelled gun, built on the chassis of a half-track armored personnel carrier, could be called classic. The body of the self-propelled gun was distinguished by its simplicity of shape and lines; the box-like structure with vertically located sides and rear walls was assembled using armor plates mounted on a frame made of corners. In the manufacture of the T48 anti-tank self-propelled gun, components from commercial trucks were widely used, mainly in the controls and transmission. In the front part of the body was the engine, hidden under an armored hood, behind which was the driver's cabin. At the same time, American designers borrowed the hood and cabin from the Scout Car M3A1 wheeled reconnaissance armored personnel carrier, which was supplied to the USSR and became the most popular armored personnel carrier of the Red Army during the Second World War.

The armored hull of the self-propelled gun was open on top and featured bulletproof armor; the thickness of the armor on the front hull sheets reached 13 mm; in general, armored steel sheets up to 6.5 mm thick were used in the design of the combat vehicle. A 57-mm American M1 anti-tank gun was installed in the open body, which received a semi-automatic vertical wedge breech. The gun was mounted on a T-5 machine, which was placed in the front of the hull immediately behind the control compartment. The gun was installed in a shelter covered from precipitation from above with a box-shaped shield, which protected the crew from bullets and shell fragments; the ammunition carried was 99 shells. The gun had excellent horizontal pointing angles - 56 degrees, vertical gun pointing angles ranged from -5 to +16 degrees. To fire from a 57-mm donut, three types of unitary shots were used: two armor-piercing (blunt-headed tracer and sharp-headed tracer) projectiles and a fragmentation grenade. At a distance of 500 meters, the gun allowed the crew to penetrate up to 81 mm of armor (at an impact angle of 60 degrees).

The real heart of the self-propelled unit can be called the White 160AX carburetor 6-cylinder engine, which developed a power of 147 hp; some vehicles were equipped with a slightly weaker engine - the International RED-450-B, which developed a power of 141 hp. Weak firepower and lack of armor were compensated by good mobility and speed. With a combat weight of about 8 tons, such an engine provided the vehicle with a specific power of 17.1 hp. per ton. When driving on a highway, the T48 self-propelled gun accelerated to a speed of 72 km/h; the self-propelled gun's range was estimated at 320 km.

The front wheels of the self-propelled gun were steerable. For each side, the caterpillar propulsion system of the Lend-Lease self-propelled gun consisted of four dual rubber-coated road wheels; the rollers were combined in pairs into two balancing bogies. On some self-propelled guns, a single-drum winch was located in the front part of the hull. At the same time, on some combat vehicles the winch was replaced with a buffer drum with a diameter of 310 mm. With such a device, the cross-country ability of the self-propelled guns increased; the presence of the drum facilitated the process of overcoming scarps, ditches and trenches up to 1.8 meters wide.

Features of the combat use of the SU-57

The half-track chassis and low weight provided the anti-tank self-propelled gun with good maneuverability even on soft soils and snow.

At the same time, the self-propelled gun predictably lost control. When turning the front wheels, the combat vehicle was not always ready to get to the required direction of movement. To be fair, it is worth noting that similar shortcomings were inherent in German half-track armored personnel carriers. An open combat clash with enemy tanks left the Lend-Lease T48 self-propelled guns with virtually no chance of success. The use of these self-propelled guns from ambushes and from pre-fortified positions was considered effective. Moreover, the new combat vehicle was originally created for approximately such actions on the battlefield. By 1943, the 57 mm gun was experiencing problems in the fight against the new German Tiger and Panther tanks. At the same time, it penetrated the frontal armor of medium German tanks Pz.IV modifications G and H; it was possible to hit the Tiger or even the Ferdinand self-propelled gun on the sides of the hull. From a distance of 200 meters, one could try to hit a “Tiger” or “Panther” directly in the forehead, but with such actions without a well-prepared and camouflaged position, it was a one-way ticket. It can be noted that with certain restrictions, often quite significant, the self-propelled gun still coped with its duties, actively participating in battles on the Eastern Front.

If armor penetration made it possible to hit enemy equipment, albeit with a large number of restrictions, then the impact of the 57-mm gun on infantry and field fortifications was very weak. Such a weapon was not suitable for the destruction of prepared defense lines and fortifications. The power of 57-mm high-explosive fragmentation ammunition was clearly insufficient. The high-explosive fragmentation shot of such a gun weighed only 3.3 kg, and the mass of the explosive was only 45 grams.

Lend-Lease anti-tank self-propelled guns, designated SU-57, were widely used as part of three separate self-propelled artillery brigades, each of which had 60-65 combat vehicles of this type. The SU-57 was the standard weapon for the 16th, 19th and 22nd (later to become the 70th Guards) self-propelled artillery brigades, which fought as part of the 3rd, 1st and 4th Guards Tank Armies, respectively. . In the Red Army, American self-propelled guns were also used by battery and division; in this case, they were included in motorcycle battalions and separate reconnaissance companies in armored vehicles. In such units, T48 self-propelled guns were used especially effectively, acting in their direct role - a half-track armored personnel carrier with a reinforced weapon system.

Experienced self-propelled guns SU-76d and SU-57b (GAZ-74). USSR.1943-44.

Home » Real story » Little-known and unrealized projects of tanks and other armored vehicles » Experienced self-propelled guns SU-76d and SU-57b (GAZ-74). USSR.1943-44.

Little-known and unrealized projects of tanks and other armored vehiclesUnrealized projects of tanks and other armored vehicles of the USSR

Serg 30.10.2012 2106 189

0

in Favoritesin Favoritesfrom Favorites 0

In the summer of 1943, GAZ designers, led by N. Astrov , together with the NATI Design Bureau, prepared two projects for armored self-propelled guns, which appeared in correspondence with the People's Commissariat of the Tank Industry as “turretless GAZ-74 fighter tanks.”

Between themselves, these two self-propelled guns differed in the location of the fighting compartment. In the first vehicle - GAZ-74a - the fighting compartment was to be located in the rear of the vehicle, similar to the GAZ-71 and the already adopted SU-12 (better known as the SU-76), which improved the distribution of the weight of the self-propelled guns on the road wheels, increased maneuverability, however, this had to be paid for with a relatively larger silhouette and weight of the car.

The second option ( GAZ-74b ) was very similar to the SU-IT-76, proposed by NII-13 in 1942. The vehicle had a low silhouette, good armor (45 mm in the frontal part) with inclined armor plates, and was armed with a 76-mm S-1 cannon (the same cannon was installed on the production SU-76I). The new fighter was supposed to receive a GMC-71 diesel engine (supplied under Lend-Lease), the organization of production of which in the USSR was planned at the YaMZ plant.

The self-propelled gun was created on the basis of the T-70 light tank and is a closed-type self-propelled gun.

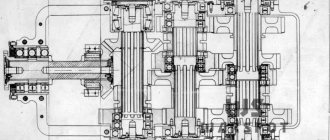

Structurally, the GAZ-74b self-propelled unit was a “hybrid” of components and assemblies of the T-70 tank, an American engine and original developments. In general, the Soviet project was close to the later German Hetzer, inferior to it in terms of weapon power and security. The chassis of the self-propelled guns, applied to each side, consisted of five road wheels from the T-70 tank with an individual torsion bar suspension and four support rollers. The drive wheels were located at the rear, the guides at the front. The caterpillar is small-linked with cast tracks. The body was made from sheets of rolled armor steel with a thickness of 10 to 35 mm, which were connected to each other by welding. In the front part of the hull there was a combined control compartment and combat compartment, which housed a crew of four: driver, commander, gunner and loader. An embrasure for a 76 mm cannon mounted on the frame is cut into the front frontal plate of the armored hull.

The main armament, consisting of one 76.2 mm S-1 cannon, was installed in the frontal plate of the superstructure. Maximum vertical guidance angles ranged from -5° to +14°. Along the horizon, the gun could be aimed within 13.5° in both directions. The gun installation, including the mantlet, was largely similar to the SU-76I. Rational angles of inclination, in order to ensure an acceptable internal volume for the crew to work, had armor plates only on the front part of the hull. In the aft part there was an engine-transmission compartment where the American GMC-71 engine was installed, which began to be produced at the Yaroslavl plant under the designation YaAZ-206. There are three hatches with covers on the roof of the hull; A turret with six observation devices is installed on the roof of the commander's hatch. Air cleaner of oil-inertia type.

The GAZ-74b was built, passed factory tests, was generally approved by the military, and was even admitted to state tests SU-76-I or SU-74 Which she successfully passed.

But in 1943, arming such vehicles with a 76-mm cannon with a 41-caliber barrel was no longer considered sufficient to combat German heavy tanks. Therefore, launching the GAZ-74b self-propelled guns with the 76-mm S-1 cannon into production was considered an unpromising endeavor.

In the summer of the same 1943, Gorky Artillery Plant No. 92, at the instigation of the head of the TsAKB V. Grabin with the support of D. Ustinov , resumed production of 57-mm ZIS-2 anti-tank guns, as well as their ZIS-4 tank variants, which had been discontinued at the end of 1941. These guns had very good armor penetration performance. This circumstance again spurred designers to create anti-tank self-propelled guns.

GAZ stubbornly continued to work on its tank destroyer. Moreover, at the same time, both the creation of a new GAZ-74b vehicle with a 57-mm long-barreled S-1-57 cannon, and the improvement of a vehicle equipped with a 76-mm cannon (for it, the TsAKB was waiting for a 76-mm high-power S-54 cannon with a long barrel about 60 calibers).

The version with a 57 mm cannon was called SU-57B.

The self-propelled artillery mount was developed on the basis of the SU-76D.

In the front frontal plate of the hull in the embrasure there is a 57-mm ZIS-4 tank gun with manual guidance mechanisms.

The armor-piercing projectile provided armor penetration of up to 90 mm at a range of 1000 m and up to 100 mm at a distance of 500 m at a zero angle of contact between the projectile and the armor.

Despite the fact that the SU-57B passed almost all the proposed tests, it was not accepted for service. Among the reasons for not adopting it into service were the high cost of self-propelled guns and the need to produce a new diesel engine that had not been mastered by the domestic industry (to depend on foreign supplies in a war would be the height of imprudence).

!?.S.S: An extremely controversial statement, considering that the supplied GMC-71s were installed on the YaMZ-12 artillery tractor. In addition, a number of sources say that the SU-57B was equipped with a ZIS-16 carburetor engine with a power of 100 hp. The letter “B” in the name of the self-propelled gun itself speaks about this.

Work to improve the GAZ-74 in 1944 led to the creation of an improved self-propelled gun, designated GAZ-76D , or SU-76D (“diesel”). True, they never received the S-54 cannon for it, but the armor in the frontal part was brought to a thickness of 60 mm and in this form, with the 76-mm S-1 cannon, was allowed to undergo state tests under the symbol SU-80 . But it was not accepted for service again due to the lack of obvious advantages(?) over the serial SU-76M and due to the presence of imported diesel, the production of which was not mastered either in Yaroslavl, or in Mias, or in the area that was subjected to repeated bombing in 1943 , Gorky Automobile Plant.

It is interesting to note that at the beginning of 1945, the Hetzer self-propelled gun captured in Hungary was tested together with the SU-57b, and the conclusion stated:

“Thus, the German experience of tank building shows that the use of small-sized turretless tanks in modern warfare has fully justified itself... A comparison of the German turretless tank of the Osa type with the SU-57b vehicle of the Gorky plant, which have a similar mass, shows some of the advantages of the domestic vehicle associated with the use diesel engine... The installation of a defensive machine gun on the roof of a German tank with the ability to fire from behind the armor should be considered very successful... The disadvantages of the SU-57b include the lack of a powerful fragmentation or high-explosive fragmentation projectile in its ammunition..."

Afterword.

These little-known, but very promising Soviet self-propelled guns seem to have fallen victim to an evil fate. Problems with engines, inflated expectations and not entirely correct assessments of the enemy’s forces were the reason why they never joined the army. Although, having appeared earlier than Hetzer, they could well have taken their rightful place in Soviet armored vehicles. Especially the SU-57B with its powerful 57 mm anti-tank gun. The SU-57B and SU-76D could reasonably replace the T-70 light tank with its 45-mm cannon (let me remind you that during the Battle of Kursk, the share of the T-70 light tank was about a third of all Soviet tanks taking part in the battle). And the SU-76M was clearly inferior to GAZ self-propelled guns, and was larger and higher in terms of protection.

The fact that Hetzer was heavier than the SU-57B and Su-76D by 6 and 5 tons, respectively, somehow fell out of the attention of NKBTV specialists. In addition, the mentioned “high cost” of the new self-propelled guns seems to me somewhat far-fetched.

| C U-74 | SU-57B | SU-76D | Hetzer | |

| Combat weight, t | 11,6 | 9,56 | 11,6 | 16,1 |

| Length, mm | 5850 | 7440 | 5850 | 6380 |

| Width, mm | 2430 | 2430 | 2430 | 2630 |

| Height, mm | 1960 | 1960 | 1960 | 2170 |

| Wed. beat pressure on the ground, kg/cm2 | 0,68 | 0,55 | 0,68 | |

| Ground clearance, mm | 340 | 330 | 340 | |

| Engine type diesel | GMC-71 | ZIS-16 | GMC-71 | Praga AC/2 |

| Maximum power, hp | 110 | 100 | 110 | 160 |

| Fuel capacity, l | 270 | 300 | 270 | 320 |

| Specific power, hp/t | 9,5 | 10,5 | 9,5 | |

| Maximum speed, km/h | 36 | 40 | 36 | 42 |

| Cruising range, km | 250 | 150 | 200 | 177 |

| Reservation, mm | ||||

| – front/side/stern of the hull | 35/15/15 | 25/15/15 | 60/15/15 | 60/20/10 |

| – front of the cabin | 35 | 25 | 60 | 60 |

| – roof / bottom | 10/6 | 10/6 | 10/6 | 10/8 |

| Crew, people | 4 | 4 | 4 | 4 |

| Radio station... | 12-RT | 12-RT | 12-RT | FuG5 |

| Intercom | TPU-ZF | TPU-ZF | TPU-ZF | FuG Spr f |

| Artillery weapons: | 76.2 mm C-1 | 57 mm ZIS-4 | 76.2 mm C-1 | 75 mm Pak 39/L 48 |

| Initial projectile speed, m/s: | ||||

| – high-explosive fragmentation | 662 | 662 | ||

| – armor-piercing | 680 | 990 | 680 | |

| - sub-caliber | 965 | 965 | ||

| Max, firing range, m. | 12100 | 8400 | 12100 | |

| Direct shot range, m | 950 | 1120 | 950 | |

| Rate of fire, rds/min: | ||||

| – maximum | 20 | 20 | 20 | |

| - combat... | 15 | 15 | 15 | |

| Ammunition, shots | 71 | 72 | 71 | 41 |

Alternative option.

If the problem with the GMC-71 engine was solved, it was put into production, or all engines received under Lend-Lease were sent to equip self-propelled guns instead of artillery tractors, the launch of self-propelled guns into production could well have taken place. In addition, we should not exclude the possibility of installing forced domestic gasoline engines or GAZ-203 twin engines on the self-propelled guns, as on the Su-76.

Use of a diesel engine with a power of 150-250 hp. at 1700-1800 rpm, would allow increasing the thickness of the armor protection of self-propelled guns

The reinforced version of the self-propelled gun could have 60 mm frontal armor and increased to 25 mm side armor.

If this vehicle, relatively speaking the SU-76D/B and SU-57B/D, had begun to enter service with the troops by the end of 1943 in place of the T-70 and SU-76, then our enemy would have had a very hard time.

In addition, installing a 76-mm ZiS-3 gun in place of the S-1 would make it possible to create a completely powerful and universal self-propelled gun on the same base.

The SU-76D/B could be an excellent infantry support vehicle. And the SU-57B/D is a relatively cheap and serious anti-tank weapon.

To be continued.

Sergey Sych.

Reconstruction: Sergey Sych.

Sources

: Solyankin A.G., Pavlov M.V., Pavlov I.V., Zheltov I.T. 2.1.1 Light self-propelled artillery units/Domestic armored vehicles 1941-1945. Volume 2. - “Exprint”, 2005

A.V. Karpenko Part 1. Light self-propelled artillery installations / Domestic self-propelled artillery and anti-aircraft installations. — St. Petersburg: “Bastion”, 2000

American-made SU-76

Unlike numerous tanks, self-propelled guns were supplied to the USSR in limited quantities under the Lend-Lease program.

The only exception is the Gun Motor Carriage T 48, or SU-57, created on the chassis of the M 3 half-track armored personnel carriers. They were originally developed in the USA by order of the British, but they practically did not use them. The T48 was received in a completely different way in the USSR: a total of 650 vehicles of this type were delivered here, they were very actively used and showed themselves to be an effective anti-tank weapon. As for self-propelled guns on a tank chassis, the only Western model that was adopted by the Red Army was the American tank destroyer Gun Motor Carriage M10

, now widely known under the British name Wolverine.

On the same chassis as M4A2

The story of how the Main Armored Directorate of the Red Army (GBTU KA) first became acquainted with the GMC M10 is a bit comical. The first information about this vehicle was not an intelligence report, but a letter devoted to the operation of the M4A2 medium tanks. On March 15, 1943, the deputy head of the engineering department of the People's Commissariat of Foreign Trade, Colonel Khryaev, sent a letter to GBTU. It indicated that the American operational center had sent out a circular about the specifics of using the main clutch locking buttons. An error crept into the instruction manual for the M4A2 tank, which led to accidents. It was in this letter that the “M-10 tank fighter” was first mentioned.

GMC M10 at the NIIBT Test Site, September 1943. Fastenings for additional armor are clearly visible, which, however, were never hung.

By that time, the American military made no secret of their existence as GMC M10s. The fact that such vehicles are in service with the American army was reported by Major Baraev, assistant military attaché in the United States, back on March 1, 1943. But Khryaev’s later report arrived at GBTU faster. According to Baraev, the vehicle was designed with versatility in mind, that is, with the ability to perform tasks typical of tanks. For this purpose, her armor had special mounts on which additional protection was hung. This is true, although in reality additional armor was never installed on production vehicles.

The Americans also shared information about the combat use of the GMC M10 with the assistant military attache. According to the report, the first 10 vehicles were sent to North Africa at the end of 1942. The battles with their participation showed that the self-propelled gun was successful. It was assumed that it would be adopted not only by tank destroyer units, but also by all armored units of the US Army.

She's in front

In fact, the first real combat debut of the GMC M10 took place a little later. On March 23, 1943, during the battle of El Guettar in Tunisia, these vehicles played an important role, at the same time showing clear superiority over the GMC M3 half-track tank destroyers. The Americans were not lying when they said that the car turned out to be successful. This is eloquently evidenced by the fact that the GMC M10 has become the most popular American self-propelled gun.

Rear view of the car

These machines did not arouse much interest among the management of GBTU KA. True, Baraev’s report indicated that the firepower of the 76-mm cannon mounted on the GMC M10 is approximately equal to the power of the German 88-mm anti-aircraft gun. This point was even emphasized in the report. Which is not surprising: just in the spring of 1943, tests were carried out on the captured German tank Pz.Kpfw.Tiger Ausf.E, which showed disappointing results. Soviet tank artillery turned out to be almost powerless against this tank. Thus, means of combating the “Tiger” were urgently needed.

Another argument in favor of the American self-propelled gun was that it was built on the same base as the already familiar Medium Tank M4A2, which began to arrive in the USSR from the end of 1942.

This photo shows the installation of the awning, which was attached in the stowed position

The issue of supplying self-propelled guns of this type was returned to in early June 1943. According to a memorandum from the People's Commissar of Foreign Trade A.I. Mikoyan to Stalin, the departments had differing opinions on the purchase of self-propelled artillery. Yakovlev, who headed the Main Artillery Directorate (GAU), considered the purchase of the GMC T48 a priority, and wanted to purchase the remaining vehicles only for review. Fedorenko, who headed the GBTU, offered to purchase a wide range of self-propelled artillery, but the GMC M10 was not on this list. Voronov, commander of the artillery of the USSR Armed Forces, had a separate opinion. It was he who proposed to purchase 50 “three-inch guns on the chassis of the M-10 medium tank.” In the end, the solution turned out to be a compromise. It was decided to take two such machines for testing, and if the tests were successful, it was planned to order a batch of 50 units.

No worse than domestic analogues

They did not delay the delivery of self-propelled guns for long. On August 3, 1943, Khryaev reported that a convoy had arrived in the Persian Gulf, delivering two “M-10 fighter tanks.” Soon the cars ended up in Baku. There their paths diverged. One vehicle was sent to the training ground of the Research Institute of Armored Vehicles (NIIBT Polygon) in Kubinka, and the second was planned to be sent to the Gorokhovetsky Artillery Scientific Testing Experimental Range (ANIOP). This was logical: the chassis was tested at the NIIBT Test Site, and the artillery gear was tested at the ANIOP.

True, there was a hitch with the testing of the gun, since the necessary American ammunition of 76 mm caliber was not supplied to the USSR. As a result, firing tests were carried out much later than running ones.

The stripes that are visible on the sides of the hull are the remains of the “packaging” that was placed on the car during transportation by sea

The American self-propelled gun arrived in Kubinka in September 1943. As in the case of ANIOP, the vehicle arrived here without ammunition. Also at the NIIBT Test Site it was stated that there were no additional armor plates. However, as we remember, they were not among the American troops.

To begin with, the test site specialists studied the machine in detail, compiling a brief technical description. At the same time, maintenance of the self-propelled gun was carried out. This turned out to be easy to do, since the vehicle largely replicated the M4A2 medium tank, which the testers were already familiar with. American motor oil was replaced with domestic one.

Combat compartment. Testers mistakenly believed that the commander was sitting to the left of the gun, but in fact his place was to the right

The content of the technical description was mainly reduced to the general structure of the vehicle, with minimal attention being paid to the M10 chassis due to its almost complete identity with the M4A2. The control compartment and the fighting compartment were briefly described. According to the NIIBT Polygon testers, the vehicle commander was located to the left of the gun, but in fact this was the gunner’s position. As with American tanks, the commander's position here was on the right side of the gun.

They did not engage in a detailed study of the fighting compartment in Kubinka, focusing on other issues. In general, the conclusions regarding the convenience of the crew’s work were positive. However, the turret open at the top did not cause positive emotions, because there were many reviews from the front about the defeat of the crews of the SU-76M, which was open at the top. Also, NIIBT Polygon specialists studied the visibility of the M10, which was found to be quite satisfactory.

Installation of the Browning M2HB anti-aircraft machine gun

The main part of the program, however, was not the study of the vehicle’s design, but its sea trials. According to the plan, the self-propelled unit was supposed to travel 1000 kilometers, of which 300 along the highway, 500 along the country road and 200 over rough terrain. In addition to determining the maximum and average speed, as well as the level of fuel consumption, it was necessary to determine the M10's cross-country ability over various types of terrain.

Diagram of visibility from a self-propelled gun indicating the size of the “dead zones”

Sea trials took place from September 24 to October 14, 1943. In practice, they roughly coincided with the program: out of 1000 kilometers, 302 of the car traveled along the Moscow-Minsk highway, the rest along country roads and slopes. During highway testing, maximum speed measurements were simultaneously taken. Based on the results of four attempts, it was 50 km/h, which was even slightly higher than the official data. The average pure speed was 37.5 km/h, and the technical speed was 30 km/h, while the car was moving mainly in 5th gear. Fuel consumption was 158 liters per 100 kilometers. For comparison, the M4A2 tank had a consumption of 162 liters per 100 kilometers. It was indicated that the driver’s seat was conveniently located and the car was easy to drive.

Without spurs, the maximum angle of climb that was overcome was 22 degrees

I walked 660 kilometers along the M10 country road, while moving mainly in 4th gear. It took the self-propelled gun 32 hours to cover this distance, 8 of which were downtime due to technical reasons. They were associated with the failure of the road wheels, of which 6 were lost during the tests. In five cases, the roller bearings collapsed, and in the sixth skating rink, the rubber band collapsed. The bearings, in turn, collapsed due to the failure of the seals, which caused grease to leak out and dirt to get into the bearings.

Despite the breakdowns, in general the self-propelled unit performed well on a dirty country road. The average pure speed was 20.5 km/h, and the technical speed was 16.5 km/h. Fuel consumption was 259 liters per 100 kilometers, which was slightly more than that of the M4A2 (246 liters per 100 kilometers).

In addition, maneuverability tests were carried out. As the testers indicated in their report, in general the self-propelled gun showed good agility. However, the M10 performed sharp turns, 180-degree turns and low-speed turns poorly. However, this was not a problem with the M10 itself, but a characteristic feature of tracked vehicles with a double differential as a turning mechanism.

The final chord was testing to overcome ascents and descents. It was at this stage that the main problems began. The fact is that the M10 arrived with T51 rubber-metal tracks. They, like the T41s that preceded them, which were installed on the Medium Tank M3, had complaints in terms of cross-country ability. The smooth working surfaces of the tracks did not contribute to traction at all. This turned out to be especially critical from the point of view of overcoming climbs. The steepest slope that was overcome was 22 degrees. Further, the caterpillar tracks simply did not have enough traction with the ground.

Climbing with spurs installed

American engineers knew about this problem, so special spurs were included with the self-propelled guns. 11 spurs were installed on each belt. It helped, but only partially. The self-propelled gun alternately overcame climbs at an angle of 24 and 28 degrees. When the testers tried to climb a slope at an angle of 31 degrees, the car began to helplessly dig the ground with its spurs: it again lacked traction. During tests on a slope, the maximum roll angle was 22 degrees, after which the vehicle began to slide. This test was carried out on tracks without spurs.

The overall verdict based on the results of sea trials was quite positive:

"1. The American M-10 self-propelled gun has good driving characteristics. In terms of speed, it is not inferior to domestic self-propelled units SU-122, SU-85 and is equivalent to the American M4A2 tank.

2. Overcoming obstacles with the M-10 self-propelled unit on rubber-metal tracks without spurs - ascent 22o, descent 25o, roll 22o - insufficient, with the use of spurs the ascent overcome is 28o, descent 28o.

3. The large dimensions of the turret (the clear diameter of the turret ring is 1740 mm) ensures convenient placement of weapons and crew in it.

The disadvantages of the design include the lack of a roof on the turret; this creates the danger of quickly incapacitating the crew on the battlefield due to fragments of mines, shells, bombs, machine-gun fire from aircraft, grenades and incendiary bottles.

4. All units and mechanisms of the self-propelled unit, with the exception of the chassis, have sufficient reliability. The chassis of the self-propelled unit is unreliable due to the poor design of the road wheel seals.”

Claims to the fighting compartment

Artillery tests of the American self-propelled guns took a long time. A hitch with ammunition led to the fact that the test program, as well as the order of the Artillery Committee of the GAU KA, were signed only on January 14, 1944. However, the problems did not end there: high-explosive fragmentation rounds were not received at the test site, so on February 19, instructions were given to conduct tests without them. In addition, there were no spare parts and documentation for the 76-mm M-7 gun, which was installed on the GMC M10.

The self-propelled gun arrived at the Gorokhovets Artillery Range (ANIOP) on February 9. Due to the lack of spare parts and documentation, devices for its maintenance had to be made by the laboratory staff at the test site. This, of course, led to a further delay in the start of testing. During this time, work was carried out in parallel to describe the self-propelled gun, as well as the gun. As a result, the vehicle went directly to firing only on March 13, 1944. They continued until April 4, with 390 shots fired, 25 of them with reinforced charges.

Self-propelled gun M10 at the Gorokhovets training ground, March 1944

Firing was carried out with M62 armor-piercing tracer shells. Based on the results, conclusions were drawn that were not in favor of domestic ammunition of the same caliber. It turned out that the strength of American shells was sufficient to destroy armor up to 120 mm thick, while Soviet ammunition of a similar caliber could hit armor no more than 100 mm thick. This was explained by the more advanced design of the M62 projectile, correctly selected materials and a more rational regime for its heat treatment. According to calculations, the M62 projectile hit armor 120 mm thick at a distance of 500 meters. Accuracy tests were also quite successful.

General view of the M7 gun, which was installed in the GMC M10 as the main weapon

Meanwhile, a self-propelled gun does not consist of just one gun. As already mentioned, in addition to shooting, ANIOP specialists were studying the design of the self-propelled gun itself, and here they had a number of questions. Oddly enough, the artillerymen had complaints about the position of the driver. In their opinion, the presence of only one periscope greatly impaired visibility. To be fair, the Medium Tank M4 initially had two viewing devices, but combat operations showed that periscopes in the front hull should be removed.

M62 shells after firing at a 100 mm thick armor plate

The assessment of the fighting compartment looked much more significant. A separate five-page report was devoted to this, eloquently designated as “Remarks on the issues of combat maintenance of the American self-propelled 3-dm gun “M-7”. The first point of criticism was the lack of a roof on the fighting compartment. Here both artillerymen and tankmen were in solidarity. By the way, on some American M10s during the battles of 1944-1945, these same roofs were installed by the crews themselves.

However, this was not the only thing that Soviet specialists did not like. Since there were no hatches in the turret, exiting and entering the fighting compartment turned out to be inconvenient from the point of view of vulnerability. When leaving the vehicle under enemy fire, ANIOP specialists predicted personnel losses.

But the complaints didn’t end there either. Unlike the NIIBT Polygon, at the ANIOP the positions of the crew members in the turret were correctly determined. They were considered insufficiently rational. To begin with, the commander had a flywheel for the vertical gun guidance mechanism, an electric trigger button and a panoramic sight, but he could not aim the gun horizontally. The gunner had a full set of flywheels, but they were located inconveniently, being too close to each other. It was inconvenient to turn them at the same time, despite the small efforts made. The telescopic sight was positioned so that when using it, the gunner rested his chest against the flywheels. It was simply impossible to point the weapon and take aim at the same time with this placement of the sight.

Diagram of the fighting compartment attached to the report on comments on its layout

There were also complaints about the loader’s working conditions. Placing his place on the right side was quite rightly called irrational. There followed a sensible proposal to move the loader’s position to the left. The seats, which reclined in battle, were rejected by Soviet experts because they were hard, uncomfortable, and placed high (at a height of 68 cm). Loading the gun was also considered inconvenient. The first 6 shots were mounted in the first stage stowage on the rear wall of the turret, and the rest were in cases in the fenders. In tests when using the first stage stacking, the rate of fire reached 10–12 rounds per minute. As soon as the shots were finished in the first round, the rate of fire dropped to 4–6 rounds per minute.

The results of testing the GMC M10 at INIOP turned out to be ambiguous. In conclusion, it was stated that the “American M-7 self-propelled gun” passed the tests. On the other hand, the impressive volume of comments on the fighting compartment hardly went unnoticed.

Self-propelled guns displaced by tanks

The fact that there would be deliveries of GMC M10 to the Red Army became clear at the end of 1943, after they were tested at the NIIBT Test Site. As expected in June 1943, the first batch of M10 self-propelled guns was limited to 50 copies. The first vehicles were expected to arrive at training centers by early February 1944. These were not the only American-made self-propelled guns that began to arrive in early 1944. Together with them, GMC T48s literally poured in, against the background of which the M10s got a little lost. From December 14, 1943 to March 5, 1944, 257 such vehicles arrived in the USSR, here receiving the designation SU-57.

Late GMC M10, NIIBT Polygon, summer 1944

As was the case with the first M10s that arrived “for testing,” the main batch of self-propelled guns was supplied via the southern route, via Baku. The first vehicles arrived back in January, but for a number of reasons their shipment to the training center was delayed. In the second half of February, batches of 15, 22 and 5 vehicles arrived in three echelons at the Self-Propelled Artillery Training Center in the village of Klyazma (Moscow Region). Judging by the photographs, vehicles of the middle and late series came to the Soviet Union, which outwardly differed from each other in the shape of the turret. Later, one of the late series vehicles ended up at the NIIBT Test Site.

A heated correspondence immediately broke out around the arriving cars on a very sensitive issue. The fact is that the vehicles received were 80% complete. On four M10s there were no spare parts at all, and along with them there were no machine guns or optics. There was no company spare parts at all. The car with registration number 40110927 had a broken clutch housing, flywheel housing and release plate. Another car was not running.

Sergeant A. M. Ryazanovsky from the 37th OTP against the background of the M10, 1944. It is possible that this is one of the six cars that arrived last. The photo was taken in the classroom. Interestingly, the car has already received T54E1 tracks with developed lugs

The management of the Self-propelled Artillery Training Center sounded the alarm. Soon a letter was sent to GBTU signed by the head of the training center, Major General of Artillery N.S. Kasatkin. This time the complaint turned out to be of a different nature. The head of the center reported that the personnel arriving for staffing had very poor training. Many saw self-propelled guns for the first time. For example, 15 driver mechanics and gunners who arrived on March 4 did not know the car at all. The same thing happened to another 25 crews who arrived on March 9 and had previously trained on the SU-76M.

There is nothing surprising in this, since literature on the machines has not been prepared. To solve the problem, the head of the training center demanded that officers who were familiar with the machine be sent, as well as urgently provide the center with educational literature. True, the head of the center clearly failed with the demand for trained officers, since before that only the specialists of the NIIBT Polygon had become acquainted with the M10.

Gradually the situation improved, although some confusion noticeably delayed the time of sending self-propelled guns to units. It is worth adding that as of January 27, 1944, there were only 875 armor-piercing rounds for the M10, and there were no high-explosive fragmentation rounds at all: 5,000 of such ammunition arrived only in early March. A little later, additional supplies of armor-piercing ammunition were established. On April 26, the USA GBTU KA approved the composition of the ammunition load of the M10 self-propelled gun: armor-piercing and high-explosive fragmentation rounds were allocated 27 pieces per vehicle.

There are very few shots of “American” SU-76s. In this case, the 1223 SAP machine was removed

The last 6 vehicles arrived in Baku at the end of February 1944 and were sent to Pushkino on March 8 by train No. 33387. These 6 self-propelled guns continued to be in reserve as of June 1, 1944. As for the remaining 44 M10s, they entered the 1239th and 1223rd self-propelled artillery regiments (SAP). In the army, these vehicles received the designation SU-76, already “occupied” by a Soviet self-propelled gun with a gun of a similar caliber, which greatly complicates the study of the combat use of these vehicles.

It is known that the 1223rd SAP, as part of the 29th Tank Corps (TK) of the 5th Guards Tank Army, participated in the liberation of Belarus and the Baltic states. Further information is contradictory. According to some data, the M10 disappeared from its composition already in the Baltic states, according to others, on May 1, 1945, it had 10 such vehicles, of which 4 were operational. Another document, dated February 7, 1945, indicates the presence of 37 SU-76s in the regiment, of which 18 were serviceable. What kind of SU-76 this is: American or their Soviet “namesakes” is extremely difficult to say. As for the 1239th SAP, it actively participated in the liberation of Poland as part of the 16th Tank Corps of the 2nd Tank Army.

There were no further orders for M10 self-propelled guns. By the summer of 1944, it became known that the M4A2(76)W medium tanks were being launched into a series; the first such vehicles arrived in the USSR in September. Having almost the same gun, they turned out to be much better than self-propelled guns with an open top turret.

Warspot Editorial

/

Panzer fighter

American anti-tank self-propelled gun 3-inch Gun Motor Carriage M10 from the Overlord Museum in France

- WWII

- tanks

- artillery

- USA

Sources:

- Materials of TsAMO RF.

- Materials of RGAKFD.

- Materials from the author's photo archive.

US Army self-propelled guns: America's shame

The American publication The National Interest, in its revision of Russian weapons, went as far as self-propelled artillery units (self-propelled guns), which are tracked howitzers. The comparison with American weapons of this type turned out to be very one-sided, since the American expert could offer for comparison only one howitzer used in the US Ground Forces - the M109. More precisely, two of its modifications. The Russian army uses almost ten self-propelled guns with calibers ranging from 120 mm to 240 mm, which are useful for solving various combat missions. That is, there is no need to hit, as they say, sparrows with a 240-mm self-propelled mortar. For this, there are guns with more modest firepower.

The conclusions that conclude the article are also highly original. Yes, this type of Russian weapon is more effective than that of the US Army, but the American concept of self-propelled artillery is more progressive.

Here's what they say about the most popular self-propelled gun M109A6 "Paladin" of 155 mm caliber: "This is a reliable and accurate system, but its firepower is superior to Russian, European, and Asian artillery installations." The author primarily considers its advantages to be a quick change of position in order to evade the enemy's counter-battery fire.

"Palladin" does not have an automatic loader; the entire process is carried out manually. Therefore, the self-propelled gun has a record low rate of fire - 1 shot per minute. The ammunition load includes 28 projectiles of various types - conventional, active-reactive (with a jet engine) and adjustable. Russian self-propelled guns have up to fifty rounds of ammunition.

The basic modification of the M109 began fighting in Vietnam in the early 70s. The Paladin modification is the penultimate, but most used in the American army. It has several, one might say, atavistic mechanisms. Thus, not only the recoil mechanism, but also the aiming mechanism is hydraulically driven. The barrel is finished mechanically - manually. An optical sight is used.

The firing range of conventional shells is 14.5 km, with active-reactive shells – 19.5 km.

“Made with us” and on Yandex.Zen

© img.geliophoto.com

The fifth-generation multirole fighter Su-57 is designed to destroy all types of air targets in long- and close-range combat, and engage ground and surface targets. At the same time, the aircraft can overcome air defense systems, control airspace at a long distance, and destroy enemy aircraft control systems.

1. The Su-57 is a universal machine that combines the functions of an attack aircraft and a fighter. A new avionics complex with a high level of control automation and intelligent crew support is deeply integrated into the design.

© img.geliophoto.com

2. The aircraft was developed by specialists from the development bureau of P. O. Sukhoi. Over many decades, OKB engineers have developed about 100 types of aircraft and their modifications - fighters, fighter-interceptors, bombers, reconnaissance fire spotters, attack aircraft, passenger and airborne cargo aircraft, sports aircraft, cargo aircraft, and agricultural aircraft. More than 60 types of aircraft were mass-produced. The Su-57 became the first fifth-generation supersonic fighter.

© img.geliophoto.com

3. The concept of using the Su-57 was developed taking into account network-oriented operations - this aircraft can work in concert with both fighters of the same type and with other types of combat vehicles. The onboard equipment of the new aircraft allows you to exchange data in real time and coordinate actions with ground control systems, as part of an aviation group, and also perform tasks autonomously.

© img.geliophoto.com

4. The complex of technical solutions incorporated into the Su-57 made it possible to obtain a qualitatively new level of performance and ensure superiority over modern aircraft of this class. The main advantages are versatility, increased survivability in real combat conditions, efficiency of use and automation of problem solving.

© img.geliophoto.com

5. The history of the aircraft begins in the early 2000s - it was then that the decision was made to develop a fifth-generation fighter. At the same time, the Su-57 contains the most modern components of the onboard equipment complex, which will allow it to remain a modern fighter for many decades. In addition to this, the platform has an open architecture and allows the use of a wide range of new technologies with minimal changes to the core solution.

© img.geliophoto.com

6. The Su-57, both with stage 1 and stage 2 engines, has outstanding performance in its class. The solutions incorporated in the second stage engine allow it to have the characteristics of the next generation in certain areas.

© img.geliophoto.com

7. Evgeniy Marchukov, general designer and director of the A. M. Lyulka Design Bureau, calls the new engines generation 5+ because they produce maximum specific thrust, have minimal specific consumption and weight. No other engine of this class in the world has such indicators.

© img.geliophoto.com

8. The engines have controlled thrust vectoring - this gives a tremendous advantage during piloting. “We can spin around the tail at minimum speed and control all the enemy’s movements,” say the pilots.

© img.geliophoto.com

9.

© img.geliophoto.com

10. One of the requirements for fifth-generation fighters is stealth. In the Su-57, radar protection is provided by a special shape and the inclination of all surfaces in a clearly limited range. In addition, the casing uses materials that absorb radio waves. Compliance with these requirements influenced the shape and design of the fighter.

© img.geliophoto.com

11. The Su-57 was the star of the 2018 Victory Day parade, but most of its technical specifications are kept secret. It is known that the aircraft can rise to a height of up to 20 km and reach speeds of up to 2600 km/h - 2.2 times the speed of sound.

© img.geliophoto.com

12. The export version of the fighter is called Su-57E. Due to its high characteristics, it has high export potential.

© img.geliophoto.com

13. The cabin of the Su-57 is more ergonomic and comfortable than that of the Su-27. Inside there is a new life support system, oxygen supply and equipment. The design provides an updated ejection seat with automatic analysis of the height, speed and angular movement of the aircraft, as well as the height and weight of the pilot.

© img.geliophoto.com

14. The fighter uses a built-in oxygen production unit - the flight time is practically unlimited, and oxygen refueling at stops is not required.

© img.geliophoto.com

15. Two 15-inch screens are used to display information.

© img.geliophoto.com

16. Engines with thrust vector control increase the maneuverability of the fighter, facilitate takeoff, allow it to perform complex maneuvers in the air, and sharply change roll and pitch.

© img.geliophoto.com

17. It is difficult to get close to a fighter within an effective firing range - the package includes a radar station and optical-electronic detection systems that track enemy aircraft at a great distance.

© img.geliophoto.com

18. One of the differences of the fifth generation engine is the ability to fly in cruising mode at supersonic speed.

© img.geliophoto.com

19. The first Su-57 (then still under the factory name T-50) took wing in 2010. In subsequent years, developers improved the design. In 2022, the next stage of state joint testing was completed, and deliveries of the first production aircraft are planned.

© img.geliophoto.com

20. The aircraft is equipped with air-to-air and air-to-surface guided missiles, adjustable bombs, and an aircraft cannon that can fire bursts at a speed of up to 1,500 rounds per minute. This set of weapons allows you to solve any fighter and strike missions.

© img.geliophoto.com

21. The coloring of fighter jets is not accidental - it makes an aircraft invisible to radar more difficult to detect visually. Camouflage paint helps the aircraft blend into the background or visually distorts the shape of the fighter.

© img.geliophoto.com

22. Currently, the first prototype aircraft are used as flying laboratories in new projects of the Sukhoi Design Bureau.

© img.geliophoto.com

23. The Su-57 was first presented at a static display at the International Aviation and Space Salon (MAKS) in 2022. Before this, the aircraft participated only in the flight program - since 2011, pilots demonstrated the capabilities of the fighter to air show participants.

© img.geliophoto.com

24. The Su-57 also participated in the MAKS-2021 program - with an experienced pilot, the fighter smoothly passed complex figures, abruptly changed its flight direction, and turned almost on the spot.

© img.geliophoto.com

25. At MAKS 2021, not only the fighter was presented, but also its digital version - a VR simulator that accurately simulates the situation inside and outside the cockpit. Such simulators are already being supplied to the troops and are used to train pilots.

© img.geliophoto.com

26. Due to the installed radar equipment, the Su-57 fighter can detect enemy aircraft at a great distance, and maneuverability and modern weapons reduce the enemy’s chances of hiding or conducting a successful attack. The pilots say: “One of the main advantages of air combat is that whoever saw it first won.”

© img.geliophoto.com

27.

© img.geliophoto.com

28. Su-57 is a single-seat aircraft. The developers call the co-pilot an automatic avionics complex, which reduces the load on the pilot and allows him to concentrate on performing tactical tasks.

© img.geliophoto.com

29. In foreign media, the Su-57 fighter is often called a threat and it is believed that the aircraft will dominate in any battle, and especially if used in conjunction with unmanned attack drones.

© img.geliophoto.com

30. The Su-57 alone is an ideal vehicle for military use, but the possibility of coordinated use in tandem with an unmanned attack drone increases the capabilities of the fighter.

© img.geliophoto.com

31. Drones operate on the principle of “faithful wingmen”, increase combat power, take on enemy fire, help suppress air defense systems and preserve the fighter, and reduce risks for the pilot.

© img.geliophoto.com

32. The use of drones in conjunction with a manned fighter is one of the trends in future combat. A slave drone can carry an arsenal for air combat and ground attacks, helping to penetrate enemy lines and deliver precise strikes. In 2022, the Su-57 made its first joint flight with the S-70 Okhotnik.

© img.geliophoto.com

33. The wing of the Su-57 has a root flap with a rotating front part. This design improves aerodynamic performance, especially at high angles of attack.

© img.geliophoto.com

34. According to NATO terminology, the Su-57 is called Felon - “criminal”. The military of the North Atlantic Alliance names all code designations of fighters with “F”: Su-47 - Fishpot (“fish pot”), Su-17 — Fitter (“fitter”). In Russia, this terminology is rarely used and certainly does not reflect the characteristics and capabilities of the technology.

© img.geliophoto.com

35. News constantly appears in the media about possible improvements to the design: the use of voice control and an eye movement reader to control mechanisms, the development of a two-seat version of the Su-57 to work in conjunction with drones, and the installation of new weapons.

© img.geliophoto.com

36. One of the possible new products is a real-time technical condition monitoring system. The integrated control system consists of strain and acoustic emission sensors that collect data throughout the entire life cycle of the aircraft.

© img.geliophoto.com

37. The Su-57 uses composite materials - acoustic emission sensors will read measurements that occur during operation. When the material wears out, there are more sound pulses - this will help localize the destruction zone and perform aircraft maintenance in a timely manner. Strain sensors are installed on highly loaded elements.

© img.geliophoto.com

38. The fighter makes extensive use of composite materials - they occupy about 24% of the weight in the structure and approximately 70% of the outer surface area.

© img.geliophoto.com

39. The developers introduced a maximum of large-sized parts into the project to facilitate assembly and increase the reliability of the aircraft. Compared to the Su-27, the airframe of the new fighter has 4 times fewer parts.

© img.geliophoto.com

40.

© img.geliophoto.com

41. The exact parameters of the Su-57 are kept secret. You can look at the plane from the outside, see piloting at a car show, and even try yourself as a pilot on a VR simulator - but the developers do not disclose technical specifications.

© img.geliophoto.com

42. The chief engineer of the Shenyang Institute of Aircraft Engineering, Wang Yongqing, shared his impressions of the new Russian fighter: “Enemy pilots, when meeting a Su-57 in the sky, do not need a cannon, but a trouble-free catapult.”

© img.geliophoto.com

43. The Su-57 is ideal for both long- and close-range combat - this distinguishes it from most stealth fighters, which only perform well at long ranges. The fighter's high maneuverability at supersonic speeds gives the Su-57 a huge advantage in real combat.

© img.geliophoto.com

44. Serial production of the Su-57 has already begun, samples of the pilot batch have been transferred to the Ministry of Defense. The flight performance and capabilities of on-board equipment, weapons and low visibility have been confirmed during real combat operations - twice a pair of fighters was transferred to Syria to the Khmeimim airbase in the province of Latakia.

© img.geliophoto.com

45. The developers do not stop there. The Su-57 is developing towards increasing its combat capabilities and introducing modern technologies. The designers made sure that the Su-57 platform was universal and allowed to implement various tasks.

© img.geliophoto.com

Light self-propelled guns with large guns

The SU-76M self-propelled gun, which became the second most popular combat vehicle of the Red Army during the war, was armed with a 76-mm ZIS-3 divisional gun. This system was one of the best created by V.G. Grabin, and had good characteristics. At the same time, attempts to install more powerful guns on a self-propelled gun have been made repeatedly, and some options, for example, SU-85B

, were even close to launching into series.

Nevertheless, the Red Army never received a domestic analogue of the Marder .

Disposal of unnecessary guns

Even at the design stage of the SU-12 and SU-71, the direct predecessors of the SU-76M, the idea arose to create a specialized tank destroyer. This vehicle was supposed to receive a 45-mm M-42 anti-tank gun. True, work on this topic did not go beyond the creation of tactical and technical requirements. But another system V.G. The Grabina, a 57-mm ZIS-2 anti-tank gun, appeared and disappeared from the self-propelled artillery armament program with enviable consistency.

Prototype SU-57, May 1944

The ZIS-2 and its tank version ZIS-4 were remembered once again in the spring of 1943 after shelling tests of the German Pz.Kpfw.Tiger Ausf.E heavy tank. It turned out that the ZIS-2 is one of the few Soviet systems that hit a German heavy tank not only on the side, but also in the forehead. Although the front of the Tiger was hit by ZIS-2 fire from minimal distances, this was enough to urgently restore production of the gun.

The order for the production of a tank version of the ZiS-2, ZIS-4, came from the Main Artillery Directorate (GAU). But Grabin and plant No. 92 took the initiative, and in parallel with the construction of the ordered guns to arm four T-34s, mass production began at the enterprise. While tanks with new guns were being tested, Plant No. 92 managed to build more than one and a half hundred of these guns. The ZIS-4 was also tested on the experimental self-propelled unit SU-74B. Compared to the 1941 design, the new ZIS-4 turned out to be more technologically advanced.

Just at the time when the T-34 with the ZIS-4 arrived for testing, the first phase of the Battle of Kursk, which had a serious impact on Soviet tank building, ended. Among other things, it became clear that the ZIS-4 is not entirely suitable for arming tanks. The Germans used many new products, including the Pz.Kpfw.Panther medium tank, the upper frontal plate of which could not be penetrated even by an 85-mm gun. The ZIS-4 gun now looked quite pale.

The fighting compartment of the vehicle remained virtually unchanged

Production of the ZIS-2 continued, but the tank version of the gun had to be abandoned. But, as mentioned above, plant No. 92 took the initiative, and by the end of 1943, 154 new ZIS-4s hung like dead weight in the warehouse of plant No. 183 in Nizhny Tagil. The plant retained twelve more systems manufactured in 1941 since 1941, bringing them during the evacuation from Kharkov.

Of course, long-term storage did not make the gun any better. There were demands from the plant to do something with the rusting illiquid stock. The GAU and the Main Armored Directorate of the Red Army (GBTU KA) found themselves in a difficult situation. 57 mm guns were still of combat value, but their path to tanks was already closed: at the end of 1943, the final choice was made in favor of 85 mm tank guns. A way out of the impasse could be the use of the ZIS-4 to arm light self-propelled guns.

Since only the barrel of the gun was changed, the sight remained the same as that of the ZIS-3. Testers didn't like it

The continuation of the story with long-suffering guns was another initiative, this time from the GAZ design bureau (KB) named after. Molotov. In April 1944, a self-propelled gun was developed here, which received the designation “57-mm self-propelled anti-tank gun.” The frequently encountered index SU-57 appeared much later - in September 1944. They did not invent the bicycle at GAZ: the design of the SU-76M remained the same, but the barrel of the ZIS-3 system was replaced. Taking into account the interchangeability of ZIS-2 and ZIS-3 parts, this operation did not cause any problems.

It is interesting that in some documents the development of the SU-57 is called an initiative of GAZ named after. Molotov, others indicate that the car appeared in agreement with the State Agrarian University and the State Technical University. There is also a third version of events. A document dated April 24, 1944 reads:

“Based on personal negotiations between the Head of the Main Artillery Directorate of the Red Army, Marshal of Artillery Comrade Yakovlev and the People's Commissar of Medium Mechanical Engineering of the USSR Comrade Akopov, the Gorky Automobile Plant was given the task of developing a project and manufacturing a prototype of a 57-mm anti-tank self-propelled gun, which is an installation of a rotating part 57-mm anti-tank gun model 1943 on the chassis of the SU-76M self-propelled gun.

Since this task is extremely urgent, I ask for your orders to produce a prototype by May 1 of this year and immediately submit it to the Artillery Scientific Research Experimental Test Site for field testing.

ANIOP-GAU was given instructions to conduct tests within three days.”

Taking into account the fact that the testing program was signed on April 27, and the tests at the Gorokhovetsky ANIOP took place from May 1 to 4, it is very difficult to call this development initiative.

To build a prototype of the vehicle, a serial SU-76M with serial number 404855, produced in April 1944, was taken. Its first firing tests took place at the plant on April 30. A total of 25 shots were fired, 20 of them with a reinforced charge. Another 270 shots were fired at the ANIOP, 107 of them with an enhanced charge. The accuracy of the high-explosive fragmentation projectile was considered satisfactory, and the accuracy of the armor-piercing tracer projectile was considered unsatisfactory. This was not a problem with the self-propelled gun, but with its guns: ANIOP noted similar problems when testing the ZIS-2 in the fall of 1943. The results were better when firing a sub-caliber projectile.

The targeted rate of fire reached 10 rounds per minute, and the maximum - up to 15. The testers did not like the sights. The SU-76M received not the ZIS-2, but a barrel from it: the panoramic sight from the ZIS-3, poorly suited for shooting at moving targets, remained in place. I also didn’t like the fighting compartment, which was partially open at the back and sides.

Second version of the car. Periscope surveillance devices installed on the roof are visible

The experimental self-propelled gun was recognized as having passed the tests, but requiring a number of alterations. Instead of a panoramic sight, a 10-T telescopic sight should have been installed. It was also necessary to install an electric trigger with a button in the handle of the flywheel of the lifting mechanism and make the fighting compartment completely closed. The roof needed to be made from sheets 5-8 mm thick, and the sides and stern - 15 mm. A double-leaf hatch was provided in the stern.

Taking into account these requirements, GAZ Design Bureau named after. Molotov developed the second version of the self-propelled guns. Instead of manufacturing a new vehicle, in June 1944 an existing model was redesigned. The fighting compartment has undergone the greatest changes, which has become completely closed. The combat weight of this vehicle is indicated to be the same as the SU-76M, which looks doubtful. Most likely, it has grown by about half a ton. To improve visibility, MK-IV periscope surveillance devices appeared in the roof. The conversion of weapons was carried out in accordance with the assignment received.

The fighting compartment has become completely closed

The car arrived at the Gorokhovetsky ANIOP on June 29, without drawings or documents. The next day, firing tests began, but they soon stopped because ANIOP received another urgent task. Due to fuel shortages, tests were not carried out from July 5 to July 28; they were completed on July 30. 358 shots were fired, 113 of them with an enhanced charge. The target rate of fire and accuracy of shooting at stationary targets have not changed. The accuracy of shooting at moving targets became worse, but this was due to the fact that the shooting was carried out according to the tables of the 85-mm gun: this is exactly the scale that was cut on the 10T-15 sight.

When fired from small arms, it turned out that some bullets hit inside the fighting compartment

Reworking the second option did not provide any particular benefit. The completely enclosed fighting compartment became more polluted. Deficiencies in the protection in the frontal area were revealed: when fired with small arms, individual bullets flew inside the fighting compartment. Nevertheless, Artcom GAU considered that the vehicle passed the test according to the second version. In September 1944, a draft decree of the State Defense Committee appeared on the adoption of the 57-mm self-propelled gun SU-57 for service. During the fourth quarter of 1944, it was planned to build 165 of these vehicles, the order executor was GAZ named after. Molotov.

The never implemented GKO resolution on the release of the SU-57

It was at this moment that the Self-Propelled Artillery Directorate (USA) of the GBTU KA began to actively oppose the adoption of the SU-57 for service. They compiled a list of shortcomings, among which was, for example, insufficient armoring of the vehicle. Attempts to “push through” the production of the car were repeated several times, the last time in 1945. By that time, however, the SU-57 was no longer relevant at all, especially considering the fact that in mid-1944 GAZ named after. Molotov developed a self-propelled gun with a much more powerful weapon.

Transition to medium caliber

Even in the summer of 1943, it became clear that the armor penetration of the ZIS-2 was insufficient to combat the new German tanks. Under the leadership of N.A. Astrov at GAZ named after. Molotov at the end of 1943, the SU-85 GAZ self-propelled unit was developed and built, which also had the factory index GAZ-75. This vehicle was a development of the GAZ-74 self-propelled guns, differing from it not only in a more powerful weapon, but also in enhanced armor protection. With a combat weight of 14.5 tons, the thickness of its upper frontal plate was 82 mm. The tests, which took place from January 3 to March 8, 1944, were generally successful, but the vehicle was not modified.

The reason for this was the “torpedoing” of A.A. Liphart, the brainchild of Astrov. Since the end of 1943, the chief designer began a quiet (and in some places not at all quiet) war against military production at GAZ. No, Andrei Aleksandrovich was not a saboteur: he was driven by the need to reorient the plant to the production of “peaceful” products. In addition, since the GAZ-75 self-propelled gun was in many ways a new vehicle, its production required a major restructuring of the plant’s capacities. Since the production volume of self-propelled guns needed to be increased, the introduction of the GAZ-75 into the series turned out to be impossible.

A special stand on which the operation of the chassis was tested with an increase in weight to 12 tons

With the death of the GAZ-75, attempts to strengthen the armament of light self-propelled guns did not stop. In May 1944, the factory design bureau, instead of creating a fundamentally new vehicle, decided to develop it on the basis of the SU-76M. Work in this direction became possible thanks to the position of military acceptance, primarily engineer-colonel Okunev. The new development received the index SU-15A. The absence of the GAZ designation in the index was explained simply: the base of the vehicle was the SU-15M, developed by the design bureau of plant No. 38.

Astrov headed the work on the SU-15A, and I.V. became the leading engineer of the vehicle. Gavalov. During his long design career, Igor Valentinovich often had to solve complex technical tasks, and this development was no exception: a gun that was originally created for heavy and medium tanks had to be built into a light chassis.

This document is one of the few evidence of work on installing the 122-mm M-30 howitzer on the SU-76M. It didn't even get to the preliminary design stage

In May 1944, several versions of the vehicle were developed. We chose the simplest one: the 85-mm D-5S-85 system was installed on the existing SU-15M hull. The system's armor was similar to that received by the GAZ-75. The rear part of the vehicle was changed, in particular, the lower rear sheet was made vertical so that the increased stowage of cartridges for the D-5S-85 could fit inside. Since the combat weight, according to calculations, grew to 12 tons, it was necessary to strengthen the chassis. The rear and front balancers of the road wheels were received as additional elastic spring elements. Instead of support rollers, runners (slides) were installed.

SU-85A in the factory yard, August 1944

In order to verify the possibility of installing the D-5S-85 on a light chassis, in May 1944 the conventional SU-76M was armed with this system. Firing tests gave satisfactory results. The vehicle was shown to Marshal of the Armored Forces Fedorenko, who approved the development.

At the end of May 1944, the head of the GBTU KA, Lieutenant General Vershinin, contacted GAZ named after. Molotov and to plant No. 9 with a request to develop another self-propelled gun. It was proposed to install a 122-mm M-30 howitzer on the SU-76M base. Instead of GAZ, plant No. 38 took up the work, having been working on this topic since April 1944. Alas, in July 1944, work was curtailed due to the decision to transfer plant No. 38 from Kirov to Kharkov to the site of plant No. 75. The preliminary design of the vehicle was not even completed (unlike the OSU-76 and ZSU-37 projects, which were transferred to plant No. 40). The Soviet light howitzer self-propelled gun died without really being born.

But the SU-15A was not only built, but also had a very stormy fate. However, this car could also “disappear” even before construction. In June 1944, the GBTU KA proposed in a letter to stop work on the “SU-85 based on the SU-76”, since the SU-76M met all the requirements that were placed on it.

The large D-5S-85A system was able to fit into a fairly small base

In June-July, the fate of the vehicle, which at that time began to be designated as SU-85A, hung in the balance. There was a very hectic correspondence between the GBTU KA, the People's Commissariat for Medium Engineering (NKSM) and the State Autonomous Institution KA. The fate of the SU-85A was determined at the end of July 1944, when the chairman of the Arktom GAU, Lieutenant General Khokhlov, in a letter called the topic of this self-propelled gun urgent. GBTU KA surrendered: on August 2, an order was signed by the NKSM and GBTU KA to conduct factory tests of the vehicle.

By that time, the prototype SU-85A was already ready. Its combat weight slightly exceeded the calculated one and amounted to 12.2 tons. Instead of the D-5S-85, the vehicle received a different system - the D-5S-85A from plant No. 8. Due to the fact that the dimensions of the 85 mm cartridges were larger, the ammunition load was reduced to 42 pieces. True, everything turned out to be relative: on the larger SU-85, the ammunition load turned out to be not much more - 48 rounds of ammunition for the D-5S-85A. The SU-85A was equipped with a breakable telescopic sight TSh-15, which was more convenient for the gunner to use. The track of the prototype was widened by 40 mm, and it received more durable torsion bars.